Are you a DIY enthusiast, ready to embark on a journey of creativity and innovation? Imagine the thrill of crafting a one-of-a-kind wooden coffee table, adorned with sleek aluminium accents. The fusion of these contrasting materials can add an undeniable touch of elegance and sophistication to any design. But here’s the challenge: how do you successfully glue aluminium to wood, when their properties are so different?

Intrigued? Let’s dive right in and unravel the mystery behind the art of bonding aluminium to wood.

Hook:

Picture this – a moment of awe as you unveil your masterpiece; a symphony where strength meets beauty, where wood embraces metal in perfect harmony.

Main Points:

- Material compatibility: Aluminium and wood possess distinct physical properties that demand an adhesive capable of bonding these surfaces effectively.

- Surface preparation: Achieving a strong bond requires meticulous preparation. We’ll explore techniques for cleaning and priming both aluminium and wood surfaces, ensuring maximum adhesion.

- Adhesive selection: Choosing the right adhesive is paramount for durability and longevity. Discover the wonders of epoxy, polyurethane, and cyanoacrylate – adhesives that work like magic when it comes to aluminium-to-wood bonding.

- Application techniques: Mastering the art of adhesive application is key to success. We’ll guide you through step-by-step processes, from clamping techniques to curing times, guaranteeing optimal results every time.

- Finishing touches: Once your bond is secure, we’ll show you how to seamlessly integrate aluminium and wood for a flawless finish that showcases the true beauty of both materials.

So, grab your tools, mix your adhesives, and let’s delve into the realm of aluminium-to-wood bonding – where artistry and craftsmanship collide.

Choosing the Right Adhesive for Gluing Aluminium to Wood

Contents

Achieving a robust and long-lasting bond between aluminium and wood requires careful selection of the right adhesive. In this comprehensive guide, we will explore the key factors to consider when choosing an adhesive for gluing aluminium to wood.

Additionally, we will delve into the various types of adhesives commonly used for this application, as well as provide valuable tips on surface preparation and application techniques.

Factors to Consider:

- Compatibility: Select an adhesive that is compatible with both aluminium and wood surfaces to ensure a strong bond between these two materials.

- Strength: Due to the differing properties of aluminium and wood, it is crucial to choose an adhesive that can provide exceptional strength when bonding them together.

- Environmental Resistance: Consider the environmental conditions that the bonded assembly may encounter. Opt for an adhesive that exhibits excellent resistance to moisture, high temperatures, or other specific environmental factors.

- Curing Time: Assess the project’s requirements and select an adhesive that aligns with the desired timeline. Quick-curing adhesives are ideal for situations where immediate bonding strength is necessary.

- Manufacturer Recommendations: Consult the manufacturer’s guidelines or recommendations for bonding aluminium and wood. Following their advice can enhance the chances of a successful bond.

Commonly Used Adhesives:

- Epoxy Adhesive: Renowned for its remarkable strength and excellent bonding capabilities, epoxy adhesives are a popular choice for gluing aluminium to wood. While they offer a reliable and durable bond, they do require longer curing times.

- Polyurethane Adhesive: Known for their versatility and flexibility, polyurethane adhesives can effectively bond various materials, including aluminium and wood. They provide good strength and are suitable for applications where movement or vibration may occur.

- Cyanoacrylate Adhesive: Commonly referred to as super glue or instant glue, cyanoacrylate adhesives deliver rapid bonding between aluminium and wood surfaces. While they exhibit exceptional initial bond strength, their long-term durability may be slightly lower compared to other adhesives.

Surface Preparation and Application Techniques:

Clean and Dry Surfaces: Prior to applying the adhesive, ensure that both the aluminium and wood surfaces are meticulously cleaned, dried, and devoid of any dirt, grease, or coatings. This meticulous preparation will enhance adhesion.

Preparing the Surfaces for Bonding

Embarking on a project to join aluminum and wood together? Well, buckle up because the secret to a rock-solid bond lies in the art of surface preparation. This is where the real magic happens. In this comprehensive guide, we’ll explore the essential steps needed to prepare surfaces for bonding aluminum and wood. Get ready to unleash your DIY skills and create an unbreakable connection. Safety goggles on, and let’s dive in.

Step 1: The Power of Cleanliness

Before we do anything else, we need to ensure that both the aluminum and wood surfaces are immaculate. Dirt, dust, grease, or debris can be formidable adversaries when it comes to bonding. Arm yourself with a mild detergent or suitable solvent for both materials and scrub away any impurities. Remember, dry them completely before moving on – cleanliness is next to bonding-ness.

Step 2: Rough is Tough

Smooth surfaces may be visually pleasing, but when it comes to bonding aluminum and wood, roughening things up is the way to go. Grab your fine-grit sandpaper and delicately sand both the aluminum and wood surfaces. This creates a textured terrain that allows the adhesive to grip tightly. Exercise caution not to overdo it – a gentle touch is all you need.

Step 3: Primer Up for Success

Some adhesives demand an extra boost to ensure an exceptional bond between aluminum and wood. That’s where our trusty primer comes into play. Acting as an intermediary layer, the primer enhances compatibility between different materials. Check your adhesive’s instructions to see if a primer is recommended, and if so, follow the suggested application method – consider it a head start for your bond.

Step 4: Choosing the Adhesive Superstar

Now it’s time for the fun part – selecting the adhesive that will bring your aluminum and wood together in perfect harmony. Epoxy, polyurethane, or cyanoacrylate (super glue) – the power is in your hands. However, choose wisely. Consider factors such as load-bearing capacity, flexibility, and temperature resistance to ensure you pick an adhesive that suits your project’s unique demands.

Applying the Adhesive

Today, we embark on a magical journey where aluminum and wood come together in perfect harmony. In this guide, we will explore the intricate process of applying adhesive to glue aluminum to wood, unlocking the secret behind a bond that can withstand the test of time. So, prepare yourselves, for we are about to unleash the power of adhesion.

Step 1: A Clean Canvas for Bonding Brilliance

Before we dive into the world of adhesive, we must ensure that our aluminum and wood surfaces are pristine. Imagine these surfaces as a canvas waiting to be painted with the perfect bond. By wiping down the surfaces with a cloth dampened in mild detergent or rubbing alcohol, we eliminate any obstacles that may hinder our adhesive’s full potential. Let cleanliness pave the way for an extraordinary bond.

Step 2: Embracing Roughness for Enhanced Adhesion

Now, let us embrace the power of roughness to strengthen our bond. We’re not here to start a fight; rather, we seek to create a surface texture that amplifies our adhesive’s grip. With the gentle touch of sandpaper or a wire brush, we introduce a slight roughness to both the aluminum and wood surfaces. This texture shall serve as a foundation for our adhesive to firmly hold onto.

Step 3: Choosing Our Adhesive Champion

Behold. The time has come to select our adhesive champion, the catalyst that will bring aluminum and wood together as one. We have three contenders vying for our attention: epoxy, polyurethane, and cyanoacrylate (super glue). Let us explore their unique qualities and choose wisely.

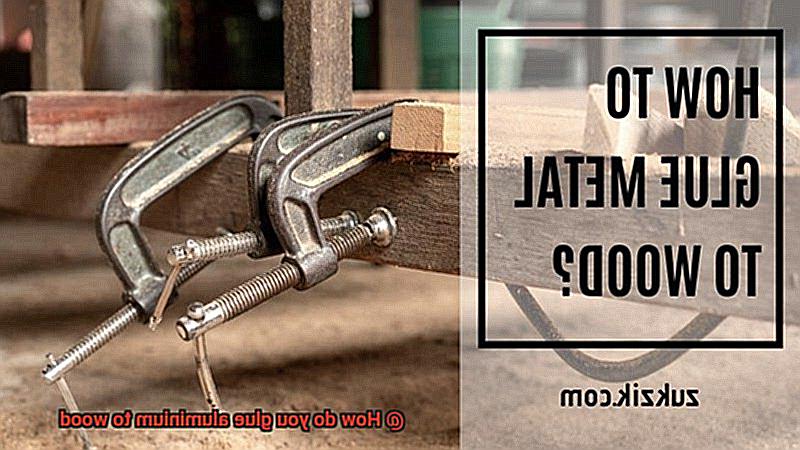

For epoxy adhesives, we must first mix the resin and hardener as instructed by the manufacturer. With a brush or spatula, we delicately apply a thin layer of this mixture to one of the surfaces. Then, with precision and care, we press the aluminum and wood together, ensuring their perfect alignment. To hold them steadfast during the adhesive’s curing process, we employ clamps or weights, sealing their fate as an inseparable duo.

Joining the Surfaces Together

Today, we will unravel the secrets of epoxy resin, a mystical adhesive that creates unbreakable bonds between these two materials. Prepare to be spellbound as we embark on a journey filled with magic and ingenuity.

Step 1: Purify the Surfaces

Before we begin our alchemical adventure, we must cleanse the aluminium and wood surfaces to ensure a flawless bond. Like cleansing a sacred artifact, we use solvents like acetone or isopropyl alcohol to remove any traces of dirt, dust, or grease. Only then can our surfaces be ready to embrace the transformative power of epoxy resin.

Step 2: Awaken Hidden Strengths

To enhance the bond’s resilience, we must awaken the hidden strengths within our materials. This is achieved by gently roughening up the surfaces, allowing the epoxy to grip onto them with unwavering determination. A touch of sandpaper or a wire brush is all it takes to unleash their inherent power.

Step 3: The Elixir of Bonding

With our surfaces prepared and empowered, it’s time to mix our magical elixir – epoxy resin. Follow the instructions provided by the alchemists who crafted this adhesive marvel. Accuracy is paramount in harnessing its full potential.

Using a delicate brushstroke, apply the epoxy evenly onto either the aluminium or wood surface. Imagine yourself an artist, carefully crafting a masterpiece that will withstand the tests of time. Leave no area untouched by the enchanting touch of epoxy.

Step 4: The Union of Worlds

Now, it is time for these two worlds to unite. Press the aluminium and wood surfaces firmly against each other, ensuring they connect intimately. A powerful bond demands complete contact; let them merge as one through your expert touch.

Step 5: The Dance of Time

Like a spell waiting to be cast, our adhesive magic needs time to work its wonders. The curing time may vary depending on the specific epoxy used. Embrace patience and allow the bond to develop its strength. You are the conductor of this symphony, orchestrating the perfect harmony between aluminium and wood.

Curing Time for Maximum Bond Strength

Today, we embark on a mystical journey to unveil the secrets of achieving unbreakable bonds between aluminum and wood surfaces. Our focus lies in the crucial stage of the curing time for maximum bond strength. So, grab your wands (or adhesive tubes) and prepare to witness the power of patience and precision.

The Epoxy Resin Enigma:

Behold, the almighty epoxy resin. This magical adhesive possesses the ability to transform aluminum and wood into a harmonious masterpiece. However, like any potion, it requires a precise amount of time to work its wonders. Each epoxy resin has its unique curing time, influenced by temperature and humidity.

Patience is a Virtue:

In our quest to achieve maximum bond strength, we must heed the wisdom of patience. Rushing the curing process, like a novice sorcerer trying to hasten their spells, can only weaken the bond’s strength. Remember, true greatness requires time to develop its full power.

Follow the Spellbook: Manufacturer’s Instructions:

To unlock the adhesive’s potential, we must consult the sacred spellbook – the manufacturer’s instructions. These guidelines reveal the secrets of proper curing time. They may recommend allowing the adhesive to cure undisturbed for a specific period, typically 24 to 48 hours. By following this mystical guidance, we ensure our bond reaches its pinnacle.

Environmental Factors: The Hidden Influencers:

Like invisible enchantments, environmental conditions such as temperature and humidity hold sway over the curing time of epoxy adhesives. Higher temperatures unleash a swift transformation, while lower temperatures slow down the process. Similarly, high humidity levels extend the time required for the magic to take hold. Thus, let us consider these hidden influencers in our bonding endeavors.

In our eagerness to witness the bond’s strength, we may be tempted to wield unauthorized spells such as accelerators or heat. However, we must exercise caution and consult the adhesive manufacturer’s guidelines before indulging in these shortcuts. Mishandling these enchantments can lead to suboptimal bonds or, in dire circumstances, complete failure. Let us not risk the destruction of our magical masterpiece.

Considerations for Extreme Temperatures and Moisture

Get ready to harness the power of your adhesive potions and embark on this magical journey.

Let’s first unravel the mysteries of extreme temperatures. When the heat is on, aluminium expands more than wood, placing tremendous strain on your bond. To conquer this challenge, you need an adhesive with unparalleled flexibility, capable of accommodating this expansion without breaking a sweat. But beware. When the mercury drops, materials contract, leaving behind gaps or cracks that can shatter your precious bond if your adhesive isn’t up to the challenge.

But wait, there’s more. Prepare to face the lurking dangers of moisture. Wood has an insatiable thirst for it, and this can spell doom for your adhesive masterpiece. Should your chosen adhesive lack resistance to moisture, it will gradually weaken or break down over time, leaving you with a feeble bond that crumbles under the weight of the elements. And if that weren’t enough, moisture can even corrode aluminium, further sabotaging your hard work.

But fear not. We possess potent considerations to help you conquer these formidable foes of extreme temperature and moisture like a true adhesive wizard:

- The art of selection: Choose an adhesive specifically crafted for aluminium-wood bonding, boasting unrivaled resistance to temperature fluctuations and moisture. Epoxy-based adhesives often emerge as heroes in this saga, renowned for their durability and ability to withstand even the most extreme conditions.

- The power of preparation: Remember that meticulous surface preparation is key to forging a robust bond. Purify those surfaces with utmost care, banishing any contaminants such as dirt, grease, or remnants of previous adhesives. Only then will your magical concoction adhere flawlessly to both aluminium and wood.

- The symphony of application: Spread your chosen adhesive evenly on both surfaces, employing a suitable applicator or brush. Obey the instructions of the adhesive’s creator, ensuring the perfect thickness and coverage for optimal results.

- The virtue of patience: Allow your adhesive masterpiece to cure completely, granting it the time it needs to reach its full potential. Curing times may vary depending on the type of adhesive, so resist the temptation to rush this magical process. Instead, consult the product instructions for specific guidelines and let your bond flourish.

Tips for Successful Glue Bonding

Gluing aluminum and wood together can be a challenging task, but with the right tips and techniques, you can achieve a strong and durable bond. In this blog post, we will explore the steps that should be taken to ensure successful glue bonding between aluminum and wood, along with some important considerations. Let’s dive in.

- Choose the Right Adhesive: Selecting the appropriate adhesive is crucial for a successful glue bond between aluminum and wood. Epoxy adhesives are highly recommended due to their excellent bonding properties and ability to adhere well to both aluminum and wood surfaces. These adhesives come in different formulations, including ones specifically designed for metal and wood bonding. Alternatively, polyurethane adhesives or construction adhesives can also provide good adhesion.

- Prepare the Surfaces: Before applying the adhesive, proper surface preparation is essential for a strong bond. Begin by thoroughly cleaning both the aluminum and wood surfaces to remove any dirt, grease, or dust particles that could interfere with the bonding process. Use a mild detergent or solvent along with a clean cloth to ensure a clean surface. Next, lightly roughen up the surfaces using sandpaper or a wire brush to create a better bonding surface. Exercise caution while doing this to avoid damaging the materials.

- Apply the Adhesive Evenly: Once the surfaces are prepared, it’s time to apply the adhesive evenly. Follow the instructions provided by the manufacturer regarding the application technique, as different adhesives may have specific requirements. In general, it is recommended to apply a thin layer of adhesive on both surfaces using a brush or spatula. The goal is to achieve an even coverage over the entire bonding area.

- Allow Proper Curing Time: After applying the adhesive, patience is key. Allow sufficient time for the adhesive to cure properly. The curing time can vary depending on the type of adhesive used, so refer to the manufacturer’s instructions for specific guidelines. It is important to avoid disturbing or putting stress on the bond during this period to ensure a strong and reliable connection. Give the adhesive the time it needs to reach its full strength.

- Apply Pressure or Use Clamps: To enhance the bond between aluminum and wood, applying pressure or using clamps can be beneficial. Depending on the size and shape of the materials being bonded, use clamps or weights to hold them together firmly during the curing process. This will ensure maximum contact between the adhesive and surfaces, resulting in a stronger bond. Follow the instructions provided by the adhesive manufacturer regarding the appropriate amount of pressure or clamping time required.

0UoQaCylSSg” >

Conclusion

When it comes to bonding aluminium and wood, there are a few key methods you can use. One option is to use an epoxy adhesive specifically designed for metal and wood bonding. These adhesives have strong bonding properties and can create a durable connection between the two materials.

Another option is to use a construction adhesive that is suitable for both aluminium and wood surfaces. These adhesives are often available in tube form and can be easily applied using a caulking gun. They provide a strong bond and are resistant to temperature changes and moisture.

If you prefer a more traditional approach, you can also consider using mechanical fasteners such as screws or nails to join the aluminium and wood together. This method provides a reliable connection but may require drilling holes in the aluminium surface.

Before applying any adhesive or fastener, it’s important to properly prepare the surfaces. Clean both the aluminium and wood thoroughly to remove any dirt, dust, or grease that could interfere with the bonding process. You can use rubbing alcohol or an appropriate cleaner for this purpose.

Once the surfaces are clean, roughen them slightly using sandpaper or steel wool. This will create a better surface for the adhesive or fastener to grip onto.

When applying the adhesive, follow the manufacturer’s instructions carefully. Apply it evenly on both surfaces and press them firmly together. Use clamps or weights if necessary to ensure proper contact between the aluminium and wood until the adhesive sets.

In conclusion, gluing aluminium to wood requires choosing the right adhesive or fastening method, preparing the surfaces properly, and following instructions diligently.