Welcome to the captivating realm of 3D printing, where resin parts bring your wildest creations to life with unmatched detail and precision. As you embark on your creative journey, you may encounter the challenge of seamlessly joining these delicate components. But fear not, fellow maker. We’re here to unravel the mysteries of bonding 3D resin parts together.

Imagine this: after countless hours designing and printing, you finally have the perfect 3D resin prototype in your hands. Now comes the crucial step of bringing all those intricate pieces together. But how can you achieve a strong bond without compromising the unique details that make your creation stand out?

With years of experience under our belts, we’ve gathered invaluable insights into gluing techniques specifically tailored for 3D resin parts. Forget about traditional adhesives that struggle to adhere to the smooth surface and chemical composition of resin. We’ve unearthed a handful of methods that guarantee long-lasting bonds and outstanding results.

Join us as we dive headfirst into the world of resin bonding secrets. In this blog post, we’ll explore a range of options at your disposal – from UV-activated adhesive to epoxy resin and even specialized bonding agents. Discover the distinctive attributes of each technique, including their pros, cons, and practical recommendations for success.

So whether you’re an enthusiastic hobbyist or an aspiring entrepreneur, get ready to elevate your 3D resin creations by mastering the art of gluing their parts together. Prepare to unleash your creativity as we unveil the wonders hidden within this fascinating world of 3D resin bonding. Let’s dive right in.

What is Resin?

Contents

Step into the captivating realm of resin, a versatile material that has taken various industries by storm. Whether you’re exploring the realm of 3D printing or indulging in creative crafting endeavors, understanding the essence of resin and its boundless potential is vital for achieving remarkable results. In this mesmerizing exploration, we will dive deep into the multifaceted nature of resin, unraveling its distinct properties, diverse applications, and invaluable insights for harnessing its power.

Resin in 3D Printing:

- Immerse yourself in the realm of 3D printing with resin, a mesmerizing photosensitive liquid material.

- Known as photopolymer resin, it undergoes a magical transformation, solidifying under the spellbinding touch of specific light wavelengths.

- Embark on a journey of flexibility and precision as different types of resin unveil their unique characteristics and applications.

- Master the art of successful printing by embracing the secrets of curing time, shrinkage rates, and post-processing requirements.

Resin Adhesives:

- Venture into the world of bonding as resin reveals its adhesive prowess.

- Unleash the power of resilience and durability with resin adhesives that conquer moisture and stand the test of time.

- Discover the art of selecting the perfect adhesive to bond plastics, as resin itself is a type of remarkable plastic material.

- Revel in the strength and fortitude of epoxy adhesives, renowned for their unwavering grip and indomitable bond.

Resin in Crafting and Jewelry Making:

- Unleash your creativity as resin triumphs in crafting and jewelry making realms.

- Embrace the artistry of pouring resin into molds or encapsulating objects, birthing extraordinary masterpieces that captivate the eye.

- Dive into a palette of endless possibilities by pigmenting resin with dyes or fusing it with glitter and tiny treasures, elevating each creation with a touch of visual splendor and textural allure.

Choosing the Right Adhesive

In this enchanting realm of 3D printing, crafting, and jewelry making, the secret to creating extraordinary resin pieces lies in choosing the perfect adhesive. Just like a skilled magician needs the right spell to perform their magic, you need the right adhesive to ensure a strong and durable bond between your 3D resin parts. So, let’s embark on a journey to discover the factors that will guide you towards selecting the adhesive that will make your resin creations stand the test of time.

Factor #1: Type of Resin:

Resins, like different flavors in a magical potion, come in various compositions such as epoxy, polyurethane, or polyester. Each type has its own unique characteristics and requires an adhesive specifically designed for its properties. By choosing an adhesive tailored for your specific type of resin, you unlock the power to create a seamless connection between your resin parts.

Factor #2: Intended Use:

Are your resin creations destined to be cherished forever or are they part of a temporary project? Will they brave the elements, facing moisture, heat, or other environmental factors? Understanding the purpose behind your resin masterpiece is key to selecting an adhesive that matches your needs. For instance, if you’re crafting something that will venture into watery depths, a marine-grade adhesive becomes your trusty companion, ensuring a secure bond even in the harshest ocean tides.

Factor #3: Surface Preparation:

Just as an artist prepares their canvas before painting a masterpiece, proper surface preparation is essential when working with resin. Your resin surfaces should be pristine – free from any dust or oils – to create a strong bond. Some adhesives may require additional preparation steps like roughening the surface or applying a primer. Don’t skip this crucial step; it’s like priming your canvas for a flawless finish.

Factor #4: Strength and Flexibility:

Every resin creation has its own unique structural requirements. Some projects demand a bond that can withstand tremendous stress, while others require flexibility to endure movement. Striking the perfect balance between strength and flexibility is vital when selecting an adhesive. This ensures that your resin parts remain securely connected, defying the challenges of everyday use and preserving the beauty of your creation.

Preparing the Surfaces for Gluing

Just like a skilled magician needs the perfect spell to perform their magic, you need the ideal adhesive to ensure a robust and enduring bond between your 3D resin parts. However, before you embark on the enchanting process of gluing, there’s a vital step that must take place: preparing the surfaces.

Preparing the surfaces for gluing is akin to setting the stage for a magnificent performance. It lays the groundwork for a bond that will withstand the test of time. So, let’s unlock the secrets to properly preparing surfaces before gluing 3D resin parts together.

First and foremost, cleanliness is paramount. Resin parts often harbor residues from the printing process or handling, which can hinder the bonding process. Imagine trying to join two pieces of paper with a layer of dirt in between – it simply wouldn’t work, would it? The same principle applies to resin parts. Ensure that the surfaces are meticulously cleaned using a mild detergent or isopropyl alcohol. This will eliminate any obstacles that may impede a sturdy bond. And remember to allow the surfaces to thoroughly dry before proceeding.

Now that your surfaces are immaculate, it’s time to add some texture. Resin parts typically possess smooth surfaces, which may not provide adequate surface area for the adhesive to grip onto. To overcome this challenge, delicately sand the surfaces with fine-grit sandpaper or employ a deburring tool. The objective here isn’t to remove material but rather to create small grooves or scratches that will enhance the adhesive’s mechanical grip. Picture it as giving your adhesive tiny hooks to latch onto – a surefire way to reinforce the bond.

But wait, there’s more. To elevate your bonding experience, consider applying a primer or adhesion promoter. These enchanting products are specifically formulated to heighten bonding between certain materials, such as resin and adhesives. They form a thin layer on the surface that fosters chemical adhesion, enhancing the overall strength of the bond. It’s like adding a secret ingredient to your adhesive concoction – it amplifies its power.

Mixing the Adhesive

In our quest for perfection in bonding 3D resin parts, we’ve already explored the importance of surface preparation. Now, let’s dive into the next crucial step in our adhesive adventure – mixing the adhesive. Join me as we uncover the secrets to mastering this critical process, ensuring a bond that not only withstands the test of time but also astounds with its flawless strength.

Choose the Right Adhesive:

Before we embark on our mixing journey, let’s ensure we have the perfect adhesive for our unique project. Among the diverse options available, epoxy resin, cyanoacrylate glue (also known as super glue), and UV resin reign supreme. Each possesses distinctive characteristics and applications. Select an adhesive that aligns perfectly with your specific needs to guarantee a bond that dazzles.

Read the Instructions:

In any grand performance, preparation lays the foundation for success. Take a moment to immerse yourself in the instructions provided by the adhesive manufacturer. These sacred texts hold valuable insights into mixing ratios and curing times. By following them diligently, you set yourself up for a masterpiece of bonding.

Gather Your Materials:

Now that we’re ready to embark on our mixing odyssey, let’s gather all the necessary tools and materials. Typically, adhesives consist of two components: a resilient resin and a formidable hardener. Equip yourself with a reliable scale or measuring device and ensure you check if any additional components or additives are required for your chosen adhesive. Let’s prepare ourselves for greatness.

Measure Accurately:

Once your components stand before you, it’s time to measure them with utmost precision. Pay heed to the recommended mixing ratio outlined in the sacred instructions. The balance of these elements is crucial in attaining optimal bond strength. Let no imbalance mar your path to greatness. Measure with precision and accuracy.

Mix Thoroughly:

With your components poised and measurements precise, transfer them into a pristine mixing container. Take up your stir stick or spatula and let the symphony of resin and hardener begin. Stir gently yet thoroughly, ensuring a harmonious union devoid of streaks or inconsistencies. Let each stroke blend the elements seamlessly, creating a mesmerizing performance.

Applying the Adhesive

In our journey to achieve flawless bonds between 3D resin parts, we have already explored the secrets of mixing adhesive. Now, let’s embark on the next step – the art of applying adhesive. Get ready to dive into this fascinating process and create bonds that will endure the test of time.

Choosing the Right Adhesive:

Before we begin, let’s revisit the importance of selecting the right adhesive. With options like epoxy, super glue (cyanoacrylate), and UV-curing adhesives, it’s crucial to choose one that fits your project like a tailored suit. Consider your needs and make a wise choice.

Prepping Your Surfaces:

A clean canvas is vital for a masterpiece. Prepare your surfaces by ensuring they are free from dust and debris. Gently wipe them with a clean cloth or, if needed, a mild detergent solution. But beware of harsh chemicals that could harm your precious resin or jeopardize bonding properties.

Test Your Compatibility:

Before committing to gluing all your parts together, conduct a compatibility test on a small area. This rehearsal will save you from surprises or issues later on. It’s a crucial step before the grand performance.

Follow the Manufacturer’s Instructions:

Now comes the moment of truth – applying the adhesive. Follow the manufacturer’s instructions meticulously for success. Apply the recommended amount evenly across the surfaces you’re gluing. Remember, less is more – a thin layer outperforms excessive amounts that may lead to messy joints or weak bonds.

Curing Conditions:

Different adhesives have different curing requirements, so pay attention to specific instructions. Some may demand pressure during curing, while others require UV light or heat exposure. To achieve optimal bond strength, understand and adhere to these requirements. Think of it as creating a perfect stage for your adhesive’s performance.

Keep It Steady:

Once the adhesive is applied, it’s time to maintain stability. Avoid any movement or disturbance using clamps, tape, or other securing methods recommended by the manufacturer. Give your adhesive the perfect environment to work its magic.

Allow for Sufficient Curing Time:

Patience is a virtue in the world of adhesive bonding. Allow the glued parts to cure for the recommended time specified in the instructions before subjecting them to stress or load-bearing activities. This ensures that your bonds are strong and reliable.

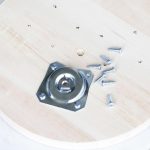

Aligning and Pressing the Parts Together

Title: The Masterful Dance of Aligning and Pressing 3D Resin Parts: Unleashing the Power of the Perfect Bond

Welcome, fellow adhesive enthusiasts, to a realm where precision and finesse reign supreme – aligning and pressing 3D resin parts together. Brace yourselves for an enchanting journey that will elevate your craftsmanship to new heights, as we unravel the secrets behind creating an unbreakable bond. Let us delve into the intricate art of aligning and pressing, where every step is a brushstroke towards perfection.

- Purify with Precision: Just as a sculptor meticulously prepares their marble, you must cleanse the surfaces destined for union. These resin parts bear the remnants of release agents and oils that threaten the adhesive’s grip. Embrace your inner alchemist and cleanse these surfaces with a gentle detergent or isopropyl alcohol, freeing them from any impurities that could mar the bond.

- The Prelude to Perfection: Before the grand symphony of adhesion begins, indulge in a dance of alignment. Place the parts together without adhesive, allowing them to embrace and reveal their true compatibility. This graceful act grants you the opportunity to make any subtle adjustments required before their eternal union.

- The Elixir of Adhesive: Ahh, the moment has arrived to unleash the magic potion. Referencing the sacred scrolls bestowed by the adhesive manufacturer, apply this elixir with meticulous precision. Whether it be through brushstrokes, sprays, or with a surgeon’s precision using a syringe, ensure a whisper-thin, even layer on one of the surfaces yearning for connection. Remember, this is where your artistry meets science.

- The Dance of Alignment: With your heart pounding in anticipation, embark on a pas de deux of alignment. Every movement must be deliberate and precise as you guide the parts together. They must intertwine flawlessly, like two celestial bodies drawn together by an invisible force. And if the cosmic alignment requires it, let alignment guides and jigs be your guiding stars.

Clamping and Curing the Bond

In this captivating dance of craftsmanship, we will delve into the pivotal role these two steps play in creating a flawless bond between 3D resin parts. As an expert guide in this enchanting art form, I am here to lead you through the nuances of clamping and curing, providing you with essential tips to achieve adhesive perfection. So, let us embark on this cosmic journey of mastery and elevate our adhesive skills to new heights.

The Mighty Clamping Force:

Clamping is not merely a mundane task; it is the conductor orchestrating a symphony of strength and security in your bond. Immerse yourself in these key points:

- Embrace Equilibrium: To banish weak spots and gaps from your bond’s existence, unleash the power of even distribution. Spread the clamping force evenly across the entire surface area. Multiple clamps or gentle hand pressure can transform chaos into harmony.

- Selecting the Perfect Partner: Size and shape are paramount. For smaller resin parts, embrace the elegance of C-clamps, bar clamps, or spring clamps. However, when dealing with larger parts, seek refuge in specialized clamping systems tailored to their needs.

- A Delicate Touch: When placing your clamps, tread carefully to provide optimal pressure without causing harm to delicate resin parts. Avoid placing clamps directly on fragile areas that may crumble under their firm embrace.

The Enigmatic Curing Process:

Curing is where true enchantment occurs; it metamorphoses your adhesive into a bond that defies time itself. Marvel at these secrets:

- Unveiling Instructions: Each adhesive possesses its own unique curing requirements. Honor its essence by meticulously following the manufacturer’s instructions regarding time and temperature. Patience becomes your ally on this mystical journey.

- A Haven for Transformation: Nurture your bond’s evolution by providing a stable and controlled environment during the curing process. Shield it from the tumultuous winds of extreme temperatures or fluctuations that threaten its strength and durability. Seek solace in a temperature-controlled room or the embrace of a curing oven.

Removing Excess Adhesive

In our cosmic journey of adhesive mastery, we have explored the intricate world of clamping and curing. Today, we delve into the art of removing excess adhesive from 3D resin parts. Whether you’re a seasoned pro or just starting out, this guide will equip you with the knowledge to achieve a clean and professional bond. So, let’s embark on this adhesive adventure together.

Step 1: Patience is Key – Let it cure.

Before tackling the excess adhesive, it’s crucial to allow it ample time to cure. Remember, a well-cured adhesive is a strong bond. Check the instructions for the recommended curing time and exercise some patience. Trust us, it’ll be worth the wait.

Step 2: Gentle Scrape or Swipe

Once your adhesive is fully cured, it’s time to bid farewell to those unsightly excesses. Grab a trusty plastic scraper or even a credit card and gently scrape off the excess glue. Take care not to scratch or damage the delicate surface of your precious resin parts while doing this. We want those parts looking flawless.

Step 3: Stubborn Adhesive? Meet Your Solvent Match.

Sometimes, even the most obedient adhesives refuse to budge. Fear not. For those stubborn spots, reach for a solvent specifically designed for that type of glue. Read and follow the instructions carefully because different adhesives may require different solvents for effective removal. Show that adhesive who’s boss.

Step 4: Smooth as Silk with Sandpaper or an Emery Board

For larger areas of excess glue, sandpaper or an emery board comes to the rescue. Gently sand away the dried adhesive until the surface becomes smooth and even. Remember, we’re aiming for perfection here, so be cautious not to sand too aggressively and unintentionally mar the resin parts. Smooth, steady strokes are the key.

Step 5: Cleanliness is Next to Adhesive Mastery

After removing the excess adhesive, it’s time to don your cleaning hat. Thoroughly clean the bonded surfaces to eliminate any residue or leftover glue. A mild soap and water solution or a specialized resin cleaner will do the trick. Ensure you dry the area properly before moving on to any finishing touches. Cleanliness is crucial for a flawless bond.

Conclusion

When it comes to gluing 3D resin parts together, there are a few key techniques to keep in mind. First and foremost, preparation is essential. Before you even think about applying any glue, make sure the surfaces you plan to join are clean and free from any dirt or residue. This will ensure a strong bond between the parts.

Next, choose the right adhesive for the job. Epoxy resin glue is often recommended for bonding resin parts due to its strength and durability. It’s important to follow the manufacturer’s instructions when using epoxy resin glue, as different brands may have slightly different application methods.

Once you have your adhesive ready, apply a thin layer onto one of the surfaces you want to join. Be careful not to use too much glue as it can create excess mess and potentially weaken the bond. Press the two surfaces firmly together and hold them in place for a few minutes to allow the glue to set.

If you’re dealing with larger or heavier resin parts, consider using clamps or other tools to secure them while the glue dries. This will help ensure that the bond remains strong and sturdy.

It’s worth noting that some 3D resins may require special adhesives or techniques for optimal bonding. If you’re unsure about which adhesive to use or how best to proceed, consult the manufacturer’s guidelines or seek advice from experienced hobbyists or professionals in the field.

In conclusion, gluing 3D resin parts together requires careful preparation, choosing the right adhesive, and following proper application techniques. By taking these steps and allowing sufficient drying time, you can achieve strong and reliable bonds between your resin parts.