Got an old concrete surface that needs to be connected to a new one? No worries. Whether you’re renovating or extending, attaching old concrete to new concrete is totally doable. It’s all about maintaining that structural integrity and making sure the transition is as smooth as possible. Lucky for you, I’ve got the lowdown on how to get it done efficiently and effectively.

To make this concrete bonding magic happen, we’ll break it down into four simple steps: surface prep, bonding agents, reinforcement placement, and pouring that fresh new concrete. Let’s dive into each step and get you on your way.

Surface Prep:

First things first, clean both the old and new concrete surfaces like there’s no tomorrow. Get rid of any loose bits, oil stains, or other pesky contaminants that might mess with the bond. You can use a wire brush, power washer, or some trusty chemicals depending on how stubborn the gunk is. The goal here is to create a clean and rough surface for better adhesion.

Bonding Agent Application:

Now it’s time for some bonding agent action. Grab yourself a top-notch epoxy-based adhesive or polymer-modified cementitious product made specifically for concrete bonding. These bad boys create a chemical and mechanical bond between the old and new concrete surfaces that’ll blow your mind (not literally). Follow the instructions from the manufacturer on how to apply it properly – coverage area, drying time – all that good stuff.

Reinforcement Placement:

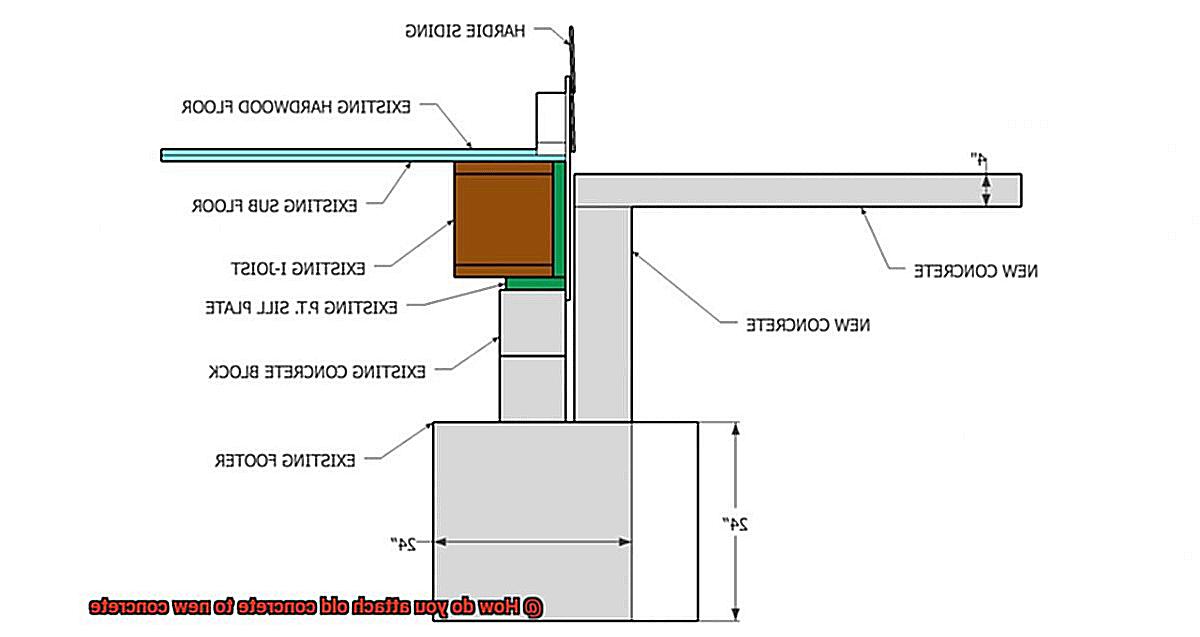

Let’s reinforce that bond even more. Depending on what you need in terms of strength and load capacity, add some steel rebars or wire mesh into the bonding agent applied on the existing concrete surface. Make sure you place them just right so they provide enough support for your structure. We don’t want any wobbly business going on here.

Pouring New Concrete:

Last but not least, it’s time to pour that fresh new concrete onto the prepped old surface. Make sure your new concrete mixture matches up with the existing structure in terms of composition, strength, and color for a seamless look. Be gentle when pouring so you don’t disturb the bonding agent or push away those reinforcements. We want everything to stay put.

What is Attaching Old Concrete to New Concrete?

Contents

When it comes to construction projects involving old and new concrete, creating a reliable bond between the two surfaces is of utmost importance. This ensures structural integrity, prevents cracking or separation, and creates a seamless transition. In this blog post, we will explore the various methods and techniques used to attach old concrete to new concrete.

Method 1: Epoxy Adhesives

Epoxy adhesives are a popular choice for attaching old concrete to new concrete due to their excellent strength and resistance to moisture, chemicals, and temperature fluctuations. The process involves applying the adhesive to both surfaces and allowing it to cure before joining them together. This chemical bond provides a durable connection that can withstand heavy loads.

Method 2: Mechanical Anchors

Using mechanical anchors, such as expansion bolts or anchor plates, is another effective method for attaching old concrete to new concrete. These anchors are embedded into the existing concrete and serve as attachment points for the new concrete. They provide a secure and reliable connection, especially in applications where high tensile or shear forces are expected.

Surface Preparation

Proper surface preparation is crucial for a successful attachment. Both the old and new concrete surfaces must be cleaned thoroughly to remove any loose particles, dirt, oil, or contaminants. Techniques such as pressure washing, grinding, or shot blasting can be employed to achieve a clean and roughened surface, which enhances adhesion.

Reinforcement Installation

In some cases, reinforcing bars or steel dowels may be required to enhance the connection’s strength. These mechanical connectors distribute loads evenly and minimize stress concentrations at the joint. Reinforcement installation should be done according to industry standards and guidelines.

Professional Guidance

For complex or critical applications, it is always recommended to consult with a professional contractor or structural engineer. They have the expertise to assess the specific needs of your project and determine the most suitable method for attaching old concrete to new concrete. Their guidance ensures that the desired results are achieved while adhering to safety and quality standards.

Preparation of Existing Concrete Surface

In the world of construction, creating a strong bond between old and new concrete is like building a bridge between two worlds – it ensures stability, prevents cracks, and seamlessly blends the past with the present. So, how do we achieve this feat? Well, let’s dive into the methods and techniques that experts use to prepare existing concrete surfaces for attachment to new concrete.

Thorough Cleaning: Clearing the Path

Before attaching anything, proper surface preparation is key. Thoroughly clean both the old and new concrete surfaces to remove any loose particles, dirt, oil, or contaminants. Techniques such as pressure washing or grinding give us a clean canvas with a roughened texture that enhances adhesion. This ensures a strong bond and minimizes the risk of failure or disintegration over time.

Repairing Damages: Restoring Strength

Inspect the existing concrete for any cracks, spalling, or other forms of damage. These issues should be repaired before proceeding with the attachment process. Cracks can be filled with appropriate concrete repair materials, while spalled areas may require more extensive repairs or even replacement. By restoring the strength and integrity of the existing surface, we lay the foundation for a successful attachment.

Etching: Creating a Rough Surface

Once the surface is clean and any necessary repairs have been made, it is recommended to etch the existing concrete. Etching involves applying an acid solution or mechanical means to roughen the surface and provide a better grip for the adhesive. This step enhances the bond strength between the old and new concrete surfaces, ensuring a secure connection that withstands the test of time.

Choosing the Right Adhesive: The Glue that Holds it All Together

The choice of adhesive is crucial in ensuring a successful attachment of old concrete to new concrete. Epoxy adhesives are commonly used due to their high bond strength and durability. They are available in different formulations, including epoxy paste, epoxy mortar, and epoxy injection systems. The specific adhesive chosen should be suitable for both the existing and new concrete surfaces. Apply the adhesive evenly onto both surfaces, following the manufacturer’s instructions regarding coverage rate and curing time.

Proper Alignment and Finishing: A Seamless Integration

Once the adhesive is applied, the new concrete can be placed or attached onto the existing surface. Care should be taken to ensure proper alignment and contact between the two surfaces. Any excess adhesive or mortar should be removed to achieve a neat and professional finish. This attention to detail ensures a seamless integration of old and new concrete, creating a visually appealing and structurally sound result.

Using a Bonding Agent or Adhesive

When it comes to renovating or building structures, the challenge of bonding old and new concrete surfaces together can seem insurmountable. However, with the right bonding agent or adhesive, this task becomes much easier. In this article, we will explore the world of bonding agents and adhesives and how they facilitate the seamless attachment of old concrete to new concrete. So, put on your hard hats and join us as we delve into this fascinating process.

Preparation is Key:

Before applying any bonding agent, thorough preparation of both the old and new concrete surfaces is essential. This involves a meticulous cleaning to remove dirt, dust, and debris that could hinder the bond. Additionally, any loose or damaged concrete should be repaired or removed, ensuring a solid foundation for the attachment.

Choosing the Perfect Bonding Agent:

Selecting the right bonding agent is crucial for a successful attachment. Various types of adhesives are available, including epoxy, polyurethane, and acrylic-based options. The choice depends on factors such as the condition of the concrete and the desired strength of the bond. Each adhesive acts as the perfect puzzle piece for your specific project.

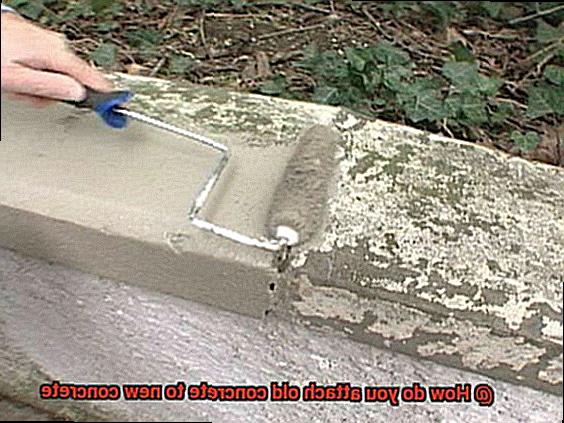

Application Techniques:

Once you have chosen your bonding agent, it’s time to apply it to both surfaces. Following the manufacturer’s instructions, ensure a thin and even layer of adhesive covers each surface. Imagine brushing on a coat of paint – you want complete coverage without excess application that could lead to pooling or dripping.

Pouring with Precision:

With the bonding agent applied, it’s time to pour or apply the new concrete onto the old surface. Working swiftly and efficiently before the adhesive dries is crucial for proper alignment and consolidation, resulting in a strong bond between the two surfaces. Think of it as fitting puzzle pieces together – each element must interlock seamlessly.

Curing for Strength:

To allow for optimal bonding, the newly attached concrete should undergo proper curing. This may involve using curing compounds or employing methods like wet curing or plastic sheeting. Just as a delicate piece of artwork needs time to set, the bond between concrete surfaces requires the right conditions to strengthen.

Using Mechanical Fasteners

Imagine standing on a construction site, admiring the newly poured concrete surface. But did you know that beneath that surface lies the secret to seamlessly joining old and new concrete? Today, we dive into the world of mechanical fasteners, highlighting their importance in creating strong connections. So grab your construction hat and let’s get started.

Types of Mechanical Fasteners:

When it comes to attaching old concrete to new concrete, mechanical fasteners are the unsung heroes. Let’s explore some popular options:

- Anchor Bolts: These heavy-duty bolts join large structural elements like walls or columns. Embedded in existing concrete and secured with epoxy or grout, anchor bolts create a rock-solid foundation for the new concrete.

- Expansion Anchors: Ideal for lighter objects, expansion anchors tightly grip pre-drilled holes in old concrete. With types like wedge anchors, sleeve anchors, and drop-in anchors, there’s a perfect match for every application.

- Concrete Screws: With impressive pull-out resistance and shear strength, these specialized screws easily attach non-structural elements like handrails or fixtures. Simply drill a hole into the old concrete and drive the screw in for a secure connection.

Proper Installation – The Key to Success:

Now that we’ve explored the types of mechanical fasteners, let’s delve into proper installation:

- Depth Matters: Embed fasteners deep enough into the old concrete to provide strength and stability for a secure connection that withstands the test of time.

- Mind the Gap: Maintain proper spacing between fasteners to evenly distribute the load across attachment points, preventing stress points that could lead to failure.

Preparing for Success – The Importance of Surface Preparation:

Before attaching old concrete to new concrete, consider these preparatory steps:

- Cleanliness is Next to Bond-iness: Thoroughly clean both surfaces, removing loose debris and contaminants that could compromise the bond. A clean canvas provides the best backdrop for a masterpiece.

- Enhancing the Bond: Use a concrete bonding agent or adhesive to enhance the connection between old and new concrete. Add an extra layer of magic for a strong bond.

Conclusion:

In the world of construction, attaching old concrete to new concrete may seem like a puzzle. However, with the right mechanical fasteners, proper installation, and surface preparation, you can create seamless connections that stand the test of time. So put your knowledge into practice, grab your tools, and let your construction prowess shine.

Creating a Roughened Surface

If you’re seeking to achieve a flawless bond between old and new concrete, you’ve come to the right place. In this article, we will explore the various methods that can be employed to create a roughened surface, ensuring an impeccable attachment. So grab your hard hat and get ready for an exciting journey.

First and foremost, let’s delve into the world of mechanical roughening. This technique involves the use of powerful tools like chipping hammers or scarifiers to physically roughen the concrete surface. It’s a tried and true method that eliminates any loose or deteriorated concrete, providing you with a fresh canvas to work on. However, be prepared for the possibility of investing significant time and physical effort, especially when dealing with extensive areas.

Now, let’s move on to the captivating realm of abrasive blasting. This method employs a high-pressure stream of abrasive material, such as sand or shot, to roughen the surface. The result? Contaminants are swiftly eradicated, leaving behind a textured surface that is ideal for bonding. However, it’s crucial to note that specialized equipment is required, along with extra safety precautions to safeguard yourself and adjacent structures.

For those seeking a chemical solution, chemical etching is your best bet. This method entails applying an acid-based solution to the concrete, triggering a reaction with the cement paste and exposing the aggregate. The end result is a beautifully textured surface that enhances adhesion. Nonetheless, remember to adhere strictly to safety guidelines when handling chemicals and dispose of waste responsibly.

Last but certainly not least, we have an array of surface preparation products readily available in the market. These ingenious products contain special chemicals that react with the concrete surface, creating micro-fractures and improving adhesion. The best part? They are incredibly user-friendly and can be conveniently applied using a brush or roller.

Regardless of the method you choose, always remember that cleanliness is paramount. Prior to roughening the old concrete surface, ensure that it is meticulously cleaned. Any traces of dirt, oil, or other contaminants can hinder the effectiveness of the bonding process. Additionally, it is essential to diligently follow the manufacturer’s instructions when utilizing specific products.

Creating a roughened surface is merely the initial step in the process of attaching old concrete to new concrete. Once you have achieved that desired texture, it’s time to apply a bonding agent or adhesive to guarantee a robust and long-lasting bond. However, we’ll save that topic for another captivating discussion.

Factors Affecting Successful Attachment

Today, we’re diving deep into the world of successful attachment between old and new concrete. Hold onto your hard hats as we explore the factors that can make or break your glue game. From the condition of the old concrete to the curing time, we’ve got you covered. So, let’s get started.

Factor 1: Old Concrete Condition

Picture this: you’re trying to attach new concrete to an old, cracked surface. Well, my friend, that’s not going to cut it. Before you even think about bonding, make sure the old concrete is in good shape. Fill any cracks, repair spalling, and ensure a solid foundation for the new concrete to adhere to. Remember, a strong bond starts with a strong base.

Factor 2: Choosing the Right Adhesive

Now that we’ve got a stable old concrete, it’s time to choose the perfect adhesive. Epoxy-based adhesives, polyurethane-based adhesives, or cementitious bonding agents are all on the menu. Each type has its own strengths and applications, so pick one that suits your needs. And whatever you do, read those manufacturer instructions like your life depends on it. Proper application is key to a successful bond.

Factor 3: Surface Preparation Magic

Cleanliness is next to godliness in the world of concrete bonding. Say goodbye to loose debris, dust, oil, grease, and paint before you even think about attaching new concrete. Mechanical roughening, abrasive blasting, and chemical etching are all fantastic techniques for creating a textured surface that screams “stick with me.” Remember, a rough surface is a glue’s best friend.

Factor 4: Curing Time – Patience Pays Off

We live in a fast-paced world, but when it comes to concrete bonding, patience is a virtue. Curing time is crucial for both the adhesive and the new concrete to reach their full potential. Follow the adhesive manufacturer’s recommendations and keep the bonded area moist and protected from extreme temperatures. Your reward? A bond that can withstand the test of time.

Conclusion:

Congratulations, my fellow concrete enthusiasts. You’ve just unlocked the secrets of successful attachment between old and new concrete. Remember the importance of a solid old concrete foundation, choosing the right adhesive, preparing your surfaces like a pro, and giving your bond the time it needs to cure. With these factors in mind, you’re well on your way to achieving a bond that will leave others green with envy. Stay tuned for more captivating discussions on all things glue-related. Until next time, keep bonding.

Consulting with an Expert

Whether you’re embarking on a home renovation project or looking to enhance your business strategy, tapping into the knowledge and experience of an expert can lead to remarkable results. So, let’s dive in and discover why consulting with an expert is a wise choice.

Specialized Knowledge and Experience:

Experts possess specialized knowledge and years of experience in their respective fields. They have dedicated countless hours to mastering their craft and staying up to date with the latest industry trends. By consulting with them, you gain access to their expertise, enabling you to make informed decisions and avoid costly mistakes.

Customized Solutions:

Experts understand that every situation is unique. They take the time to thoroughly analyze your specific needs and challenges before providing tailored solutions. Whether it’s developing a personalized fitness plan or devising a growth strategy for your business, experts have the skills to create solutions that align with your goals and circumstances.

Problem-solving Abilities:

When faced with complex problems or obstacles, experts excel at finding innovative solutions. Their ability to think critically and apply their knowledge allows them to navigate challenges efficiently. By consulting with an expert, you gain a fresh perspective on your problem and benefit from their creative problem-solving skills.

Time and Cost Efficiency:

Consulting with an expert can save you valuable time and money in the long run. Instead of spending hours researching and experimenting on your own, an expert can provide you with proven methods and strategies that have been tried and tested. Their guidance helps you avoid unnecessary detours and ensures that your efforts are focused on the most effective approaches.

Network of Resources:

Experts often have extensive networks within their industries. Consulting with them gives you access to these valuable connections, including other professionals, suppliers, and potential collaborators. This network can open doors to new opportunities and provide you with additional resources to support your goals.

Confidence and Peace of Mind:

One of the greatest advantages of consulting with an expert is the confidence and peace of mind it brings. Knowing that you have sought guidance from someone with expertise in the field can alleviate stress and uncertainty. Experts provide reassurance and support throughout the process, empowering you to make informed decisions and move forward with confidence.

ElNThXvtJ18″ >

Conclusion

When it comes to attaching old concrete to new concrete, there are a few key steps you need to follow. First and foremost, you’ll want to ensure that the surface of the old concrete is clean and free from any debris or loose material. This can be achieved by using a wire brush or pressure washer to thoroughly clean the area.

Once the old concrete is clean, it’s time to apply a bonding agent. This adhesive substance helps create a strong bond between the old and new concrete surfaces. Make sure to choose a bonding agent that is specifically designed for use with concrete.

Next, it’s important to prepare the new concrete surface. This involves roughening up the area where the new concrete will be applied. You can do this by using a chisel or grinder to create a textured surface. This texture provides more surface area for the bonding agent to adhere to.

Now comes the exciting part – applying the new concrete. Start by dampening the old concrete surface with water. This helps prevent premature drying of the fresh concrete and allows for better adhesion. Then, mix your new concrete according to the manufacturer’s instructions and pour it onto the prepared area.

Using a trowel or float, spread and level out the new concrete until it matches the surrounding surface. Take care to ensure that there are no air pockets or voids in the newly poured concrete.

Lastly, allow ample time for curing and drying before subjecting your newly attached old and new concrete surfaces to any heavy loads or traffic. Follow any additional instructions provided by your chosen bonding agent or concrete manufacturer.