Whether you’re a DIY enthusiast or a pro engineer, this question pops up all the time. From industrial gear to everyday stuff, we’ll show you how to create a strong bond between these two materials.

Get ready for step-by-step guidance and pro tips. We’ll cover everything from prepping surfaces and picking the perfect adhesive to tackling common hiccups.

So let’s jump in and unlock the secrets of sticking rubber to metal like a boss.

Adhesive Bonding Agents for Rubber-to-Metal Bonding

Contents

The secret lies in the utilization of adhesive bonding agents specifically designed for rubber-to-metal bonding. In this insightful blog post, we will delve into the world of adhesive bonding agents, exploring their different types and highlighting their crucial role in creating reliable bonds between rubber and metal surfaces.

Types of Adhesive Bonding Agents:

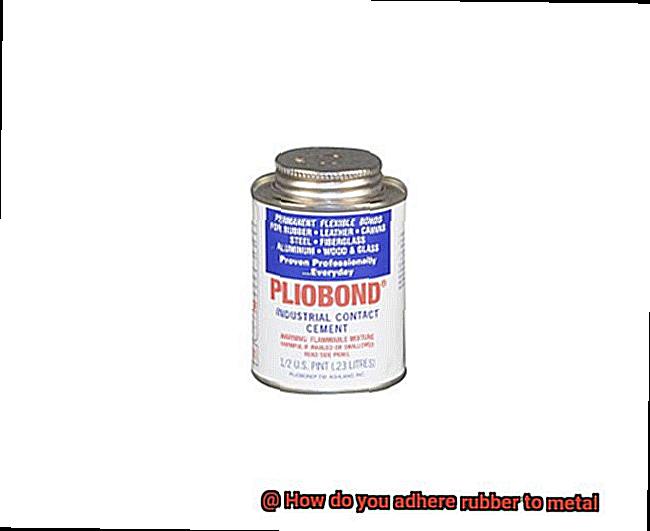

- Solvent-based adhesives: These adhesives are widely favored for rubber-to-metal bonding due to their rapid drying properties and exceptional initial bond strength. By evaporating volatile solvents during the curing process, they leave behind a robust and flexible bond. Solvent-based adhesives are versatile, effectively bonding various rubber compounds to different metals.

- Water-based adhesives: Renowned for being environmentally friendly and low in volatile organic compound (VOC) content, water-based adhesives offer commendable adhesion and flexibility. They serve as an excellent alternative to solvent-based adhesives, particularly in applications where environmental concerns take precedence, such as the automotive industry.

- Heat-activated adhesives: Requiring the application of heat to activate their adhesive properties, these adhesives exhibit outstanding resistance to temperature extremes. Frequently employed in industries like aerospace and electronics, where high bond strength is imperative, heat-activated adhesives ensure long-lasting durability.

Importance of Adhesive Bonding Agents:

- Strength and Durability: Adhesive bonding agents are instrumental in establishing sturdy and durable bonds between rubber and metal surfaces. This quality is vital for products subjected to constant stress or harsh environmental conditions.

- Flexibility: Rubber-to-metal bonded assemblies often necessitate flexibility to accommodate movement or vibration. Adhesive bonding agents provide the necessary flexibility without compromising bond strength, ensuring the longevity of the bond.

- Resistance to Environmental Factors: Formulated to resist exposure to moisture, chemicals, and temperature fluctuations, adhesive bonding agents guarantee the endurance of the bond, even in harsh environments.

Tips for Successful Rubber-to-Metal Bonding:

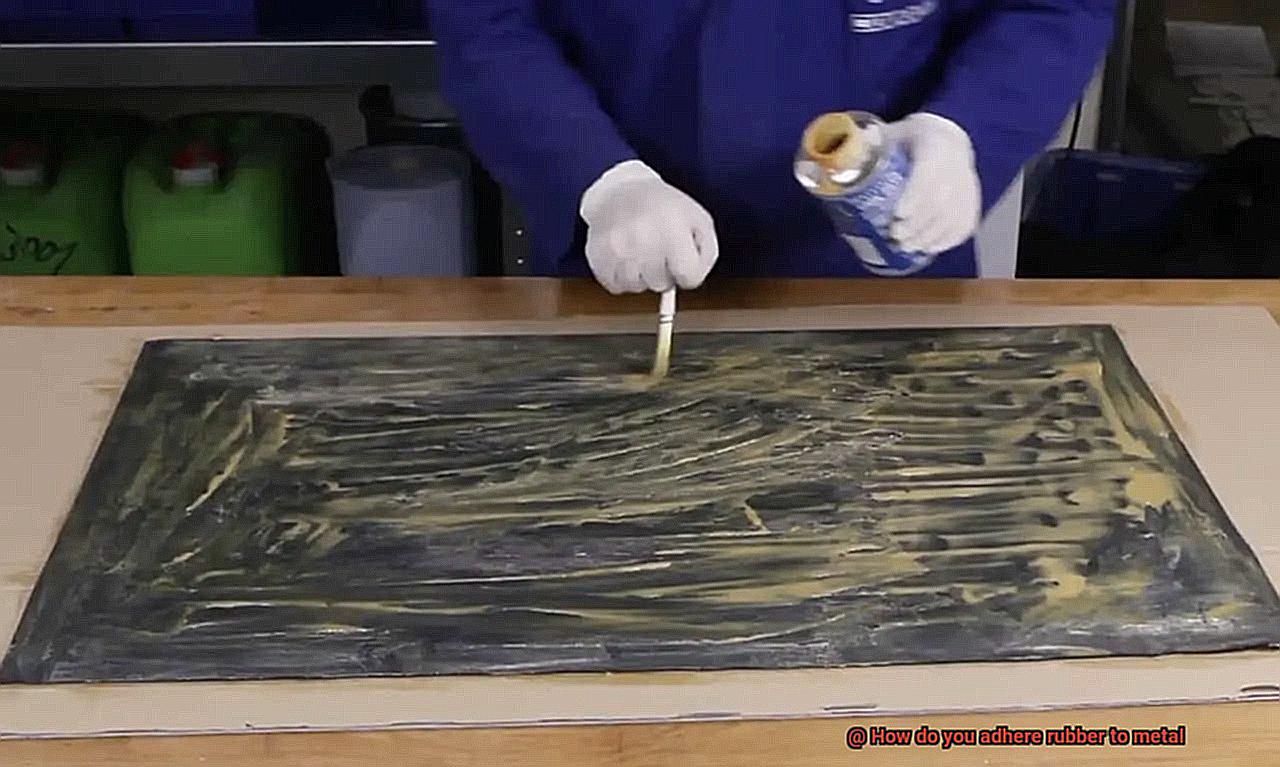

- Surface Preparation: Thoroughly clean both rubber and metal surfaces to eliminate any contaminants that may impede the bonding process. Enhance adhesion by roughening the metal surface with sandpaper or a wire brush.

- Application Technique: Adhere to the manufacturer’s instructions regarding application methods and curing time for optimal results. Apply the adhesive evenly on both surfaces using a brush, roller, or spray.

- Proper Pressure Application: Apply firm pressure to the bonded assembly to ensure complete contact between rubber and metal surfaces. Clamps, weights, or other appropriate means can be utilized during curing to apply sufficient pressure.

Cyanoacrylate Adhesives

In the world of adhesives, there is a powerful force that brings rubber and metal together in perfect harmony: cyanoacrylate adhesives. Commonly known as super glues, these remarkable adhesives are renowned for their fast curing time and exceptional bond strength.

Before embarking on the bonding journey, it is essential to prepare the surfaces to be joined. A pristine canvas is paramount, free from any dirt, oil, or unwanted contaminants that could hinder the adhesive’s effectiveness. For optimal adhesion, a touch of roughness is needed. By lightly sanding or filing the rubber and metal surfaces, a textured landscape is created, enhancing the bond’s grip.

Now, it is time to unleash the power of cyanoacrylate adhesives. A little goes a long way with these mighty glues, as their high bonding strength ensures that only a small amount is needed. Apply the adhesive evenly on both surfaces, ensuring uniform coverage. Then, bring the two materials together with conviction, pressing firmly to ensure maximum contact and union.

To secure the bond’s success, it is recommended to employ additional measures such as clamping or securing the bonded parts until the adhesive reaches its full cure. While this usually takes only a matter of minutes, it is always wise to consult the manufacturer’s instructions for precise curing times tailored to your specific adhesive.

The bond forged by cyanoacrylate adhesives possesses impressive resilience against moisture, heat, and even chemicals. It proves itself worthy in applications where durability and reliability are paramount.

However, as with any adhesive adventure, challenges may arise. Not all rubber types are compatible with cyanoacrylate adhesives. Silicone rubber or rubber with low surface energy may require specialized adhesives specifically designed for bonding those particular materials to metal. When faced with such situations, it is advisable to seek guidance from adhesive manufacturers or industry experts who hold the key to unlocking successful bonding solutions.

Two-Component Epoxy Adhesives

Today, we embark on an epic journey through the realm of glue, where rubber and metal yearn to unite. Our hero? The mighty two-component epoxy adhesive – a super glue that possesses the strength and durability to conquer any challenge. So grab your cape and let’s dive into the fascinating world of adhesive bonding.

Preparing for Glory:

Before our hero can work its magic, proper surface preparation is essential. Think of it as creating a clean canvas for a masterpiece. Cleanse the rubber and metal surfaces of any dirt or oil using your trusty cleaning tools. But wait, there’s more. To add texture to our adhesive artwork, lightly sand or file the surfaces for optimal grip. Now we’re ready to bring our superhero to life.

Mixing the Magic:

Like a brilliant chemist, our two-component epoxy adhesive requires careful mixing of its secret ingredients – the resin and hardener. Follow the manufacturer’s instructions to ensure the perfect balance. Just imagine you’re creating a potion with just the right amount of each ingredient, stirring until you achieve a homogenous mixture.

The Epic Bonding Battle:

It’s showtime. Take your applicator or brush and apply an even layer of our superhero adhesive onto either the rubber or metal surface. Make sure it covers the entire bonding area – no weak spots allowed. With unwavering determination, press the rubber and metal together firmly. This is where the magic happens.

Waiting for Victory:

To ensure a successful union, our superhero needs time to work its wonders. Apply pressure or use clamps to hold the surfaces together until the epoxy cures completely. The length of this heroic battle varies depending on the specific adhesive used, but patience is key. Give it at least 24 hours for full curing.

Unlocking Maximum Strength:

Some superheroes have hidden powers, and our two-component epoxy adhesive is no exception. Some may require additional post-curing treatments, such as heat or UV exposure, to unleash their ultimate strength. Don’t forget to consult the manufacturer’s recommendations for the best results.

Conclusion:

Congratulations, brave readers. You’ve successfully navigated the world of two-component epoxy adhesives and their heroic quest to unite rubber and metal. Armed with proper surface preparation, careful mixing, and patience during curing, you can achieve a bond that defies the elements. Remember, every adhesive adventure is unique, so consult the manufacturer’s instructions for specific guidance. Now go forth and conquer your own adhesive challenges with the power of two-component epoxy adhesives.

Mechanical Fastening Methods

When it comes to joining rubber and metal, mechanical fastening methods offer a reliable alternative to traditional adhesives or glues. These techniques rely on physical means to create a strong bond, ensuring durability and longevity in various applications.

In this blog post, we will delve into the world of mechanical fastening methods used to adhere rubber to metal, exploring popular options and their unique advantages.

Screws and Bolts: The Tried and True Method

One of the most widely used mechanical fastening methods is the utilization of screws or bolts. By drilling holes through the rubber and metal surfaces, screws or bolts can be inserted, providing a secure grip through their threaded design. This method is particularly beneficial in industrial machinery or automotive components, where a robust and permanent bond is required.

Rivets: Solidifying Strength

For applications demanding high shear strength, rivets come into play. These permanent fasteners consist of a cylindrical shaft with a head on one end and a tail on the other. After drilling holes through the rubber and metal components, rivets are inserted and the tail is deformed or “peened” to create a tight bond. Rivets excel in structural components or heavy-duty equipment where strength is paramount.

Clips and Clamps: Versatility Meets Convenience

Clips or clamps provide an easily detachable solution for bonding rubber to metal. By applying pressure, these devices hold the materials together securely. Their flexibility makes them perfect for applications requiring frequent assembly or disassembly, such as temporary structures or prototypes.

Interlocking Mechanisms: A Puzzle of Perfection

Interlocking mechanisms offer an innovative approach to mechanical fastening. By designing rubber and metal components to fit together like puzzle pieces, a tight and secure bond is achieved. This method can take the form of tabs and slots or hooks and loops, commonly found in consumer products like rubber grips on tools or handles on kitchen utensils.

Conclusion:

Using Rivets and Screws

When it comes to bonding rubber to metal, most people immediately think of glue or adhesive. But did you know that there’s another option that offers exceptional strength, durability, and versatility? Mechanical fasteners, such as rivets and screws, provide reliable connections that can withstand heavy loads and constant movement. In this blog post, we’ll explore the world of rivets and screws and delve into their advantages and techniques for adhering rubber to metal.

The Power of Rivets:

Rivets, those small cylindrical metal pieces, create a permanent connection between rubber and metal. By inserting them through pre-drilled holes in both materials and deforming them on one side, a secure bond is formed. Rivets are known for their exceptional strength, making them ideal for applications that require rubber to withstand heavy loads or constant movement. Automotive, construction, electronics, and manufacturing industries frequently rely on rivets due to their reliability.

Screws: The Versatile Option:

If you need a strong bond that allows for easy disassembly or regular replacement of the rubber component, screws are your go-to choice. By drilling pilot holes in the rubber and metal surfaces, screws can be inserted and tightened using a screwdriver or power drill. This versatile option ensures a secure connection while offering convenience when it comes to maintenance or repairs.

Techniques for Success:

Achieving a successful bond with rivets or screws requires proper alignment. Precise positioning prevents misalignment and ensures a secure connection between the rubber and metal surfaces. Additionally, selecting the right size and type of fastener is essential. Consider factors such as material thickness, load-bearing capacity, and environmental conditions to make an informed decision.

Surface Preparation for Adhering Rubber to Metal

When it comes to bonding rubber to metal, surface preparation is the unsung hero that ensures a strong and long-lasting connection. In this article, we will unveil the secrets of achieving a perfect bond between these two materials, guiding you through the intricate process of surface preparation. So, grab your cleaning agents and sandpaper, because we’re about to dive into the world of surface preparation.

Step 1: Cleaning the Metal Surface

Before any bonding can take place, it’s crucial to clean the metal surface thoroughly. Think of it as preparing a canvas for a masterpiece. Use solvents or cleaning agents that are compatible with both the metal and rubber. Acetone or isopropyl alcohol are excellent options as they evaporate quickly, leaving no residue behind. Say goodbye to dirt, grease, oil, and other contaminants that can hinder adhesion. Embrace the purity of the metal surface.

Step 2: Roughening the Metal Surface

Creating texture on the metal surface is essential for optimal adhesion. It’s like adding texture to a painting, giving it depth and dimension. You can achieve this by sanding the surface with coarse-grit sandpaper or using a wire brush. Feel the roughness under your fingertips, knowing that it’s increasing the surface area available for bonding. Alternatively, you can opt for abrasive blasting techniques such as sandblasting or bead blasting. Imagine tiny particles dancing on the metal surface, creating a roughened texture that beckons the rubber to adhere.

Step 3: Preparing the Rubber Surface

Just like with the metal surface, proper preparation is necessary for the rubber material as well. It’s time to cleanse and purify its essence. Degrease the rubber using solvents or detergents to remove any oils, lubricants, or release agents that may hinder adhesion. Imagine the rubber surface becoming pristine and ready to embrace the metal with open arms. A clean rubber surface ensures a strong bond, like two souls intertwining.

Step 4: Drying Time

After both surfaces have been cleaned and prepared, it’s essential to ensure they are completely dry before applying any adhesive. Moisture can be the enemy of a perfect bond. Let them bask in the warmth of time, or if time is of the essence, you can apply heat to accelerate the drying process. Feel the anticipation in the air as the surfaces become ready for their destined union.

Cleaning the Surfaces

Imagine working on a project that involves bonding rubber to metal. You have all the necessary materials and adhesives ready, but have you considered the crucial step of cleaning the surfaces? In this article, we delve into the significance of surface cleaning, its benefits, and provide you with practical tips to ensure exceptional results.

Enhanced Adhesion:

Surface cleaning plays a pivotal role in achieving superior adhesion when bonding rubber to metal. By eliminating dirt, dust, and contaminants, you create an ideal environment for the adhesive to work its magic. A clean surface facilitates maximum contact between rubber and metal, resulting in a robust and durable bond.

Reduced Contamination:

Contaminants such as oils, grease, and residues can act as barriers, impeding the adhesive’s ability to form a solid connection. Thoroughly cleaning the surfaces eliminates these potential roadblocks and prevents future issues arising from contamination.

Improved Overall Performance:

The cleanliness of the surfaces directly impacts the performance of the bonded rubber and metal. Proper cleaning allows the adhesive to penetrate into the microstructures of both materials, enhancing strength and durability. Consequently, this translates to improved resistance against environmental factors such as moisture, temperature fluctuations, and mechanical stress.

Types of Cleaners:

Choosing the right cleaner is critical for effective surface preparation. Mild soapy water or isopropyl alcohol are generally safe options that effectively remove most contaminants without causing damage. However, it is essential to consider the specific properties of your rubber and metal when selecting a cleaner to ensure compatibility.

Techniques for Surface Preparation:

Begin by removing loose debris using a soft brush or cloth. Apply the chosen cleaner onto a clean cloth or sponge and gently wipe down both surfaces. Pay attention to hidden crevices and hard-to-reach areas. Rinse off any residue with clean water and ensure thorough drying before proceeding.

Safety Precautions:

When handling cleaning solutions, adhering to safety guidelines is crucial. Wear appropriate protective gear, such as gloves and goggles, and work in a well-ventilated area. Avoid using abrasive cleaners or excessive force during cleaning, as they may damage the surfaces.

Roughening the Metal Surface

Achieving a strong and lasting connection between rubber and metal requires the unsung hero of roughening the metal surface. Just like preparing a stage for a grand performance, every detail matters to ensure flawless execution. In this article, we will explore the different methods of roughening metal surfaces and how they contribute to better adhesion between rubber and metal.

Mechanical Roughening:

One effective method is mechanical roughening, which physically alters the metal surface using abrasive materials like sandpaper, wire brushes, or abrasive wheels. This process eliminates contaminants and oxidation while creating microscopic grooves that increase the bonding surface area. It gives your adhesive a better grip, ensuring a stronger connection. Remember to choose the appropriate abrasive material for optimal results.

Chemical Etching:

Chemical etching is another method that relies on applying a chemical solution to the metal surface. This solution reacts with the metal, creating a textured surface that enhances adhesion. Chemical etching can be applied through dipping, brushing, or spraying, depending on the size and shape of the metal substrate. However, it’s crucial to select a compatible chemical solution that won’t compromise the properties of both the metal and rubber.

Thermal Methods:

For alternative options, thermal methods present intriguing possibilities. Flame treatment involves passing a controlled flame over the metal surface for a specific duration. The heat causes micro fractures and increased surface roughness, promoting better adhesion. Grit blasting propels abrasive particles onto the metal surface using air or centrifugal force, effectively removing contaminants and creating a textured finish. Both methods require caution to prevent excessive heat or overly abrasive particles from damaging the metal surface.

crzEogUOFrs” >

Conclusion

When it comes to adhering rubber to metal, there are several effective methods you can use. One common approach is using adhesive bonding agents specifically designed for this purpose. These adhesives are formulated to create a strong and durable bond between the rubber and metal surfaces.

Another method is mechanical bonding, which involves creating physical interlocking between the rubber and metal. This can be achieved through techniques such as molding the rubber onto the metal or using mechanical fasteners like screws or rivets.

In addition, surface preparation plays a crucial role in ensuring a successful bond. Both the rubber and metal surfaces should be clean, dry, and free from any contaminants that could hinder adhesion. Proper surface treatment methods like degreasing, sanding, or using primers can enhance the bond strength.

It’s also important to consider the specific application requirements when choosing an adhesive or bonding method. Factors such as temperature resistance, flexibility, and chemical compatibility should be taken into account to ensure long-lasting adhesion.

In conclusion, adhering rubber to metal requires careful consideration of the appropriate bonding method and surface preparation. By using specialized adhesives or mechanical bonding techniques and ensuring proper surface treatment, you can achieve a strong and reliable bond between rubber and metal surfaces.