Whether you’re a DIY enthusiast, an inventive soul looking to attach magnets to your latest creation, or simply someone who loves a good challenge, we’ve got you covered. In this post, we’ll delve into the mesmerizing world of magnet adhesion, uncovering the secrets to achieving a secure and long-lasting bond.

But hold on tight – while we aim to keep things casual and friendly, we also understand the gravity of handling these powerful little wonders. So grab your trusty toolbox and prepare for a plunge into the realm of magnet adhering prowess. From prepping surfaces with finesse to selecting the perfect adhesive partner, we’ll guide you step by step, sharing invaluable tips and tricks along the way.

So whether you’re new to magnet adhesion or eager to polish your skills, get ready for a magnetic adventure. Let’s embark on this journey together and unlock the full potential of these captivating forces of nature.

Adhesive Materials for Adhering Magnets

Contents

- 1 Adhesive Materials for Adhering Magnets

- 2 Epoxy Resin as an Adhesive Option

- 3 Cyanoacrylate Glue as an Adhesive Option

- 4 Other Methods of Adhering Magnets

- 5 Magnetic Tape or Strips for Temporary or Removable Magnet Attachment

- 6 Surface Preparation for Adhering Magnets

- 7 Strength and Weight of the Magnets

- 8 Important Considerations for Optimal Results

- 9 Conclusion

Magnets are versatile objects with a wide range of applications, but ensuring they stay securely in place requires choosing the right adhesive material. In this comprehensive guide, we will explore various adhesive options and provide insights into their advantages and considerations.

Epoxy Resin: Strength and Versatility

Epoxy resin is a popular choice for adhering magnets due to its excellent adhesion properties. It forms a durable bond between magnets and surfaces like metal, plastic, and wood. Offering high strength, it can withstand shear and tensile forces. It’s important to select an epoxy adhesive specifically formulated for bonding magnets to ensure optimal results.

Cyanoacrylate Glue: Quick and Reliable

Cyanoacrylate glue, or super glue, quickly forms a strong bond. Compatible with magnets, it adheres well to surfaces such as metal, ceramic, and glass. Ideal for applications requiring a quick and reliable bond, it may not be suitable for high temperatures or moisture exposure.

Silicone Adhesives: Flexibility and Resistance

Silicone adhesives are a great choice for applications requiring flexibility and resistance to temperature variations. They provide good adhesion while allowing some movement without compromising the bond. Resistant to moisture, chemicals, and temperature changes, they are suitable for indoor and outdoor use. However, they may not offer the same strength as epoxy or cyanoacrylate.

Specialized Magnet Adhesives: Enhanced Performance

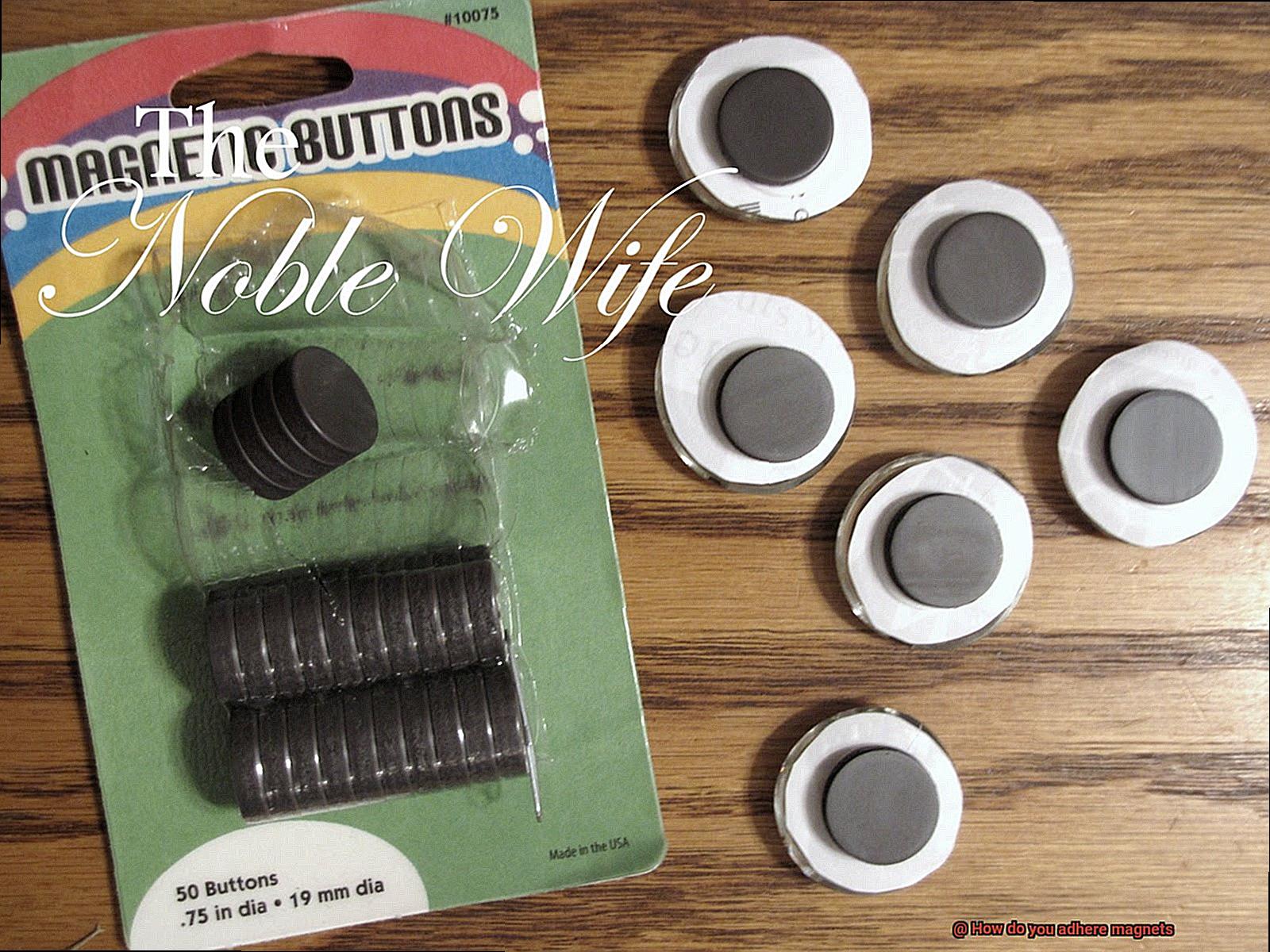

Specialized magnet adhesives offer enhanced performance in terms of strength and durability. Designed specifically for bonding magnets, they often come in tape or sheet form with adhesive backing, providing convenience and ease of use for various applications.

Considerations and Precautions:

When selecting an adhesive material for magnets, consider factors such as surface type, temperature exposure, moisture resistance, and required strength. Follow manufacturer’s instructions and properly prepare the surface before applying the adhesive to ensure a strong and durable bond.

Epoxy Resin as an Adhesive Option

Whether you’re trying to hang up a picture or organize your tools, finding the right adhesive can be a challenge. But fear not. We’ve got the perfect solution for you – epoxy resin.

Epoxy resin is like the superhero of adhesives. It’s strong, durable, and can withstand just about anything you throw at it. And when it comes to adhering magnets, epoxy resin is the way to go.

So, what makes epoxy resin so great? Let’s break it down:

- Strength: Epoxy resin forms a bond that can handle some serious stress. It can withstand vibrations, movement, and even extreme pressure. So no matter how much you jiggle or shake those magnets, they’re not going anywhere.

- Gap-filling: Have an uneven surface? No problem. Epoxy resin has the magical ability to fill in gaps and voids, ensuring a seamless bond between the magnet and the surface. Say goodbye to wobbly magnets.

- Temperature and moisture resistance: Whether you’re using magnets indoors or outdoors, epoxy resin can handle it all. It can withstand extreme temperatures and exposure to water or humidity without compromising the bond. So go ahead and stick those magnets on your fridge or use them in your backyard – epoxy resin has got your back.

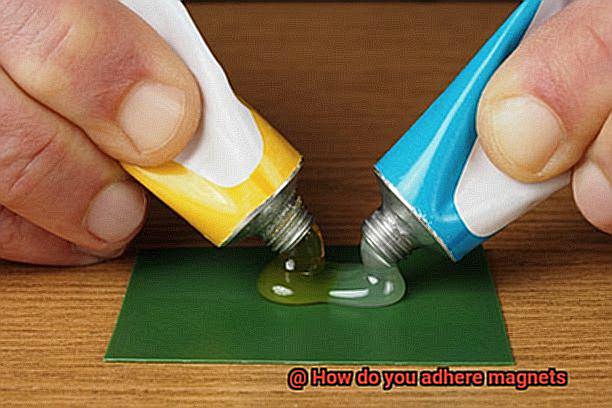

Now that you know why epoxy resin is the bee’s knees when it comes to adhesive options for magnets, let’s talk application. It’s important to properly prepare the surfaces by cleaning them and removing any oils or contaminants. A light sanding will also help create a rough texture that enhances bonding strength.

Next, mix the epoxy resin according to the manufacturer’s instructions and apply it evenly on both the magnet and the surface. Press the magnet firmly onto the surface and hold it in place until the epoxy cures. Be patient and follow the recommended curing time provided by the manufacturer to ensure maximum strength.

Cyanoacrylate Glue as an Adhesive Option

Cyanoacrylate glue, commonly known as super glue or CA glue, is a versatile and popular adhesive option for various applications. When it comes to adhering magnets, cyanoacrylate glue offers several advantages that make it an attractive choice.

One of the key advantages of cyanoacrylate glue is its fast-drying nature. This adhesive forms an instant bond when applied to surfaces, allowing for quick and efficient magnet installation. No need to wait around for hours for the glue to dry – with cyanoacrylate, you can get your project done in no time.

Furthermore, cyanoacrylate glue is available in different viscosities, ranging from thin to thick. This variety allows for flexibility in application methods. Whether you need a thin adhesive for precise and delicate projects or a thicker one for stronger bonding, cyanoacrylate glue has got you covered.

Some cyanoacrylate glues are specifically formulated for bonding magnets, offering enhanced strength and durability. These specialized formulas provide added assurance that your magnets will stay securely in place. No need to worry about your magnets falling off – cyanoacrylate glue has the strength to keep them firmly attached.

However, there are some considerations to keep in mind when using cyanoacrylate glue as an adhesive option for magnets. Firstly, surface preparation is crucial. To ensure a strong bond, it is important to clean both surfaces thoroughly, removing any dirt, oil, or debris. A clean surface maximizes the effectiveness of the adhesive and ensures a secure bond.

It is also important to check the manufacturer’s guidelines and conduct a small test before applying cyanoacrylate glue. While it can be an effective adhesive option, it may not be suitable for all types of magnets and surfaces. Ensuring compatibility between the adhesive and the materials being bonded is essential for a successful application.

Handling precautions should be taken when working with cyanoacrylate glue. This adhesive bonds skin together almost instantly, so it is crucial to handle it with care. Wearing protective gloves during application can prevent accidental skin contact and potential injuries.

Additionally, the curing time for cyanoacrylate glue can vary depending on the brand and viscosity. Although the bond forms quickly, it may take up to 24 hours for the adhesive to reach its full strength. Patience is key to ensure a secure bond between the magnets and the surfaces.

In case of accidental spills or excess glue, acetone can be used to remove cyanoacrylate adhesive from surfaces. However, care must be taken not to damage the magnets or the surface during the removal process.

Other Methods of Adhering Magnets

When it comes to adhering magnets, cyanoacrylate glue may be the go-to option for many, but there are several other methods that can be equally effective and versatile for your projects. Let’s explore some alternative options for attaching magnets, including magnetic tape, magnetic sheets, and magnetic adhesive.

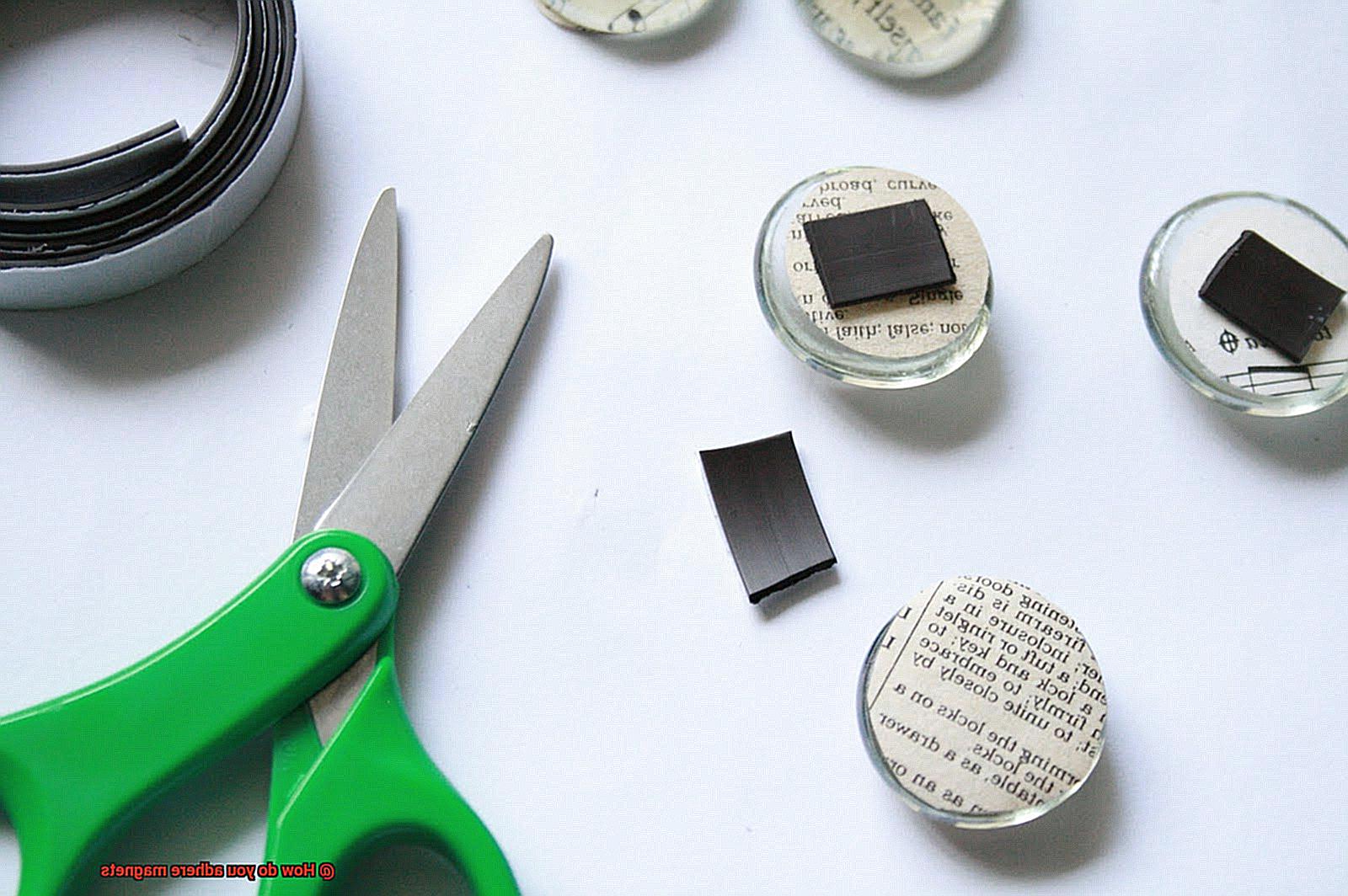

Magnetic Tape:

Imagine a flexible strip that effortlessly attaches lightweight objects to metal surfaces. That’s magnetic tape for you. With a strong adhesive backing on one side and a magnetized side on the other, this ingenious invention makes displaying artwork or photos on refrigerators or whiteboards a breeze. The adhesive backing ensures a secure bond, while the magnetized side provides the magnetic attraction needed to keep your creations in place.

Magnetic Sheets:

If you’re looking for something more customizable, magnetic sheets are the answer. These thin, flexible sheets feature a magnetized side and an adhesive side, allowing you to cut them into various shapes and sizes to adhere to different surfaces. Whether you’re creating custom magnets or attaching signs to metal surfaces, magnetic sheets offer convenience and versatility. Simply peel off the protective backing, press the adhesive side onto a clean and dry surface, and let the magnetism do its magic.

Magnetic Adhesive:

For a more direct approach, consider using magnetic adhesive. This special glue contains magnetic particles that create a strong bond between magnets and other materials such as wood or plastic. Apply it directly onto the magnet or onto the surface where the magnet will be adhered for a secure connection. Just remember to follow the manufacturer’s instructions for proper application and curing time to ensure optimal results.

In addition to these methods, specialized magnet mounting systems are also available in the market. These systems often include brackets or holders that provide a secure and adjustable way to attach magnets to different surfaces, giving you even more flexibility in your projects.

When choosing an adhesive method for adhering magnets, it’s important to consider factors such as the weight and size of the magnets, as well as the material of the surface they will be attached to. Some adhesives may not be suitable for heavy-duty applications or certain types of materials, so it’s crucial to assess the specific requirements of your project before making a decision.

While adhesives can be an effective way to adhere magnets, it’s worth noting that they may not provide as strong of a bond compared to other methods like mechanical fasteners such as screws or bolts. Therefore, it’s important to carefully evaluate the demands of your application and choose the most appropriate method accordingly.

Magnetic Tape or Strips for Temporary or Removable Magnet Attachment

When it comes to temporary or removable magnet attachment, magnetic tape or strips are the go-to solution. These versatile inventions offer a hassle-free way to attach lightweight objects to metal surfaces without the sticky residue or damage caused by glue or other adhesives. Let’s dive deeper into the advantages and disadvantages of both magnetic tape and strips, as well as when each option would be most appropriate.

One of the greatest advantages of using magnetic tape is its flexibility. Made from a flexible material like rubber or plastic, magnetic tape can be easily cut to the desired size for your specific application. Whether you need a small strip to mount a photo on your fridge or a longer piece to hang artwork on a whiteboard, magnetic tape has got you covered.

Another perk of magnetic tape is its repositionability. Unlike glue or other adhesives, magnetic tape can be easily removed and repositioned without leaving any residue or damaging the surface it was attached to. This feature makes it perfect for those who like to change their mind or frequently rearrange their space.

Magnetic tape is commonly used for mounting lightweight objects such as photos, artwork, or signage onto metal surfaces like refrigerators or whiteboards. It can also be used for organizing tools or other small metal items by attaching them to magnetic surfaces. The possibilities are endless.

However, it’s important to note that magnetic tape may not be suitable for all applications. If you’re dealing with heavier objects or irregularly shaped items that require a stronger and more permanent bond, you may need to explore other adhesive methods. In such cases, combining magnetic tape with additional adhesive or using alternative methods might be your best bet.

To ensure optimal adhesion when using magnetic tape, it’s important to clean the surface it will be attached to and remove any dust or debris. This will help create a secure bond between the tape and the metal surface.

Surface Preparation for Adhering Magnets

The secret to achieving a strong and long-lasting bond between magnets and substrates lies in proper surface preparation. In this article, we will explore the importance of surface preparation when adhering magnets and delve into various techniques that can enhance adhesion. Get ready for an exciting magnetic adventure.

Cleanliness – The First Step to Success:

Before applying any adhesive, ensure that the surface is squeaky clean. Dust, dirt, oil, or other contaminants can weaken the adhesive bond. Thoroughly clean the surface using a mild detergent or solvent, followed by rinsing with clean water and allowing it to dry completely.

Roughening – Creating a Rough and Tough Surface:

Smooth and non-porous substrates like metal or glass may need roughening to improve adhesion. Sanding or using abrasive materials creates a rough texture, providing more surface area for the adhesive to bond with. This simple step significantly enhances the grip between the magnet and substrate.

Degreasing – Banishing Grease for Good:

Grease and oils act as barriers between magnets and substrates, hindering proper adhesion. Use a suitable degreaser or solvent to remove these pesky substances. Ensure compatibility with both the substrate and adhesive being used.

Priming – The Primer for Success:

Some substrates require priming before applying adhesive to enhance adhesion. Primers create a layer that promotes bonding between the surface and adhesive. They work wonders on challenging surfaces like plastic or painted metals. Choose a primer compatible with both the substrate and adhesive, following the manufacturer’s instructions.

Surface Activation – Unleash the Adhesive Potential:

To improve adhesion on non-ferrous metals or plastics, surface activation techniques are invaluable. Flame treatment, corona treatment, or plasma treatment alter the surface chemistry, making it more receptive to adhesives. Follow recommended guidelines and safety precautions for these techniques.

Temperature and Humidity – The Perfect Conditions:

Temperature and humidity play a significant role in adhesive performance. Follow the manufacturer’s recommendations for optimal adhesion. Extreme temperatures or high humidity levels can compromise bond strength and durability. Keep an eye on those numbers.

Strength and Weight of the Magnets

Today, we embark on a fascinating journey into the world of magnets. In this article, we will delve into the factors that influence both the strength and weight of magnets when adhering them. Whether you are a DIY enthusiast or simply curious about the science behind magnets, this article is for you.

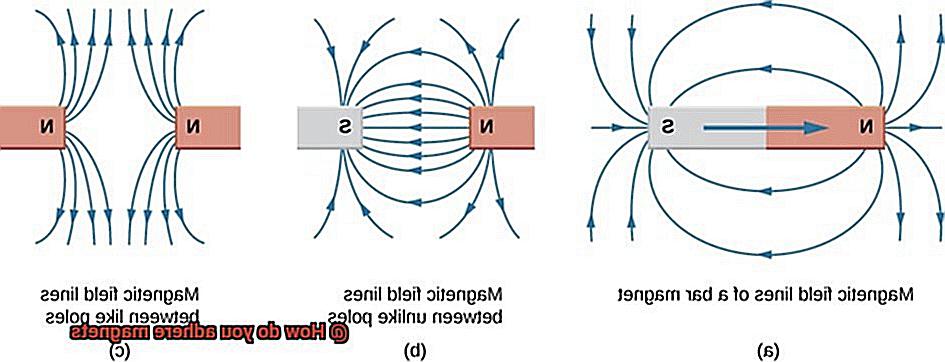

Unleashing the Power: Understanding Strength

When it comes to magnet strength, several factors come into play. The material, size, and shape of the magnet all contribute to its magnetic force. Neodymium magnets steal the show when it comes to strength. Composed of neodymium, iron, and boron, these magnets exhibit exceptional magnetic properties. Their immense strength makes them indispensable in industries like machinery, electronics, and medicine. However, caution must be exercised with neodymium magnets due to their brittleness, which makes them prone to breakage.

The Weighty Matter: Considering Weight

The weight of a magnet plays a significant role in its adhesive capabilities. Smaller magnets made from ceramic or ferrite tend to be lighter compared to larger neodymium magnets. When choosing an adhesive, it is crucial to select one that can support the weight of the magnet without causing detachment or sagging.

Factors Influencing Weight-Bearing Capacity

To ensure a secure bond between magnets and surfaces, several factors need consideration. The surface area of the magnet being adhered is critical, as well as the type of material it is attached to (metal or plastic). Additionally, the adhesive’s strength is a key determining factor. It is essential to choose an adhesive specifically designed for bonding magnets with a high weight-bearing capacity.

Conclusion:

By carefully considering both the strength and weight of magnets when selecting adhesives, you can achieve a powerful and durable bond. Neodymium magnets offer exceptional strength but require delicate handling due to their brittleness. On the other hand, smaller magnets made from ceramic or ferrite are lighter in weight. With proper surface preparation and the right adhesive, you can ensure that your magnets stick like glue.

Important Considerations for Optimal Results

Achieving optimal results when adhering magnets requires careful planning and attention to detail. Let’s dive into the important considerations that need to be taken into account for a successful bond.

- Prepare the surface: Before adhering magnets, ensure the surface is clean, dry, and free of any oil, grease, or dirt. Imagine trying to stick a magnet onto a greasy surface – it’s like trying to stick two magnets together with butter. Not very effective, right?

- Choose the right adhesive: There are various types of adhesives available, such as epoxy, super glue, or adhesive tape. However, not all adhesives are suitable for magnets. Look for adhesives specifically designed for bonding magnets and labeled as “magnet adhesives” or “magnetic adhesive.”

- Mind the temperature: Some adhesives require specific temperature ranges for optimal bonding. Applying and curing the adhesive at the right temperature can make a world of difference in achieving a strong bond. Follow the manufacturer’s instructions for temperature requirements.

- Match adhesive strength to magnet size: Consider the size and weight of the magnets you are adhering. Larger or heavier magnets may require stronger adhesives or additional support systems like brackets or screws to ensure a secure bond. It’s like finding the perfect fitting puzzle piece – matching the right glue strength to your magnet size.

- Consider the environment: Think about the intended use and environment of the magnet. Will it be exposed to extreme temperatures or moisture? Choose an adhesive that can withstand these conditions. Look for adhesives specifically designed for outdoor or high-temperature applications.

cdmTX3-0e5M” >

Conclusion

When it comes to adhering magnets, there are several methods you can use.

One option is to use adhesive or glue specifically designed for bonding magnets. This ensures a strong and secure bond that will withstand the test of time.

Another method is to use magnetic tape or strips, which have adhesive backing that allows you to easily attach the magnet to any surface. If you’re looking for a more temporary solution, you can also use double-sided tape or Velcro, which provide a less permanent bond but still offer convenience and versatility.

Additionally, make sure to follow the manufacturer’s instructions for the specific adhesive or tape you’re using to achieve optimal results.