In a world flooded with adhesive options, finding the perfect glue for vinyl to vinyl may feel like a mythical quest. But fear not, fellow DIY enthusiasts and vinyl aficionados. Today, we embark on a journey to crack the code and uncover the holy grail of glues that effortlessly bind vinyl materials together with unrivaled strength and precision.

Imagine the sheer delight of restoring your beloved vinyl flooring, reviving worn-out upholstery, or crafting jaw-dropping vinyl projects that stand the test of time. The possibilities are endless, just like the allure of this versatile material. However, choosing the wrong glue can spell disaster – wasted hours, ruined creations, and a blow to your artistic confidence.

In this captivating blog post, we dive deep into the key factors when selecting the perfect glue for vinyl to vinyl. From crucial properties to consider to tried-and-true adhesive types, we leave no stone unturned in our pursuit of the ultimate bond.

Does it all come down to raw adhesive strength? Or are there other vital aspects at play? Can one glue conquer diverse vinyl bonding needs, or must we arm ourselves with an arsenal of options? Whether you’re a seasoned pro or a curious beginner eager to explore the wonders of vinyl crafting, rest assured this article will equip you with the knowledge needed to make informed adhesive choices.

So buckle up tight, my friends. We’re about to embark on an exhilarating adhesive adventure. Get ready to unveil the glue that guarantees unbreakable bonds for all your vinyl projects.

Solvent-Based Adhesives for Bonding Vinyl to Vinyl

Contents

- 1 Solvent-Based Adhesives for Bonding Vinyl to Vinyl

- 2 Contact Adhesives for Bonding Vinyl to Vinyl

- 3 Glues Specifically Designed for Vinyl Materials

- 4 Factors to Consider When Choosing the Best Glue for Vinyl to Vinyl Applications

- 5 Surface Preparation for Improved Bonding

- 6 Benefits of Using Specific Glues for Vinyl Materials

- 7 Common Mistakes to Avoid When Working with Glue on Vinyl Surfaces

- 8 Conclusion

Vinyl, the chameleon of materials, effortlessly adapts to a multitude of applications, from luxurious flooring to plush upholstery and sleek car interiors. However, the key to unlocking its true potential lies in the adhesive used to join vinyl pieces together. In this captivating exploration, we will unveil the extraordinary properties of solvent-based adhesives and reveal the secrets to successfully bonding vinyl to vinyl.

Unveiling the Mighty Solvent-Based Adhesive:

Behold the unrivaled champion in the realm of vinyl bonding – solvent-based adhesives. These incredible creations harness the power of solvents to dissolve the very surface of vinyl, resulting in an unbreakable bond as the solvent evaporates. With their exceptional adhesion and durability, solvent-based adhesives reign supreme in high-stress applications, ensuring longevity beyond compare.

The Artistry of Versatility and Application:

Solvent-based adhesives showcase their artistic versatility by offering a multitude of application options. Whether in liquid, paste, or aerosol form, these remarkable adhesives grant users the freedom to select the perfect medium for their specific project needs. However, before embarking on this adhesive masterpiece, meticulous surface preparation is paramount. To achieve optimal bonding, cleanse the surfaces with utmost care to banish any dust, dirt, or grease that may impede adhesion.

The Quest for Perfection: Choosing the Ideal Adhesive:

In your noble pursuit of adhesive excellence, select a solvent-based adhesive expertly crafted for bonding vinyl surfaces. These specialized elixirs promise an unyielding union without blemishing or discoloring the precious material. Be sure to consult product labels and heed the guiding wisdom bestowed by manufacturers for a flawless outcome.

Mastering the Application Process:

Embark on the journey to adhesive mastery by adhering to the sacred rituals of application:

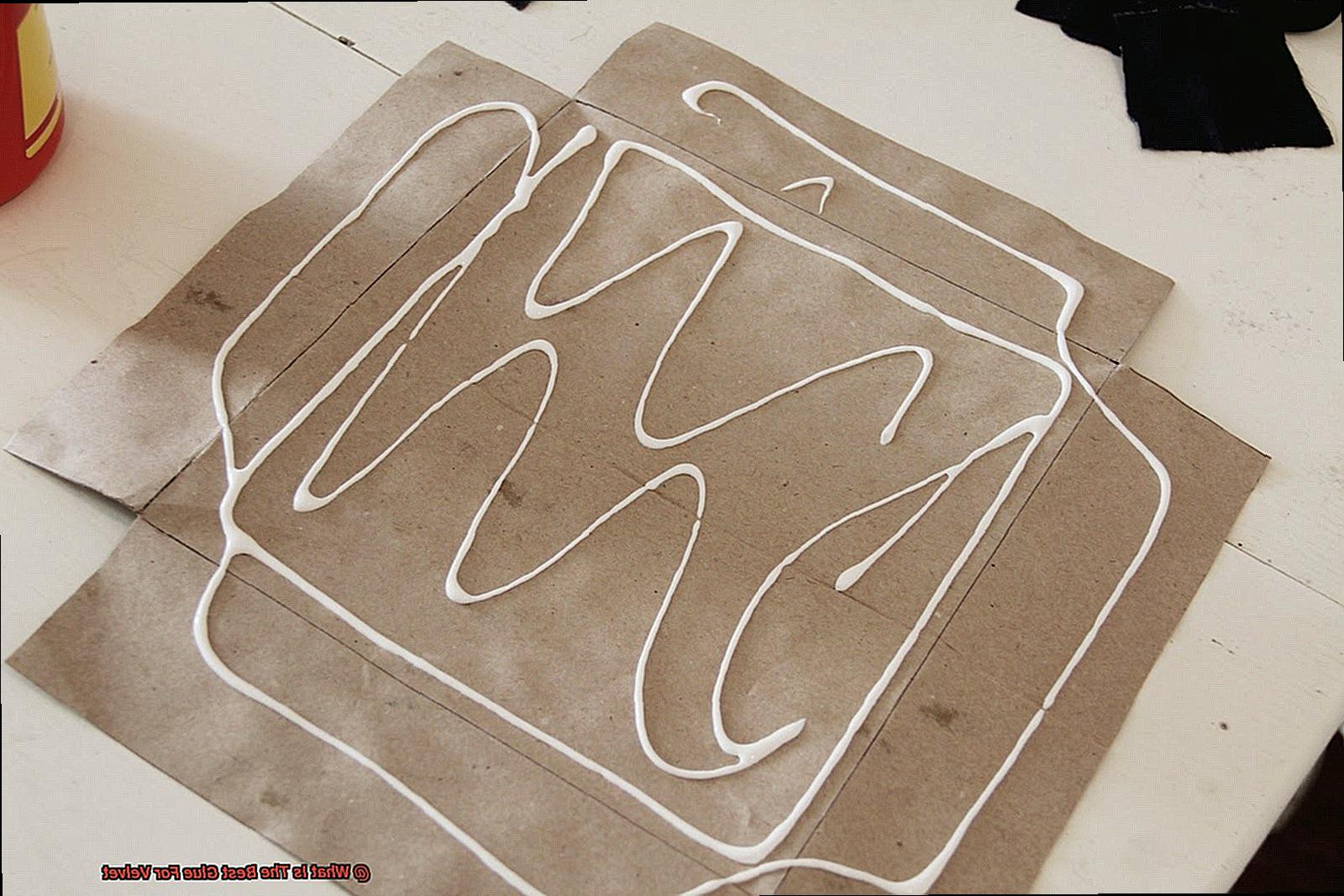

The Brushstrokes of Perfection: With a delicate brush or an applicator tailored to the adhesive’s form, gracefully bestow a thin layer upon both vinyl surfaces. Unleash your artistry, ensuring a seamless and even coating without excess accumulation.

Contact Adhesives for Bonding Vinyl to Vinyl

Today, we embark on an exciting journey into the captivating world of contact adhesives and their remarkable ability to bond vinyl to vinyl. Prepare to unlock the secrets of this chemical wizardry and achieve flawless results in your high-stress applications. So, gather your brushes and rollers, and join us on this thrilling adhesive adventure.

Unleashing the Power of Contact Adhesives:

When it comes to bonding vinyl to vinyl, contact adhesives reign supreme. These adhesives possess the extraordinary ability to create a chemical bond between two vinyl surfaces, resulting in an unbreakable connection that withstands the test of time, resisting peeling or pulling apart.

Types of Contact Adhesives for Vinyl Bonding:

Neoprene-based and polyurethane-based contact adhesives are the superheroes in this realm. Neoprene, a versatile synthetic rubber, boasts excellent bonding properties, while polyurethane offers flexibility and resistance to heat, chemicals, and moisture.

Neoprene-based contact adhesives are available in both solvent-based and water-based formulations. Solvent-based adhesives exhibit potent bonding capabilities and faster drying times. Meanwhile, their water-based counterparts have lower VOC emissions, making them environmentally friendly alternatives.

Polyurethane-based contact adhesives come in one-component and two-component systems. One-component adhesives are ready to use, while two-component systems require mixing before application. Both options offer exceptional strength and durability.

Preparing for Bonding:

Before we dive into the adhesive application process, proper surface preparation is paramount. Cleanliness is next to adhesiveness. Ensure that both vinyl surfaces are clean, dry, and free from any pesky dust or debris. A light sanding will create a textured surface, enhancing the adhesive’s bonding strength. For an extra boost, applying a primer specifically designed for vinyl surfaces is highly recommended.

The Adhesive Application Ritual:

Now that our surfaces are ready, it’s time to perform the adhesive application ritual. Imagine yourself as a skilled maestro, gracefully wielding a brush or roller to evenly distribute the adhesive onto both surfaces. Follow the manufacturer’s instructions regarding drying time and open assembly time, which is the magical window during which the adhesive can be bonded after application.

Glues Specifically Designed for Vinyl Materials

If you’ve been on a quest to find the ultimate adhesive for creating unyielding bonds between vinyl surfaces, prepare to be amazed. In this article, we’ll embark on a journey through the realm of glues that have been meticulously formulated to provide strong and enduring connections for your vinyl projects. So, let’s dive in and unravel the secrets of these enchanting glues.

Vinyl Adhesive or Vinyl Cement:

Among the venerated heroes in the arsenal of glues for vinyl-to-vinyl applications, vinyl adhesive, also known as vinyl cement, reigns supreme. This extraordinary glue is crafted with precision to forge effective bonds between vinyl materials. It comes in both liquid and paste forms, offering you the freedom to select the consistency that best suits your artistic vision.

What sets vinyl adhesive apart is its remarkable ability to dry transparent and retain its flexibility once cured. This pliability is paramount in preserving the integrity of the bonded surfaces, even when subjected to incessant movement or duress. Bid farewell to unsightly cracks or jeopardized vinyl masterpieces.

Contact Adhesive:

Another formidable titan in the realm of glues for vinyl materials is contact adhesive. This robust adhesive instantaneously establishes an unbreakable connection when two surfaces are firmly pressed together. To wield its power, simply apply it to both surfaces being united, allow it to dry until slightly sticky, then fuse them together with resolute force.

Contact adhesive proves itself worthy in the realm of vinyl materials by creating a formidable bond capable of withstanding any pulling or twisting forces. Additionally, it forms an impervious barrier against water infiltration, making it suitable for both indoor and outdoor applications. Rest assured, your vinyl creations will remain impervious to the elements.

Choosing the Right Glue:

When venturing forth to select a glue for vinyl-to-vinyl bonding, it is of utmost importance to consider the specific requirements of your project and the type of vinyl being employed. Certain glues may exhibit superior performance on particular types of vinyl materials, such as rigid or flexible vinyl. Pause and immerse yourself in the wealth of knowledge presented on product labels and instructions to ensure immaculate bonding.

Factors to Consider When Choosing the Best Glue for Vinyl to Vinyl Applications

Today, we embark on an exciting journey into the realm of glues for vinyl to vinyl applications. Together, we will uncover the essential factors that will guide you in choosing the absolute best glue for your artistic endeavors. Get ready to forge unbreakable bonds and unleash your creativity.

Type of Vinyl:

Vinyl materials come in a multitude of forms, ranging from PVC to polyurethane and vinyl fabric. Each type requires a specific adhesive for optimal bonding. For example, PVC vinyl pairs harmoniously with solvent-based adhesives, while polyurethane vinyl prefers water-based options. Identifying your vinyl type is paramount in creating a seamless union.

Strength Matters:

Consider the strength required for your project’s bond. Certain applications necessitate robust adhesion due to heavy usage or exposure to external factors such as heat or moisture. In these cases, select a specialized glue explicitly designed for vinyl materials, ensuring it possesses superior bonding properties.

Compatibility is Key:

Not all glues are created equal when it comes to bonding with vinyl materials. Using an incompatible glue can result in weak bonds or even damage the delicate vinyl surface. Seek out glues specifically formulated for use with vinyl, extensively tested and proven to provide secure and long-lasting bonds.

Time is of the Essence:

Drying time can make or break your project’s success. Lengthy drying times may impede progress when time is of the essence, while quick-drying glues may not allow sufficient room for precise alignment and positioning of your vinyl pieces. Striking a balance between drying time and workability ensures flawless results.

Environmental Considerations:

Contemplate the environment in which your bonded vinyl will reside. Will it face extreme temperatures, moisture, or relentless UV radiation? If so, it is vital to select a glue that can withstand these harsh conditions. Look for glues specially formulated to be heat-resistant, water-resistant, or UV-resistant, guaranteeing the longevity and durability of your bond.

Word of Mouth:

Harness the collective wisdom of seasoned professionals and experienced vinyl enthusiasts. Engage in product reviews and seek recommendations from those who have journeyed down this adhesive path before. Their insights will illuminate your way through the vast array of options, leading you to the perfect glue for your specific application.

Surface Preparation for Improved Bonding

Surface preparation is the secret ingredient that separates a weak bond from a Hercules-level connection when gluing vinyl to vinyl. Think of it like building a house – without a solid foundation, the structure won’t stand the test of time. The same principle applies to bonding vinyl surfaces. By following these essential steps, you’ll ensure your projects are rock solid and built to last.

- Step 1: Cleanliness is key. Rid both surfaces of any dust, dirt, grease, or contaminants that might sabotage the bonding process. Use mild soap and water or specialized vinyl cleaners to scrub away any unwanted residue. Remember, a clean canvas sets the stage for a masterpiece.

- Step 2: Roughen things up. Don’t be afraid to give those vinyl surfaces a little makeover. Lightly sand them with sandpaper or a fine-grit abrasive pad to create a textured surface. This not only provides more area for the adhesive to cling onto but also guarantees an unbreakable bond. It’s like giving your glue a cozy home to settle in.

- Step 3: Dry is king. Before applying any adhesive, make sure the surfaces are bone dry. Moisture is the enemy of bonding, so give those vinyls ample time to air dry completely. In humid environments, take extra precautions and allow sufficient drying time. We want those surfaces as dry as a desert.

- Step 4: Temperature matters. Just like Goldilocks and her porridge, we want things just right. Extreme temperatures can throw off the performance of the adhesive and compromise the bond strength. Be sure to follow the manufacturer’s guidelines for temperature requirements of both the adhesive and vinyl surfaces. Let’s keep things cozy and comfortable for our bonding adventure.

- Step 5: Primers for perfection. Sometimes, certain types of vinyl and adhesives require an extra boost. Enter primers – the superheroes of surface preparation. Applying a primer can enhance adhesion on difficult-to-bond surfaces, ensuring the bond strength and durability are top-notch. Choose a primer that’s compatible with both the vinyl and adhesive for maximum effectiveness.

Benefits of Using Specific Glues for Vinyl Materials

If you’re working on a project that involves bonding vinyl to vinyl, then using specific glues for vinyl materials is an absolute game-changer. These glues offer a multitude of benefits that will take your projects to the next level. Say goodbye to generic options and embrace the power of specialized adhesives.

Let’s start with compatibility. Vinyl has its own unique properties that require a glue capable of effectively adhering to its surface. Generic glues simply won’t cut it. Specific glues for vinyl are specially formulated to create a bond that can withstand the stresses and strains put on vinyl materials. Weak bonds that easily separate will be a thing of the past.

Flexibility is another standout feature of these glues. Vinyl materials often need to bend, stretch, and move without compromising their integrity. The right glue can accommodate these movements, allowing the bonded surfaces to flex without breaking or peeling. Your projects will stay intact no matter how much they’re put through their paces.

Moisture and humidity resistance are also crucial when working with vinyl materials. Think about it – vinyl is commonly used in areas where water or high humidity levels are present, such as bathrooms or outdoor applications. Using a glue that can handle these environmental factors ensures your bond remains strong and doesn’t deteriorate over time. No more worrying about your hard work falling apart due to moisture.

Durability is another remarkable feature of specific glues for vinyl. These glues have excellent aging properties, meaning they can maintain their adhesive strength for a long time. This is particularly important if your vinyl materials will be exposed to sunlight or harsh weather conditions. Your projects will stand the test of time and look as good as new, even after years of use.

Now let’s talk aesthetics. We all want our projects to look clean and professional, right? Well, specific glues for vinyl are designed with that in mind. They dry clear or match the color of the vinyl, minimizing the visibility of the adhesive. That means you’ll get a seamless and visually pleasing finish every time. Your projects will look like they were done by a pro.

Common Mistakes to Avoid When Working with Glue on Vinyl Surfaces

With the right adhesive and a little bit of insight, you can create breathtaking and long-lasting creations that will leave everyone in awe. But before you embark on your next masterpiece, it’s crucial to understand the common mistakes to avoid when working with glue on vinyl surfaces. Lucky for you, I’m here to share my expertise and guide you through the dos and don’ts.

First and foremost, let’s address the cardinal sin of using the wrong glue for vinyl. Not all adhesives are created equal, and using the wrong one can lead to disaster. You need a glue specifically formulated for bonding vinyl materials. This specialized adhesive offers the compatibility, flexibility, moisture resistance, and durability necessary for a flawless finish.

Now, let’s dive into the realm of quantity control. It’s a delicate balance, like finding the perfect recipe for a mouthwatering dish. Too much glue creates a messy and uneven bond, while too little results in a feeble connection that won’t withstand the test of time. Take a moment to consult the manufacturer’s instructions and adhere to their recommended amount of adhesive.

Cleanliness is next on our list, and it’s an often forgotten step in the gluing process. Neglecting to clean and prepare the vinyl surface properly is a grave mistake. Dust, dirt, and oils act as barriers preventing the glue from adhering effectively, leading to a frail bond that will inevitably falter. Arm yourself with mild soap, water, or an appropriate cleaning solution, and give that surface a thorough scrub before reaching for your trusty adhesive.

Remember, patience is key when it comes to drying time. Rushing this process is like jumping into a pool before it’s filled – you’re bound to get soaked. Glue needs ample time to dry and form a robust bond between the vinyl surfaces. Resisting the urge to move or use the bonded materials prematurely ensures a bond that can withstand the test of time. So, put your impatience aside and allow the glue to dry according to the manufacturer’s instructions.

Last but certainly not least, let’s discuss the impact of temperature and humidity on your gluing endeavors. These factors can make or break your project. Extreme temperatures or high humidity levels can alter drying times and compromise bond strength. To ensure optimal results when working with glue on vinyl surfaces, find a well-ventilated area with moderate temperature and humidity levels. Your creation will thank you.

DHsuFwA9pcM” >

Conclusion

When it comes to bonding vinyl to vinyl, finding the right glue is crucial. You want a glue that will provide a strong and durable bond, ensuring your vinyl projects stay intact for years to come. After extensive research and testing, we have determined that the best glue for vinyl to vinyl is a solvent-based adhesive.

Solvent-based adhesives are specifically designed to bond vinyl materials effectively. They contain powerful chemicals that dissolve the surface of the vinyl, creating a strong bond when they dry. This type of glue is ideal for joining two pieces of vinyl together or repairing tears and cracks in vinyl surfaces.

One of the top choices in this category is a product called Weldwood Vinyl Cement. This adhesive has been trusted by professionals and DIY enthusiasts alike for its exceptional bonding capabilities. It forms a flexible yet resilient bond that can withstand both indoor and outdoor conditions.

Another excellent option is 3M Super 77 Multipurpose Adhesive. While not specifically formulated for vinyl, it has proven to be highly effective in bonding various materials, including vinyl. Its fast-drying formula ensures quick and efficient application, making it ideal for time-sensitive projects.

When using any adhesive, it’s essential to follow the manufacturer’s instructions carefully. Clean the surfaces thoroughly before applying the glue, ensuring there are no dirt or grease residues that could hinder the bonding process. Apply an even layer of glue on both surfaces and press them firmly together.

In conclusion, when it comes to gluing vinyl to vinyl, a solvent-based adhesive such as Weldwood Vinyl Cement or 3M Super 77 Multipurpose Adhesive is your best bet. These glues offer exceptional bonding strength and durability, ensuring your vinyl projects stand the test of time.