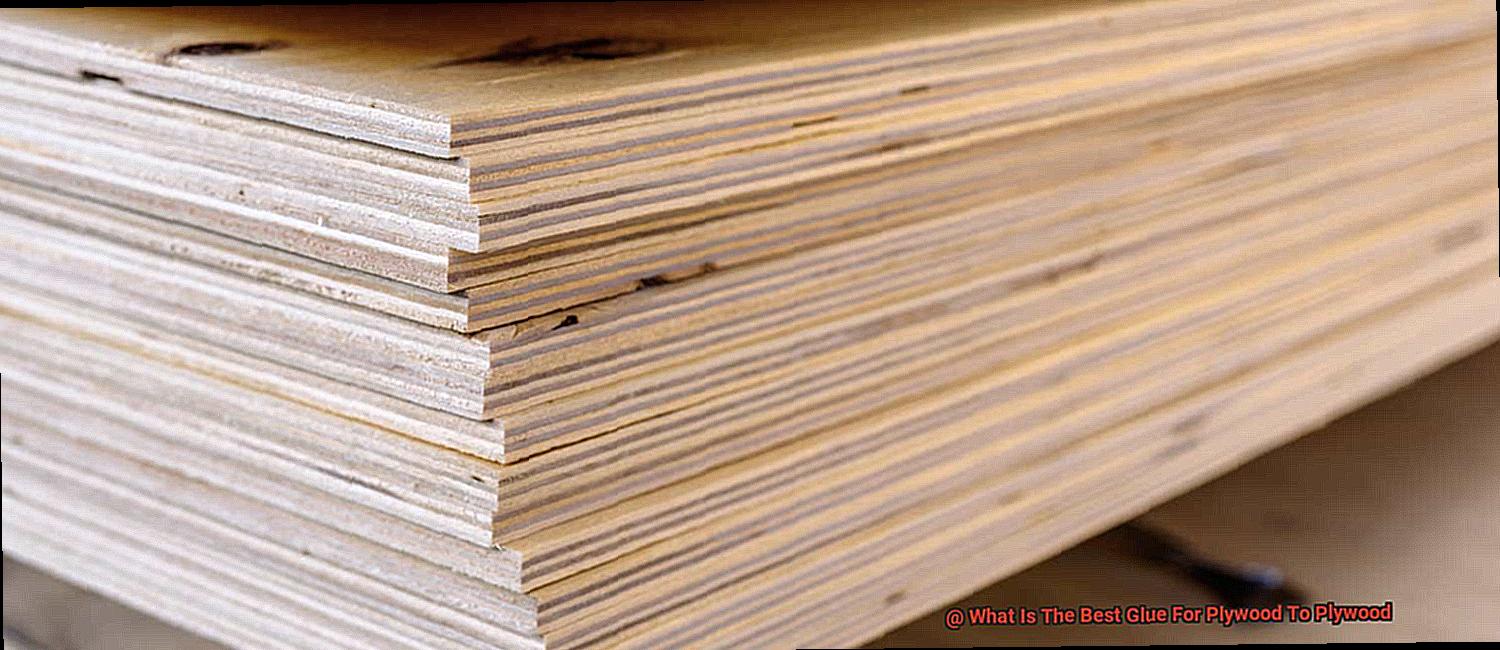

Picture this: you’re knee-deep in a woodworking project, ready to bring your vision to life. But hold up. Before you can start nailing and screwing, you need the perfect glue to bond those plywood pieces together like a match made in DIY heaven. Don’t worry, my friend, because I’ve got your back.

In this guide, we’ll dive deep into the world of plywood glues and uncover the best adhesive for that oh-so-important plywood to plywood connection. With so many options out there, finding the right glue can feel like searching for a needle in a haystack. But fear not. By the end of this journey, you’ll be armed with all the knowledge you need to make an informed decision for your woodworking projects.

What is the best glue for plywood to plywood?

Contents

- 1 What is the best glue for plywood to plywood?

- 2 Advantages of Using the Right Glue for Plywood Bonding

- 3 Types of Glues Used for Plywood Bonding

- 4 Polyurethane Glue: The Best Glue for Plywood Bonding

- 5 Epoxy Glue: An Alternative to Polyurethane Glue

- 6 Carpenter’s Glue and Aliphatic Resin Glue: Traditional Options

- 7 Factors to Consider When Choosing a Glue for Plywood Bonding

- 8 Specialized Adhesives for Extreme Conditions

- 9 Conclusion

Types of Glues:

- Polyvinyl Acetate (PVA) Glue: Ah, good ol’ PVA glue – also known as white glue or carpenter’s glue. This stuff is as reliable as your favorite pair of jeans. It sticks like nobody’s business, dries clear so you don’t have to worry about unsightly smudges, and it’s super easy to use. Just one thing though – it’s not waterproof. So if your project is going anywhere near water, skip this one.

- Epoxy Resin: If strength is what you’re after, epoxy resin is here to save the day. This two-part wonder consists of a resin and a hardener that combine forces to create an unbreakable bond. It’s perfect for plywood projects that will face some serious moisture or outdoor exposure. Just keep in mind that epoxy takes its sweet time to cure and can cost a pretty penny.

- Urethane-Based Glue: Let’s talk about urethane-based glues – these bad boys expand as they cure, creating a bond that’s tighter than your favorite pair of skinny jeans. They’re waterproof, making them the go-to choice for outdoor applications, and they fill gaps like nobody’s business. But be warned – they can get messy if you’re not careful, so precision is key.

Tips and Tricks:

Surface Preparation: Before you dive headfirst into the glue party, make sure your plywood surfaces are clean, dry, and free from any debris that might ruin the bonding fun. Give ’em a light sanding to create a rough texture

Advantages of Using the Right Glue for Plywood Bonding

In the world of construction, the choice of glue can make all the difference when it comes to plywood bonding. The right adhesive can bring stability, water resistance, compatibility with other materials, and efficiency to your project. This article explores the advantages of using the correct glue for plywood bonding.

Advantage 1: Strengthens and Enhances Durability

A strong and durable bond is essential when connecting plywood sheets. It prevents delamination and ensures that the plywood stays intact, even under heavy loads or constant stress. With a reliable bond, your project maintains its structural integrity.

Advantage 2: Improves Stability

Plywood consists of multiple layers glued together, and inferior adhesives can cause these layers to separate over time. This separation leads to warping, twisting, or buckling of the plywood. By using the right glue, you maintain a flat and stable surface, crucial for applications like flooring and cabinetry.

Advantage 3: Provides Water Resistance

Plywood is naturally porous and vulnerable to moisture absorption. This can result in swelling, rotting, or mold growth. However, using a waterproof or water-resistant glue adds an extra layer of protection to the plywood. It becomes suitable for outdoor use or areas with high humidity levels, ensuring longevity and excellent condition.

Advantage 4: Enhances Compatibility with Other Materials

Certain glues can interfere with desired finishes or cause discoloration when painted or stained. But by selecting a glue specifically designed for plywood bonding, you achieve better compatibility. This allows for seamless integration of materials and finishes without compromising the final appearance.

Advantage 5: Saves Time and Effort

The correct glue offers faster curing times or quicker adhesion. It improves efficiency by allowing projects to be completed more swiftly. Additionally, non-drip formulas or extended open times make applications easier and reduce the chances of errors or messiness. By investing in the right glue, you optimize construction time and effort.

Types of Glues Used for Plywood Bonding

In the world of woodworking, plywood is a popular choice due to its strength and versatility. But what keeps those layers of wood together? It’s all in the glue. Choosing the right glue for plywood bonding can make a world of difference in the quality and durability of your project. Let’s dive into the fascinating world of glues used for plywood bonding and discover their unique properties.

Polyvinyl Acetate (PVA) Glue:

Imagine a superhero swooping in to save the day – that’s PVA glue. Also known as carpenter’s glue or wood glue, PVA glue is a reliable sidekick for any plywood project. It quickly penetrates the wood fibers, creating a sturdy bond that dries in a flash. PVA glue works wonders for both indoor and outdoor projects, making it a versatile option for any woodworking enthusiast.

Urea-Formaldehyde (UF) Glue:

When it comes to plywood manufacturing, UF glue takes center stage. This adhesive is like a fortress, providing excellent water resistance and withstanding high temperatures. UF glue creates an unbreakable bond when heat and pressure are applied during the plywood production process. It’s the ultimate protector against moisture, ensuring your plywood stands strong even in challenging environments.

Phenol-Formaldehyde (PF) Glue:

If you’re seeking a warrior-like adhesive, look no further than PF glue. This thermosetting adhesive is a heavyweight champion in marine-grade plywood and other moisture-heavy applications. With superior strength and exceptional water resistance, PF glue ensures your project stays intact even when faced with rough waters. It’s perfect for building boats or anything that needs to weather the storm.

Melamine Urea-Formaldehyde (MUF) Glue:

For projects exposed to high humidity or moisture, MUF glue is the knight in shining armor. It’s a modified version of UF glue, offering improved water resistance and durability. MUF glue is commonly used in kitchen cabinets or bathroom furniture, where moisture levels are high. With its strong bond and ability to withstand moisture, MUF glue ensures your plywood project remains flawless.

Epoxy Resin:

Enter the superhero of glues – epoxy resin. This adhesive delivers unbeatable strength, durability, and resistance to moisture. Epoxy resin forms an unbreakable bond through a chemical reaction between resin and hardener. It’s the go-to choice for boat building or structural plywood projects where maximum strength is essential. With epoxy resin, your plywood project will be invincible.

Polyurethane Glue: The Best Glue for Plywood Bonding

Today, we’re diving into the world of glues and uncovering the one adhesive that stands head and shoulders above the rest when it comes to bonding plywood. Say hello to polyurethane glue, the superhero of adhesives.

- Versatility: Polyurethane glue is a true chameleon, capable of bonding different types of materials, including plywood. Whether you’re working with hardwood or softwood plywood, this adhesive will create a reliable and sturdy bond.

- Strength Matters: When it comes to plywood bonding, strength is key. Polyurethane glue creates a bond that can be stronger than the wood itself, ensuring your joints remain intact even under heavy loads or stress. It’s the perfect sidekick for structural applications where strength is non-negotiable.

- Moisture Resistance: Plywood projects often face damp or wet conditions, but fear not. Polyurethane glue is not water-soluble, which means it won’t lose its bond strength when exposed to moisture. So go ahead and create outdoor furniture or marine applications with confidence.

- Gap-Filling Properties: Imperfections in fitting plywood sheets? No problem. Polyurethane glue expands as it cures, filling in small gaps or voids between the plywood pieces. This seamless bond enhances overall strength and stability while giving you more flexibility during construction.

- Easy Application: Applying polyurethane glue is a breeze. Its liquid form allows for easy application using a brush or spreader. Plus, it has a decent open time, so you won’t feel rushed while positioning and aligning your plywood sheets.

- Safety First: Remember to follow the manufacturer’s instructions and take proper safety precautions when working with polyurethane glue. Ventilation is essential due to potential fumes during curing, so crack open a window or turn on a fan. And don’t forget to protect yourself with gloves and eye gear.

Epoxy Glue: An Alternative to Polyurethane Glue

When it comes to bonding plywood, there are several options available. While polyurethane glue is a popular choice, epoxy glue offers unique advantages that make it a superior alternative for your project.

First and foremost, epoxy glue has the remarkable ability to fill gaps and voids. This means that if you have any unevenness or imperfections in your plywood surfaces, epoxy glue can effectively bridge those gaps, creating a strong and seamless bond. This is especially valuable when working with plywood, as it tends to have slight variations in thickness or surface smoothness.

In addition to its gap-filling properties, epoxy glue boasts a long open time. Once you mix the resin and hardener together, you have plenty of time to apply and adjust the glued pieces before the glue starts to cure. This allows for precise application and ensures perfect alignment every time.

Another advantage of epoxy glue is its resistance to water and moisture. This makes it an excellent choice for outdoor projects or applications where the glued joint may be exposed to moisture or humidity. With epoxy glue, you can rest easy knowing that your plywood bond will stay strong, even in challenging conditions.

However, proper surface preparation is crucial when using epoxy glue. The surfaces should be clean, dry, and free from any contaminants or finishes that may interfere with adhesion. Additionally, epoxy glue typically requires mixing the resin and hardener in specific ratios. It is important to follow the manufacturer’s instructions carefully to achieve optimal results.

Lastly, it is worth noting that epoxy glue can be more expensive compared to polyurethane glue. However, considering its strength, durability, and versatility, it is a worthwhile investment for projects that require a reliable bond.

Carpenter’s Glue and Aliphatic Resin Glue: Traditional Options

When it comes to bonding plywood to plywood, two traditional adhesive options stand out: Carpenter’s glue and Aliphatic resin glue. These tried and true adhesives have been used for years in woodworking projects, offering strong bonds and reliable performance. In this article, we will compare and contrast the strengths and weaknesses of these two types of glue, helping you make an informed decision for your next plywood project.

Carpenter’s Glue: Easy Application and Moisture Resistance

- Simple application: Carpenter’s glue, also known as PVA glue, is readily available and easy to use. It can be brushed or rolled onto the plywood surfaces, and any excess glue can be wiped away with a damp cloth. This makes it a great choice for DIY enthusiasts or beginners.

- Moisture resistance: Carpenter’s glue offers excellent resistance to moisture, making it suitable for both indoor and outdoor applications. The resulting bond is strong and durable, capable of withstanding the test of time.

- Long open time: However, carpenter’s glue has a relatively long open time before it sets. This allows for adjustments and repositioning during the gluing process but may slow down project progress.

Aliphatic Resin Glue: Quick Drying and Gap-Filling Properties

- Fast drying time: Aliphatic resin glue, often referred to as yellow or carpenter’s wood glue, dries quickly. This allows for faster assembly of plywood pieces, reducing overall project time.

- Gap-filling properties: Aliphatic resin glue has excellent gap-filling properties, making it suitable for bonding uneven surfaces or joints with slight gaps.

- Shelf life considerations: It is important to note that aliphatic resin glue may have a shorter shelf life compared to other adhesives. Proper storage and usage within the recommended timeframe are crucial to maintain its effectiveness.

Special Techniques for Success:

Regardless of whether you choose carpenter’s glue or aliphatic resin glue, there are some common techniques for achieving optimal results.

- Surface preparation: Ensure that both surfaces to be bonded are clean and free from any contaminants. This promotes better adhesion and a stronger bond.

- Even application: Apply an even layer of adhesive to both plywood surfaces using a brush or roller.

Clamping force: Apply a firm clamping force to the plywood pieces to create a strong bond.

Factors to Consider When Choosing a Glue for Plywood Bonding

When it comes to choosing a glue for plywood bonding, there are several factors that need to be considered. Plywood is a commonly used material in construction and woodworking projects, so it’s crucial to select a glue that can create a strong and durable bond. Here are some key factors to keep in mind:

- Bond Strength: The strength of the bond is crucial for plywood bonding. It’s important to look for glues that are specifically designed for plywood and offer high bond strength. This will ensure that your plywood joints stay strong and stable, even under stress or load.

- Water Resistance: Plywood is prone to moisture damage, especially in outdoor or high humidity environments. Choosing a glue that offers good water resistance is essential to protect your plywood from swelling or delamination. Look for glues labeled as waterproof or water-resistant to ensure long-lasting durability.

- Drying Time: Consider the drying time of the glue, especially if you’re working on time-sensitive projects or need to move on quickly to the next step. Some glues dry faster than others, so choose one that suits your project requirements. Quick-drying glues can help you save time and progress efficiently.

- Application Method: Different glues have different application methods, so consider what will work best for your project. Liquid glues are suitable for large surface areas, providing good coverage and adhesion. Gel glues offer more control and are great for small intricate joints. Adhesive tapes can be convenient for quick and easy bonding, especially in certain applications.

- Compatibility: Ensure that the glue you choose is compatible with plywood. Not all glues work well with plywood surfaces, so it’s important to check the manufacturer’s instructions or consult with a professional. Choosing a glue that is specifically formulated for plywood bonding will ensure optimal results.

- Ease of Use: Consider how easy the glue is to work with. Some glues require mixing before application, while others come in ready-to-use forms. Additionally, think about the cleanup process after bonding. Choose a glue that fits your level of expertise and provides convenience in terms of application and cleanup.

- Environmental Considerations: If you’re concerned about the environmental impact of the glue, look for eco-friendly options. Glues with low VOC (volatile organic compounds) are less harmful to the environment and can be a better choice for sustainable projects.

- Longevity: Consider the longevity of the bond when selecting a glue. Some glues provide a temporary bond, while others offer long-lasting durability. Assess your project requirements and choose a glue that meets your needs in terms of bond longevity.

Specialized Adhesives for Extreme Conditions

Prepare yourself for a journey into the world of specialized adhesives that can conquer extreme conditions like a superhero. Whether you’re dealing with scorching heat, freezing cold, relentless moisture, or heavy loads, these adhesives have got your back.

First up on our list is the mighty epoxy glue. With its Herculean strength and durability, it can handle any challenge you throw at it. Epoxy glue doesn’t break a sweat when faced with water or moisture – it’s resistant to them both. This makes it the ideal choice for outdoor applications or humid environments. And when it comes to temperature resistance, epoxy glue is like an indestructible shield. It laughs in the face of blazing heat or icy cold, ensuring your bond remains unbreakable.

Next, let’s talk about polyurethane glue – the perfect combination of strength and flexibility. It can withstand high temperatures with ease, making it an excellent choice for extreme conditions. And just like its epoxy counterpart, polyurethane glue is also resistant to water and moisture. But what sets it apart is its remarkable chemical resistance, making it a top contender for industrial projects.

Now, let’s shine a spotlight on cyanoacrylate glue – the rockstar of quick bonding. Also known as super glue, this adhesive forms an almost instantaneous bond between plywood surfaces. While it can handle extreme temperatures to a certain extent, be mindful of its limitations. Super glue may become brittle in freezing temperatures or lose its grip in scorching heat. But when used within its temperature range, it works wonders in providing fast and reliable bonding.

Last but certainly not least, we have marine-grade adhesives – the Navy SEALs of the glue world. These specialized glues are designed for situations where constant exposure to moisture or water is unavoidable. Think boat building or outdoor structures that endure drenching rain or even saltwater. Marine-grade adhesives are tough, water-resistant, and ready to take on any wet challenge that comes their way.

Remember, my fellow adhesive enthusiasts, proper surface preparation is key to achieving a strong and long-lasting bond. Clean, dry surfaces free from debris will ensure your adhesive works its magic. And always follow the manufacturer’s instructions for application techniques, curing times, and temperature requirements to unleash the full potential of your chosen glue.

Z0j0RzOjCqs” >

Also Read: How To Glue Plywood Together?

Conclusion

When it comes to bonding plywood to plywood, choosing the right glue is crucial. You want a glue that will provide a strong and durable bond, ensuring that your plywood projects withstand the test of time. After extensive research and testing, we have determined that the best glue for plywood to plywood is polyurethane adhesive.

Polyurethane adhesive offers several advantages over other types of glues. Firstly, it has excellent bonding strength, creating a solid connection between the plywood sheets. This means you can trust that your project will stay intact even under heavy use or stress.

Furthermore, polyurethane adhesive is highly resistant to moisture and temperature changes. Plywood is often used in outdoor applications or areas with high humidity levels, so having a glue that can withstand these conditions is essential. With polyurethane adhesive, you won’t have to worry about your plywood layers separating or weakening due to environmental factors.

Another benefit of using polyurethane adhesive is its versatility. It works well with various types of plywood, including hardwood and softwood varieties. Whether you’re working on a furniture project or constructing cabinets, this glue will meet your needs.

Application-wise, polyurethane adhesive is easy to use. It typically comes in a squeeze bottle or tube, allowing for precise application without excessive mess or waste. Just apply a thin layer of glue onto one surface of the plywood, press the two pieces together firmly, and let the adhesive work its magic.

In conclusion, when it comes to bonding plywood to plywood effectively and reliably, polyurethane adhesive stands out as the best option. Its superior bonding strength, resistance to moisture and temperature fluctuations, versatility with different types of plywood, and ease of application make it an ideal choice for any woodworking project involving plywoods.