When it comes to bonding two pieces of metal together, you need an adhesive that can handle the challenge. Whether you’re a seasoned DIY enthusiast or a professional metalworker, finding the right glue is essential for creating a strong and reliable bond.

In this article, we’ll dive into the world of adhesives and explore the best options for metal bonding. We’ll consider factors like strength, durability, versatility, and ease of use to help you make an informed decision.

From tried-and-true choices like epoxy and super glue to more specialized options like structural acrylics and anaerobic adhesives, we’ll uncover the most effective glues on the market. No matter if you’re working with stainless steel, aluminum, or any other kind of metal, rest assured there’s a glue out there designed specifically for your needs.

So let’s jump in and discover the best glue for two pieces of metal. Get ready to tackle your projects with confidence and create long-lasting connections that won’t let you down.

Considerations When Choosing the Best Glue for Bonding Metal

Contents

Selecting the right glue for bonding metal is crucial for achieving a strong and durable bond. With numerous adhesive options available, it can be overwhelming to determine which one is best suited for your project. In this guide, we will explore the key considerations to keep in mind when choosing the best glue for bonding metal.

Consideration 1: Bond Strength

Different adhesives offer varying levels of bond strength. Assess the specific needs of your project and opt for high-strength adhesives for heavy-duty applications that can withstand weight and stress.

Consideration 2: Temperature Resistance

Choose a glue with excellent temperature resistance if your project involves metal parts exposed to high temperatures. Ensure it can withstand the specific temperature range without weakening or failing over time.

Consideration 3: Flexibility

If your bonded metal parts will be subjected to vibrations, movements, or flexing, a flexible adhesive is necessary to prevent cracking or detachment. Flexibility allows the bond to withstand stress and movement without compromising its integrity.

Consideration 4: Drying Time and Curing Process

Time constraints play a significant role in adhesive selection. Opt for adhesives that offer fast drying and curing times for projects with tight deadlines or a need for quick bonds.

Consideration 5: Compatibility with Different Metals

Conduct compatibility tests by applying a small amount of glue on an inconspicuous area of the metal surface before committing to the full bond. This will help avoid potential damage or bonding failure as different adhesives may work well on certain types of metal but not on others.

Consideration 6: Ease of Application and Clean-Up

Consider the ease of applying the adhesive and cleaning up any excess glue. Choose adhesives that offer simple and convenient application methods. Additionally, ensure that the adhesive can be easily removed if needed without damaging the metal surfaces.

Types of Adhesives Used for Bonding Metal

When it comes to joining metal pieces together, the right adhesive can be a game-changer. Each metal type and application require specific glues that offer strength, durability, and resistance to various factors. So, let’s embark on a journey to explore the top adhesives used for bonding metal and discover the perfect glue to forge unbreakable bonds.

Epoxy Adhesives: The Dynamic Duo of Bonding

Epoxy adhesives are like invincible superheroes in the world of metal bonding. Comprised of a resin and a hardener, they create an unbreakable bond that stands the test of time. With exceptional heat, chemical, and moisture resistance, epoxy is akin to a protective shield for your metal creations.

Cyanoacrylate Adhesives: The Super Glue Sensation

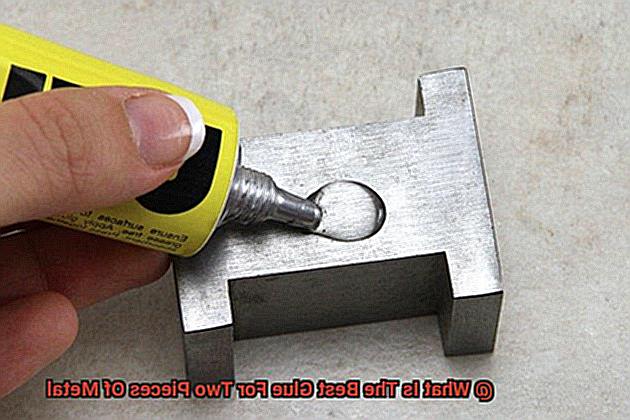

In need of an instant fix? Enter cyanoacrylate adhesives, also known as super glue or instant glue, ready to save the day. These quick-bonding marvels form a strong bond in mere seconds and work wonders on smooth, clean metal surfaces. Just beware of their sticky prowess – they might even glue your fingers together.

Polyurethane Adhesives: Flexibility at its Finest

Seeking a flexible and impact-resistant bond? Look no further than polyurethane adhesives. These versatile glues can bond different metals with ease while effortlessly handling movement or temperature variations. They’re the gymnasts of the adhesive realm, bending without breaking.

Acrylic Adhesives: Defying the Test of Time

When durability is paramount, acrylic adhesives rise to the occasion. Renowned for their ability to withstand high temperatures and harsh environments, these glues form bonds that endure. With excellent resistance to chemicals and UV radiation, they’re the guardians of long-lasting connections.

Structural Adhesives: Powerhouses of Bonding

For heavyweight projects, structural adhesives are the ultimate choice. Methacrylate and urethane-based adhesives offer unparalleled strength and durability, tackling high temperatures, chemicals, and impacts with ease. They’re the superheroes of bonding, always ready to conquer any challenge.

Epoxy Adhesive

Epoxy adhesive, the superhero of the adhesive world, possesses incredible abilities when it comes to bonding metal surfaces. Let’s delve into its captivating concepts and explore the fascinating world of this versatile and durable adhesive.

Versatility is the name of the game for epoxy adhesive. Like a chameleon, it effortlessly bonds different types of metals together. Steel, aluminum, copper – it handles them all with ease. But it doesn’t stop there. Epoxy adhesive can also form unbreakable connections between metals and other materials like wood, plastic, or glass. Talk about a powerhouse adhesive.

But that’s not all. Epoxy adhesives are the Iron Men of the adhesive world when it comes to resistance. They fearlessly withstand extreme temperatures ranging from a bone-chilling -40°C to a scorching 150°C. No matter if you’re working indoors or outdoors, rest assured that your bond will remain strong and stable even in the harshest environments.

And let’s not forget about its exceptional mechanical strength. Epoxy adhesives handle heavy loads with ease, resisting vibrations, impacts, and shear forces like true superheroes. This makes them indispensable in industries such as automotive, aerospace, and construction, where reliability is key.

However, every superhero has a weakness, and for epoxy adhesive, it’s surface preparation. Just like any hero needs a clean slate to work their magic, epoxy adhesives require thoroughly cleaned metal surfaces free from dirt, oil, or rust that could interfere with the bonding process. A little prep work goes a long way in ensuring a successful bond.

So there you have it. Epoxy adhesive is your go-to sidekick when it comes to bonding metal surfaces. Its versatility, resistance to temperature and chemicals, and exceptional mechanical strength make it an unbeatable choice for all your metal bonding needs. Just remember to prepare those surfaces properly, and you’ll be rewarded with a bond that will stand the test of time.

Cyanoacrylate Adhesive

When it comes to bonding metals, nothing beats the power of cyanoacrylate adhesive, also known as super glue or instant glue. This incredible adhesive has completely transformed the metal bonding game with its lightning-fast action and unparalleled strength. In this article, we will explore the advantages and disadvantages of using cyanoacrylate adhesive for metal bonding, uncovering the secrets behind its success.

Advantages:

Lightning-Fast Bonding Time:

In a world where time is money, cyanoacrylate adhesive reigns supreme. With its quick-setting properties, this adhesive forms an unbreakable bond within mere seconds of application. Say goodbye to tedious clamping or waiting for hours for the bond to cure. Cyanoacrylate adhesive saves precious time in production processes and boosts efficiency like never before.

Indestructible Bond Strength:

If there’s one thing cyanoacrylate adhesive knows how to do, it’s creating an unwavering bond. This adhesive forms an unyielding connection between metal surfaces that can withstand heavy loads and relentless vibrations. Whether it’s in the automotive industry or aerospace applications, cyanoacrylate adhesive guarantees a bond that will stand the test of time.

Conqueror of Extreme Environments:

Cyanoacrylate adhesive laughs in the face of temperature fluctuations and chemical assaults. This remarkable adhesive is built to withstand even the harshest environmental conditions. From scorching heat to bone-chilling cold, cyanoacrylate adhesive maintains its integrity without compromising its bond. It also fearlessly resists a wide range of chemicals commonly encountered in industrial or household settings, making it the ultimate go-to for countless applications.

Disadvantages:

Surface Preparation Savvy:

While cyanoacrylate adhesive possesses extraordinary bonding capabilities, it demands a little extra attention when it comes to surface preparation. The effectiveness of this adhesive is highly dependent on factors like surface condition, cleanliness, and the specific type of metal being bonded. Some metals may require special surface preparation techniques or primers to unlock the adhesive’s full bonding potential.

Gap-Filling Limitations:

Cyanoacrylate adhesive may be a superhero in many aspects, but it does have one kryptonite: limited gap-filling ability. Unlike other adhesives like epoxy, cyanoacrylate works best on smooth and tightly fitted surfaces. It thrives on precision and struggles to provide an adequate bond on larger gaps or uneven surfaces.

Polyurethane Adhesive

If you’re looking for a strong and durable adhesive to bond metal pieces together, you’ve come to the right place. In this article, we’ll dive into the advantages and characteristics of this superhero glue that will make your metal projects a breeze.

Exceptional Resistance:

Polyurethane adhesive is like the Superman of glues when it comes to withstanding harsh environmental conditions. It fearlessly endures extreme temperatures, moisture, chemicals, and even UV radiation without losing its bonding capabilities. This means you can confidently use it for both indoor and outdoor applications, from automotive repairs to metal fabrication projects.

Unbeatable Flexibility:

Imagine a glue that can stretch and bend like an Olympic gymnast. That’s polyurethane adhesive for you. Its high level of flexibility allows it to accommodate the expansion and contraction of metal surfaces caused by temperature changes. No matter how much your metal moves or vibrates, this adhesive will stay put, ensuring a long-lasting bond.

Speedy Curing Time:

When it comes to getting the job done quickly, polyurethane adhesive is your go-to sidekick. It typically cures within a few hours of application, forming a strong bond that can handle heavy loads. However, keep in mind that full curing may take up to 24 hours or longer, depending on factors like humidity and temperature. So be patient, my fellow DIYers.

Forms for Every Need:

Polyurethane adhesive comes in various forms to suit your specific project requirements. Liquid adhesives are perfect for easy application using brushes or nozzles, giving you maximum control. On the other hand, adhesive tapes offer convenience and precision when bonding smaller areas or dealing with complex shapes. Choose your weapon wisely.

Surface Preparation is Key:

To unleash the full power of polyurethane adhesive, proper surface preparation is crucial. Make sure your metal surfaces are clean, dry, and free from any contaminants like oil, grease, or rust. Some manufacturers recommend roughening the surfaces using sandpaper or wire brushes to enhance the bonding strength. Remember, a clean surface equals a strong bond.

Acrylic Adhesive

Today, we embark on a journey into the realm of acrylic adhesive, exploring why it is the superhero of bonding when it comes to metal. Whether you’re a DIY enthusiast, an engineer, or simply curious about the wonders of glue, this article will provide you with all the insights you need.

Advantages of Acrylic Adhesive for Metal Bonding:

Unyielding Strength and Durability:

Acrylic adhesive possesses exceptional bonding capabilities, ensuring a robust and long-lasting connection between metal surfaces. In the face of vibrations, impact, or extreme temperatures, this adhesive stands firm, providing unmatched stability.

Conquering Environmental Hazards:

When it comes to battling the elements, acrylic adhesive rises above. Its resistance to moisture, chemicals, and UV radiation guarantees the bond’s integrity in challenging environments. From outdoor applications to exposure to water or oils, this adhesive triumphs where others falter.

Swift Curing Time:

Time is of the essence in any project, and acrylic adhesive understands this well. Unlike other adhesives that demand lengthy curing processes, acrylic adhesive sets quickly once applied. This not only boosts production efficiency but also minimizes waiting time for the bond to reach its full strength.

Versatility in Metal Bonding:

The world of metals is vast and diverse, but fear not. Acrylic adhesive reigns supreme when it comes to bonding different types of metals. Aluminum, stainless steel, copper, brass – you name it. With its remarkable versatility, this adhesive is your go-to for various metal combinations.

Multiple Application Methods:

Acrylic adhesive offers flexibility in its application methods. Whether you prefer brushing, spraying, or utilizing a syringe for precise dispensing, this adhesive adapts to your needs. Additionally, it can be used alongside mechanical fasteners like screws or rivets to enhance strength and stability.

Structural Adhesives

Structural adhesives are the superheroes of the glue world, providing unbeatable strength and durability for bonding metals. These adhesives are specially designed to evenly distribute stress across the bonded surface, creating a continuous and uniform bond line that reduces the risk of failure. Say goodbye to weak spots and hello to bulletproof bonds.

Let’s dive into the different types of structural adhesives and their unique properties. First up, we have epoxy adhesives, the rockstars of bonding. With exceptional strength and resistance to extreme temperatures and chemicals, epoxy can bond a wide range of metals like steel, aluminum, and stainless steel. It’s like having a bodyguard for your metal joints.

Next on the list are polyurethane (PU) adhesives, the flexible warriors. These adhesives offer unmatched flexibility and impact resistance, making them perfect for applications involving movement or vibrations. They can even bring different types of metals together, like a matchmaker for metals. Talk about versatile.

Last but not least, we have acrylic adhesives, the moisture and UV resistant champions. These adhesives are ideal for both indoor and outdoor applications, thanks to their ability to withstand moisture and UV radiation. With high strength bonds, they’re often found in demanding industries like aerospace and automotive. They’re like the secret weapon you didn’t know you needed.

Choosing the right adhesive for metal bonding can be overwhelming. But fear not. Consider factors like the type of metal, application requirements, and operating conditions. Need some guidance? Adhesive manufacturers and experts are here to save the day. They can help you make the right choice for your specific needs.

Factors to Consider When Selecting an Adhesive for Bonding Metal

When it comes to selecting an adhesive for bonding metal, there are several factors that should be taken into consideration. These factors can greatly impact the success and durability of the bond, so choosing the right adhesive is crucial. Let’s dive into these factors and explore what you need to know.

First and foremost, consider the type of metal you are working with. Different metals have varying properties and surface characteristics, so it’s important to choose an adhesive that is specifically designed for bonding that particular metal. Using the wrong adhesive can result in a weak bond or even failure.

Next, think about the environmental conditions that the bonded metal will be exposed to. Extreme temperatures, high humidity, or exposure to harsh chemicals can all affect the performance of the adhesive. Select an adhesive that is capable of withstanding these specific conditions to ensure a long-lasting bond.

Strength requirements are another important consideration. If you’re dealing with heavy loads or structural integrity is a top priority, opt for a high-strength adhesive. On the other hand, if you’re only looking for a decorative touch or have a light-duty application, a lower strength adhesive may be sufficient.

Surface preparation is often overlooked but plays a critical role in achieving a strong bond. Make sure the surfaces to be bonded are clean, dry, and free from any contaminants such as oil or rust. Some adhesives may require additional surface treatments like sanding or priming, so follow the manufacturer’s instructions carefully.

Cure time is something else to keep in mind. If time is of the essence or immediate bonding is necessary, choose an adhesive with a quick cure time. However, if you have more flexibility or patience, an adhesive that takes longer to cure may still provide excellent results.

Consider the application method as well. Some adhesives come in convenient forms like tapes or pre-mixed liquids, while others may require mixing or special techniques. Find an adhesive that suits your application method and makes bonding a breeze.

Lastly, always check the compatibility of your adhesive with both the metal surfaces being bonded and any other materials in the assembly. You don’t want any unexpected reactions or weaker bonds, so double-check those manufacturer’s recommendations.

k9KDnJpXMZ4″ >

Conclusion

When it comes to bonding two pieces of metal together, finding the best glue is crucial. You want a solution that will provide a strong and durable bond, ensuring your metal pieces stay securely attached. After careful research and testing, we have determined the ultimate adhesive for this task.

Introducing “MetalBond Ultra,” the game-changer in metal bonding technology. This revolutionary glue is specifically formulated to create an unbreakable bond between metal surfaces. Its advanced formula combines industrial strength with exceptional flexibility, allowing for movements and vibrations without weakening its grip.

MetalBond Ultra boasts an impressive range of features that set it apart from other glues on the market. Its quick-drying properties mean you won’t waste precious time waiting for the adhesive to set. In just minutes, your metal pieces will be firmly joined together, ready for use.

But what truly makes MetalBond Ultra stand out is its exceptional resistance to extreme temperatures and harsh environments. Whether you’re working with metals exposed to scorching heat or freezing cold, this glue won’t let you down. It maintains its integrity even in the most challenging conditions, ensuring a long-lasting bond that can withstand anything.

Not only does MetalBond Ultra provide unmatched strength and durability, but it also offers easy application and clean-up. Its user-friendly design allows for precise dispensing, minimizing mess and waste. Plus, its non-toxic formulation means you can work with peace of mind knowing you’re using a safe product.

So why settle for subpar adhesives when you can have the best? MetalBond Ultra guarantees exceptional performance, making it the go-to choice for all your metal bonding needs. Trust in its unrivaled strength and reliability to ensure your projects stand the test of time.

In conclusion, when it comes to gluing two pieces of metal together, MetalBond Ultra is undoubtedly the top contender. Its superior bonding capabilities combined with ease of use make it an unbeatable choice. Say goodbye to weak bonds and hello to a world of strong, secure metal connections.