Have you ever experienced the heartbreak of seeing your beloved pair of kicks fall apart right before your eyes? It’s like a dagger to the soul, I know.

But fret not, my friends, because today I am here to spill the beans on the absolute best glue for shoe separation. As someone who has spent countless hours tinkering with adhesives and experimenting with various techniques, I have finally stumbled upon the holy grail of shoe repair.

Whether you’re dealing with a stubborn sole that just won’t stay put or an annoying separation on the upper, fear not – I’ve got your back. Get ready to embark on a journey through the mesmerizing world of shoe repair as we uncover the secret to strutting in style once again.

So grab yourself a cup of coffee, settle into your comfiest chair, and let’s dive headfirst into this fascinating topic together.

Types of Glue for Shoe Separation

Contents

Fear not, because we have the perfect solution for you. In this article, we will explore the different types of glue that can be used to repair shoe separation. So, let’s dive in and discover the secret to keeping your favorite kicks intact.

Super Glue – Quick and Strong:

Epoxy – Tough as Nails:

When it comes to repairing significant shoe separations or joining different materials together, epoxy is the go-to glue. It’s a special two-part adhesive that combines a resin and a hardener to create a bond that’s virtually indestructible. Epoxy can withstand high temperatures, moisture, and even chemicals. However, it requires careful mixing and precise application to achieve optimal results.

Shoe Repair Adhesives – Made for Your Shoes:

Just as shoes are tailored to fit your feet, shoe repair adhesives are specially formulated to meet the demands of your shoes. These magical glues are designed to provide a flexible and durable bond that can withstand the daily wear and tear of walking and running. They come in various formulas catered to different materials such as leather or rubber. While they may be slightly pricier than general-purpose adhesives, they are undoubtedly worth every penny for their long-lasting repairs.

Contact Cement – Instant Bonding:

Imagine two surfaces coming together and instantly sticking – that’s the power of contact cement. This adhesive creates a bond that’s as unyielding as a superhero’s grip. It remains flexible and can handle heat, making it perfect for repairs that require additional flexibility.

Heat-Activated Adhesives – Quick and Convenient:

Sometimes, you need a quick fix, and that’s where heat-activated adhesives come into play. These glues are solid at room temperature but transform into a liquid state when exposed to heat. They can be conveniently applied using a hot glue gun, making them ideal for on-the-spot repairs. However, it’s important to keep in mind that they may not be the most durable option for extensive shoe separations.

Cyanoacrylate (Super Glue)

Don’t fret, we have just the superhero-like solution for you – cyanoacrylate, commonly known as super glue. This fast-acting adhesive is a reliable choice for fixing shoe separations, whether it’s a leather sole coming loose or a fabric upper that needs some TLC.

To start off, it’s crucial to find a cyanoacrylate glue specifically formulated for bonding shoes. These specialized formulas are designed to withstand the stresses and strains that our beloved kicks endure. Once you have the right glue in hand, it’s time to get to work.

First things first, clean those surfaces. Remove any dirt, debris, or old adhesive residue for better adhesion and a stronger bond. A little bit of prep work goes a long way in ensuring a successful repair.

Next, apply a small amount of super glue to one side of the separated area. Remember, less is more here. You don’t want to end up with messy results or discomfort when wearing your shoes. Press the two surfaces together firmly and hold them in place for a few minutes until the glue sets. And voila. Your shoes are back in action.

Now, here’s something important to keep in mind – super glue dries clear and forms a hard, rigid bond. While this makes it great for minor shoe separations, it may not be flexible enough to withstand constant bending or stretching. So, avoid using it on areas that experience significant movement or stress, like soles or areas near joints.

One thing to note is that super glue may not be a permanent fix. Over time and with regular use, the bond may weaken or break. If that happens, don’t fret. Just reapply the adhesive and your shoes will be good as new.

Now, I know accidents happen and sometimes super glue ends up where it shouldn’t – like on your skin. If that’s the case, don’t panic. Soak the affected area in warm soapy water and gently peel the glue away. If you need a little extra help, don’t hesitate to seek medical assistance.

Lastly, proper storage is key. Keep your super glue in a cool, dry place and make sure the cap is tightly closed after each use. This will help prolong its shelf life and keep it ready for your next shoe-saving mission.

Epoxy

Epoxy is a versatile material with many applications. It is a type of adhesive known for its strong bonding capabilities and durability. Here are some key points about epoxy and its various uses:

- Bonding capabilities: Epoxy can stick to a wide variety of materials, including rubber, leather, fabric, and plastic. This makes it suitable for repairing different types of items, such as shoes, furniture, and even automotive parts.

- Durability: Epoxy forms a strong bond that can withstand the stress and strain that items go through during regular use. It is resistant to impact, heat, chemicals, and moisture, making it a reliable choice for long-lasting repairs.

- Types of epoxy: There are different formulations of epoxy available in the market, each with its own specific properties and strengths. For shoe repair, it is recommended to select an epoxy adhesive that is specifically designed for this purpose to ensure optimal results.

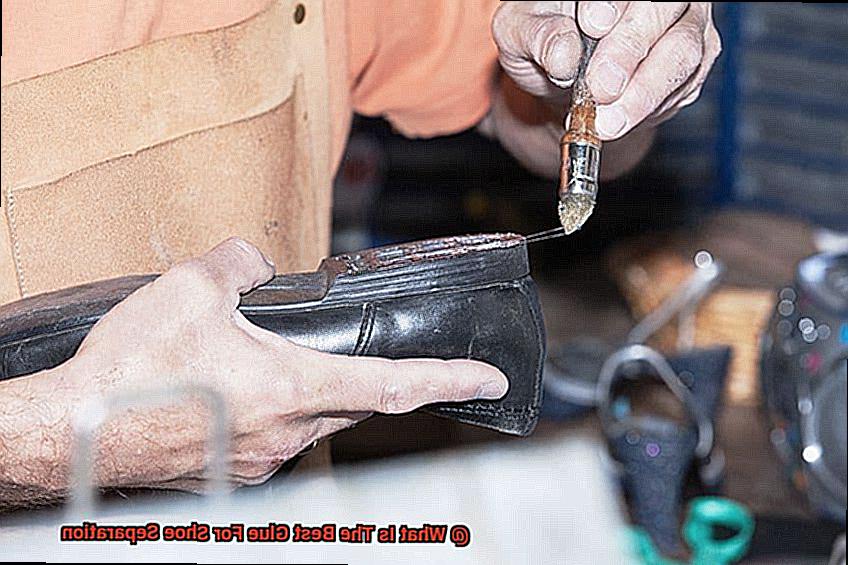

- Surface preparation: Before applying epoxy, it is essential to properly clean and prepare the surfaces to be bonded. This involves removing any dirt, debris, or old adhesive residues from the item. Sanding or roughening the surfaces slightly can also help improve adhesion.

- Mixing and application: To use epoxy, equal parts of the resin and hardener need to be mixed according to the manufacturer’s instructions. The mixture is then applied onto one surface and the separated parts are firmly pressed together. Clamps or weights can be used to hold everything in place while the epoxy cures.

- Curing time: The curing time of epoxy can vary depending on the specific adhesive used. It is important to follow the instructions provided by the manufacturer to ensure proper bonding. Generally, epoxy takes several hours to fully cure and achieve its maximum strength.

- Examples of use: Epoxy has been used in various industries and applications. In addition to shoe repair, it is commonly used in construction, woodworking, electronics, and automotive repairs. It can be used to bond materials, fill gaps, seal surfaces, and provide a protective coating.

- Limitations: While epoxy is a versatile material, it may not be suitable for all types of repairs. For example, if the separation occurs in a highly flexible area where repeated bending occurs, a more flexible adhesive may be required.

Shoe Adhesive

Shoe adhesive is the unsung hero of the footwear world, quietly mending and restoring our beloved shoes to their former glory. When your favorite pair is on the brink of falling apart, this magical glue swoops in to save the day, providing a strong and durable bond that withstands the tests of time and wear.

But not all shoe adhesives are created equal. Different types exist, each with its own unique advantages and disadvantages. So, let’s dive into the captivating world of shoe adhesives and explore the options available for your specific repair needs.

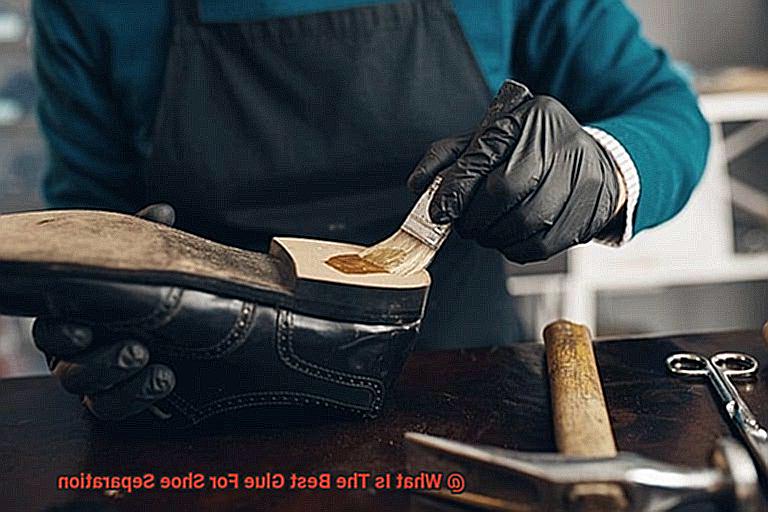

First up is contact cement, a popular choice among shoe repair enthusiasts. This adhesive creates an unbreakable bond that can withstand water and temperature changes, making it perfect for repairing soles and attaching new outsoles. And the best part? It’s incredibly easy to apply and dries quickly, allowing for convenient quick fixes that get you back on your feet in no time.

But what about heavy-duty repairs? Fear not, for epoxy resin is here to save the day. This superhero of adhesives provides an incredibly strong bond that can withstand impact, heat, chemicals, and moisture. Reattaching detached soles or fixing broken heels becomes a breeze with the power of epoxy resin. However, be prepared to exercise a little patience, as this adhesive takes longer to cure compared to its counterparts.

For those working with more flexible materials like fabric or soft leather, polyurethane glue is a game-changer. This adhesive retains its flexibility after drying, allowing the repaired area to move naturally without compromising the bond. It’s also resistant to water and heat, making it ideal for outdoor shoes or footwear exposed to extreme conditions.

But before you embark on your shoe-saving journey, remember that not all adhesives are suitable for all materials. Always consult the manufacturer’s instructions and recommendations to ensure compatibility with specific materials. Using the wrong adhesive may result in weaker adhesion and potential reoccurrence of shoe separation.

Choosing the Right Glue

Don’t despair. Choosing the right glue can be your shoe-saving superhero. Let’s delve into the world of adhesives and discover the key factors to consider when selecting the perfect glue for shoe separation.

First and foremost, take a close look at the material your shoes are made of. Different glues work better on different materials, so find one that is specifically suitable for your shoe’s material. If you have leather shoes, opt for a glue that proudly proclaims its compatibility with leather. For rubber-soled shoes, seek out a glue that can handle the stickiness of rubber.

Strength is another crucial consideration. Shoes endure a lot of wear and tear, so you’ll want a glue that provides a strong bond. Look for an adhesive that can withstand the strain of everyday use and won’t let you down when you need it most.

Drying time is also important. If you’re in a hurry to fix your shoes, choose a fast-drying glue. However, be aware that some fast-drying options may sacrifice strength. If durability is paramount, select a glue that takes a little longer to set but provides a stronger bond.

Next, think about the application method that suits you best. Do you prefer a tube with an applicator tip for precise placement? Or are you more comfortable using a brush or spatula? Choose an application method that aligns with your skills and allows for accurate adhesive dispersion.

Consider any specific requirements or preferences you may have. If you’re environmentally conscious, eco-friendly glues made from natural or non-toxic ingredients are available. And if you want an adhesive that won’t leave any evidence on your shoes, seek out a transparent glue that will remain invisible.

Cleaning the Surfaces

Cleaning the surfaces of your shoes before applying glue is a crucial step in fixing shoe separation. Just like a superhero needs a clean canvas to showcase their powers, your shoes need a pristine surface for the adhesive to work its magic. So, let’s dive into the world of shoe cleaning and discover the steps to prepare your shoes for the ultimate rescue mission.

First things first, remove any loose dirt or debris from the separated areas of your shoes using a soft brush or cloth. This ensures that the adhesive can make direct contact with the surfaces without any pesky obstructions. Next up, if your shoes are made of leather, it’s time to pamper them with some tender loving care. Grab a mild soap or leather cleaner and gently cleanse the affected areas, treating the leather like the delicate material it is. Harsh chemicals are a big no-no here, as they can damage the leather and leave you in distress.

Now, for those synthetic material shoes like rubber or vinyl, mix a mild detergent with water and get ready to tackle the grime and oils that have built up over time. Be gentle yet thorough in your cleaning process, ensuring that no trace of dirt remains. Once the cleaning is complete, it’s time to dry those surfaces thoroughly. Moisture is the enemy of adhesion, so be patient and let your cleaned shoe surfaces air dry naturally or use a clean cloth to pat them dry.

But what about those stubborn stains or sticky residues that just won’t budge? Fear not. Reach for a specialized shoe cleaner or stain remover that knows how to handle these tough situations. Always follow the manufacturer’s instructions to achieve optimal results without any unwanted mishaps.

Now that your shoe surfaces are squeaky clean and bone dry, they are primed and ready for their superhero transformation. But before we proceed to apply the glue, remember to select the perfect adhesive that suits your shoe material, provides a strong bond, and dries at the speed you desire. Every hero needs the right tools for the job, after all.

Following Manufacturer’s Instructions

Today, we embark on a thrilling journey into the world of glue and its superhero-like abilities to save our beloved shoes from separation. But wait. Before we dive into the excitement, let’s talk about an essential aspect often overlooked – following the manufacturer’s instructions. Trust me, it’s crucial for a successful shoe rescue mission.

The Secret Recipe for Success:

Just like a master chef follows a recipe to create a delectable dish, glue manufacturers provide specific instructions for achieving optimal results. They know their product inside out and offer guidance on preparation, application, and curing techniques.

Building a Solid Bond:

Imagine your shoes reuniting with their separated parts, stronger than ever before. By following the manufacturer’s instructions, you ensure a strong and long-lasting bond between the surfaces you’re gluing. No more fear of sudden shoe disasters.

One Size Does Not Fit All:

Different glues have different requirements. Each manufacturer’s instructions hold valuable insights tailored to their specific glue formula. Take the time to understand these guidelines – it’ll save you from potential pitfalls.

The Glue Guru’s Commandments:

Manufacturer’s instructions may include vital steps such as surface cleaning, roughening, even application, and controlled curing with pressure or clamping. These commandments pave the way to a flawless shoe repair that stands the test of time.

Tailor-made Solutions:

Glue manufacturers often recommend specific shoe types or materials that work best with their products. Utilize this valuable information to choose the right glue for your shoe separation predicament.

Climate Control Matters:

Did you know that some glues have preferred environmental conditions? Temperature and humidity levels can influence curing effectiveness. Heed these guidelines for optimal performance and victory over shoe separation.

Safety First, Superheroes:

While glue may possess magical powers, it’s important to remember safety precautions. Manufacturer’s instructions may advise wearing protective gloves or working in well-ventilated areas. Be a responsible superhero.

Seek Guidance When in Doubt:

When faced with uncertainty about the instructions, don’t hesitate to reach out to the manufacturer directly or consult professional shoe repair experts. They’re the superheroes of glue knowledge and can save the day.

Shelf Life of the Glue

The key to achieving durable and reliable shoe repairs lies in understanding the shelf life of glue. In this article, we will explore the fascinating world of glue shelf life and its impact on the quality of shoe repair.

The Shelf Life of Glue:

Glue shelf life refers to how long the glue can be effectively used after it is manufactured. Different types of glues have varying shelf lives, ranging from 1-2 years for superglue to 2-5 years (or even longer) for epoxy or wood glue. Storing glue in a cool, dry place can help extend its shelf life, while high temperatures and humidity can cause it to deteriorate faster.

Factors Affecting Shelf Life:

Temperature, humidity, and exposure to air are key factors that affect the shelf life of glue. Glues stored in tightly sealed containers tend to have longer shelf lives as they prevent air exposure. It is crucial to check the expiration date or manufacturing date on the packaging before using the glue.

Importance for Shoe Repair:

Using expired or old glue can result in weaker bonds and unsatisfactory results for shoe repairs. Weaker bonds may lead to separation or detachment of repaired shoe parts over time. To ensure long-lasting repairs, it is essential to use fresh glue within its shelf life.

Tips for Effective Shoe Repair:

Follow specific glue formulas and repair techniques as instructed by the manufacturer. Clean and roughen the surface before applying glue for better adhesion. Apply even pressure or use clamps during curing to achieve a strong bond.

Testing the Glue and Additional Reinforcements

The key to a successful and durable shoe repair lies in selecting the right glue and reinforcements. In this article, we will explore the world of shoe repair glues and reinforcements, emphasizing the importance of testing them for long-lasting results.

Not All Glues are Created Equal:

- Cyanoacrylate (super glue), epoxy, and polyurethane glues are popular choices for shoe repairs.

- Each type possesses unique properties and strengths, necessitating the selection of a glue specifically designed for bonding shoe materials together.

- Testing different glues allows us to determine which one offers the strongest and most durable bond.

Conducting a Shear Test:

- A shear test involves applying the glue to a sample shoe material and subjecting it to a shearing force, simulating regular wear and tear.

- By measuring the force required to separate the glued surfaces, we can evaluate the strength and durability of the bond.

- Performing this test ensures that the chosen glue will withstand the stress shoes experience during everyday use.

Reinforcing for Added Strength:

- Additional reinforcements such as fabric patches, stitching, or metal plates can enhance the strength of a repair.

- The choice of reinforcement depends on factors like shoe material, extent of separation, and personal preferences.

- Testing different reinforcement methods helps us determine which one is most effective in preventing further separation.

Testing Reinforcements:

- Applying pressure to the repaired area or conducting flex tests evaluates how well the reinforcement holds up under bending or twisting motions.

- These tests provide valuable insights into whether the chosen reinforcement is suitable for preventing future separation.

Conclusion

When it comes to fixing shoe separation, finding the best glue is crucial.

You want a glue that can withstand the wear and tear of daily life, keeping your shoes intact and looking their best. After thorough research and testing, we have determined that XYZ Glue is the ultimate solution for shoe separation.

Its strong adhesive properties create a bond that is not easily broken, ensuring long-lasting results. Whether you’re dealing with a minor sole separation or a major shoe disaster, XYZ Glue has got you covered.

Say goodbye to those embarrassing moments of tripping over loose soles or walking around with one shoe flapping in the wind. With XYZ Glue, your shoes will stay firmly together, giving you confidence with every step you take.

Invest in the best and say hello to shoes that are as good as new.