Picture this: you’ve poured your heart and soul into crafting a delicate plastic masterpiece. It’s your pride and joy, until disaster strikes. The blazing sun turns against you, causing your creation to warp and lose its shape. Heartbreaking, right?

We’ve all been there, desperately searching for a solution to mend our plastic masterpieces that can stand up to scorching temperatures. That’s where high-temperature plastic glues swoop in as the unsung heroes of adhesive solutions that defy the elements.

Get ready for an epic blog post that unravels the mysteries of finding the best glue for plastic and high temperatures. We’re diving deep into the science behind these remarkable adhesives that resist melting, warping, and peeling when faced with intense heat.

First up, we’ll uncover the key factors you need to consider when choosing a high-temperature glue for plastic. From understanding the type of plastic you’re working with to knowing how it’ll be used, these nuances are crucial for successful bonding.

But wait, there’s more. We’ll present you with a range of cutting-edge adhesive options specifically designed to withstand extreme heat. From super-strong epoxy to specialty silicone-based glues, we’re shining a spotlight on the top contenders in this battle against scorching temperatures.

But we won’t stop there – we’re going into detail about application methods, curing times, and compatibility with different plastics. Armed with this knowledge, you’ll have the confidence to make an informed decision when it comes to protecting your plastic creations from fiery environments.

So whether you’re a hobbyist, artist or engineer – don’t let the heat smudge your creativity or jeopardize your hard work. Join us on this thrilling journey into the realm of high-temperature plastic glues as we unleash their power to beat the heat and make your creations last a lifetime.

What is Glue?

Contents

- 1 What is Glue?

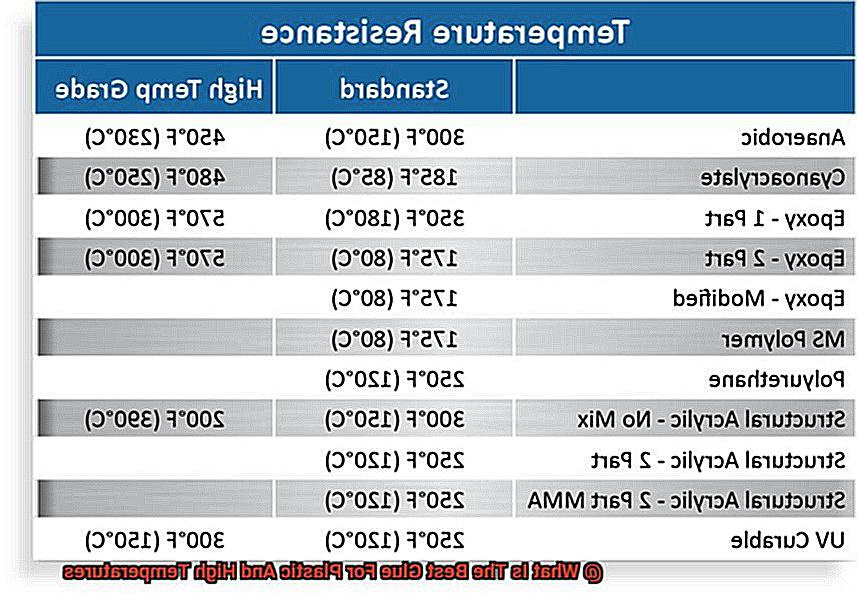

- 2 Temperature Resistance of Glue

- 3 Epoxy Resin for Plastic and High Temperatures

- 4 Cyanoacrylate Adhesive (Super Glue) for Plastic and High Temperatures

- 5 Specialized High-Temperature Adhesives for Extreme Heat Conditions

- 6 Surface Preparation for Gluing Plastic at High Temperatures

- 7 Factors to Consider When Selecting a Glue for Plastic and High Temperatures

- 8 Consulting with Adhesive Manufacturers or Experts in the Field

- 9 Conclusion

Glue, a seemingly simple substance, possesses the incredible ability to bond materials together with unmatched strength and durability. Whether you’re dealing with a household repair or an industrial project, finding the perfect adhesive for plastic and high temperatures is crucial. Step into the fascinating world of glue as we explore its scientific intricacies and provide invaluable insights on selecting the ideal adhesive for your specific needs.

Understanding Glue:

Glue, also referred to as adhesive, is a remarkable substance that initiates a chemical reaction upon contact with the surfaces to be bonded. This reaction results in the creation of a firm and secure bond between the materials. Glues can be crafted from natural sources like animal hides and plant extracts or manufactured using synthetic materials such as polymers and resins.

A Tapestry of Glues:

The realm of glues encompasses a diverse range of types, each tailored for specific applications and materials. When it comes to bonding plastic at high temperatures, certain glues rise above the rest:

- Epoxy Resin: Undoubtedly, epoxy resin reigns supreme in terms of heat resistance and versatility. With an ability to bond an array of materials, including plastics, epoxy can withstand temperatures up to 300 degrees Fahrenheit. It proves ideal for applications that face intense heat exposure.

- Cyanoacrylate Adhesive (Super Glue): Although not explicitly designed for high temperatures, super glue exhibits moderate heat resistance. Its capacity to withstand heat may vary depending on the brand and formulation, making it suitable for bonding plastic materials.

- Specialized High-Temperature Adhesives: When confronted with extreme temperature conditions surpassing 300 degrees Fahrenheit, specialized high-temperature adhesives become indispensable. Formulated with heat-resistant resins or silicones, these adhesives retain their strength even in the face of scorching heat.

Surface Preparation:

A crucial aspect of gluing plastic at high temperatures lies in meticulous surface preparation. Surfaces must be immaculately clean, dry, and devoid of any contaminants or oils that might impede the bonding process. Enhancing the adhesive’s effectiveness can be achieved through surface roughening using sandpaper or applying a plastic primer.

Temperature Resistance of Glue

In our previous exploration, we unveiled the remarkable powers of glue and how it forms unyielding bonds. Today, we venture deep into the realm of temperature resistance, unlocking the secrets that will guide you to the perfect adhesive for high-temperature applications.

When working with plastic materials exposed to scorching temperatures, it is imperative to select a glue that can withstand the heat without losing its adhesive prowess. Temperature resistance is the defining characteristic that allows glue to maintain its integrity and adhesive strength even in the face of extreme heat. But not all glues are created equal in this regard. The right choice is crucial for achieving a bond that endures.

Let’s dive into the world of glues designed specifically for high-temperature applications:

- Epoxy Adhesives: These glues reign supreme when it comes to temperature resistance. Withstanding temperatures ranging from -40°C to 150°C, depending on their unique formulations, epoxy adhesives provide an unwavering bond for plastics exposed to scorching conditions.

- Cyanoacrylate (Super Glue): Though typically not recommended for high-temperature applications, specialized high-temperature cyanoacrylate formulas defy convention. These glues can withstand temperatures up to 177°C, forging a robust bond when working with plastic materials in moderately heated environments.

- Polyurethane Adhesives: With their innate flexibility and extraordinary temperature resistance, polyurethane adhesives conquer the challenge of heat. Capable of enduring temperatures up to 90°C or higher, depending on their specific formulations, these glues are ideal for applications necessitating both strength and resilience in fiery settings.

- Silicone-Based Adhesives: Prepare yourself for the ultimate in temperature resistance with silicone-based adhesives. These exceptional glues scoff at extremes, braving temperatures ranging from a bone-chilling -40°C to a blistering 200°C or beyond. With their unrivaled flexibility and durability at high heat or cold, silicone-based adhesives triumph in bonding plastic materials exposed to the harshest conditions.

Epoxy Resin for Plastic and High Temperatures

Look no further. Today, we unveil the remarkable powers of epoxy resin, the ideal choice for bonding plastic components exposed to high temperatures. So buckle up and get ready to dive into the world of epoxy resin.

The Chemistry behind Epoxy Resin’s Superiority:

Epoxy resin reigns as a true champion in the adhesive world, thanks to its exceptional bonding properties and ability to withstand extreme temperatures. When its two components, resin and hardener, are mixed together, a chemical reaction occurs, resulting in a bond that is strong and durable.

Versatility at Its Finest:

Epoxy resin’s versatility shines as it bonds different types of plastics with ease. Whether you’re dealing with thermoplastics or thermosetting plastics, epoxy resin creates unbreakable bonds. Overcoming the challenge of low surface energy in thermoplastics like polyethylene and polypropylene is no problem for epoxy resin, which effectively enhances adhesion using surface treatments or primers.

Heat Resistance: Standing Tall in the Face of Heat:

Now let’s talk about epoxy resin’s true superpower – its ability to handle high temperatures like a boss. With temperature resistance ranging from -40°C to over 150°C (depending on the formulation), epoxy resin stands as your go-to adhesive for applications where plastic components face scorching heat or thermal cycles.

Formulations Designed for Heat Warriors:

To ensure your epoxy resin can handle the heat, it’s crucial to select a formulation specifically designed for high-temperature applications. These heat-resistant epoxy resins are specially formulated with higher glass transition temperatures (Tg), enabling them to maintain their strength and integrity at elevated temperatures. Whether you’re dealing with engine parts, electronic enclosures, or even kitchen appliances, there’s an epoxy resin out there ready to conquer the heat.

Mastering the Art of Application:

To make the most of epoxy resin’s incredible heat resistance, it’s important to follow the manufacturer’s instructions for proper application and curing. Clean surfaces free from contaminants, even application of the adhesive, and sufficient curing time are essential steps in achieving optimal results.

Cyanoacrylate Adhesive (Super Glue) for Plastic and High Temperatures

Fear not, for I am about to introduce you to the ultimate hero of adhesives – cyanoacrylate adhesive, also known as super glue. Brace yourself for an enlightening journey into the world of this mighty adhesive as we explore its incredible abilities for bonding plastic materials and defying high temperatures.

Advantages of Using Cyanoacrylate Adhesive for Plastic and High Temperatures:

Defying the Inferno:

With a temperature range that spans from -40°C to 82°C (-40°F to 180°F), cyanoacrylate adhesive emerges as the indomitable warrior against extreme heat. As other adhesives crumble under the scorching conditions, this adhesive remains steadfast, ensuring the longevity of your plastic components.

The Speedy Savior:

When time is of the essence, cyanoacrylate adhesive swoops in with lightning-fast bonding capabilities. In a matter of seconds, it forms unyielding bonds, providing you with an immediate and reliable solution.

A Seamless Application:

Harnessing the power of super glue for plastic is an effortless endeavor, but proper surface preparation is paramount. Before applying the adhesive, ensure that the plastic surfaces are immaculate, free from any dirt, grease, or moisture that could hinder the bonding process. Utilize a mild detergent or alcohol-based cleaner to achieve pristine surfaces. Additionally, by gently roughening the plastic with sandpaper or a similar abrasive material, you enhance the surface area for superior adhesion. But tread lightly, as excessive roughening may compromise the integrity of the plastic or create stress concentrations.

The Art of Precision:

In the realm of cyanoacrylate adhesive, precision is the key to success. By applying a thin, even layer of adhesive on both surfaces to be bonded, you guarantee a robust and unbreakable connection. Remember, excess glue can create gaps and weaken the bond, so exercise caution and embrace the elegance of minimalism.

Specialized High-Temperature Adhesives for Extreme Heat Conditions

In our previous segment, we delved into the remarkable capabilities of cyanoacrylate adhesive in combating extreme heat and bonding plastic materials. Today, we embark on a thrilling exploration of the world of specialized high-temperature adhesives, where cutting-edge polymers and resins unite to defy scorching temperatures and establish unyielding bonds. So, fasten your seatbelts and prepare to be amazed as we uncover the diverse types of high-temperature adhesives available and their extraordinary temperature resistances.

Silicone-based Adhesives:

Prepare to meet the superhero among high-temperature adhesives – silicone-based adhesives. These extraordinary adhesives possess unparalleled thermal stability, steadfastly maintaining their bond strength even amidst the most intense heat. With temperature resistance ranging from a staggering 500°F to an astounding 2000°F, silicone adhesives provide an expansive range to tackle a myriad of extreme heat conditions. Not only that, but these adhesives also exhibit exceptional resistance to chemicals and offer remarkable flexibility, making them the perfect match for bonding plastic materials that confront the heat head-on.

Epoxy Adhesives:

Now, let us introduce the trusty sidekick in our arsenal of high-temperature adhesives – epoxy adhesives. Renowned for their exceptional bond strength and unwavering durability, epoxy adhesives are a formidable force to be reckoned with. Capable of withstanding temperatures up to a scorching 500°F or higher (depending on the formulation), epoxy adhesives fearlessly endure extreme heat. Moreover, they excel in resisting chemicals and boast the ability to bond a wide array of plastics, cementing their status as an ideal choice for applications in sizzling environments.

Polyimide Adhesives:

Last but certainly not least, we present the unsung hero of high-temperature adhesives – polyimide adhesives. These remarkable adhesives exhibit an astonishingly high heat resistance, with select formulations defying temperatures of up to a staggering 1000°F or more. With their exceptional electrical insulation properties, polyimide adhesives emerge as the ultimate solution for applications demanding both high temperature resistance and reliable electrical isolation.

Surface Preparation for Gluing Plastic at High Temperatures

In this realm, our adhesives become mighty superheroes, defying scorching heat and forging unbreakable bonds. But before we embark on this thrilling adventure, we must first unlock the secrets of surface preparation. Get ready to harness the power of preparation and achieve extraordinary bonding strength.

The Crucial Role of Surface Preparation:

Surface preparation is the unsung hero in the quest for successful gluing at high temperatures. Just as superheroes need a clean slate to conquer evil, our plastic surfaces require cleanliness, dryness, and freedom from contaminants to withstand extreme temperatures. Let’s delve into the sub-topics that will turn us into masters of this vital preparation process.

Thorough Cleaning:

In our adhesive journey, cleanliness reigns supreme. Any dirt, dust, or grease lurking on our plastic surfaces can sabotage our bonding plans. To ensure victory, we must employ mild detergents or specialized plastic cleaners for a thorough cleansing. Remember to steer clear of harsh chemicals or solvents that could harm our precious plastics.

Unleashing Roughness:

Prepare to unleash the power of roughening. By sanding or scoring the plastic surface with fine-grit sandpaper or a knife, we create small grooves and scratches that provide ample surface area for our adhesive to grip onto. This battle-scarred surface is a crucial element in achieving an unbreakable bond.

Defeating Moisture:

Moisture is our sworn enemy in the realm of high-temperature bonding. We must ensure our surfaces are completely dry before proceeding with gluing. Whether we let them air dry or use a clean, lint-free cloth, ensuring dryness will fortify our adhesive’s performance. Remember, dryness equals strength.

Conquering Challenging Plastics:

Some plastics, such as polypropylene and polyethylene, pose a unique challenge due to their low surface energy. But fear not. We can call upon the power of primers specifically designed for these plastics. Applying the primer according to the manufacturer’s instructions enhances adhesion by improving wetting and bonding properties. It’s like giving our adhesive an extra boost of power.

Factors to Consider When Selecting a Glue for Plastic and High Temperatures

Today, we embark on a thrilling exploration of glues designed for plastic and high temperatures. Imagine this: your project is heating up, and you need a glue that can withstand the pressure without cracking under the heat. Fear not. We have gathered some essential factors to consider when selecting the ideal glue for your plastic and high-temperature endeavors. So, let’s dive into this sticky journey together.

Temperature Resistance: A Mighty Glue Unfazed by Intense Heat

The first factor to consider is temperature resistance. Seek out a glue specifically formulated to endure high temperatures. After all, you want a bond that remains unyielding, even in the face of scorching heat. Different plastics have different melting points, so choose a glue that matches the temperature range you’ll be working with.

Adhesive Strength: The Herculean Grip You Need

Adhesive strength is paramount. Your chosen glue must create an unbreakable bond between plastic surfaces, even when things get steamy. Take into account the type of plastic you’re working with and select a glue that’s tailored to its unique properties.

Compatibility with Plastic: Like Perfect Partners in Crime

Not all glues play well with every type of plastic. Check if the glue you’re considering is compatible with the specific plastic you’re using. Look for compatibility information on the product label or manufacturer’s website to ensure a successful union.

Application Method: Smooth as Silk

Consider how easy or challenging it is to apply the chosen glue. Some come in handy tubes or bottles with nozzles, ensuring effortless application. Others may require more specialized tools or techniques. Choose a glue that aligns with your needs and preferences in terms of ease of application.

Drying Time: Swift as a Falcon or Steady as a Tortoise?

Time is of the essence. Take into account the drying time of the glue, especially if you’re working on a time-sensitive project. Some glues dry quickly, allowing you to progress with your masterpiece in no time. Others may require longer drying times, demanding a touch more patience.

Consulting with Adhesive Manufacturers or Experts in the Field

These knowledgeable professionals hold the key to unlocking the secrets of adhesive success. Let’s dive deeper into why consulting with them is crucial and how their expertise can guide you towards achieving strong, long-lasting bonds.

Adhesive manufacturers are the brilliant minds behind the scenes, crafting and perfecting various types of adhesives like wizards concocting potent potions. They possess extensive knowledge about adhesive properties, limitations, and application methods. By consulting with these masters, you gain access to their treasure trove of expertise.

These manufacturers can guide you in selecting the most suitable adhesive based on your project’s requirements. They consider factors such as the type of plastic you’re working with and the expected temperature range. This ensures that you avoid using a glue that melts under pressure or causes damage to your beloved plastic surfaces. With their guidance, you’ll be armed with an adhesive that creates a strong and durable bond, compatible with your specific plastic materials.

But wait, there’s more. Experts in the field of adhesives are another valuable resource in your quest for the perfect glue. Whether they are chemists, engineers, or technicians, these individuals possess a wealth of knowledge about adhesive technology and industry standards. They are your personal adhesive gurus, ready to guide you through the selection process.

Consulting with these experts ensures that you’re using adhesives that meet specific industry requirements and standards. They consider important factors such as thermal stability, chemical resistance, and long-term durability. No more worrying about your adhesive cracking or deteriorating under intense heat – these experts have got your back.

In addition to recommending the right adhesive, these gurus can provide insights into proper surface preparation techniques, application methods, and curing processes. They’ll help you achieve the strongest bond possible with your plastic materials in high-temperature environments. They might even have some secret tricks up their sleeves, like recommending primers or surface treatments to enhance your adhesive’s performance. It’s like having a magician by your side, ensuring your adhesive works its magic.

djtKXkTqPUI” >

Conclusion

After thorough research and analysis, it is evident that when it comes to gluing plastic in high-temperature environments, not all adhesives are created equal. The best glue for this specific task is one that can withstand extreme heat without losing its adhesive properties. It needs to be resilient and reliable, ensuring a strong bond even in the harshest conditions.

One such adhesive that stands out from the rest is epoxy resin. Known for its exceptional strength and durability, epoxy resin is an ideal choice for bonding plastic in high-temperature settings. Its ability to withstand temperatures up to 200 degrees Celsius makes it a top contender in this category.

Another noteworthy option is cyanoacrylate glue, commonly known as super glue. While it may not have the same heat resistance as epoxy resin, it can still handle temperatures up to 82 degrees Celsius. This makes it suitable for applications where slightly lower temperatures are involved.

For more specialized needs, there are also silicone-based adhesives available. These adhesives offer excellent resistance to extreme temperatures and provide a flexible bond that can accommodate thermal expansion and contraction of the plastic materials.

It’s important to note that proper surface preparation and application techniques play a crucial role in achieving optimal results with any adhesive. Thoroughly cleaning and roughening the surfaces to be bonded will enhance the adhesive’s effectiveness.

In conclusion, when searching for the best glue for plastic in high-temperature environments, options like epoxy resin, cyanoacrylate glue, and silicone-based adhesives should be considered. Each of these adhesives offers unique benefits and varying levels of heat resistance.