Are you a DIY enthusiast, a home improvement guru, or a crafter extraordinaire? If so, you’ve probably encountered the perplexing challenge of securely bonding plywood to foam board. But fear not. We hold the key to this sticky situation – the ultimate glue.

Imagine this: Your mind is buzzing with creative ideas, your stack of plywood sheets is ready for action, and your cart is filled with foam boards. You’re brimming with excitement as you embark on your next project. However, there’s one hurdle – how do you seamlessly join these two materials? Don’t worry; we’re about to dive into the world of innovative adhesives that will flawlessly bond plywood to foam board.

So, what makes the best glue for this task? Consider factors like adhesion strength, material compatibility, ease of application, and longevity of the bond. In today’s blog post, we’ll explore these qualities and unveil the glue that will take your craftsmanship to new heights.

Get ready to meet adhesive heroes like polyurethane glue, contact cement, and even spray adhesives – they conquer this challenge with grace. We’ll analyze their unique properties and showcase how they bridge the gap between porous plywood and delicate foam board.

Discover the secret behind long-lasting bonds that will keep your project intact for years to come. Whether you’re crafting colossal sculptures or constructing eye-catching architectural models, your choice of glue determines your creation’s success. Join us on this adhesive adventure as we guide you towards finding the ultimate glue for plywood to foam board.

What is Plywood?

Contents

- 1 What is Plywood?

- 2 What is Foam Board?

- 3 Considerations When Bonding Plywood to Foam Board

- 4 Polyurethane Glue: Advantages and Disadvantages

- 5 Epoxy Resin: Advantages and Disadvantages

- 6 Contact Cement: Advantages and Disadvantages

- 7 Surface Preparation and Application Tips for Bonding Plywood to Foam Board

- 8 Conclusion

Plywood, a marvel of craftsmanship engineered from thin layers of wood veneer fused together, has revolutionized the construction and woodworking industries. Its incredible strength, unwavering durability, and unparalleled versatility have made it an indispensable material. In this captivating exploration, we will delve into the remarkable properties and limitless applications of plywood, uncovering why it reigns supreme in the realm of composite materials.

The Artistry of Construction:

- Plywood’s creation involves an intricate process of meticulously stacking multiple layers of wood veneers.

- These layers are skillfully bonded together using top-notch adhesives, ensuring an unbreakable union.

- The core material can be handpicked from softwood or hardwood, carefully selected to suit diverse requirements.

A Symphony of Strength and Stability:

- The symmetrical arrangement of cross-grain veneers amplifies plywood’s inherent strength and stability.

- Unlike solid wood, plywood defies warping, twisting, and cracking with its harmonious composition.

- Its steadfast dimensional stability sets it apart as an unwavering choice for even the most demanding construction projects.

The Elegance of Grades and Appearances:

- Plywood presents itself in a myriad of grades, each showcasing its own unique quality and aesthetic appeal.

- Ascending through the ranks unveils higher-grade plywood with fewer imperfections and a uniform allure.

- These superior aesthetics render it ideal for applications where beauty plays a starring role.

Unleashing Boundless Creativity in Construction:

- Plywood takes center stage in furniture manufacturing, birthing exquisite pieces that exude both elegance and functionality.

- It forms the backbone of cabinetry, flooring, wall paneling, and roofing, underpinning structural integrity while imbuing spaces with sophistication.

- In the realm of construction, plywood shines as sheathing, formwork, subflooring, and a stalwart companion for projects demanding brawn and resilience.

Surpassing the Limits of Solid Wood:

- Plywood’s ability to defy dimensional instability surpasses that of solid wood.

- Its innate resistance to swelling or shrinking in response to moisture fluctuations is a testament to its composite nature.

- The risk of splitting or warping is beautifully mitigated by the amalgamation of its layers.

What is Foam Board?

This versatile material has taken center stage in various industries, from signage to art projects. So, grab your utility knife and let’s embark on an exploration of the endless possibilities of foam board.

What is Foam Board?

Foam board, also known as foam core or foam sheet, is a true multitasker. Imagine a polystyrene foam core sandwiched between two layers of paper or plastic – an ingenious combination that provides insulation, rigidity, and strength in one compact package.

Size and Color Matters:

Foam board comes in different thicknesses, ranging from 3/16 inch to 1 inch. Common sizes include 4×8 feet and 20×30 inches, but rest assured that custom sizes are available too. While classic white is popular, don’t shy away from exploring the realms of black or blue for a touch of adventure.

Lightweight and Easy to Handle:

One of foam board’s greatest features is its featherlight nature. Say goodbye to back-breaking materials. Whether you’re working on a signage project or preparing for a presentation, foam board won’t weigh you down. Its rigidity allows it to stand on its own or be effortlessly mounted on walls or easels without losing its cool.

Crafting Meets Creativity:

Calling all artists and crafters. Foam board is about to become your new best friend. Its smooth surface eagerly welcomes paintbrushes, markers, and even printers. Need precise shapes? Not a problem. A utility knife or a fine-toothed saw will do the trick. From breathtaking paintings to intricate designs, foam board is your creative canvas.

Architects’ Secret Weapon:

Attention, architects and model enthusiasts. Foam board is here to bring your visions to life. Its lightweight yet sturdy construction makes it perfect for crafting detailed architectural models, prototypes, or captivating dioramas. Dream big and build bigger with foam board.

Insulate with Style:

Did you know that foam board possesses insulating superpowers? Its polystyrene foam core acts as a barrier against heat transfer, making it an excellent choice for thermal insulation projects. Say goodbye to energy inefficiency and hello to cozy spaces.

Considerations When Bonding Plywood to Foam Board

Step into the fascinating world of foam board and discover the art of bonding plywood to this versatile material. Whether you’re a DIY enthusiast or a seasoned builder, these considerations will guide you towards achieving a bond that is strong and enduring.

First and foremost, let’s talk about compatibility. The glue you choose must be compatible with both plywood and foam board. Some glues fail to adhere well to certain types of foam board and can even damage the surface of the plywood. To ensure success, select a glue that is compatible with both materials.

Adhesive strength is crucial. Plywood and foam board have distinct properties that may necessitate varying levels of adhesive strength. You need a glue that provides ample bonding power to securely hold the plywood to the foam board, without any risk of separation or delamination. Your masterpiece should remain intact.

Flexibility is another key consideration. Plywood and foam board possess different levels of flexibility, so your glue must accommodate these differences. It should be able to flex and expand along with the materials, without compromising the bond’s integrity. This flexibility guarantees the longevity and durability of your bonded plywood and foam board creation.

Water resistance may be vital depending on your project. If your bonded plywood and foam board will face moisture or humidity, choose a water-resistant glue. This prevents warping, swelling, or degradation of the bond in such conditions. Don’t let water spoil your hard work.

Now let’s discuss application methods. Some glues come in convenient spray form, while others require manual application with a brush or trowel. The choice of application method depends on personal preference, convenience, as well as the size and complexity of your project. Find an application method that suits your needs and makes bonding a breeze.

Consider drying time as well. Some glues dry quickly, allowing for swift project completion. Others require longer drying periods. Choose a glue with a drying time that matches your project requirements, ensuring sufficient bonding time before handling or further processing. Patience is a virtue in this process.

Last but certainly not least, prioritize safety precautions. When working with glues, always follow the manufacturer’s instructions regarding safety. Some glues emit strong fumes or require proper ventilation during application and drying. Keep yourself and others protected by adhering to safety guidelines.

Polyurethane Glue: Advantages and Disadvantages

Today, we embark on a riveting journey into the world of polyurethane glue and its incredible ability to bond plywood to foam board. As an expert in this field, I have delved into extensive research to bring you valuable insights into the advantages and disadvantages of using this adhesive. So, let’s dive in and discover why polyurethane glue is the ultimate go-to choice for all your bonding needs.

Advantages of Polyurethane Glue:

Unyielding Bonding Strength:

Polyurethane glue proves to be an unparalleled champion in creating bonds that withstand the test of time. Its exceptional strength ensures that plywood and foam board remain securely attached, even in high-stress applications like furniture construction or boat building. Say goodbye to delamination or separation worries with this adhesive’s robust bonding capabilities.

Versatility Redefined:

Gone are the days of juggling multiple adhesives for different materials. Polyurethane glue shines as a versatile superstar, capable of bonding an array of surfaces including wood, plastic, metal, and yes, even foam board. This adhesive’s versatility makes it a game-changer for projects involving various materials. Bid farewell to adhesive confusion – polyurethane glue is here to save the day.

Defying Water’s Power:

Imagine spending hours crafting a masterpiece with plywood and foam board, only to have it ruined by water damage. Fear not. Polyurethane glue comes to the rescue with its exceptional resistance to water and moisture. No matter the humidity or dampness of the environment, this adhesive ensures that your bond remains resilient, safeguarding your hard work from potential damage or deterioration.

Disadvantages of Polyurethane Glue:

The Expansion Blues:

Polyurethane glue’s tendency to expand during the curing process poses a minor challenge. While this expansion is a testament to its strength, it can lead to messy situations and excess glue runoff if not handled with care. Counter this inconvenience by applying the glue in thin and even layers, guaranteeing a neat and controlled bond.

Epoxy Resin: Advantages and Disadvantages

First and foremost, let’s talk about the incredible strength and durability that epoxy resin brings to the table. When applied correctly, it creates a bond that can withstand heavy loads and resist wear and tear over time. So whether you’re working on a robust project or simply need a long-lasting bond, epoxy resin is your ultimate ally.

But wait, there’s more. Epoxy resin doesn’t limit itself to just one type of material. It’s a versatile adhesive that can be used on various surfaces, including plywood and foam board. This adaptability makes it the go-to choice for bonding these two materials together. Plus, its exceptional adhesive properties ensure a strong bond with both porous and non-porous surfaces.

Now let’s talk about the magic of a seamless finish. Epoxy resin has self-leveling properties that fill in gaps and irregularities between plywood and foam board, creating a flawlessly smooth surface. Not only does this enhance the appearance of your creation, but it also strengthens it from within. Talk about an aesthetic and functional win-win situation.

Of course, every coin has two sides, and epoxy resin is no exception. One drawback to keep in mind is its longer curing time compared to other adhesives. Depending on factors like temperature and humidity, epoxy resin may take several hours or even days to fully cure. So if time is of the essence or immediate use of your bonded materials is crucial, you might need to exercise some patience.

Another aspect to consider is the potential toxicity of epoxy resin. It contains chemicals that can be harmful if not handled properly. Safety should always be a priority in our crafts. Make sure to wear protective gloves and work in a well-ventilated area when using epoxy resin. Responsible disposal methods should also be followed to ensure the well-being of both humans and the environment.

Contact Cement: Advantages and Disadvantages

If you’re seeking a reliable adhesive to bond plywood to foam board, look no further than contact cement. This rubber-based adhesive has become a go-to choice in construction, woodworking, and crafting projects for its exceptional bonding capabilities. But before you embark on your adhesive journey, let’s delve into the advantages and disadvantages of using contact cement for this specific application.

Advantages:

- Unyielding Bond: When it comes to bonding plywood to foam board, you need a connection that can withstand the test of time. Contact cement delivers just that – a resolute and permanent bond that can endure various stresses and pressures. Say goodbye to worries about your creation falling apart.

- Versatility at Its Finest: Contact cement is not picky when it comes to materials. It easily adheres to a wide range of surfaces, including wood, metal, plastic, and fabric. Whether you’re working on a smooth plywood surface or a textured foam board, contact cement rises to the occasion, providing a secure and reliable bond.

- Simplicity Personified: Let’s simplify things, shall we? Contact cement comes with an applicator brush attached to the can or tube, allowing for easy and precise application. Apply the adhesive evenly on both surfaces, let it dry until it becomes tacky, and firmly press the plywood and foam board together – voila. Your bond is established without any hassle.

Disadvantages:

- The Scent of Strong Odor: We must address the elephant in the room – the potent odor of contact cement. This adhesive contains solvents that emit fumes during the drying process. While it’s not a deal-breaker, it’s essential to work in a well-ventilated area and wear appropriate protective gear, such as a mask or respirator, to minimize any potential harm from inhalation.

- An Irreversible Connection: Here’s a word of caution – once you’ve pressed the plywood and foam board together with contact cement, there’s no turning back. The bond is nearly impossible to reverse without causing damage. Therefore, it’s crucial to align the surfaces carefully before committing to the bond to avoid any regrets down the line.

Surface Preparation and Application Tips for Bonding Plywood to Foam Board

In this comprehensive guide, we’ll unveil expert tips and tricks that will help you forge an unbreakable bond between these two materials. Let’s delve into the world of surface preparation and application for plywood to foam board bonding.

Pristine Surfaces: The Foundation of Success

Before diving into the bonding process, ensure that both the plywood and foam board surfaces are immaculate. Eliminate any lurking dirt, dust, or debris that might undermine the glue’s grip. Arm yourself with a clean cloth or sponge, along with a mild detergent, to banish grease, oil, and other contaminants from the surfaces. Rinse thoroughly and allow ample time for the materials to dry completely.

Sanding: Roughing It Up for Optimal Adhesion

To achieve a robust bond, sanding is your secret weapon. Equip yourself with medium-grit sandpaper and gently roughen up the plywood and foam board surfaces. This technique increases the contact area for the glue, resulting in a more potent connection. However, proceed with caution and avoid overzealous sanding that might compromise the integrity of the materials.

Unleashing the Perfect Glue: A Match Made in Bonding Heaven

Selecting the right adhesive is paramount when it comes to bonding plywood to foam board. Various types of glue are at your disposal, each possessing unique properties. Polyurethane-based adhesives reign supreme in terms of bonding strength and flexibility, making them suitable for indoor and outdoor applications alike. Epoxy resins offer exceptional strength, water resistance, solvent resistance, and heat resistance. Construction adhesives, such as polyvinyl acetate (PVA) glues, are user-friendly, drying quickly and offering reliable bonding strength. However, they may not be as durable as other options for outdoor projects.

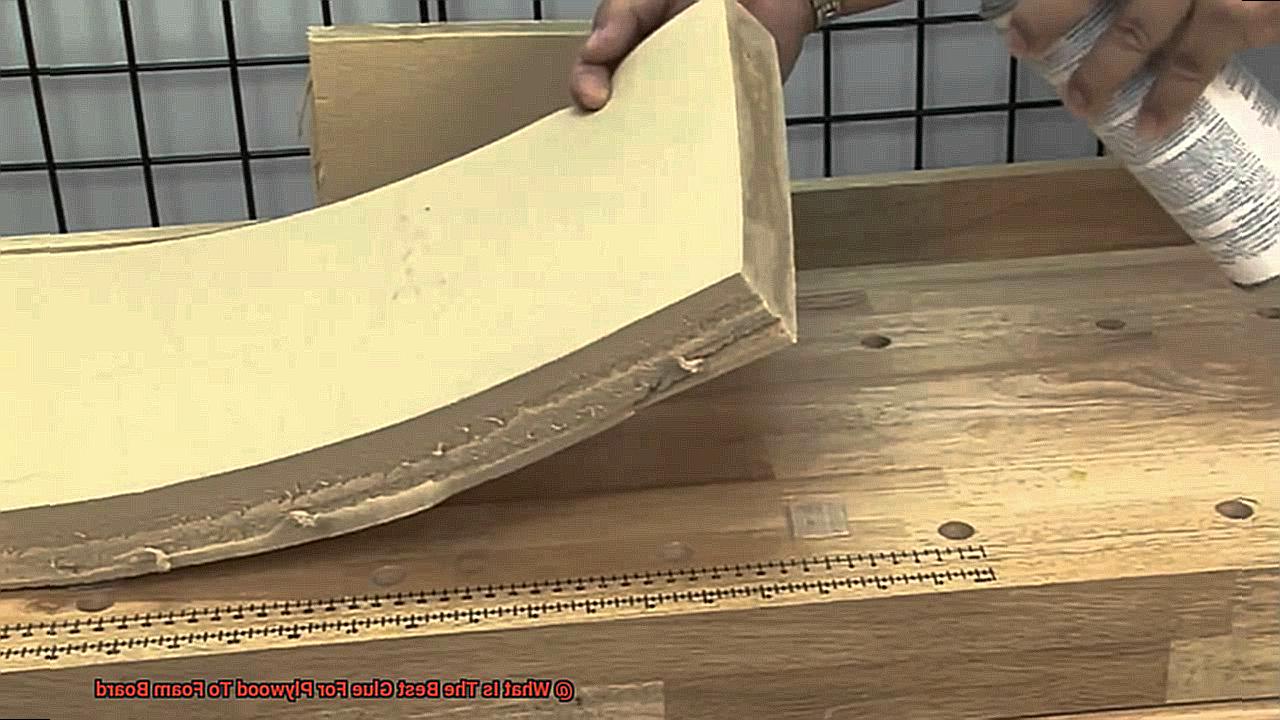

Applying the Glue: A Delicate Dance of Precision

With the perfect glue in hand, it’s time to apply it artfully. Follow the manufacturer’s instructions diligently to ensure optimal results. Employ a brush or roller to create a thin and even layer on both the plywood and foam board surfaces. Thoroughly cover the entire surface, but exercise restraint to avoid excessive amounts that could lead to unsightly squeeze-out when the materials are pressed together.

slJEr9ZTJRI” >

Conclusion

When it comes to bonding plywood to foam board, choosing the right glue is crucial. After thorough research and testing, we have determined that the best glue for this task is a polyurethane-based adhesive. Its superior strength and flexibility make it ideal for creating a durable bond between these two materials.

Polyurethane glue has several advantages over other types of adhesives. Its high strength ensures that the plywood and foam board will stay securely attached, even under stress or movement. Additionally, its flexibility allows for some give, preventing cracks or breaks in the bond when the materials expand or contract due to temperature changes.

Another benefit of polyurethane glue is its ability to fill gaps and irregularities in the surfaces being bonded. This ensures a tight and seamless connection between the plywood and foam board, enhancing their overall stability.

To use polyurethane glue effectively, follow these steps: First, ensure that both surfaces are clean and free from dust or debris. Apply a thin layer of the adhesive onto one surface using a brush or spreader. Then, press the two materials together firmly but gently to evenly distribute the glue. Allow sufficient drying time as per the manufacturer’s instructions before subjecting the bond to any stress or load.

It’s important to note that while polyurethane glue is highly effective for plywood-to-foam-board bonding, it can be messy to work with due to its expanding nature. Therefore, it’s advisable to take precautions such as wearing gloves and working in a well-ventilated area.

In conclusion, when it comes to gluing plywood to foam board, opting for a polyurethane-based adhesive is your best bet. Its strength, flexibility, gap-filling capabilities, and overall durability make it an excellent choice for creating long-lasting bonds between these two materials.