Imagine this: You’ve poured your heart and soul into crafting those perfect PLA miniatures. Countless hours spent printing, assembling, and meticulously bringing every intricate detail to life. From the fierce warrior brandishing a deadly weapon to the mythical creature adorned with ornate armor, each piece is a labor of love. But now comes the make-or-break moment – finding the glue that will fuse these delicate masterpieces together, ensuring their resilience and longevity.

Choosing the right adhesive for PLA miniatures can feel like navigating a labyrinth. With countless options vying for your attention, it’s crucial to identify the one that will seamlessly unite your creations and stand the test of time. Fear not. We’re here to guide you through this adhesive odyssey by handpicking the most reliable and highly acclaimed glue specially formulated for PLA plastics.

In this blog post, we’ll dive deep into what makes an adhesive ideal for PLA miniatures and explore the crème de la crème of glues available on the market. Whether you’re a seasoned hobbyist or a wide-eyed newcomer stepping into the captivating realm of miniature gaming, we’ve got your back with all the knowledge you need to forge unbreakable bonds.

So, take a breather from wielding your paintbrushes for just a moment, and join us on this thrilling adhesive adventure as we unveil the ultimate glue for your precious PLA miniatures.

What is PLA Plastic?

Contents

PLA plastic, or polylactic acid, is a remarkable thermoplastic polymer derived from renewable resources like cornstarch or sugarcane. This eco-friendly alternative to traditional petroleum-based plastics is making waves in the industry for its biodegradability and compostability. When exposed to specific conditions, such as heat and moisture, PLA plastic breaks down into harmless substances, leaving behind no trace of its existence. This degradability sets it apart from other plastics that can languish in our environment for centuries.

Not only is PLA plastic kinder to the planet, but it also boasts a lower carbon footprint during production. Made from renewable resources, it requires less energy and releases fewer greenhouse gases compared to its petroleum-based counterparts. Industries and individuals eager to reduce their ecological impact are increasingly turning to PLA plastic as a sustainable solution.

But PLA plastic isn’t just environmentally friendly; it’s also mechanically impressive. With high stiffness and strength, this material is more than capable of holding its own. Its appearance and texture closely resemble traditional plastics, making it suitable for a wide range of applications.

In the last few years, PLA plastic has become particularly popular in the world of 3D printing. Its compatibility with this technology has made it one of the go-to materials for desktop printers. Easy to work with and producing high-quality prints, PLA plastic filaments come in an extensive range of colors and finishes, ensuring vibrant and detailed creations.

Of course, like any material, PLA plastic does have its limitations. It has a relatively low melting point compared to other plastics, making it unsuitable for high-temperature applications. Additionally, it can be more prone to brittleness than some other materials, demanding careful handling of delicate miniatures.

Advantages of Using PLA Plastic for Miniatures

PLA plastic, derived from renewable resources and known for its biodegradability and low carbon footprint, offers several advantages when used for creating miniatures. Here are the key benefits of using PLA plastic for miniatures:

- Ease of Use: PLA plastic is incredibly easy to work with. It can be melted and molded into various shapes and sizes, making it perfect for creating intricate details and complex designs. Whether you’re crafting a tiny knight or a mythical creature, PLA plastic allows you to bring your imagination to life.

- Compatibility with 3D Printers: PLA plastic has a relatively low melting point compared to other plastics, making it compatible with common 3D printers. This means you don’t need specialized equipment or high-temperature settings to print your miniatures. Simply load your design onto your printer and watch as it effortlessly creates your desired figurines.

- Dimensional Accuracy: When it comes to miniatures, precision matters. PLA plastic excels in dimensional accuracy, ensuring that the final miniature closely resembles the intended design without significant distortions or deviations. Every detail, from the delicate facial features to the finely crafted weapons, will be faithfully replicated.

- Variety of Colors and Finishes: PLA plastic comes in a wide range of vibrant colors, allowing you to create miniatures in different shades and tones. Whether you’re aiming for a bright and bold dragon or a subtle and sophisticated elf, there’s a color option that suits your vision. Additionally, post-processing techniques such as sanding, painting, or acetone vapor smoothing can be employed to achieve desired textures or glossiness.

- Lightweight and Durable: Despite its lightweight nature, PLA plastic maintains good structural integrity and can withstand minor impacts without breaking or cracking easily. This makes it perfect for handling during gaming sessions or displaying your miniatures without worrying about accidental damage.

- Non-Toxic and Safe: Safety is paramount, especially when working with materials that involve heating and melting. PLA plastic is non-toxic and does not release harmful fumes or chemicals during the printing process. This makes it safe for home-based 3D printing projects, allowing you to create your miniatures without any health concerns.

- Cost-Effective: Creating miniatures can be an expensive hobby, but PLA plastic offers a cost-effective solution. Compared to other materials used for miniatures, such as resin, PLA plastic is readily available and relatively inexpensive. This accessibility makes it suitable for hobbyists and enthusiasts with varying budgets.

- Biodegradable and Environmentally Friendly: PLA plastic decomposes naturally over time without leaving behind toxic residue or contributing to landfill waste. Its biodegradability makes it an environmentally friendly choice for miniature creation, allowing you to enjoy your hobby while being mindful of the planet.

Types of Glue for Attaching PLA Miniatures

Super glue, also known as cyanoacrylate glue, is a popular choice for attaching PLA miniatures. This glue is a favorite among hobbyists due to its quick-drying and strong bonding properties. It forms a tight bond that can withstand moisture and temperature changes. However, it’s important to note that super glue can be quite brittle, so it may not be the best option for parts that will experience a lot of stress or movement.

Epoxy glue is another option that provides a strong and durable bond for PLA miniatures. It consists of two components, resin and hardener, which need to be mixed together before application. Epoxy glue is known for its ability to withstand stress and movement, making it ideal for parts that need to bend or flex. However, it does take longer to cure compared to super glue, so clamping or holding the pieces in place may be necessary until it sets.

For those looking for a specialized adhesive, plastic cement is specifically designed for bonding plastic materials like PLA. It works by chemically melting the plastic surfaces together, creating a seamless bond. Plastic cement is often used in model making and can be a good option for attaching PLA miniatures with smooth surfaces. However, it may not be as effective on textured or rough surfaces.

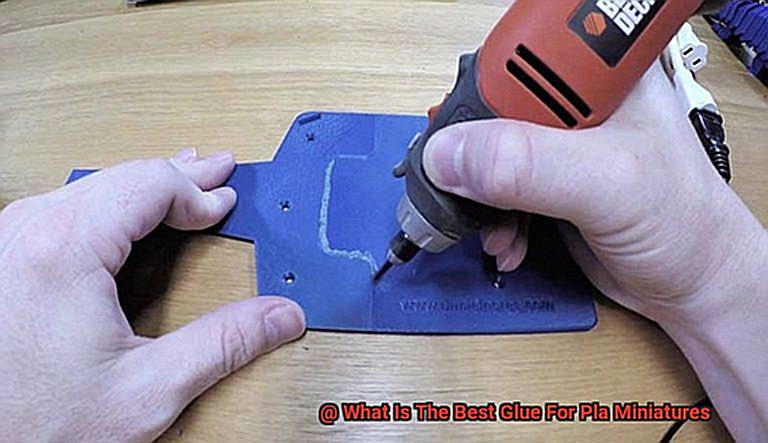

Some hobbyists also recommend using hot glue guns for attaching PLA miniatures. Hot glue guns are easy to use and provide a quick bond. However, hot glue may not be as strong as other types of glue and can sometimes leave visible residue.

It’s important to keep in mind that not all glues are compatible with PLA plastic. Some glues may not adhere well or may even damage the surface of the miniature. Therefore, it’s always a good idea to test a small area before applying glue to the entire piece.

Cyanoacrylate (CA) Glue

Cyanoacrylate (CA) glue, also known as super glue or instant glue, is a powerful adhesive used for bonding PLA miniatures. Known for its rapid drying time and strong bond strength, CA glue is a popular choice among hobbyists and professionals alike.

One of the main advantages of CA glue is its quick drying time. Unlike other adhesives that can take hours or even days to fully cure, CA glue sets in just a matter of seconds. This allows for efficient assembly of miniature parts, saving time and enabling faster progress in your projects.

In addition to its fast drying time, CA glue forms a durable and reliable bond between PLA surfaces. This is crucial for miniatures that may be handled or transported, as it minimizes the risk of parts becoming detached or damaged. With CA glue, you can have peace of mind knowing that your miniatures will stay securely in place.

Furthermore, CA glue offers versatility in application. It can be used to bond various materials commonly used in miniature assembly, including PLA plastic, metal, and resin. This makes it a versatile adhesive choice that can be used across different projects and materials.

To achieve optimal results when using CA glue for PLA miniatures, it is important to follow best practices. Thoroughly clean the surfaces before bonding to remove any dust, grease, or debris that could compromise the adhesive’s effectiveness. Apply a small amount of CA glue to one surface and press the parts together firmly but gently. Excessive force may result in excess glue squeeze-out or misalignment of parts.

It is worth noting that while CA glue is excellent for bonding PLA miniatures, it may not be suitable for all situations. If you require a more flexible bond or need to fill gaps between parts, other types of adhesives like epoxy or plastic cement may be better suited.

Epoxy Resin

Its unique properties make it an excellent choice for gluing PLA miniatures, offering advantages that set it apart from other types of glue.

One of the key benefits of epoxy resin is its incredible strength and durability. PLA miniatures often undergo frequent handling and gaming, so a strong bond is essential. Epoxy resin creates a permanent bond that can withstand the rigors of use and transportation, ensuring the miniature remains intact for a long time.

Another advantage of epoxy resin is its gap-filling properties. Miniature models often have small gaps or uneven surfaces that need to be filled for a smooth finish. Epoxy resin can be easily manipulated and spread over these areas, ensuring a seamless appearance once it cures. This allows hobbyists to achieve a flawless result, enhancing the overall aesthetic appeal of the miniature.

Epoxy resin is also highly versatile when it comes to different materials. It adheres well not only to PLA plastic but also to other commonly used materials in miniature modeling, such as metal or wood. This makes it an ideal choice for projects that involve combining different materials or adding additional components to the miniature.

Furthermore, epoxy resin offers a longer working time compared to instant-drying glues like cyanoacrylate (CA) glue. This provides hobbyists with more flexibility in assembling and positioning the miniature parts before the glue sets, ensuring precise placement and alignment.

Lastly, epoxy resin is known for its resistance to chemicals. It can withstand exposure to solvents and cleaners commonly used in cleaning or painting processes without compromising the integrity of the bond. This ensures that the miniature remains intact even when subjected to common cleaning agents or paint thinners.

Plastic Cement or Model Glue

Plastic cement and model glue are two common types of adhesive used for bonding PLA miniatures. While both are designed specifically for plastic models, they have distinct differences in their composition and application.

Plastic cement, also known as solvent cement, is a strong adhesive that works by melting the plastic pieces together, creating a seamless and permanent bond. It is ideal for joining large surfaces or seams, as it creates a strong connection that can withstand minor movements and vibrations without breaking. The longer drying time of plastic cement allows for repositioning of the pieces before the glue sets completely. This flexibility is beneficial when working on intricate projects that require precise alignment.

However, plastic cement does have limitations. It is not suitable for bonding small parts or delicate details that require precision. Its solvent-based composition gives it a strong odor, so it is important to use it in a well-ventilated area. Additionally, excessive amounts of plastic cement can cause the glue to seep out of the joints, resulting in messy and unsightly residue.

Model glue, specifically cyanoacrylate adhesive, offers its own set of advantages. It dries quickly and forms a strong bond within minutes, making it ideal for bonding small parts or delicate details that require precision. Model glue can be used on various materials such as PLA plastic, metal, and wood, making it suitable for mixed media projects. It creates a bond that can withstand regular handling and minor movements.

However, model glue does have limitations as well. It sets quickly, leaving little room for repositioning once applied. This can be challenging when working on complex models with multiple components. In some cases, model glue may leave a white residue if excessive amounts are used or if it comes into contact with moisture.

To determine which type of adhesive to use, consider the specific needs of your project. If you need to join large surfaces or seams, plastic cement may be the better option due to its strong and flexible bond. If you are working with small parts or require quick drying time, model glue may be more suitable. Some modelers even choose to use a combination of both glues, utilizing plastic cement for larger connections and reinforcing the bond with model glue for extra strength.

Other Factors to Consider When Choosing the Best Glue for PLA Miniatures

When it comes to selecting the best glue for PLA miniatures, there are several other factors to consider in addition to the adhesive’s strength and compatibility with PLA plastic. These factors can greatly impact your crafting experience and the longevity of your miniatures.

One important factor to consider is the drying time of the glue. Waiting for hours for the glue to dry can be frustrating when you’re trying to assemble or repair delicate PLA pieces. Look for glues that have a fast-drying formula, allowing you to move on with your project without having to wait too long.

The application method of the glue is also crucial. Miniatures often have small and intricate parts that require precision when applying adhesive. A glue with a fine applicator or a precision tip can make it easier to apply the adhesive exactly where you need it, minimizing mess and potential damage to the miniature.

Odor is another factor to consider. Some glues have a strong chemical smell that can be unpleasant or even harmful if inhaled for extended periods. Opting for a low-odor or odorless glue can make your crafting experience more enjoyable and safe, especially if you are sensitive to strong smells or prefer working in a well-ventilated area.

Ease of use is essential for any glue. Glues that come in convenient squeeze bottles or have applicators specifically designed for miniatures can make the process smoother. Additionally, glues that are easy to clean up, either by wiping away excess adhesive or by dissolving any accidental spills, can save you time and frustration.

Long-term durability is worth considering as well. While most glues will bond PLA effectively in the short term, some may not hold up well over time or under specific conditions. If you plan on displaying or handling your miniatures frequently, look for glues that offer strong and long-lasting bonds.

Lastly, it’s always a good idea to check customer reviews and recommendations when choosing a glue for PLA miniatures. Hearing from other hobbyists or enthusiasts who have used the glue can provide valuable insights into its performance, reliability, and suitability for your specific needs.

DzDCnzNqcoU” >

Conclusion

In conclusion, the quest for the perfect glue for PLA miniatures offers a range of options to explore. Each adhesive brings its own unique advantages and limitations, allowing you to tailor your choice to meet your specific needs.

Enter cyanoacrylate (CA) glue, also known as super glue. This popular option boasts lightning-fast drying time and an iron grip on miniature parts. With CA glue, you can assemble your precious creations efficiently and securely. However, be mindful that it may not offer the flexibility or gap-filling capabilities required for certain situations.

For those seeking unwavering strength and durability, epoxy resin emerges as a formidable contender. Its bond is unyielding, making it ideal for miniatures that endure frequent handling or transportation. Additionally, epoxy resin grants you more working time compared to instant-drying glues and allows for effective gap filling.

If precision is your priority, plastic cement or model glue steps into the spotlight. Plastic cement utilizes chemical magic to meld PLA surfaces together seamlessly and permanently. On the other hand, model glue dries swiftly, forming a robust bond within minutes.

When selecting the ultimate glue for PLA miniatures, consider crucial factors such as drying time, application method, odor tolerance, ease of use, long-term durability, and customer reviews. These elements hold immense power in shaping your crafting experience and ensuring the longevity of your cherished creations.

Always remember to conduct small-scale compatibility tests before committing to applying glue across an entire piece. With meticulous consideration and adept application techniques at your disposal, you can forge unbreakable bonds that will safeguard your treasured PLA miniatures for years of crafting joy.