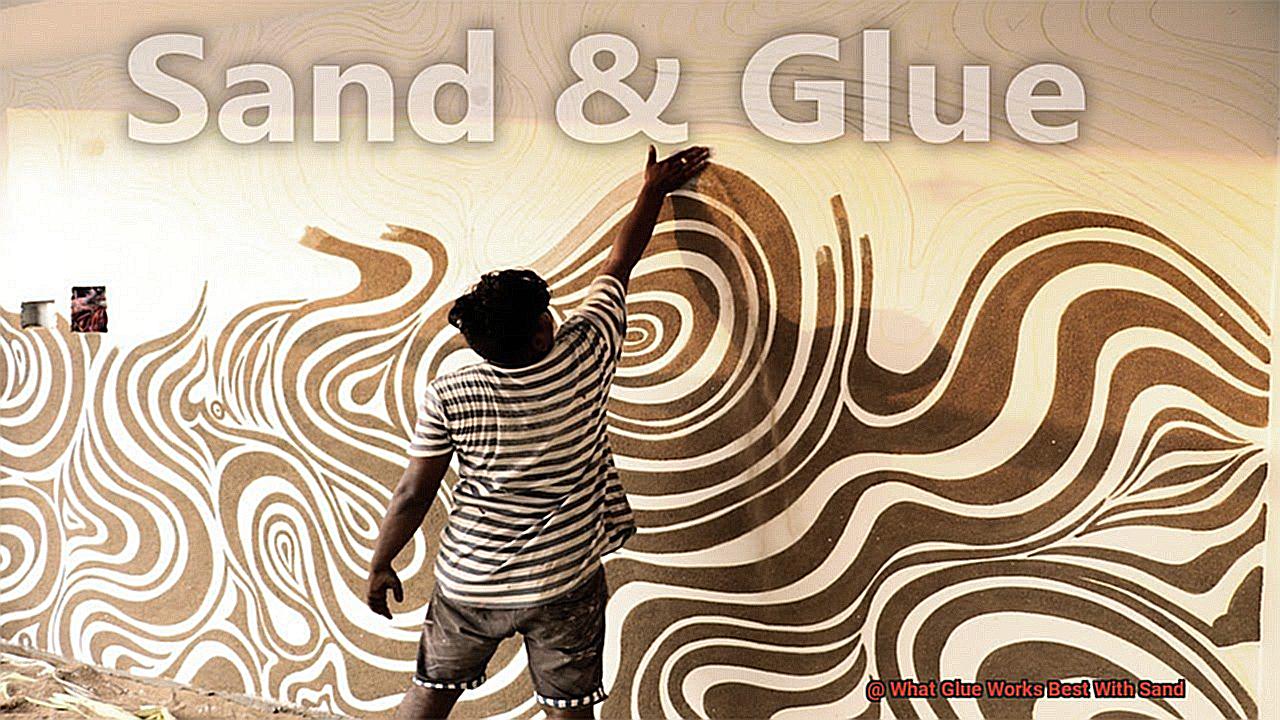

Are you ready to embark on a sandy adventure, where creativity and craftsmanship collide? From mesmerizing sandcastles to intricate sand art pieces, working with sand is an exhilarating experience. But here’s the catch – finding the best glue for your sandy endeavors is essential to ensure your masterpiece stands strong against the test of time.

Choosing the right adhesive might seem like a daunting task, but fear not. In this blog post, we’ll take a deep dive into the world of glues that work wonders with sand. Whether you’re a seasoned sand enthusiast or a diligent DIYer stepping into this sandy terrain for the first time, these tips will be your trusty guide to success.

So, get ready to unlock the secrets of adhesives and discover the perfect glue that will make your sand creations stick like never before. Let’s dive in and unveil the ultimate bonding solution for your sandy projects.

What is Sand?

Contents

Imagine standing on a beach, feeling the soft grains of sand slip through your fingers. Have you ever wondered what sand truly is? Prepare to be captivated as we embark on a journey to unravel the mysteries of this remarkable substance. From its origins and composition to its unique properties and versatile uses, sand reveals itself as nature’s masterful creation.

Origins and Composition:

Sand is an exquisite masterpiece crafted by the forces of nature. It is formed through the patient craftsmanship of weathering and erosion, where rocks are gradually broken down into tiny fragments over time. These fragments, known as sand grains, consist of finely divided rock and mineral particles that vary in size, shape, and composition. At the heart of every grain lies silica, a captivating compound composed of silicon and oxygen atoms. While silica dominates the scene, other minerals like feldspar, calcite, and gypsum make occasional guest appearances, adding their own unique touch to this grand tapestry.

Diverse Types of Sand:

Just as art comes in various forms, sand embraces diversity in all its glory. Here are some notable types of sand, each with its own distinct characteristics and purpose:

- Fine Sand: Delicate and refined, fine sand boasts smaller particles and a silky texture. It finds its place in construction projects that demand a compact surface.

- Coarse Sand: Bold and rugged, coarse sand stands tall with its larger particles and rough texture. It partners with cement to create robust concrete structures.

- Beach Sand: Enchanting and alluring, beach sand graces coastlines with its radiant presence. Composed mostly of quartz grains, it may carry fragments of shells or organic treasures.

- Play Sand: Lively and carefree, play sand is designed for children’s joyous adventures. Non-toxic and finely textured, it promises safe and delightful playtime.

Sand’s Enigmatic Properties:

Sand possesses a mesmerizing array of properties that set it apart:

- Grain Size: From the delicate embrace of fine sand to the rugged resilience of coarse sand, the size of grains determines their purpose and potential.

- Porosity: Sand’s high porosity creates a network of interconnected spaces, allowing water to flow effortlessly through its intricate web. This quality makes sand an excellent choice for filtration and drainage systems.

- Permeability: Sand’s remarkable permeability enables it to be a conduit for fluids, making it the ideal medium for constructing wells or underground drainage systems.

- Stability: With its loosely packed particles, sand exhibits a captivating ability to shift and move when faced with external forces. This dynamic quality is crucial in applications such as construction and retaining walls.

The Versatility of Sand:

Sand’s allure extends far beyond the shores. It finds its purpose and place in numerous industries and sectors:

- Construction: Sand is the cornerstone of construction, lending strength, stability, and durability to materials like concrete, mortar, and asphalt.

- Glass Manufacturing: Silica sand plays a pivotal role in the creation of transparent, resilient, and thermally resistant glass products.

- Foundry Casting: Sand molds take center stage in foundries, providing the perfect canvas for intricate metal castings to come to life.

- Landscaping: Sand transforms landscapes into breathtaking works of art. It creates pathways, play areas, and stunning sand sculptures that captivate the imagination.

Different Types of Glue for Bonding Sand

Sand is a versatile material that can be transformed into stunning art pieces or used in various DIY projects. However, keeping sand in place can be a challenge. Luckily, the world of glue offers a range of options for bonding sand securely. In this article, we will explore the different types of glue suitable for bonding sand, their advantages and disadvantages, and how they compare to each other.

Epoxy Resin – The Mighty Protector:

Epoxy resin is the superhero of sand bonding. It creates a strong and durable bond that can withstand water and heat, making it ideal for crafts and DIY projects where durability is essential. However, it can be quite expensive and requires special handling due to its strong odor and fumes.

Super Glue – The Quick Fixer:

Super glue, or cyanoacrylate adhesive, is the go-to option for small-scale projects and repairs. It forms an instant bond when it comes into contact with moisture in the sand. Although it may not be as durable as epoxy resin, it gets the job done quickly and is budget-friendly.

Silicone Sealant – The Flexible Friend:

For flexibility, silicone sealant is your best friend. It creates a strong yet flexible bond with the sand particles, making it ideal for arts and crafts or decorative items that need to adapt to different shapes and textures. However, it may not provide as strong of a bond as other types of glue.

Polyurethane Glue – The Expanding Wonder:

Polyurethane glue is a versatile adhesive that expands when exposed to moisture. It forms a strong bond with the sand particles and is resistant to water and heat. However, it can be messy during application and requires proper ventilation.

Construction Adhesive – The Heavy-Duty Hero:

For heavy-duty applications, construction adhesive, such as liquid nails, can be a reliable choice. It is designed to withstand tough conditions and is perfect for industrial projects. However, it may take longer to dry compared to other types of glue.

Advantages and Disadvantages of Epoxy Resin

Look no further. In this article, we’ll delve into the remarkable advantages and potential drawbacks of utilizing epoxy resin as a glue for sand-related projects. Whether you’re a seasoned crafter or a passionate DIY enthusiast, understanding the strengths and weaknesses of epoxy resin will empower you to make informed decisions when it comes to bonding sand.

Advantages of Epoxy Resin:

- Unyielding Bond: Renowned for its exceptional adhesive properties, epoxy resin forms an unbreakable bond with various materials, including sand. This makes it an ideal choice for firmly uniting sand particles, ensuring your creations remain intact against all odds.

- Indestructible Durability: When it comes to enduring extreme conditions, epoxy resin is an unrivaled champion. Once cured, it creates a resilient surface that can withstand moisture, heat, and chemicals. This durability is particularly vital for sand-related projects exposed to the unforgiving elements.

- Endless Versatility: Whether you’re working with fine, coarse, or even colored sand, epoxy resin embraces diversity with open arms. It seamlessly bonds with different sand types and various materials such as wood, metal, and plastic. Its versatility unlocks boundless potential for your imaginative ventures.

- Captivating Clarity and Transparency: Some epoxy resins offer extraordinary clarity when paired with sand, allowing you to showcase the mesmerizing beauty of each grain. This feature serves as a significant advantage for decorative items or jewelry where the visual allure of the sand takes center stage.

Disadvantages of Epoxy Resin:

- Time for Precision: Achieving the desired consistency when working with epoxy resin demands meticulous attention to detail in measuring and mixing ratios. Additionally, epoxy resin often requires lengthier curing times compared to other glues, testing the limits of your patience when working on time-sensitive projects.

- Safety First: Epoxy resin contains chemicals that can be hazardous if mishandled. Adhering to safety precautions, such as donning protective gloves and working in well-ventilated spaces, is crucial. Allergic reactions are also possible, so taking necessary precautions is imperative.

- A Price to Pay: While epoxy resin boasts remarkable bonding properties, it does come with a higher price tag compared to alternative glues. The cost varies based on factors like brand, quality, and project size. If you’re working with budgetary constraints, this may limit your options.

- Forever Bound: Once epoxy resin cures, it forges an unbreakable bond. While this is advantageous for long-term durability, it becomes a disadvantage if you need to separate or modify the sand bond in the future.

Advantages and Disadvantages of Super Glue

Super glue, the go-to adhesive for countless DIY projects and repairs, offers a range of advantages and disadvantages. Let’s explore them in detail.

Advantages:

- Strong Bonding: Super glue excels at creating a sturdy and long-lasting bond. Whether you’re working with wood, metal, plastic, ceramic, or glass, this versatile adhesive can handle it all. It’s your trusty companion for various projects and repairs.

- Quick Drying Time: Time is precious, and super glue understands that. It sets within seconds or minutes, depending on the brand and formulation. Say goodbye to waiting around for hours – super glue gets the job done efficiently and conveniently.

- Easy Application: With its precision applicator tips, super glue allows for accurate bonding. The application process is a breeze, ensuring neat results every time. No mess, no fuss – just smooth and precise adhesion.

- Resistance to Moisture: Once cured, super glue forms a waterproof seal that can withstand exposure to water, humidity, and other environmental factors. Indoor or outdoor projects? Not a problem. Super glue has got you covered.

Disadvantages:

- Brittle Bond: While super glue creates a strong bond, it tends to be brittle. Excessive flexing or impact might cause the bond to break. So if flexibility is crucial for your project, consider alternative adhesives.

- Limited Gap-Filling Ability: Super glue works best when the surfaces being bonded fit closely together with minimal gaps. Uneven or large gaps? Super glue might not be the answer you’re looking for.

- Potential Skin Irritation: Beware of potential skin irritation or allergic reactions caused by cyanoacrylate, a component of super glue. Take precautions while using it and avoid direct contact with your skin.

- Limited Temperature Resistance: Extreme temperatures can be a challenge for super glue. High heat or extreme cold may cause it to become brittle and lose its adhesive strength. If you need an adhesive that can withstand temperature fluctuations, specialized high-temperature adhesives are worth considering.

Advantages and Disadvantages of Silicone Sealant

Silicone sealant, the superhero of adhesives, is here to save the day on all your sealing needs. However, like any superhero, it has its strengths and weaknesses. Let’s dive into the advantages and disadvantages of using silicone sealant.

Advantages:

- Versatility: Silicone sealant is like a chameleon, able to adhere to a variety of surfaces such as glass, metal, ceramics, and plastics. This makes it a go-to choice for sealing windows, sinks, bathtubs, and even aquariums.

- Flexibility: Unlike some adhesives that crack under pressure, silicone sealant is flexible. It can handle temperature changes without losing its adhesive properties or cracking. Perfect for sealing joints or gaps that are prone to movement.

- Weather resistance: Rain or shine, silicone sealant can handle it all. It can withstand extreme temperatures, from freezing cold to scorching heat, without deteriorating or losing its sealing powers. This makes it ideal for indoor and outdoor applications.

- Water resistance: Say goodbye to leaks and seepage. Silicone sealant creates a watertight seal that prevents water from infiltrating joints or gaps. This makes it perfect for sealing showers, sinks, and other wet areas.

- Durability: Silicone sealant is in it for the long haul. It maintains its elasticity and adhesive properties over time, providing a reliable seal for years without frequent re-application.

Disadvantages:

- Longer curing time: Time is not always on our side when using silicone sealant. It typically takes longer to cure compared to other adhesives. So if you need quick results or have a tight deadline, this can be inconvenient.

- Limited paintability: Want to paint over your sealed surface? Think twice with silicone sealant. While some products are marketed as paintable, many don’t adhere well to paint. Keep this in mind if you’re aiming for a seamless finish.

- Strong odor: Get ready for a powerful scent when using silicone sealant. The odor can be overpowering, especially for those sensitive to strong smells. Make sure to work in a well-ventilated area to minimize exposure.

- Limited adhesion to certain materials: Silicone sealant may struggle to stick to oily or greasy surfaces, untreated wood, or specific plastics. Properly cleaning and preparing the surface is crucial for optimal adhesion.

- Difficult removal: Once silicone sealant has cured, it’s not easy to remove without damaging the surface underneath. Specialized tools or solvents may be needed, adding extra time and effort to the removal process.

Advantages and Disadvantages of Polyurethane Glue

When it comes to sand-related projects, selecting the right adhesive can have a significant impact on the outcome. Enter polyurethane glue, a versatile adhesive known for its strong bond and excellent water resistance. However, before diving into your sandcastle dreams, it’s crucial to consider the advantages and disadvantages of using polyurethane glue for sand-related projects.

Advantages:

Unwavering Bond:

Polyurethane glue possesses exceptional adhesion properties, making it perfect for bonding sand to various surfaces. Whether you’re creating intricate sand art or repairing a delicate sandcastle, polyurethane glue ensures a reliable and durable bond that will withstand the test of time.

Water Warrior:

Unlike other glues, polyurethane glue doesn’t weaken or break down when exposed to moisture. This makes it ideal for sand-related projects that may encounter water or require outdoor use. Rest assured that your beautiful sand sculpture won’t melt away in the rain.

Versatility at its Finest:

From wood to metal and even glass, polyurethane glue can be used on a wide range of materials. Its versatility has made it a go-to choice for both DIY enthusiasts and professional craftsmen alike. Whether you’re building a sand table or fixing a broken seashell ornament, polyurethane glue has got you covered.

Expanding Horizons:

Polyurethane glue goes the extra mile by expanding as it cures, ensuring a secure bond even on uneven or irregular surfaces. This unique expansion property effortlessly fills gaps, providing additional strength to your sand-related project.

Disadvantages:

The Waiting Game:

Patience is key when using polyurethane glue as it has a longer curing time compared to other adhesives. It may take several hours or even overnight to fully cure, which can be inconvenient if you’re working on time-sensitive projects or need fast results. Plan accordingly and allow ample time for the glue to dry.

Precision Required:

Polyurethane glue’s thick and sticky consistency can make the application process messy. It requires precise handling to avoid excess glue seeping out from the joints. Additionally, any spills or drips must be promptly cleaned up, as polyurethane glue becomes challenging to remove once it has dried.

Limited Lifespan:

Polyurethane glue has a finite shelf life compared to other adhesives. Once opened, the glue can start to degrade over time, especially when exposed to air or moisture. To maximize its shelf life, store the glue properly in a cool and dry place and check the expiration date before use.

Health Hazards:

Like many adhesives, polyurethane glue contains chemicals that may cause irritation or allergic reactions in some individuals. It’s crucial to use the glue in a well-ventilated area and follow the safety instructions provided by the manufacturer. Some people may also be sensitive to the strong odor emitted during the curing process, so keep that in mind when working with polyurethane glue.

Also Read: How To Glue Sand to Wood? – Glue Things

Preparing the Surface for Bonding Sand

Whether you’re crafting a mesmerizing sand art masterpiece or repairing a cherished sandstone sculpture, the key to success lies in properly preparing your surface for bonding sand with glue. In this comprehensive guide, we’ll take you through each step, ensuring that your bond is strong, durable, and visually stunning. So, put on your safety goggles and let’s dive in.

Step 1: Cleanliness is Key

To achieve a flawless bond, start by banishing any dirt, dust, or debris from the surface that will be bonded with sand. Using either a brush or a vacuum cleaner, meticulously clean the area. This not only helps the glue adhere better but also prevents any pesky particles from interfering with your masterpiece.

Step 2: Embrace the Roughness

For an unbreakable bond, embrace a touch of roughness. Gently sand the surface using sandpaper to create a textured grip that will ensure optimal adhesion. Remember, a little roughness goes a long way in securing your sand art’s future.

Step 3: Dry it Out

Moisture is the enemy of bonding. Allow at least 24 hours for the surface to completely dry after cleaning. Impatience here could lead to a weak bond, so sit back, relax, and let time work its magic.

Step 4: Primer Power (if necessary)

Sometimes, primers are essential for achieving an unbeatable bond. They enhance adhesion and optimize the connection between the glue and the surface. Choose a primer that complements both your surface material and the glue you’ll be using for picture-perfect results.

Step 5: The Glue Game

Now comes the exciting part – selecting the glue that will bring your vision to life. Epoxy adhesives are renowned for their strength, making them ideal for projects that require extra durability. Polyurethane adhesives are flexible and resistant to moisture, perfect for outdoor applications or high humidity environments. Meanwhile, construction adhesives offer versatility, bonding a wide range of materials, including sand. Choose wisely based on your desired bond strength, surface material, and project requirements.

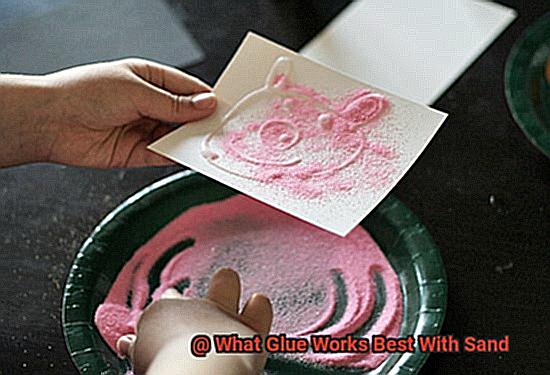

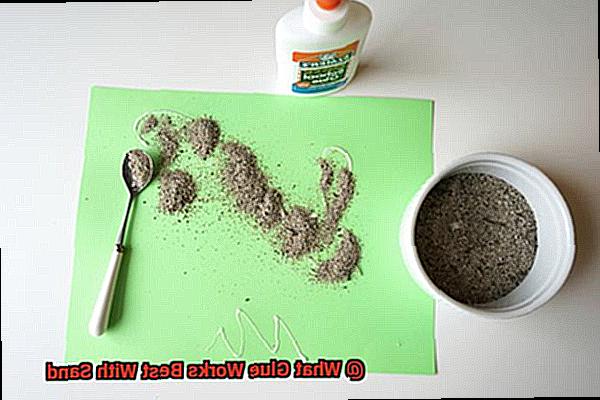

Step 6: Masterful Application

Follow the manufacturer’s instructions for applying the chosen glue. Apply the appropriate amount of glue and spread it evenly over the prepared surface. To ensure an unyielding bond, apply pressure using clamps or weights. Your masterpiece deserves nothing less.

Step 7: The Art of Patience

Allow ample time for the bond to fully develop. Curing time varies depending on the type of glue used, so consult the manufacturer’s instructions. Remember, patience is rewarded with a bond that will withstand the test of time.

Gkjte0w78zY” >