We all know the struggle of trying to glue two pieces of plastic together. It’s like finding a needle in a haystack, right? Well, fear not because we’ve got the ultimate adhesive solution that will blow your mind: Gorilla Glue. This stuff is the real deal when it comes to creating unbreakable bonds between plastic surfaces.

Now, I know what you’re thinking – with so many options out there, how do you choose the best Gorilla Glue for plastic-to-plastic bonding? That’s where we come in. In this blog post, we’re diving deep into the world of Gorilla Glue. We’ll uncover its remarkable properties and unparalleled capabilities to help you find the one that guarantees a long-lasting connection.

Whether you’re fixing up your favorite coffee mug or working on a badass DIY project, this is the glue you’ve been waiting for. Trust me, once you try it, there’s no going back.

So grab your lab coat (or just your favorite pair of comfy pants) and let’s jump right into discovering the ultimate Gorilla Glue for seamless plastic-to-plastic bonding. Get ready to say goodbye to broken plastic forever.

What is Gorilla Glue?

Contents

In the world of adhesive solutions, one name stands out for its unparalleled strength and versatility: Gorilla Glue. Since its introduction by the Gorilla Glue Company in 1999, this adhesive has become a go-to choice for professionals and DIY enthusiasts alike. With its polyurethane formula, Gorilla Glue forms bonds that can withstand the test of time across a wide range of materials, including wood, metal, stone, ceramic, foam, and plastics. In this article, we will delve into the world of Gorilla Glue, exploring its incredible bonding capabilities and highlighting its effectiveness for plastic-to-plastic applications.

Versatility and Strong Adhesive Properties:

Gorilla Glue’s reputation as a powerhouse adhesive is well-deserved. Its unique formulation allows it to bond not only different types of plastics but also a multitude of other materials. Whether you’re working on construction projects, engaging in woodworking endeavors, or fixing automotive parts, Gorilla Glue has got you covered. Its strength is unmatched, ensuring that your bonds remain intact even in high-impact or moisture-prone environments.

Types of Gorilla Glue for Plastic-to-Plastic Bonding:

- Gorilla Super Glue Gel: Precision is paramount when bonding plastics together, and Gorilla Super Glue Gel delivers just that. With its strong bonding capabilities on various materials, including plastics, it guarantees a robust and long-lasting connection.

- Gorilla Clear Grip Contact Adhesive: When it comes to transparent plastics, such as acrylic or polycarbonate, the Gorilla Clear Grip Contact Adhesive is the ideal choice. Specifically formulated for these materials, it provides a reliable bond that resists impact and moisture.

- Gorilla Epoxy: For larger surface areas or applications requiring flexibility, Gorilla Epoxy is the answer. This epoxy adhesive bonds plastics, metals, ceramics, and more, ensuring both strength and durability.

Proper Application for Optimal Results:

To achieve the best results when using Gorilla Glue for plastic-to-plastic bonding, follow these essential steps:

- Prepare the surfaces: Thoroughly clean and dry the plastic surfaces, ensuring they are free from any contaminants or residues that could hinder adhesion.

- Choose the right adhesive: Select the appropriate variant of Gorilla Glue based on your specific plastic type and bonding requirements.

- Surface roughening: To enhance bonding strength, lightly roughen the plastic surfaces with sandpaper.

Types of Plastics

Look no further than Gorilla Glue’s incredible range of adhesives. In this blog post, we will delve into the world of plastics and explore which Gorilla Glue products work best for bonding different types of plastics. Get ready for a revolution in gluing.

The Versatile Hero: Polyethylene (PE)

Polyethylene, the superhero of plastics, is flexible and adaptable, making it perfect for packaging materials and bottles. When it comes to bonding PE to PE, Gorilla Glue’s Plastic Welder is the ultimate weapon. Specially designed to create a super-strong bond, it will never let you down when it comes to joining polyethylene.

The Mighty Warrior: Polypropylene (PP)

Polypropylene is a heat-resistant plastic commonly found in automotive parts and food containers. For PP-to-PP bonding, Gorilla Glue’s Plastic Welder is your go-to solution. With its magical properties, it transforms the impossible into reality, ensuring a bond that can withstand any challenge.

The Ruler of Rigid Plastics: PVC

PVC, the king of construction materials and electrical cables, demands an adhesive fit for royalty. When bonding PVC to PVC, Gorilla Glue recommends their PVC Cement – specially formulated for a secure and enduring connection. This adhesive ensures that your construction projects or electrical fittings remain steadfast, even under immense pressure.

The Lightweight Champion: Polystyrene

Polystyrene is as light as a feather and commonly used in packaging materials and disposable cutlery. For polystyrene-to-polystyrene bonding, Gorilla Glue’s Clear Gorilla Glue is your ultimate sidekick. Its incredible strength and clarity make it the perfect partner for creating durable bonds that won’t weigh you down.

The Tough Guy: ABS

ABS plastic, often found in toys and electronic housings, is renowned for its toughness. To bond ABS to ABS, reach for Gorilla Glue’s Clear Gorilla Glue – it’ll keep your creations intact, no matter how rough the play or intense the use.

The Transparent Wonder: PET

PET, the clear and robust plastic used in beverage bottles and food containers, is a force to be reckoned with. Although Gorilla Glue doesn’t have a specific adhesive for PET-to-PET bonding, their Clear Gorilla Glue can still save the day. Its versatility and strength make it a formidable ally in any plastic bonding quest.

Choose Your Super Glue:

When it’s time to save the day with plastic-to-plastic bonding, Gorilla Glue has your back. Their Super Glue Gel is perfect for precise applications, ensuring your bond is as strong as steel. For transparent plastics, like PET or polycarbonate, Clear Grip Contact Adhesive provides an invisible yet powerful connection.

And for larger areas or flexible bonds, Gorilla Epoxy is your secret weapon – it secures even the most challenging plastic combinations with unrivaled strength.

Gorilla Super Glue Gel

Are your plastic items constantly breaking and falling apart? Say goodbye to weak bonds and hello to unbreakable connections with Gorilla Super Glue Gel. This phenomenal adhesive is specifically formulated for plastic-to-plastic bonding, and let me tell you, it’s a game-changer.

Let’s explore the remarkable features that set Gorilla Super Glue Gel apart from the competition. First and foremost, its thick, no run formula is a dream come true. No more messy glue mishaps. Once applied, this gel stays exactly where you put it, ensuring precise application and a clean, professional finish on even the most irregular plastic surfaces.

But that’s not all – Gorilla Super Glue Gel doesn’t mess around when it comes to bonding time. Unlike other glues that leave you waiting for hours on end, this glue sets lightning-fast. It’s a true time-saver, allowing you to tackle your projects without delay.

Versatility is another key aspect of this incredible adhesive. It effortlessly bonds various types of plastics together – ABS, PVC, acrylic, you name it. Whether you’re fixing broken plastic items or working on an exciting DIY project, Gorilla Super Glue Gel has got your back with its unbeatable strength and durability.

But wait, there’s more. This glue is also resistant to moisture. That means even if your plastic items come into contact with water or high humidity, the bond will remain steadfast. No need to worry about your glued pieces falling apart at the first sign of moisture.

And here’s the cherry on top – Gorilla Super Glue Gel isn’t limited to just plastic bonding. Its versatility knows no bounds. You can use it on metal, wood, ceramic, fabric – you name it. It’s like having a superhero adhesive in your toolbox.

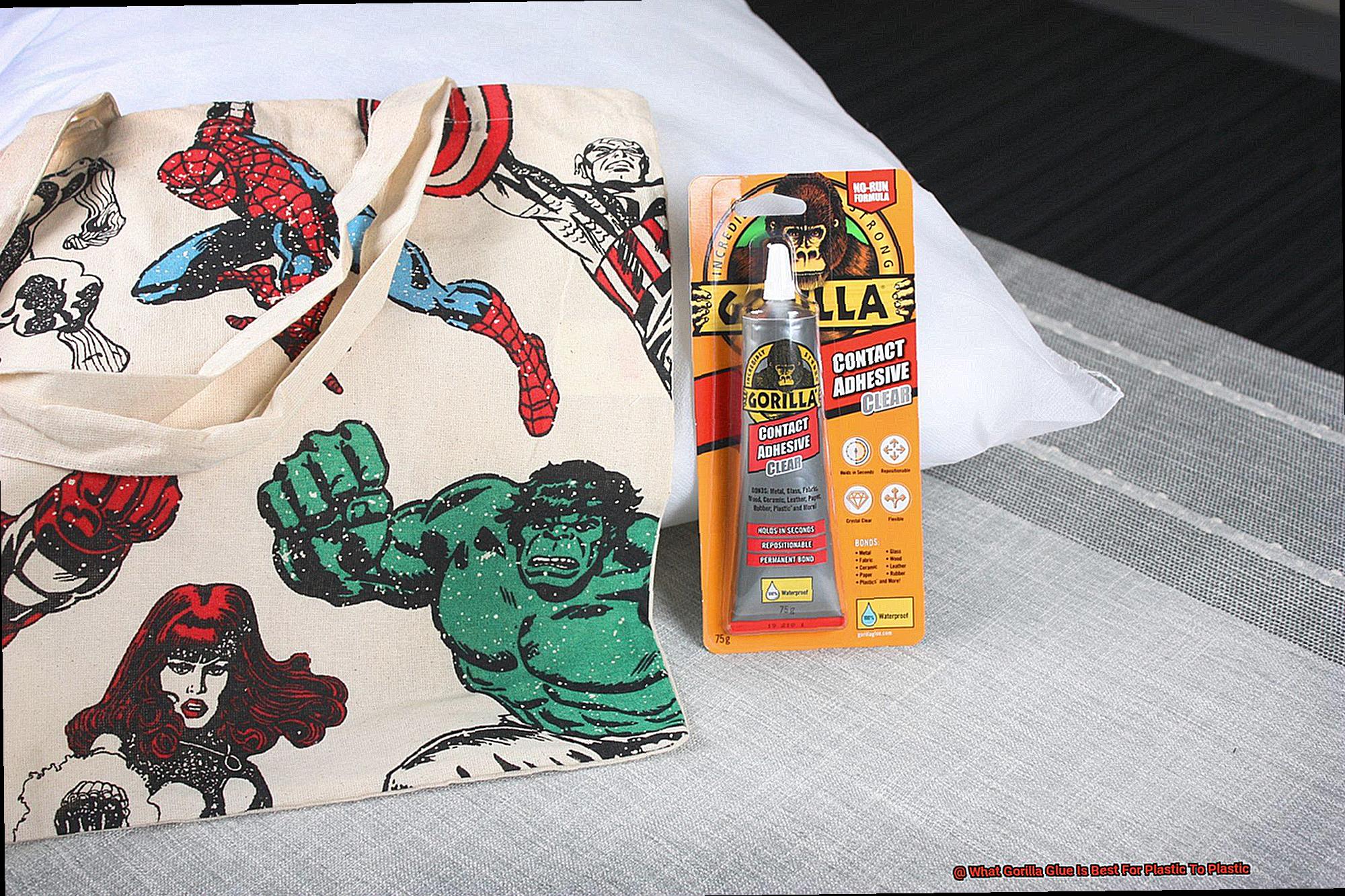

Gorilla Clear Grip Contact Adhesive

Enter Gorilla Clear Grip Contact Adhesive. This versatile adhesive is specifically designed for plastic-to-plastic bonding, offering a strong and durable hold that stands the test of time. In this article, we’ll explore the features and benefits of Gorilla Clear Grip Contact Adhesive, giving you all the information you need to make your next bonding project a success.

Clear Formula:

Gorilla Clear Grip Contact Adhesive’s standout feature? Its clear formula. No visible residue here. This adhesive dries clear, maintaining your project’s aesthetic appeal. Transparent or light-colored plastics? No problem. This adhesive won’t compromise their appearance.

Easy Application:

Say goodbye to messy glue mishaps. Gorilla Clear Grip Contact Adhesive comes in a convenient squeeze tube or bottle, making application a breeze. With its thick consistency, it won’t drip or run, ensuring precise and controlled application every time.

Proper Surface Preparation:

For optimal bonding results, preparation is key. Clean surfaces thoroughly to remove dust, dirt, and grease that hinder bonding. Want an extra-strong bond? Roughen surfaces with sandpaper or a file to increase the adhesive’s grip and enhance bond strength.

Fast Initial Bond and Full Strength Over Time:

You need your project to stay put during curing. Gorilla Clear Grip Contact Adhesive has you covered with its fast initial bond. But remember, it reaches full strength over time. Allow at least 24 hours of curing before subjecting the bond to stress or loads.

Performance and Versatility:

Gorilla Clear Grip Contact Adhesive excels in performance. Designed to withstand water, heat, and impact, it’s perfect for both indoor and outdoor projects. From plastic toys to household items to automotive parts, this adhesive has got you covered.

Gorilla Epoxy

Prepare to be amazed by the superhero adhesive known as Gorilla Epoxy. In this comprehensive guide, we will explore the exceptional qualities of Gorilla Epoxy, delve into its key features, and provide tips for achieving a strong and enduring bond. Get ready to unlock the full potential of Gorilla Epoxy.

Advantage 1: Defying the Elements

Gorilla Epoxy is a force to be reckoned with when it comes to withstanding both indoor and outdoor conditions. Whether you need to repair plastic outdoor furniture or bond plastic components in automotive or electronic devices, Gorilla Epoxy ensures a reliable and durable bond that can conquer any environment.

Advantage 2: Lightning-Fast Setting Time

No more waiting around for hours. Gorilla Epoxy sets within five minutes and completely cures within 24 hours. To achieve maximum strength, it is recommended to leave the bonded objects undisturbed for at least 24 hours. During this crucial period, make sure to clamp or hold the glued surfaces in place to prevent any movement that may compromise the bond.

Advantage 3: Water Resistance and Temperature Resilience

Gorilla Epoxy is a true hero when it comes to water resistance. It can withstand exposure to moisture and even be submerged underwater without compromising its adhesive properties. Additionally, it triumphs over extreme temperatures, making it suitable for applications where bonded plastics may encounter temperature fluctuations.

Advantage 4: Bridging Gaps with Ease

Uneven surfaces are no match for Gorilla Epoxy. This extraordinary adhesive boasts exceptional gap-filling capabilities, ensuring a strong bond even under less-than-ideal circumstances. It effortlessly fills gaps and irregular surfaces between plastic pieces, providing a seamless and robust connection.

Surface Preparation for Bonding Plastic to Plastic

When it comes to bonding plastic to plastic, proper surface preparation is key to achieving a strong and durable bond. Whether you’re repairing a broken toy or creating a DIY project, following these steps will ensure successful bonding with Gorilla Glue:

- Cleanliness: Start by cleaning the surfaces that will be bonded. Use a mild detergent or soap and water solution to remove any dirt, dust, or grease. Rinse the surfaces thoroughly with clean water and allow them to dry completely. A clean surface is essential for a secure bond.

- Roughen it up: To enhance the bond strength, lightly sand the plastic surfaces with fine-grit sandpaper. This will create a slightly rough texture, providing more surface area for the adhesive to grip onto. After sanding, wipe away any dust or debris to ensure a clean surface.

- Prime time: Applying a plastic primer designed specifically for bonding plastics can greatly improve adhesion and overall bond strength. Follow the instructions provided by the primer manufacturer for applying the primer, ensuring even coverage on both surfaces. Allow the primer to dry completely before moving on to the next step.

- Gorilla Glue application: Now it’s time to apply the superhero adhesive itself – Gorilla Glue. Depending on the specific type of Gorilla Glue you’re using, different application methods may be required. Read and carefully follow the instructions provided by Gorilla Glue for your chosen product.

- Clamp it down: After applying the glue and joining the surfaces together, it’s important to clamp or hold them firmly until the adhesive has fully cured. Each Gorilla Glue product has its own recommended curing time, so be sure to check the instructions. This ensures that the bond is secure and long-lasting.

Pros and Cons of Using Gorilla Glue for Plastic to Plastic Bonding

Embarking on a quest for the perfect adhesive to bond plastic to plastic can feel like searching for the Holy Grail. Amidst this battle of the glues, one contender stands out – Gorilla Glue. With its reputation for strength and versatility, Gorilla Glue has become a go-to option for both DIY enthusiasts and professionals. However, before you dive headfirst into your plastic bonding adventure, let’s delve into the pros and cons of using Gorilla Glue for this purpose.

The Pros of Using Gorilla Glue:

- Strong Bond: Picture your plastic connection as solid as a fortress wall – that’s what Gorilla Glue delivers. Renowned for its exceptional strength and durability, this adhesive ensures long-lasting results that can withstand the test of time.

- Versatility: Gorilla Glue isn’t one to be picky when it comes to plastic types. ABS, PVC, polycarbonate, acrylic – it handles them all with ease. This versatility makes it a convenient choice for various plastic bonding needs, eliminating the need for multiple adhesives.

- Waterproof Wonder: Don’t fret about your bonded plastics getting soggy. Gorilla Glue is resistant to water and moisture, making it an ideal option for applications where exposure to liquids is inevitable. Rest easy knowing your bond won’t dissolve in the face of water.

- Gap-Filling Guru: Uneven surfaces or tiny gaps between plastic parts? Fear not. Gorilla Glue possesses outstanding gap-filling capabilities, ensuring a seamless and secure bond even in less-than-perfect conditions. Say goodbye to unsightly cracks or weak connections.

The Cons of Using Gorilla Glue:

- Expanding Foam Woes: Alas, every hero has a flaw – and for Gorilla Glue, it’s the expanding foam characteristic during curing. While this feature is great for filling gaps in woodwork, it can cause issues when bonding plastics. The expanding foam may lead to weak bonds or misaligned pieces, challenging the integrity of your project.

- Time is of the Essence: Patience, dear adhesive seeker, is a virtue when it comes to Gorilla Glue. Depending on the variant and conditions, it can take hours, or even up to 24 hours, for the glue to fully cure. If you’re seeking quick results, this might not be the best option for you.

- Messy Business: Applying Gorilla Glue can be a messy affair due to its thick consistency. Exercise caution and precision to prevent excess glue from oozing out onto your plastic surfaces or surrounding areas. A steady hand and meticulousness are key to a tidy application.

- No Room for Repositioning: Once Gorilla Glue starts its bonding process, repositioning your plastic pieces becomes an uphill battle. It’s crucial to align everything correctly from the get-go, as readjustment after the glue sets can weaken the bond or cause misalignment. Attention to detail is paramount.

djtKXkTqPUI” >

Also Read: The Best Glues for Plastic of 2023

Conclusion

When it comes to bonding plastic to plastic, choosing the right Gorilla Glue is crucial. With a wide range of options available, it can be overwhelming to determine which one is the best fit for your project. However, fear not. I am here to guide you through this adhesive adventure and help you find the perfect Gorilla Glue for your plastic-to-plastic bonding needs.

One exceptional choice is the Gorilla Super Glue Gel. This mighty adhesive packs a powerful punch, providing a strong and durable bond between plastics. Its gel-like consistency ensures precision application, allowing you to easily control the amount of glue used. Whether you’re working on small repairs or intricate projects, this Gorilla Glue will get the job done with utmost efficiency.

If you’re looking for something more versatile, I recommend considering the Gorilla Clear Grip Contact Adhesive. This remarkable glue not only bonds plastic to plastic but also adheres to various other materials like metal, fabric, wood, and more. Its crystal-clear formula dries transparently, ensuring a seamless finish that won’t mar the aesthetic appeal of your project.

For those seeking an extra level of strength and resilience, look no further than the Gorilla Epoxy. This two-part epoxy system creates an incredibly robust bond that can withstand extreme conditions and heavy-duty use. It’s perfect for bonding plastics that are subjected to constant stress or exposed to harsh environments.

In conclusion, when it comes to bonding plastic to plastic, Gorilla Glue offers a range of excellent options. From the precise application of Gorilla Super Glue Gel to the versatility of Gorilla Clear Grip Contact Adhesive and the sheer strength of Gorilla Epoxy – there’s a solution for every project. So go ahead and unleash your creativity while trusting in the reliable performance of these top-notch adhesives from Gorilla Glue.