Ever wondered if there’s a glue that can handle scorching hot temperatures of 1000 degrees?

Whether you’re a DIY enthusiast or tackling an industrial project that requires some serious heat resistance, finding the right adhesive can be a real headache. I mean, who wants their glue to go soft and ruin everything when things get hot and heavy?

Not me, that’s for sure. So, in this blog post, we’re diving into the wild world of high-temperature glues.

If you’re itching to know which glue will keep your project rock solid even at blistering temps, stick around.

What Glues Can Withstand High Temperatures?

Contents

- 1 What Glues Can Withstand High Temperatures?

- 2 Ceramic-Based Adhesives

- 3 Epoxy Glues

- 4 Silicone-Based Adhesives

- 5 Factors to Consider When Choosing a Glue for High Temperature Applications

- 5.1 Temperature Resistance: The Crucial Element

- 5.2 Bond Strength: Weathering the Heat Storm

- 5.3 Chemical Compatibility: A Recipe for Success

- 5.4 Application Method: The Right Fit

- 5.5 Environmental Conditions: Battling More Than Just Heat

- 5.6 Safety and Health Considerations: Handle with Care

- 5.7 Testing and Certification: The Seal of Assurance

- 6 Heat Resistance Guidelines from Glue Manufacturers

- 7 Pros and Cons of Different Types of Glues for High Temperature Applications

- 8 Conclusion

Glue is a remarkable adhesive that finds its place in countless industries and applications. However, when it comes to enduring extreme heat, not all glues are created equal. In this comprehensive guide, we will delve into the world of heat-resistant glues, exploring the diverse types available and providing examples to help you make an informed choice for your next project.

Silicone-Based Glue:

Silicone adhesive takes the spotlight for its remarkable heat resistance. With the ability to withstand temperatures up to a scorching 500 degrees Fahrenheit or higher, silicone glue is the go-to option in the automotive, aerospace, and electronics industries. A prime example of this adhesive is the Hi-Temp Red RTV Silicone Gasket Maker.

Epoxy Resin:

Renowned for their durability and bonding strength, epoxy glues excel in high-temperature environments. Many epoxy varieties can resist heat up to 300 degrees Fahrenheit or more with ease. Industrial settings rely on the J-B Weld HighHeat Epoxy Putty for its exceptional performance in challenging heat conditions.

Ceramic-Based Adhesives:

When it comes to withstanding temperatures exceeding 2000 degrees Fahrenheit, ceramic adhesives reign supreme. Tailored specifically for extreme heat environments, they find their place in aerospace and automotive industries. The Cotronics Duralco 4525 Ceramic Adhesive is a prime example of a glue capable of bonding materials subjected to intense heat.

Cyanoacrylate Adhesives:

Certain cyanoacrylate adhesives, commonly referred to as super glues, exhibit impressive resistance to high temperatures. Capable of enduring temperatures up to 250 degrees Fahrenheit or more, these adhesives are versatile options for various applications. Look no further than the Loctite Ultra Gel Control Super Glue for reliability in high-temperature situations.

Ceramic-Based Adhesives

When it comes to glues, not all can handle the heat. But fear not, because we have the ultimate solution for you – ceramic-based adhesives. These remarkable glues are formulated to withstand scorching temperatures, making them the go-to choice in industries where heat resistance is crucial. Let’s dive into the world of ceramic-based adhesives and explore why they are a game-changer.

Unleashing the Power of Ceramic Fillers:

The secret behind ceramic-based adhesives lies in their ceramic fillers. Made from materials like alumina, zirconia, or silica, these fillers possess exceptional thermal properties. They fearlessly brave temperatures up to 1000 degrees Celsius (1832 degrees Fahrenheit), maintaining their strength and shape. With ceramic-based adhesives, you can confidently bond ceramics, metals, and glass even in the most extreme heat conditions.

Advantages Beyond Temperature Resistance:

Ceramic-based adhesives offer additional advantages that set them apart. Firstly, they boast excellent chemical resistance, making them suitable for corrosive environments where ordinary glues would crumble. Think acids, solvents, and other substances that could eat away at weaker bonds – ceramic-based adhesives have your back.

Furthermore, these glues provide outstanding electrical insulation properties. This makes them perfect for applications involving high voltage or sensitive electronic components. Rest assured that ceramic-based adhesives will create a reliable and safe electrical connection even amidst extreme temperatures.

Best Practices for Success:

To ensure a strong and durable bond with ceramic-based adhesives, proper surface preparation is essential. Ensure surfaces are clean, dry, and free from contaminants that could hinder effective adhesion. Additionally, always follow the manufacturer’s instructions regarding mixing ratio and curing time for optimal results.

Epoxy Glues

Epoxy glues are a remarkable solution for those seeking adhesives that can withstand high temperatures. These powerful glues are created by combining epoxy resin and a hardener, resulting in a bond that is both strong and durable, even in the face of extreme heat.

One of the defining characteristics of epoxy glues is their impressive temperature resistance. Most epoxy glues have the ability to endure temperatures up to 300-350 degrees Fahrenheit (150-175 degrees Celsius). However, there are specialized variants on the market that claim to withstand even higher temperatures, boasting an astonishing resilience of 1000 degrees Fahrenheit (538 degrees Celsius) or more.

When searching for an epoxy glue that can handle such intense heat, it is crucial to consider the specific requirements of your project. It’s important to understand that not all epoxy glues are created equal, and some may have limitations when it comes to temperature resistance. Therefore, it is vital to select a glue that is explicitly designed for high-temperature applications.

To ensure you find an epoxy glue capable of withstanding 1000 degrees Fahrenheit, it is advisable to carefully examine the product specifications provided by the manufacturer. Look for glues that explicitly mention high-temperature resistance or provide a specific temperature range on their packaging. Additionally, reading reviews and seeking recommendations from professionals who have tested these glues under extreme heat conditions can be highly beneficial.

While epoxy glues may possess the ability to endure high temperatures, it is important to note that their performance can vary based on factors such as duration of exposure and the materials being bonded. Prolonged exposure to extreme heat may weaken the bond over time. Therefore, it is critical to thoroughly assess whether the glue’s temperature resistance aligns with your intended usage.

Furthermore, it is essential to adhere strictly to the manufacturer’s instructions and guidelines for proper application and curing of epoxy glues. This will ensure optimal performance and longevity of the bond, especially when faced with high temperatures.

Silicone-Based Adhesives

Silicone-based adhesives are the unsung heroes of high-temperature applications, possessing the remarkable ability to withstand scorching heat without compromising their adhesive properties. Whether in the automotive, aerospace, electronics, or industrial manufacturing industry, understanding the benefits of silicone-based adhesives in extreme temperatures is crucial. Let’s delve into the world of these incredible adhesives and uncover their superpowers.

Unmatched Heat Resistance:

At the core of silicone-based adhesives lies a silicone polymer, a flexible and durable material engineered to thrive under extreme heat. Unlike other adhesives that break down or lose strength when exposed to high temperatures, silicone-based adhesives remain steadfast. Their stable silicone polymer backbone resists thermal degradation, ensuring they maintain adhesive properties even when faced with intense heat.

Efficient Thermal Conductivity:

What sets silicone-based adhesives apart is their excellent thermal conductivity. They efficiently dissipate heat from bonded surfaces, preventing localized hot spots that could weaken the adhesive bond. By effectively transferring heat away, these adhesives maintain their integrity and adhesive strength even in demanding temperature conditions.

Flexibility for Temperature Fluctuations:

Flexibility becomes critical in applications where temperature fluctuations are frequent. Silicone-based adhesives excel in this area, offering excellent flexibility to accommodate thermal expansion and contraction without cracking or delaminating. This adaptability ensures a reliable and long-lasting bond, even in environments where temperature changes are inevitable.

Chemical Resistance and Durability:

Silicone-based adhesives boast impressive chemical resistance, withstanding exposure to harsh chemicals and solvents without losing their adhesive properties. Additionally, they are resistant to moisture and UV radiation, making them ideal for outdoor or humid environments. Their durability in challenging conditions makes them a reliable choice for a wide range of applications.

Selecting the Right Adhesive:

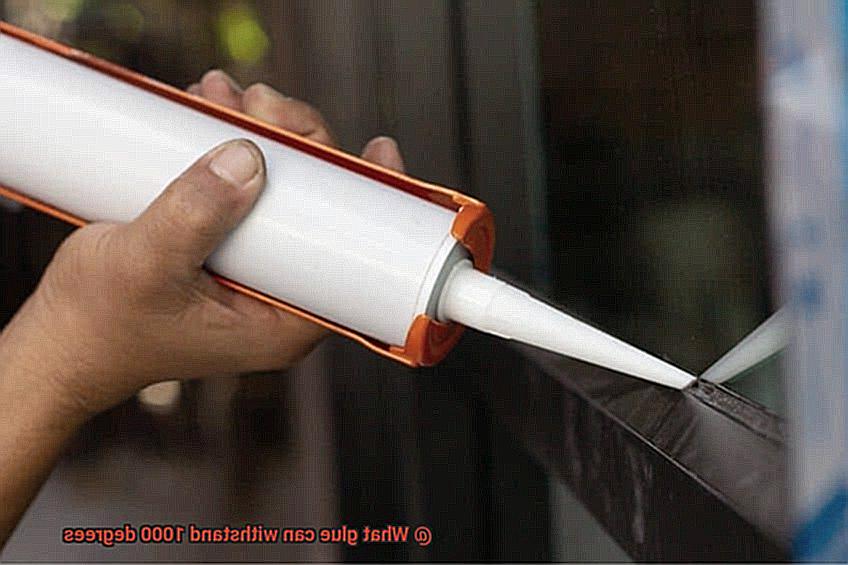

Choosing the right silicone-based adhesive for high-temperature applications requires careful consideration. Different formulations may have varying maximum temperature limits, so it’s crucial to select one that meets specific project requirements. Proper surface preparation, including cleaning and removing contaminants, is vital for optimal bonding performance. Some silicone-based adhesives may also require primers to enhance adhesion to certain substrates.

Factors to Consider When Choosing a Glue for High Temperature Applications

When it comes to high-temperature applications, finding the perfect glue can be a challenge. The adhesive needs to withstand extreme heat, maintain its strength, and resist chemical reactions. To help you make an informed decision, we have compiled a comprehensive guide on the factors to consider when choosing a glue for high-temperature applications.

Temperature Resistance: The Crucial Element

The first and most crucial factor to consider is the temperature resistance of the glue. Look for glues specifically designed to handle scorching temperatures above 1000 degrees Fahrenheit. This ensures that the adhesive will remain rock-solid and won’t crumble under intense heat.

Bond Strength: Weathering the Heat Storm

High temperatures can exert significant strain on adhesive bonds. It is essential to choose a glue with exceptional tensile and shear strengths, indicating its ability to weather temperature-induced stress. Select a glue whose bond strength matches the materials you’ll be bonding.

Chemical Compatibility: A Recipe for Success

Ensure that the glue is chemically compatible with the materials being bonded and any chemicals in the application environment. Some glues may react negatively with certain materials or chemicals at high temperatures, leading to bond failure or degradation. Double-check compatibility information provided by the manufacturer.

Application Method: The Right Fit

Consider the application method of the glue. Some high-temperature glues come in tape form, while others are liquid adhesives that require mixing or curing processes. Choose a glue that fits seamlessly into your manufacturing or repair process, making your life easier.

Environmental Conditions: Battling More Than Just Heat

In addition to high temperatures, other environmental conditions can impact glue performance. Humidity, moisture, chemical exposure, or UV radiation can all affect adhesive strength and longevity. Seek out glues specially formulated to withstand these additional challenges, ensuring a bond that endures.

Safety and Health Considerations: Handle with Care

Don’t forget about safety and health when working with high-temperature glues. Some adhesives may emit harmful fumes or require specific handling procedures. Follow the manufacturer’s safety guidelines to the letter, protecting yourself and those around you.

Testing and Certification: The Seal of Assurance

Look for glues that have undergone rigorous testing and received certifications or approvals from relevant authorities or industry standards organizations. These certifications provide peace of mind, assuring you of the glue’s performance and reliability under extreme heat conditions.

Heat Resistance Guidelines from Glue Manufacturers

Discovering a heat-resistant glue that can endure scorching temperatures above 1000 degrees Fahrenheit is like finding a rock-solid superhero. Fear not, for in this comprehensive guide, we will unlock the secrets behind heat-resistant glues and provide you with the knowledge you need to make an informed decision when selecting the perfect adhesive.

The Importance of Heat Resistance Guidelines:

Ensuring Optimal Performance:

In industries such as automotive, aerospace, and electronics, where temperature fluctuations are a constant challenge, following the heat resistance guidelines provided by glue manufacturers is crucial. These guidelines guarantee that your chosen adhesive will maintain its adhesive properties even under extreme heat conditions.

Selecting the Right Glue:

Not all glues offer the same level of heat resistance. By referring to the manufacturer’s guidelines, you can identify the maximum temperature that a particular glue can endure without compromising its bonding strength. This allows you to choose a glue that best suits your specific high-temperature application needs.

Types of Heat-Resistant Glues:

Epoxy Adhesives:

Renowned for their exceptional bonding strength and ability to withstand high temperatures, epoxy adhesives are a popular choice. However, it is important to note that not all epoxy adhesives are created equal in terms of heat resistance. Consult the manufacturer’s guidelines to select an epoxy adhesive that meets your desired temperature requirements.

Silicone-Based Adhesives:

Tolerating temperatures ranging from 400 to 600 degrees Fahrenheit, silicone-based adhesives are versatile and essential in applications where heat resistance is paramount. These adhesives find wide usage in automotive and industrial settings.

Polyurethane Adhesives:

Flexibility and heat resistance make polyurethane adhesives ideal for automotive and construction applications. However, the heat resistance of these adhesives can vary. It is crucial to consult the manufacturer’s guidelines for accurate information.

Additional Considerations:

Duration of Heat Exposure:

Consider the duration of high-temperature exposure when selecting a glue. Some glues may withstand short bursts of high temperatures, while others are designed for prolonged exposure. The manufacturer’s guidelines provide valuable information on the recommended duration of heat exposure for optimal performance.

Surface Preparation and Application Techniques:

Proper surface preparation, application techniques, and curing processes significantly impact the performance and heat resistance of the glue. Following the manufacturer’s instructions ensures the best possible bond for your high-temperature application.

Pros and Cons of Different Types of Glues for High Temperature Applications

When it comes to high temperature applications, finding the right glue is crucial. The wrong adhesive can melt away under heat, leaving your project in ruins. In this essay, we will explore the pros and cons of different types of glues commonly used for high temperature applications. From the heat-resistant superheroes to the lightning-fast bonders, let’s dive into the world of adhesives and find the one that can withstand extreme heat.

Round 1: Silicone-based Glues:

In the red corner, we have silicone-based glues. These glues are like heat-resistant superheroes, able to withstand temperatures up to 600 degrees Fahrenheit (315 degrees Celsius). They offer excellent flexibility, making them perfect for bonding metals, ceramics, and glass. However, their slow curing time can be a drawback, leaving you waiting like a kid in line for a rollercoaster.

Round 2: Epoxy-based Glues:

In the blue corner, we have epoxy-based glues. These glues are tough cookies that can handle temperatures up to 300 degrees Fahrenheit (150 degrees Celsius). They are like the Hulk of glues, offering incredible strength and durability. Epoxy glues can bond with almost anything – metal, plastic, even your wildest dreams. But beware, they can become brittle when exposed to extreme heat.

Round 3: Polyurethane-based Glues:

In the green corner, we have polyurethane-based glues. These glues are like construction workers, able to handle temperatures up to 250 degrees Fahrenheit (120 degrees Celsius). They are great for automotive and aerospace applications because they can stick to almost anything and resist chemicals like a superhero repelling villains. However, they take their time to cure like a snail on a lazy Sunday afternoon.

Round 4: Cyanoacrylate-based Glues:

In the yellow corner, we have cyanoacrylate-based glues, also known as super glues. These glues are like the Flash, offering lightning-fast bonding with temperatures up to 250 degrees Fahrenheit (120 degrees Celsius). They can bond with a wide range of materials, from plastic to metal, in the blink of an eye. However, they may become brittle when exposed to high heat for a long time.

Round 5: Ceramic-based Glues:

In the purple corner, we have ceramic-based glues. These glues are like wizards of heat resistance, able to handle temperatures up to 2000 degrees Fahrenheit (1100 degrees Celsius). They are specially designed for bonding ceramics and can withstand rapid temperature changes. However, they may not work their magic on other materials and might not provide the same level of adhesion as other glues.

mLayFRQ7jdo” >

Conclusion

In conclusion, the search for a glue that can endure blistering temperatures of 1000 degrees Fahrenheit is no small feat. But fear not, as there are several options available that rise to the occasion in high-temperature environments.

Silicone-based glues reign supreme in many industries, thanks to their extraordinary heat resistance. These marvels can withstand temperatures of up to 500 degrees Fahrenheit or even higher, making them a go-to choice for automotive, aerospace, and electronics applications. When it comes to durability and bonding strength, epoxy glues take center stage. Many variations of these powerhouses can brave heat up to 300 degrees Fahrenheit or beyond.

But if you want to push the limits even further, ceramic-based adhesives are your answer. Some of these heavyweights can endure scorching temperatures exceeding 2000 degrees Fahrenheit, finding their niche in extreme heat environments like aerospace and automotive industries. And let’s not forget about our trusty super glue – certain cyanoacrylate adhesives exhibit impressive resistance to high temperatures and can handle up to 250 degrees Fahrenheit or more.

When selecting a glue for your scorching hot endeavors, it’s vital to consider various factors such as temperature resistance, bond strength, chemical compatibility, application method, environmental conditions, safety precautions, and testing certifications.

All in all, each type of glue has its own set of pros and cons when it comes to withstanding extreme heat. It’s crucial to meticulously evaluate your specific project requirements and consult the manufacturer’s guidelines before making a decision.