When it comes to bonding rubber, finding the perfect adhesive is more important than you might imagine. Whether you’re rescuing a torn rubber sole, patching up a leaky hose, or tackling a fun DIY project, using the wrong glue can quickly turn your excitement into disappointment. But fear not. In this blog post, we’ll dive into the world of rubber adhesives and uncover the ultimate glue for all your rubber needs.

There are several types of glue available for bonding rubber, each with its own set of pros and cons. One popular choice is cyanoacrylate glue, also known as super glue. This speedy adhesive forms an instant strong bond, making it ideal for quick fixes on rubber objects. However, beware its one flaw – once dry, it can become brittle and may not withstand high stress or tension.

If you’re seeking strength and versatility, epoxy is your go-to adhesive for rubber. This powerful glue can bond rubber to a wide range of materials, making it a superhero in various applications. It’s resistant to heat, chemicals, and moisture – ensuring that your repairs will stand the test of time. Just keep in mind that working with epoxy requires precision mixing and application.

For those who prefer flexibility in their bond, neoprene-based adhesive is the secret weapon. This type of glue remains flexible even after curing, making it perfect for rubber items that endure continuous movement or stress. It creates a robust bond while providing excellent resistance to water and weathering. Just be patient as neoprene glue may take longer to cure compared to other adhesives.

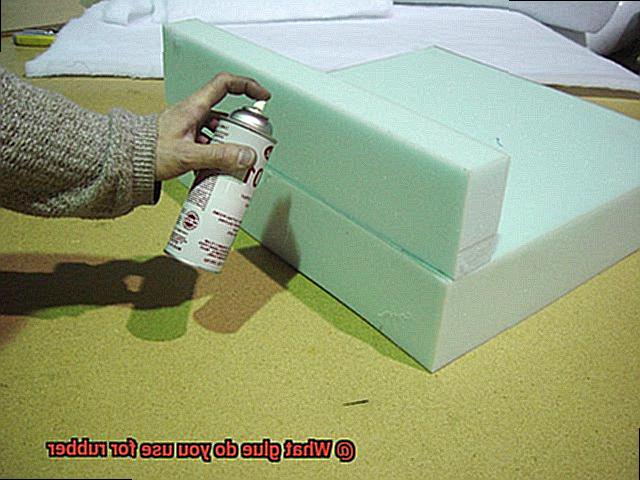

When dealing with larger surfaces or projects that require some wiggle room for adjustments, look no further than rubber cement. This adhesive allows for easy repositioning while delivering a strong bond once dried. Applying it with a brush or roller ensures even coverage across your rubber surface without any hassle. But remember that extreme temperatures or rough handling may put its strength to the test.

To guarantee a successful glue application, it’s vital to prep your rubber surface properly. Give it a thorough cleaning, removing any dirt, oil, or residue that could hinder adhesion. For an extra boost, roughen the surface with sandpaper to enhance the bond. And of course, always read and follow the manufacturer’s instructions for optimal results.

In conclusion, choosing the right glue for your rubber repairs is the key to achieving long-lasting success. Cyanoacrylate glue works wonders for small fixes, while epoxy provides unbeatable

What Is Rubber?

Contents

Rubber, derived from the sap of various plants, such as the rubber tree, is a versatile and indispensable material that has transformed the way we live. Its elastic nature and resilience have made it a crucial component in countless applications. So, what exactly is rubber and why is it so widely used?

At its core, rubber is an elastic substance with unique properties. When force or pressure is applied, it can stretch and effortlessly return to its original shape. This remarkable elasticity is attributed to the long polymer chains present in rubber, which can easily be stretched and then regain their original arrangement. It’s this property that makes rubber ideal for products requiring flexibility and resilience, such as tires and shoe soles.

Beyond its elasticity, rubber possesses excellent insulation properties. It doesn’t conduct electricity, making it safe for use in electrical equipment and wiring. Rubber’s insulating capabilities also render it perfect for sealing purposes as it effectively bars the passage of air, water, or other fluids. Consequently, rubber is heavily employed in gaskets, seals, and O-rings.

Furthermore, rubber boasts exceptional resistance to wear and tear, resulting in durability and longevity. It can withstand exposure to various substances including oils, solvents, acids, and bases without deteriorating. This chemical resistance has established rubber as a staple in industries like automotive, construction, and manufacturing.

But natural rubber isn’t the only type available; synthetic rubbers have also gained widespread usage. These synthetic variants offer similar properties to natural rubber but can be tailored to meet specific requirements. For instance, neoprene rubber excels in oil and heat resistance, making it an asset in the automotive industry.

Types of Glues for Bonding Rubber

Rubber is a versatile material used in various industries due to its flexibility, durability, and resistance to water and chemicals. However, bonding rubber to other materials or repairing rubber objects can be a challenge. In this article, we will explore the different types of glues used for bonding rubber, their strengths, weaknesses, and when to use each type.

Cyanoacrylate Adhesive (Super Glue):

Cyanoacrylate adhesive, also known as super glue, is a popular choice for bonding rubber. It forms a strong bond quickly and can be used on a wide range of rubber surfaces. The rapid drying time makes it ideal for small, precise applications. However, it may not be suitable for larger or flexible rubber surfaces as it can become brittle over time. So, if you’re working on a delicate rubber object or need flexibility, consider other options.

Epoxy Adhesive:

Epoxy adhesive is a two-part adhesive that forms a strong and durable bond. It is ideal for bonding rubber to metal or other rigid materials. Epoxy adhesives are known for their excellent resistance to chemicals and high temperatures, making them suitable for harsh environments. Whether you’re repairing a rubber gasket or bonding rubber to metal in an industrial setting, epoxy adhesive provides the strength and durability you need.

Silicone Adhesive:

For more flexible rubber surfaces like gaskets or O-rings, silicone adhesive is recommended. It provides a flexible bond that can withstand extreme temperatures and offers excellent resistance to water and chemicals. Whether you’re working on plumbing fixtures or automotive applications, silicone adhesive ensures a reliable bond that maintains the flexibility of the rubber.

Neoprene-Based Adhesives:

Neoprene-based adhesives are specifically formulated for bonding rubber. They provide a flexible bond resistant to water, oil, and heat. These adhesives are commonly used in the automotive industry for bonding rubber seals and gaskets. So, if you’re working on an automotive project or need a bond that can withstand harsh conditions, neoprene-based adhesives are a reliable choice.

Multipurpose Adhesives:

Multipurpose adhesives can also be used for bonding rubber along with other materials like metal or plastic. While they offer versatility, they may not provide the same level of strength or flexibility as specialized rubber adhesives. So, if you’re working on a project that involves bonding rubber to various materials, consider the specific requirements and choose an adhesive that meets those needs.

Cyanoacrylate Adhesive (Super Glue)

With its lightning-fast action and rock-solid bond, this adhesive is a game-changer when it comes to bonding rubber materials.

One of the greatest advantages of cyanoacrylate adhesive is its ability to create an almost instant bond. Picture this: as soon as you apply it to the surface of rubber, it springs into action, reacting with the moisture in the air and forming a powerful bond within seconds. This means that you can fix or join rubber items quickly and get back to your project in no time.

But wait, there’s more. Not only does cyanoacrylate adhesive bond quickly, but it also offers excellent adhesion to a wide range of rubber types. Whether you’re working with natural rubber, neoprene, nitrile rubber, or silicone rubber, this adhesive has got you covered. It creates a durable bond that can withstand temperature fluctuations, moisture exposure, and even vibrations. So whether you’re repairing a rubber sole on your favorite sneakers or attaching a rubber gasket to a plumbing fixture, cyanoacrylate adhesive will hold it all together.

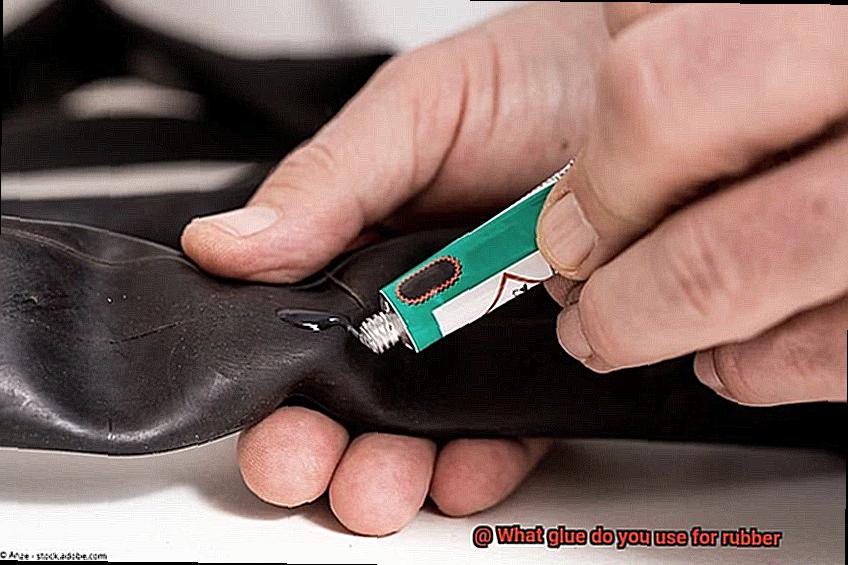

To ensure the best results when using cyanoacrylate adhesive on rubber, it’s important to properly prepare the surfaces before applying the glue. Think of it as giving your rubber materials a spa treatment. Clean the surfaces thoroughly, removing any dirt, dust, or grease that could hinder the bonding process. This ensures that the adhesive can work its magic without any obstacles in its way.

Remember, when it comes to cyanoacrylate adhesive, a little goes a long way. You don’t need to drown your rubber materials in glue. Applying too much can lead to excessive curing time or weak bonds. So be sure to use it sparingly for optimal results. A small dot or a thin line is usually all you need to create a bond that will withstand the test of time.

While cyanoacrylate adhesive is an excellent choice for bonding rubber materials, it may not be suitable for all types of rubber applications. Some rubbers contain high levels of plasticizers or additives that can interfere with the adhesive’s effectiveness. In such cases, it’s always best to test the adhesive on a small area first to ensure compatibility. Think of it as a chemistry experiment, but without the explosions.

Epoxy Adhesive

Today, we’re diving into the world of epoxy adhesive and its advantages when it comes to bonding rubber materials. If you’ve ever wondered how to create a strong and durable bond between rubber surfaces, epoxy adhesive is here to save the day.

Advantage 1: Unmatched Strength

Epoxy adhesives are renowned for their exceptional bonding capabilities. When it comes to rubber bonding, strength is crucial, especially in applications that experience high levels of stress or tension. Imagine you’re repairing a torn rubber hose that’s constantly under pressure from water flow. With epoxy adhesive, you can rest assured that your rubber components will stay firmly bonded, even under intense pressure.

Advantage 2: Chemical, Heat, and Moisture Resistance

Rubber materials often face harsh environments and chemical exposure. Epoxy adhesives offer excellent resistance to chemicals, heat, and moisture, acting as a protective shield for your rubber bonds. Picture a rubber gasket used in an automotive engine that faces extreme temperatures and oil exposure. The epoxy adhesive used to bond the rubber gasket ensures it remains intact and functional despite these challenging conditions.

Advantage 3: Proper Surface Preparation is Key

To achieve optimal adhesion with epoxy adhesive on rubber surfaces, proper surface preparation is essential. Rubber’s smooth and non-porous nature can pose a challenge for adhesion.

By cleaning the surfaces thoroughly and lightly roughening them with sandpaper, you create microscopic grooves that enhance the adhesive’s grip. These tiny grooves resemble the hooks on Velcro tape, allowing the adhesive to grab onto the rubber surface with tenacity.

Application Process:

The application process for epoxy adhesive involves mixing the resin and hardener in specific ratios according to the manufacturer’s instructions. Once mixed, apply the adhesive evenly onto both rubber surfaces that require bonding. Remember to follow the recommended curing time and temperature requirements for optimal strength development. Think of it as a superhero’s secret formula that needs the right ingredients and conditions to unleash its full power.

Silicone Adhesive

Silicone adhesive is the superhero of adhesives when it comes to bonding rubber materials. With its incredible flexibility and durability, it can keep up with the elastic nature of rubber without cracking or losing its bond. But that’s not all. Silicone adhesive also boasts an impressive resistance to moisture, temperature, and chemicals, making it a reliable choice for challenging environments.

When using silicone adhesive, proper surface preparation is key. Ensure that the surfaces are clean, dry, and free from any dirt or oils that might interfere with the bonding process. You can even roughen the surface of the rubber slightly with sandpaper to enhance adhesion.

Now it’s time to unleash the full power of silicone adhesive. Squeeze a small amount onto one surface and spread it evenly using a brush or spatula. Apply enough glue to cover the entire surface without going overboard, as excessive glue may squeeze out under pressure. Once applied, firmly press the two surfaces together and hold them in place for a few minutes to allow the bond to form.

Whether you’re repairing rubber items, sealing gaps and cracks, or creating flexible bonds between different materials, silicone adhesive is your go-to choice. It acts as a shield against the challenges that rubber faces in its daily life – water, extreme temperatures, and chemicals. With silicone adhesive on your side, your rubber bonds will remain strong and secure.

Specialized Adhesives for Specific Rubber Applications

Just like superheroes rely on their special suits and gadgets to conquer unique challenges, specialized adhesives are the secret weapon for achieving strong and long-lasting bonds in the world of rubber. In this article, we will explore the importance of choosing the right adhesive for various rubber applications and uncover the ultimate solutions for bonding.

Understanding the Rubber Landscape:

Rubber comes in different forms, each with its own set of properties and requirements. From natural rubber sourced from trees to synthetic rubbers like neoprene, nitrile rubber, and silicone rubber, each type demands a specific adhesive for optimal bonding results.

Specialized Adhesives for Different Rubber Applications:

Natural Rubber:

For applications such as footwear or conveyor belts that utilize natural rubber, contact adhesives or natural rubber adhesives are essential. These adhesives provide exceptional flexibility, durability, and adhesion.

Neoprene Rubber:

When it comes to gaskets and seals that endure high temperatures and harsh chemicals, neoprene adhesives are the heroes of choice. They offer exceptional bonding capabilities while maintaining effectiveness in challenging environments.

Nitrile Rubber:

Hoses and seals used in oil-resistant applications require adhesives with excellent resistance to oils and fuels. Nitrile adhesives provide a strong bond, ensuring durability even in the toughest oil-laden environments.

Silicone Rubber:

Silicone rubber is known for its flexibility and high temperature resistance. To effectively bond silicone rubber, silicone adhesives are specially formulated. They excel in extreme temperature fluctuations while maintaining flexibility.

The Importance of Choosing the Right Adhesive:

Using general-purpose adhesives may not deliver the desired strength or flexibility when bonding rubber. Specialized adhesives specifically designed for rubber applications provide reliable and long-lasting bonds. When selecting an adhesive, factors such as rubber type, desired flexibility, temperature resistance, and application environment should be considered.

Consulting the Experts:

When in doubt, seeking guidance from adhesive manufacturers or experts in the field is invaluable. Their experience and knowledge can guide you in choosing the most suitable adhesive for your specific rubber application, ensuring optimal results.

Factors to Consider When Choosing the Right Glue for Rubber

Rubber is a versatile material used in various industries, and finding the right glue for rubber can be a daunting task. Just like superheroes rely on their special suits and gadgets to conquer unique challenges, specialized adhesives are the secret weapon for achieving strong and long-lasting bonds in the world of rubber.

In this article, we will explore the key factors to consider when selecting the right adhesive for rubber applications.

Factor 1: Type of Rubber

Rubber comes in different forms such as natural rubber, synthetic rubber, and silicone rubber. Each type has its own unique properties, requiring specific adhesives. Natural rubber may require an adhesive that offers excellent flexibility and resistance to aging.

On the other hand, synthetic rubber may need an adhesive with high bond strength and chemical resistance. Therefore, understanding the type of rubber you are working with is crucial in selecting the appropriate adhesive.

Factor 2: Bond Strength

Consider the application and the stress or pressure the bonded rubber will be subjected to. If you need a strong and durable bond, choose an adhesive that offers high bond strength. For heavy-duty applications like automotive or industrial uses, opt for adhesives specifically designed for high-strength bonding.

Factor 3: Flexibility

Rubber is known for its elasticity and flexibility. It is essential to choose an adhesive that can handle the movement and stretching of the rubber without weakening or breaking the bond. Look for adhesives specifically designed for flexible materials or ones that mention flexibility on their packaging.

Factor 4: Temperature Resistance

Consider whether your application involves exposure to extreme temperatures. Some adhesives may lose their effectiveness or break down under heat or cold conditions. If your bonded rubber will be exposed to temperature extremes, choose a glue that can withstand those conditions.

Factor 5: Chemical Resistance

If the bonded rubber will come into contact with chemicals or solvents, it is crucial to choose an adhesive that offers good chemical resistance.

Different adhesives have varying levels of resistance to different chemicals, so ensure that the glue you choose can withstand exposure to any substances it may encounter.

Factor 6: Application Method

Consider the ease of application when choosing a glue for rubber. Some adhesives come in tubes or cartridges that can be easily squeezed out, while others may require mixing or special applicators. Choose a method that suits your skills and preferences.

Factor 7: Drying Time

Drying time is an important factor if you need quick results or if you are working on time-sensitive projects. Some glues dry rapidly, allowing for faster bonding, while others may require longer curing times. Consider the drying time and ensure it aligns with your requirements.

Factor 8: Compatibility

It is crucial to ensure that the glue you choose is compatible with both the rubber material and any other materials it will be bonded to. Some adhesives may not work well with certain rubbers or may react with other materials, leading to a weak bond or damage to the surfaces being bonded.

Also Read: How to Glue Neoprene to Rubber?

Glues That Should Not Be Used on Rubber

When it comes to bonding rubber surfaces, not all glues are created equal. Using the wrong adhesive can lead to weak bonds, peeling, or even damage to the rubber material itself. In this blog post, we’ll explore the glues that should be avoided when working with rubber surfaces and why specialized rubber adhesives are your best bet for a successful bond.

Super Glue:

While super glue is known for its fast-drying and strong bond, it falls short when it comes to rubber. It has poor adhesion to rubber surfaces, resulting in weak bonds that easily break or peel off.

Epoxy:

Although epoxy is versatile and works well with many materials, it doesn’t bond effectively with rubber. The epoxy may fail to fully cure or adhere properly to the rubber surface, leading to weak bonds or eventual failure over time.

Silicone-Based Glues:

Silicone-based glues are commonly used for sealing and bonding but are not ideal for rubber surfaces. While they may provide initial adhesion, the flexible nature of silicone can cause the bond to become less durable, especially in high-stress or dynamic applications.

Hot Glue:

Hot glue or hot melt adhesive offers a temporary bond on rubber surfaces but lacks long-term durability. The flexibility of rubber can cause hot glue to become brittle over time, resulting in a weakened bond.

Solvent-Based Glues:

Avoid using solvent-based glues like acetone-based adhesives or rubber cement on rubber. These glues can actually deteriorate the rubber material, making it weak, brittle, or even discolored.

WyM9JtRZuvc” >