Welcome to today’s blog post where we’ll explore the exciting world of glues that don’t melt. We’ve all been in situations where we need a strong bond that can handle crazy temperatures, whether it’s for heavy-duty projects or just some fun crafting. And that’s where these superglues come in – they’re like the superheroes of adhesives, standing up to heat like nobody’s business.

But what makes these glues so special? How do they keep their strength even when things get hot? Join me as we uncover the secrets behind these incredible adhesives and check out the different types you can find.

Now, before we go any further, let me tell you this: not all glues are created equal. Some can handle a little heat, while others laugh in the face of scorching temperatures. From epoxy to cyanoacrylate to silicone-based glues, each one has its own powers and advantages.

Whether you’re fixing car parts, building electronics, or creating outdoor furniture that won’t melt under the blazing sun, finding the right glue is essential.

In this ultimate guide, we’ll dive deep into these amazing glues. We’ll talk about how they’re made, what they’re made of, and most importantly, where you can use them. By the end of this blog post, you’ll know exactly which glue to grab when you need a bond that won’t back down from extreme heat.

So if you’re ready to explore the world of adhesive wonders and discover what makes these glues stand strong under scorching conditions – buckle up. We’re about to take off.

What is Glue?

Contents

Glue, a seemingly ordinary substance, has the remarkable ability to bind materials together, making it an essential adhesive in our everyday lives. In this article, we will delve into the fascinating world of glue, examining its composition, different types, and their unique properties.

Composition of Glue:

Glue is composed of three main components: the adhesive, the solvent, and various additives. The adhesive, typically a polymer, provides the glue’s bonding properties. Acting as a carrier for the adhesive, the solvent aids in its spreadability and penetration. Additives are incorporated to enhance specific properties like strength, flexibility, drying time, or resistance to moisture and heat.

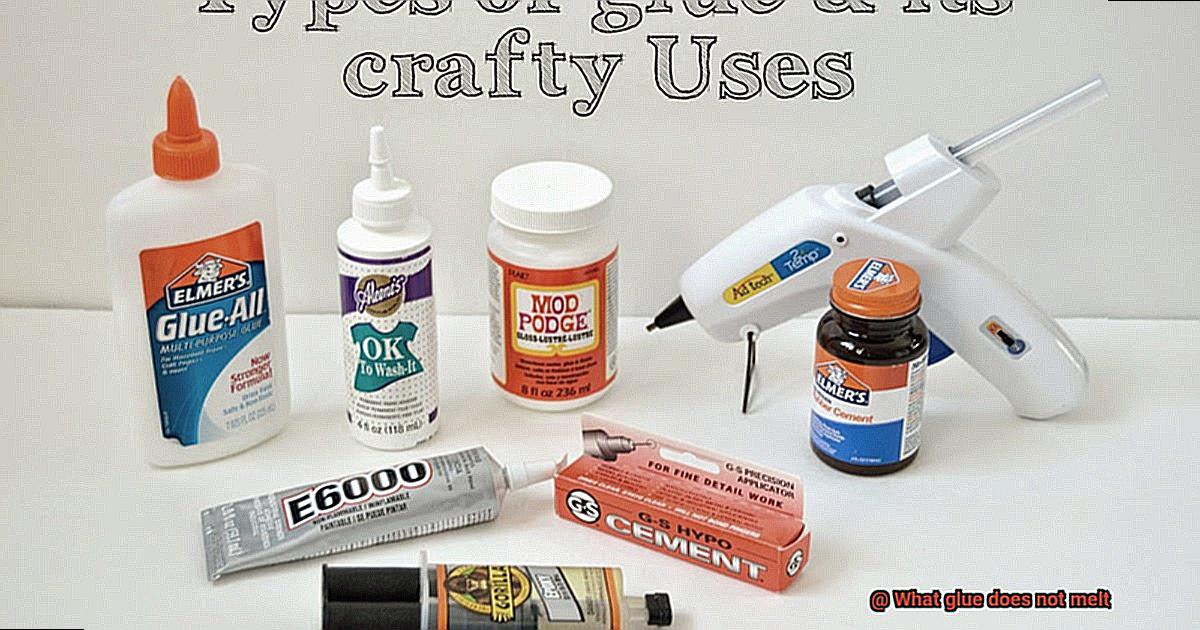

Types of Glue:

- PVA Glue: Versatile and easy to use, PVA glue is perfect for general purposes and craft projects. It dries clear and can be found in schools and households.

- Epoxy Glue: Renowned for its exceptional strength and durability, epoxy glue consists of resin and hardener components. It forms bonds resistant to heat, chemicals, and moisture.

- Super Glue: Also known as cyanoacrylate adhesive, super glue creates instant bonds and is ideal for small repairs. It dries quickly and forms permanent bonds with materials like plastic, metal, or ceramics.

- Hot Glue: Applied in a molten state using a hot glue gun, hot glue solidifies upon cooling. It is commonly used in crafts, DIY projects, and temporary bonding.

- Silicone Glue: Flexible and resistant to high temperatures and moisture, silicone glue finds extensive use in sealing applications such as plumbing or automotive needs.

Glues That Do Not Melt:

In high-temperature applications where regular adhesives would fail, specialized glues are formulated to withstand extreme heat without losing their adhesive properties. These include:

- Epoxy Adhesive: Renowned for its versatility and exceptional heat resistance, epoxy adhesive is commonly used in automotive repairs and industrial settings.

- Super Glue: With excellent heat resistance, super glue can withstand temperatures up to 180 degrees Celsius without melting or weakening its bond.

- Polyurethane Adhesive: Offering a strong bond that withstands temperature variations, polyurethane adhesive is often used in woodworking projects.

- Silicone Adhesive: Widely used in industries like electronics, automotive, and aerospace, silicone glues are flexible and exhibit excellent thermal stability.

- Specialized Heat-Resistant Glues: Industries such as aerospace, automotive, and metalworking rely on glues specifically crafted to withstand extreme heat without losing their adhesive properties.

Types of Glue That Do Not Melt

It’s all thanks to special types of glue that don’t melt under high temperatures. In this blog post, we’ll explore the different types of heat-resistant glues and where they are commonly used. So, let’s dive in and discover these stickiest superheroes.

Epoxy Resin – The Mighty Bond:

Mixing two magical potions together creates an adhesive that can withstand scorching temperatures – epoxy resin. This powerful glue forms an unbreakable bond that resists heat, chemicals, and moisture. Picture having a superhero protecting your projects from melting away. Epoxy resin is commonly used in automotive repairs, electronics manufacturing, and construction.

Cyanoacrylate – The Speedy Saver:

When you need a quick fix, cyanoacrylate, aka super glue, comes to the rescue. This speedy adhesive bonds almost instantly and holds strong even under moderate temperatures. However, it might lose its power when exposed to extreme heat for a long time. Super glue works wonders on ceramics, plastics, metals, and glass.

Silicone Adhesive – The Flexible Friend:

If you need a glue that can handle extreme temperatures without breaking a sweat, silicone adhesive is your go-to buddy. This flexible adhesive withstands scorching heat without melting or losing its sticky strength. It’s like having a friend who stays calm and collected no matter how hot it gets. Silicone adhesive is commonly used in aerospace, automotive, and electronics industries.

Polyurethane Adhesive – The Versatile Warrior:

When it comes to withstanding temperature extremes, polyurethane adhesive is a true warrior. This versatile glue can handle freezing cold and sweltering heat without melting or losing its bond. It’s like having an all-weather soldier by your side, ready to conquer any project. Polyurethane adhesive is commonly used in woodworking, construction, and automotive applications.

Acrylic Adhesive – The Reliable Companion:

For projects that require a reliable companion in high temperatures, acrylic adhesive is your best friend. This glue retains its bonding strength even when things get hot. It’s like having a loyal friend who never lets you down, no matter how much heat you face. Acrylic adhesive is commonly used in signage, plastics assembly, and HVAC systems.

Epoxy Adhesive

Are you tired of your projects falling apart like a house of cards? Fear not, for I have just the superhero glue for you – epoxy adhesive. This incredible adhesive is not only versatile and strong, but it also possesses some seriously cool superpowers that will make your DIY projects and industrial applications a breeze.

Superpower #1: Defying the Heat

Epoxy adhesive can handle scorching temperatures like no other glue out there. While ordinary glues would melt under pressure, epoxy adhesive stands tall, unfazed by the heat. So whether you’re working on a car engine, fixing electronics, or creating a masterpiece with wood and metal, epoxy adhesive has got your back and won’t let you down.

Superpower #2: Shielding Against Chemical Attacks

Imagine a glue that can withstand harsh chemicals without blinking an eye – that’s epoxy adhesive for you. It’s like having a superhero shield protecting your bonds from corrosive substances. So whether you’re dealing with solvents or harsh cleaning agents, epoxy adhesive won’t back down and will keep your projects intact.

Superpower #3: Unbreakable Strength and Durability

Epoxy adhesive is no weakling when it comes to strength. Once it cures, it forms an unbreakable bond that can withstand heavy loads and stress. It’s like having the Hulk holding your project together. Plus, it’s not picky about what it sticks to – metal, plastic, wood, ceramics, composites – you name it, epoxy adhesive can handle it all.

Superpower #4: Mastering the Art of Gap-Filling

Have you ever struggled to bond irregular or uneven surfaces? Well, epoxy adhesive has got a solution for that too. With its amazing gap-filling properties, it can seamlessly fill in gaps and voids between surfaces, creating a bond so strong, it will feel like magic.

Superpower #5: Versatility for All Your Projects

Whether you’re a DIY enthusiast or an industrial professional, epoxy adhesive is perfect for all your bonding needs. It’s available in different formulations tailored for specific applications, so you can choose the right type for your project. Just follow the manufacturer’s instructions, and you’ll be amazed at the results.

Cyanoacrylate (Super Glue)

Look no further than cyanoacrylate, better known as super glue. This remarkable adhesive is a reliable choice for various applications, thanks to its impressive resistance to melting.

Super glue, with its high melting point of up to 180 degrees Celsius (356 degrees Fahrenheit), is a heat-resistant wonder. It won’t lose its adhesive properties even in scorching environments. So whether you’re working on automotive repairs or electronic projects, super glue has got your back.

The secret behind super glue’s strength lies in its chemical composition. It contains cyanoacrylate monomers that are exceptionally stable and resistant to breakdown under heat. While other adhesives may crumble under pressure, super glue forms bonds that can withstand the test of time.

But it’s not just about strength – super glue is a versatile champ. From metal to plastic, wood to ceramics, super glue bonds with almost anything you throw at it. Its fast-acting nature ensures quick and secure adhesion, making it a go-to choice for various industries like construction and crafting.

However, it’s important to exercise caution with super glue. While it is a reliable adhesive, it does have limits. Prolonged exposure to high temperatures or direct flame might not be its forte. Also, certain materials with low surface energy, like polyethylene or polypropylene, may require specialized adhesives.

Polyurethane Adhesive

In the realm of adhesives, there exists a true superhero that can conquer extreme heat, endure the test of time, and defy the forces of water. Its name? Polyurethane adhesive. Join us as we embark on a thrilling journey through the captivating features of this remarkable adhesive and discover why it has become a beloved choice across numerous industries.

Heat Resistance:

Prepare to be amazed by polyurethane adhesive’s indomitable defense against scorching temperatures. Unlike its counterparts, this adhesive remains steadfast, refusing to yield even in the face of blistering heat. From construction projects to automotive repairs, rest assured that polyurethane adhesive will withstand the most fiery conditions with unwavering strength.

Bonding Strength:

Witness the awe-inspiring prowess of polyurethane adhesive as it forges unbreakable bonds between disparate materials. Wood, metal, plastic, concrete – no challenge is too great for this versatile adhesive. Its exceptional bonding strength makes it an invaluable asset in countless applications demanding unwavering reliability and long-lasting endurance. Say farewell to feeble bonds that crumble under pressure.

Flexibility:

Behold the extraordinary flexibility of polyurethane adhesive as it effortlessly withstands movements and vibrations without compromising its adhesion properties. A steadfast ally in automotive and construction projects, this adhesive embraces the tumultuous nature of these endeavors, ensuring your bond remains unyielding even in the face of adversity.

Resistance to Water:

Fear not the liquid realm, for polyurethane adhesive fears it not. Resisting the siren call of water and moisture, this adhesive retains its formidable bonding strength even in their relentless presence. Whether your project ventures into the great outdoors or necessitates exposure to moisture, polyurethane adhesive stands resolute, safeguarding your bond against weakening forces.

Versatility:

Prepare to be dazzled by the myriad forms and applications of polyurethane adhesive. Liquid, paste, or foam – the choice is yours. With a brush, roller, or spray, you wield the power to adapt this adhesive to the unique demands of your project. Irrespective of size or shape, polyurethane adhesive rises to the occasion, embracing versatility as its greatest strength.

Silicone Adhesive

Well, say hello to the superhero of adhesives – silicone adhesive. This incredible glue is a game-changer for applications that require bonding materials in extreme temperatures.

Silicone adhesive is known for its outstanding heat resistance. Unlike other adhesives that crumble under high temperatures, silicone adhesive remains steadfast and maintains its bonding strength. Whether it’s in an engine compartment or an electronic device, this glue can handle the heat like a champ.

Silicone adhesive also laughs in the face of freezing temperatures. It stays flexible and doesn’t become brittle when exposed to cold climates, making it perfect for outdoor applications or chilly environments.

Not only does silicone adhesive resist extreme temperatures, but it also has excellent chemical resistance. It can stand up against many chemicals, oils, and solvents, ensuring that even harsh substances won’t break the bond.

Flexibility is another superhero power of silicone adhesive. With its high elongation capacity, this glue can stretch without losing its bonding strength. So go ahead and shake things up – your bonded materials won’t budge.

And let’s not forget about variety. Like choosing your favorite flavor of ice cream, silicone adhesive comes in different forms – liquids, gels, and tapes. The liquid form is great for brush or dispenser application, while the gel form provides precise control. And if you’re in a hurry, silicone adhesive tapes are here to save the day with quick and easy bonding.

Specialized Heat-Resistant Glues

Specialized heat-resistant glues are a remarkable category of adhesives that have the unique ability to withstand high temperatures without melting or losing their adhesive properties. They are the superheroes of the glue world, coming to the rescue in industries where bonding materials exposed to extreme heat is critical.

One type of specialized heat-resistant glue is silicone-based glue. Renowned for its exceptional resistance to heat, silicone-based glue can endure temperatures up to a scorching 600°F (315°C). It is commonly used for sealing and bonding applications in high-temperature environments, making it ideal for tasks like sealing engine components or bonding materials in furnaces.

Epoxy glue is another widely-used heat-resistant adhesive. With its robust bond and capacity to withstand high temperatures, epoxy glue is a go-to choice in industries such as automotive, aerospace, and electronics. Depending on the formulation, epoxy glues can resist temperatures up to 300°F (150°C) or even higher.

Ceramic-based glues are highly sought after for applications requiring heat resistance. These glues incorporate ceramic particles that provide excellent resistance to high temperatures. They can withstand scorching temperatures up to 2000°F (1093°C) or more, making them indispensable in industries such as kiln manufacturing or foundry operations.

Polyimide glues, also known as Kapton glues, are specifically designed for extreme heat environments. These glues excel in industries like aerospace and electronics, where they must withstand temperatures up to 500°F (260°C) or higher.

Additionally, there are heat-activated adhesives available that require the application of heat to initiate the bonding process. These adhesives offer a strong and durable bond at high temperatures and act as secret weapons in challenging situations.

While specialized heat-resistant glues deliver exceptional resistance to high temperatures, it is crucial to consider other factors such as chemical resistance and flexibility. Each adhesive has its own limitations, so it is important to assess the specific requirements of the application and choose the appropriate glue accordingly.

Benefits of Using Heat-Resistant Glues

In the realm of high-temperature applications, heat-resistant glues reign supreme as the superheroes of the adhesive world. These remarkable adhesives are designed to withstand scorching temperatures without sacrificing bond strength, making them indispensable in industries like automotive, aerospace, electronics, and construction. In this article, we will delve into the extraordinary benefits of using heat-resistant glues and uncover why they are the ultimate solution for bonding materials exposed to extreme heat.

Unyielding Bond Strength at High Temperatures:

Heat-resistant glues possess a singular advantage – their unwavering ability to maintain bond strength even amidst blistering temperatures. This ensures that components and materials remain steadfastly joined together, providing unparalleled peace of mind in high-temperature environments.

Defying Thermal Expansion and Contraction:

These glues offer an extraordinary resistance to thermal expansion and contraction that often accompanies extreme temperature changes. By thwarting these forces, heat-resistant glues prevent any loosening or weakening of bonds over time, guaranteeing longevity and reliability for bonded assemblies.

Invincible against Harsh Chemical Exposure:

Another remarkable benefit of heat-resistant glues is their exceptional chemical resistance. They possess an inherent ability to withstand exposure to harsh chemicals or solvents, rendering them indispensable in applications where chemical resistance is paramount.

Withstanding the Rigors of Thermal Stress and Vibrations:

Heat-resistant glues exhibit astonishing flexibility and elasticity, enabling them to endure thermal stress and vibrations without succumbing to cracks or peeling. This ensures that bonds remain unbroken even in dynamic environments, where stability is paramount.

Durability and Longevity Par Excellence:

Renowned for their durability and unwavering longevity, heat-resistant glues retain their adhesive properties even under continuous exposure to high temperatures. This ensures that bonded materials remain securely in place over extended periods, withstanding the test of time.

Additional Powers:

Beyond their heat resistance, some heat-resistant glues offer additional desirable properties such as electrical insulation, flame retardancy, and UV resistance. This versatility makes them indispensable across a wide spectrum of applications, further enhancing the overall performance and reliability of products or assemblies.

6Lf51lg3drY” >

Also Read: Krazy Glue – Glue Things

Conclusion

When it comes to finding a glue that can withstand high temperatures, the options may seem limited.

But fear not, there are glues out there that won’t melt under intense heat. These special glues are designed to maintain their adhesive properties even when faced with extreme temperatures.

So whether you’re working on a project that requires bonding materials in a hot environment or simply want to ensure your glued items stay intact during heat exposure, these heat-resistant glues are the answer. They provide a reliable and durable bond that won’t weaken or melt away when things start heating up.

Say goodbye to worries about your glued items falling apart under high temperatures – with these glues, you can trust that your bonds will remain strong and secure.