Welcome to our blog post delving into the sheer might of epoxy glue when it comes to taming metal.

Whether you’re a DIY aficionado or a seasoned pro, uncovering the dependability and resilience of this adhesive is paramount for a plethora of metal projects. In this article, we’ll plunge headfirst into the scientific intricacies behind epoxy glue and its unparalleled bonding prowess, particularly on metal surfaces.

We’ll dissect the elements that contribute to its unyielding strength and showcase real-life instances where it has triumphed. So, if you’re itching to know whether epoxy glue is the holy grail for your metallic pursuits, you’ve stumbled upon the perfect oasis.

Let’s embark on this enlightening journey.

What is Epoxy Glue?

Contents

When it comes to bonding metal surfaces, you need an adhesive that can withstand the test of time. Enter epoxy glue, a powerful adhesive that has become the go-to choice for various industries, from construction to automotive. In this blog post, we’ll delve into the world of epoxy glue, exploring its composition, strength, and versatility.

Unleashing the Strength:

Epoxy glue derives its strength from its unique composition. It consists of two components – epoxy resin and a hardener – which, when mixed together, create a chemical reaction that forms an incredibly strong bond. This bond is often even stronger than the materials being joined together.

Penetrating at a Molecular Level:

One of the reasons why epoxy glue is so effective in metal bonding is its ability to penetrate and bond at a molecular level. Unlike other adhesives that struggle to adhere to smooth and low-porosity metal surfaces, epoxy glue creates robust intermolecular bonds with the metal, resulting in a durable and long-lasting connection.

Defying Environmental Challenges:

Epoxy glue doesn’t back down when faced with environmental factors that can compromise the strength of a bond. It boasts excellent resistance to moisture, chemicals, heat, and solvents, making it suitable for both indoor and outdoor applications. Rain or shine, your metal bond will remain intact.

Gap-Filling Magic:

Not only does epoxy glue provide exceptional strength, but it also has superb gap-filling properties. It can fill in small gaps or irregularities between metal surfaces, ensuring a more secure and reliable connection. No need to worry about slight imperfections – epoxy glue has got you covered.

Dimensional Stability at Its Finest:

Temperature fluctuations can wreak havoc on adhesive bonds. However, epoxy glue exhibits excellent dimensional stability, meaning it retains its shape and size even under different temperature conditions. So whether it’s scorching hot or freezing cold, your metal bond will stay strong.

Versatility in Applications:

Epoxy glue is not limited to metal bonding alone. It can also be used for a wide range of materials, including ceramics, plastics, and even wood. Whether you’re repairing a broken ceramic vase or creating intricate crafts, epoxy glue is a versatile adhesive that can handle the task.

Factors that Contribute to Epoxy Glue Strength

When it comes to bonding metal surfaces, epoxy glue is the superhero of adhesives. Its exceptional adhesive properties make it the go-to choice for industries ranging from automotive to aerospace. But what exactly makes epoxy glue so strong? In this blog post, we will unravel the key factors that contribute to the strength of epoxy glue when bonding metal surfaces.

Adhesive Properties of Epoxy:

Epoxy glue’s unmatched adhesive strength stems from its unique chemical composition. The resin and hardener components undergo a chemical reaction, creating cross-linking and a tight network of polymer chains. This molecular structure provides excellent bonding strength, ensuring a durable and long-lasting bond between metal surfaces.

Surface Preparation:

Proper surface preparation is crucial for maximizing the strength of epoxy glue on metal surfaces. Thoroughly cleaning the metal surface and removing any dirt, grease, or oxidation is essential. Additionally, roughening the surface using sandpaper or a wire brush enhances mechanical bonding, allowing the epoxy to grip onto the metal more effectively.

Mixing Ratio and Curing Time:

Achieving the perfect mix between resin and hardener is vital for optimal epoxy glue strength. Deviating from the recommended mixing ratio can negatively impact the curing process and weaken the bond. Similarly, allowing sufficient curing time, considering factors like temperature and humidity, ensures that the epoxy reaches its full strength potential.

Temperature Resistance:

Epoxy glues excel in withstanding extreme temperatures, making them ideal for metal bonding applications. Whether it’s high heat or freezing cold, epoxy maintains its adhesive properties. This characteristic is especially crucial for metal parts that may be exposed to varying temperature conditions during their use.

Mechanical Properties of Epoxy:

The mechanical properties of epoxy glues play a significant role in their strength. With high tensile strength, shear strength, and impact resistance, epoxy glues can withstand various stress and load conditions. By selecting an epoxy adhesive with suitable mechanical properties for the specific metal application, the bond’s strength can be further enhanced.

Compatibility with Metal Alloys:

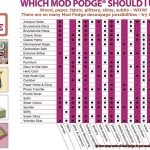

Different metals and metal alloys have unique surface characteristics that can affect adhesive strength. Choosing an epoxy adhesive that is compatible with the specific metal or alloy being bonded is essential. Some epoxy formulations are designed specifically for bonding certain metals, ensuring optimal adhesion and strength.

Tensile Strength of Epoxy Glue

Epoxy glue is like the superhero of adhesives when it comes to bonding metal surfaces. Its exceptional adhesive properties make it the go-to choice for industries ranging from automotive to aerospace. But what makes epoxy glue so special? Well, it’s all about its high tensile strength.

Tensile strength is a measure of the maximum amount of tensile or pulling force that a material can withstand before breaking or fracturing. And let me tell you, epoxy glue is no weakling in this department. In fact, the bond created by epoxy glue can often be stronger than the materials being joined, providing a reliable and long-lasting connection.

So, what factors contribute to epoxy glue’s impressive tensile strength? Let’s break it down.

- Formulation: The specific formulation of the epoxy adhesive plays a significant role. Different epoxy adhesives may have different tensile strength ratings, so it’s essential to choose the right one for your specific metal application. Industrial-grade epoxy adhesives can offer tensile strengths exceeding 10,000 pounds per square inch (psi) – that’s some serious strength.

- Chemical Composition: The unique chemical composition of epoxy glue also contributes to its high tensile strength. Epoxy adhesives typically consist of two components: resin and hardener. When these components are mixed together, they undergo a chemical reaction called curing. This process transforms them into a strong and durable adhesive by cross-linking the epoxy resin molecules with each other and with the molecules of the metal surface. These chemical bonds create a tight network of polymer chains that give epoxy glue its incredible strength.

- Surface Preparation: To achieve optimal tensile strength when using epoxy glue for metal bonding, proper surface preparation is crucial. The metal surfaces should be clean, dry, and free from any contaminants or oxides that could hinder adhesion. Abrasive techniques such as sanding or roughening the surface can enhance mechanical interlocking between the epoxy and the metal, further improving tensile strength.

However, it’s important to note that while epoxy glue offers high tensile strength for metal bonding, it may have lower shear or peel strength. Shear strength refers to the resistance of the adhesive to sliding or shearing forces, while peel strength refers to its resistance to being peeled or pulled apart. Therefore, when choosing an epoxy glue for metal applications, it’s essential to consider the specific requirements of the bonding joint and select an adhesive that provides adequate strength in all relevant directions.

Shear Strength of Epoxy Glue

Get ready to embark on a journey into the world of adhesive superheroes as we uncover the secrets behind the shear strength of epoxy glue for metal bonding. Prepare to be equipped with the knowledge to conquer any bonding challenge and witness the incredible strength of this adhesive powerhouse.

Surface Preparation: The Crucial First Step

Before diving into the nitty-gritty details of epoxy glue’s shear strength, let’s start with the basics – surface preparation. Just like a superhero needs a clean slate to save the day, epoxy glue needs a clean and dry surface to work its magic. Dust, oils, and rust are the enemies of adhesion, so thorough cleaning of metal surfaces is essential. By ensuring a pristine surface, you enhance the adhesive bond and unleash the full potential of epoxy glue’s shear strength.

Curing Conditions: The Heroic Transformation

Once the surfaces are prepared, it’s time for the transformation process known as curing. Imagine your adhesive superhero donning its cape and becoming unstoppable. Follow the manufacturer’s instructions regarding curing time and temperature to unleash the full potential of your epoxy glue’s shear strength. Cutting corners here could weaken your bond and compromise your project’s integrity. Embrace patience and allow your adhesive superhero to reach its maximum strength.

Epoxy Formulation: Finding Your Perfect Sidekick

Not all epoxy glues are created equal. Each formulation possesses its own superpowers, so choose wisely. Seek out an epoxy specifically designed for metal bonding that offers exceptional shear strength. These industrial-grade epoxies possess tensile strengths exceeding 10,000 psi, enabling them to tackle even the toughest challenges. Remember, your chosen epoxy formulation will determine the ultimate strength of your bond.

The Nature of the Metal: A Match Made in Bonding Heaven

Just like superheroes team up to save the world, epoxy glue finds its perfect match in certain metals. Rougher metal surfaces or those capable of forming chemical bonds with the epoxy tend to exhibit higher shear strength. Fear not, even metals with smoother surfaces can achieve strong bonds with proper surface preparation and the right epoxy adhesive. The key lies in understanding the unique properties of each metal and selecting an epoxy that complements its characteristics.

Impact Resistance of Epoxy Glue

Epoxy glue is renowned for its exceptional strength and bonding capabilities, but its impact resistance sets it apart as a truly formidable adhesive. When faced with the toughest challenges, epoxy glue remains unruffled, effortlessly withstanding sudden forces and impacts.

So, what makes epoxy glue so resilient? Several key factors contribute to its remarkable impact resistance. First and foremost, the specific formulation of the glue plays a pivotal role. Epoxy glues formulated explicitly for bonding metal surfaces exhibit even higher impact resistance than regular epoxy adhesives. Therefore, when working with metal, it is crucial to select the appropriate epoxy glue for the task at hand.

However, there are additional methods to bolster the impact resistance of epoxy glue. By incorporating additives or fillers during the formulation process, the flexibility and toughness of the cured epoxy can be enhanced. These additives act as an extra layer of armor, fortifying the epoxy against impacts.

Of course, proper surface preparation also factors into maximizing impact resistance. Before applying epoxy glue to metal surfaces, thorough cleaning and roughening of the surface are essential. This ensures a superior bond and improves the adhesive’s ability to withstand impacts.

Furthermore, attention must be given to the curing process. Adhering to the manufacturer’s instructions regarding curing time and temperature is imperative for achieving optimal bond strength and impact resistance. Rushing this process would be ill-advised; instead, afford your epoxy glue the time it needs to reach its full potential.

It is worth noting that while epoxy glue is a reliable choice for most applications, exceedingly high impact forces may necessitate alternative solutions such as mechanical fasteners or welding. Nonetheless, for everyday challenges, epoxy glue emerges as the go-to hero.

Surface Preparation for Optimal Bond Strength

Epoxy glue is the superhero of metal bonding, known for its incredible strength and resilience. But even superheroes need preparation to ensure they can save the day. In this article, we will explore the importance of surface preparation when using epoxy glue on metal surfaces.

Step 1: Cleanse and Purify

Before applying epoxy glue, banish all dirt, grease, oil, and contaminants from the metal surface. Give your adhesive a clean canvas by using a suitable solvent or degreaser. Make sure there is no trace of the enemy substances.

Step 2: Roughen Up

To create a bond that can stand the test of time, roughening up the metal surface is key. Use sandpaper, abrasive pads, or a wire brush to give the surface a textured makeover. By doing so, you provide more surface area for the adhesive to grip onto, ensuring a strong and lasting bond.

Step 3: Taming the Oxide Layer

Some metals, like aluminum, have a natural oxide layer that can hinder adhesion. Conquer this foe by removing or treating the oxide layer before applying epoxy glue. Chemical treatments or mechanical methods like acid etching can help you tame this villain and ensure a solid bond.

Step 4: Banish Moisture

Moisture can be the arch-nemesis of epoxy glue on metal surfaces. It can weaken bond strength and lead to failure. Make sure the metal surface is completely dry before applying the adhesive. Use compressed air or heat to eliminate any lingering moisture. Leave no room for water to sabotage your bond.

Adhesive Application Techniques for Maximum Bond Strength

Look no further. In this blog post, we will delve into the world of adhesive application techniques for achieving maximum bond strength when using epoxy glue on metal. Whether you’re a DIY enthusiast or a professional in need of a reliable adhesive, these tips and tricks will help you unleash the full potential of your epoxy glue.

Surface Preparation:

Before embarking on your adhesive adventure, it’s crucial to prepare the metal surface properly. Begin by ensuring it is clean, dry, and free from any contaminants like oil, grease, rust, or dirt. Use a degreaser or solvent to eliminate any oily residues and follow up with sanding or wire brushing to remove rust and corrosion. This step creates a pristine canvas for your epoxy glue to work its magic.

Applying the Right Amount:

To achieve a strong bond, it’s essential to apply the epoxy adhesive evenly and in the correct amount. Too little adhesive may result in a feeble bond, while excessive application can lead to wastage and messy squeeze-out. Follow the manufacturer’s instructions regarding the recommended amount of adhesive for your specific metal and application requirements.

Uniform Application:

When applying epoxy glue on metal surfaces, opt for a brush or spreader to ensure an even distribution of the adhesive. This technique guarantees that every nook and cranny is coated with the glue, maximizing contact between the adhesive and the metal. With this superhero-level coverage, your bond will be unbreakable.

Embrace the Power of Pressure:

During the curing process, applying pressure is crucial for achieving intimate contact between the adhesive and metal surfaces. Secure your bond by using clamps, weights, or even tape/straps to hold the parts together tightly. This superhero technique will ensure your bond stands strong against any challenge it may face.

Optimal Curing Conditions:

Just like superheroes need the right training to unleash their full potential, epoxy adhesives require optimal curing conditions. Follow the manufacturer’s instructions regarding temperature range and curing time to ensure your adhesive reaches its maximum strength. Don’t rush the process – patience is key for an unbreakable bond.

Advanced Techniques for Enhanced Strength:

For those seeking an extra-strong bond, consider advanced techniques such as roughening the metal surfaces with sandpaper or creating small grooves. These techniques increase the surface area available for bonding, enhancing adhesion. Additionally, using primers or adhesion promoters specifically designed for metal surfaces can take your bond strength to new heights.

XObmZIbHOzY” >

Also Read: How to Glue Metal to Glass?

Conclusion

To wrap it up, epoxy glue is a beast when it comes to sticking metal together. Its unique formula dives deep into the molecular level, conquers environmental challenges, and fills in any gaps with ease. This makes it a reliable choice for all your metal projects.

The secret behind epoxy glue’s Herculean strength lies in its adhesive properties, surface preparation, mixing ratio, curing time, temperature resistance, mechanical properties, and compatibility with different metal alloys. By mastering these factors, you can unleash the full power of epoxy glue on metal surfaces.

When it comes to tensile strength, epoxy glue is a true warrior. It can withstand pulling forces like a champ and create an unbreakable bond between metals. But don’t forget about shear strength and impact resistance – they’re important players too when choosing the right epoxy adhesive for your project.

Prepare yourself for victory by prepping those metal surfaces properly. Clean them thoroughly, roughen them up if needed, banish any oxide layers or contaminants, and make sure they’re as dry as the desert sun. Only then will you be ready to conquer your bonding mission.

Applying epoxy glue like a pro requires finesse. Spread it evenly with brushes or spreaders, use just the right amount of adhesive (no more, no less), apply pressure during curing like a boss, and follow the optimal curing conditions to achieve maximum bond strength.

For those who crave even stronger bonds, advanced techniques are at your disposal. Roughen those metal surfaces further or bring in primers or adhesion promoters specifically designed for metals – they’ll take your bond strength to new heights.

In a nutshell, epoxy glue is a force to be reckoned with when it comes to bonding metal surfaces. Its incredible strength and resilience will never let you down.