Are you looking to create beautiful works of art with metal and glass? Glueing metal to glass can seem like a daunting task. But, with the right materials and techniques, it’s easy. In this blog post, we’ll explore which adhesives work best for the job. We’ll also discuss how to prepare the surfaces before applying the glue. Plus, how to make your project run as smoothly as possible.

If you want to learn how to glue metal to glass like a pro, keep reading. You’ll be surprised at just how simple it is. With just a few basic steps, you can create stunning works of art that will last for years. Get ready to get started on your craft project.

Types of Adhesives for Gluing Metal to Glass

Contents

Gluing metal to glass can be a tricky task, but the right adhesive will make it much easier. Several types of adhesives exist that are suitable for bonding metal to glass, including epoxy, cyanoacrylate, silicone, and polyurethane. Each adhesive has unique properties that make it suitable for different types of projects.

Epoxy adhesives create a strong bond that is resistant to extreme temperatures and stress. They are ideal for large metal pieces that need a secure hold. Silicone adhesives remain flexible even after curing and are great for attaching smaller metal pieces to glass or projects in environments with moisture or UV exposure.

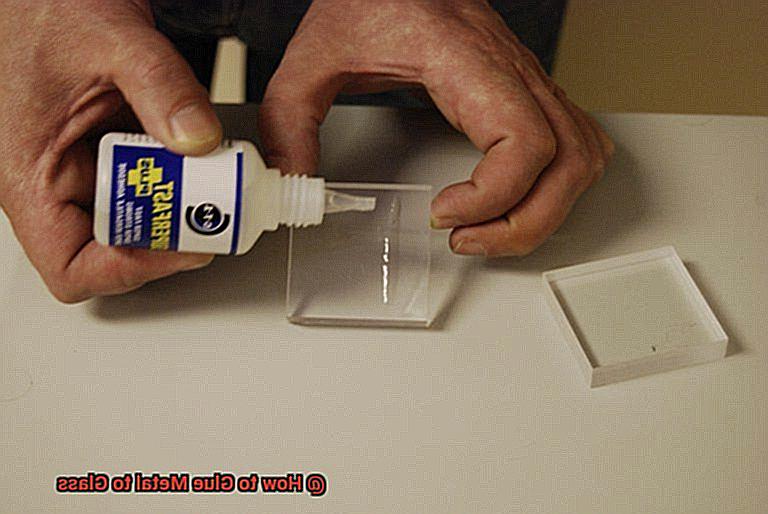

Polyurethane adhesives are the best choice if you need an adhesive that can withstand heat and vibration. This type of adhesive bonds well to various surfaces like metal and glass, making it perfect for attaching metal pieces to surfaces that experience constant movement or vibration. Cyanoacrylate (superglue) is also an excellent option for minor repairs or gluing small metal pieces to glass because it bonds quickly and forms a strong bond in seconds.

For any project involving gluing metal to glass, proper preparation is essential. Both the metal and glass must be clean, dry, and free of grease before applying the adhesive according to the manufacturer’s instructions.

Preparing the Surfaces for Gluing

Creating a successful bond between metal and glass requires careful preparation of the surfaces. To begin, it is essential to thoroughly clean both the metal and glass surfaces with a solvent such as acetone or isopropyl alcohol in order to remove any dirt, grease, or contaminants. Additionally, it is important to consider the type of metal and glass being used, as different materials may require slightly different preparation techniques.

Once the surfaces are clean, they should be roughened up slightly using sandpaper or a rough cloth. This will create a better surface for the adhesive to bond to, especially for smooth glass surfaces which can be difficult for adhesives to adhere to.

Finally, it is important to follow the manufacturer’s instructions for the adhesive being used when preparing the surfaces. Different adhesives may require different preparation techniques, and following these instructions carefully will help ensure that you achieve a strong and long-lasting bond between your metal and glass surfaces.

Gorilla Glue and its Limitations

Gorilla Glue has earned a reputation for its strong holding power, but it may not be the best choice when trying to bond metal to glass. This is because the glue expands as it dries, which can cause the glass to crack or break. In addition, Gorilla Glue is opaque and may leave behind unsightly residue that cannot be removed.

For metal and glass bonding, an epoxy or silicone adhesive is usually the better option. These adhesives are designed specifically for this purpose, and they provide a strong and lasting bond that won’t be affected by changes in temperature or humidity over time. It’s also important to consider the type of metals you’re working with; Gorilla Glue sticks best to porous surfaces, so it might not be suitable for joining two smooth or non-porous metals together.

Silicone Adhesive

Look no further than silicone adhesive. This versatile adhesive offers an exceptionally strong bond that is resistant to water, heat, and UV radiation. It is an ideal choice for applications that require a watertight seal, such as automotive, construction, and manufacturing.

Before using silicone adhesive for your project, it’s essential to prepare the surfaces properly. Start by cleaning the metal and glass with an appropriate cleaner, such as rubbing alcohol or a degreasing agent. Allow the surface to dry completely before applying the adhesive. When ready, squeeze a small amount of silicone onto one of the surfaces and spread it evenly using a brush or spatula. Press the two surfaces together firmly until the adhesive sets.

The great thing about silicone adhesive is its ability to fill gaps and provide an excellent seal. However, keep in mind that this type of adhesive may take longer to cure than other adhesives, so make sure you allow for ample curing time before using the bonded object.

Epoxy Adhesive

Epoxy adhesive is a powerful bonder when it comes to metal to glass projects. This two-part mixture of resin and hardener creates an unbreakable chemical reaction that will keep your materials together for years to come.

Make sure you clean and dry the surfaces with a degreaser or rubbing alcohol before applying the epoxy, then mix the resin and hardener according to the manufacturer’s instructions and apply a thin layer over both surfaces. Press them together and hold in place until they form a bond.

One of the best parts of epoxy adhesive is that once it has dried, you can sand it down and paint over it for a seamless finish. This makes it ideal for projects that require an invisible tie between metal and glass.

But beware: epoxy adhesives can be toxic, so make sure you use them in a well-ventilated area while wearing protective gloves and goggles. Be sure to follow the manufacturer’s instructions closely for safe and successful application.

Epoxy adhesive is truly superhero material when it comes to bonding metal to glass.

Polyurethane Adhesive

Polyurethane adhesive is an ideal solution for bonding metal to glass. It provides a strong mechanical bond that can withstand high stress and strain, making it an invisible yet reliable choice. Plus, its waterproof properties make it suitable for outdoor projects and applications.

Before you get started, ensure the surfaces of both the metal and the glass are thoroughly cleaned and dried – any oil, dirt, or dust on the surface will prevent the adhesive from bonding properly.

Once ready, apply the adhesive to one surface and press together with the other surface as soon as possible. Clamping or some sort of support may be necessary to hold them together while curing, but this typically takes a few hours to reach full strength.

The great thing about polyurethane adhesive is that it can be sanded or painted over once it has cured. Whether you need a smooth finish with no visible glue lines or just want to match the surface color – this adhesive makes it easy. If there are any excess adhesive or rough edges, simply sand them down until they’re smooth.

Polyurethane adhesive is an excellent choice for gluing metal to glass due to its strength and durability.

zXDb4cBewGo” >

Attaching Metal Legs to a Glass Table

Attaching metal legs to a glass table can seem like an intimidating task, but with the right tools and techniques, it can be done quickly and securely. The key is to choose the correct adhesive for the job.

Epoxy, cyanoacrylate (also known as super glue or instant glue), and silicone adhesive are all suitable options. Each type has its own advantages and drawbacks, so selecting the one that best suits your project is essential.

Once you’ve picked out your adhesive, it’s time to prepare the surfaces. Cleaning them with rubbing alcohol or acetone will remove any dirt, grease, or other contaminants.

When both surfaces are clean and dry, apply a thin layer of adhesive to one of them and press them firmly together. Hold them in place until the adhesive is fully cured – this may take anywhere from a few minutes to several hours depending on the brand of adhesive used and the room’s climate.

In some cases, additional support may be needed to make sure that the metal legs remain securely attached to the glass table. Adding brackets or other hardware to the underside of the table can help ensure that your glass table remains sturdy and functional for years to come.

Also Read: How to Glue Metal to Glass – Glue Things

Conclusion

Gluing metal to glass might seem intimidating, but with the right materials and techniques it’s a breeze. There are several adhesive options available, depending on your project. Epoxy and silicone adhesives provide strong, long-lasting bonds that can withstand extreme temperatures, humidity, and UV light exposure.

Polyurethane is ideal for projects requiring a waterproof coating or that are prone to vibration or movement. And aluminum-to-glass adhesive is the most suitable choice for attaching aluminum to glass as it offers superior strength and durability.

No matter which adhesive you select, proper preparation of both surfaces is essential for a strong bond. Start by cleaning them with rubbing alcohol or acetone and then roughen them up a bit with sandpaper or a rough cloth. And don’t forget to follow the manufacturer’s instructions when preparing the surfaces.