Ever found yourself in a sticky situation (literally) trying to stick metal to glass? Whether you’re crafting a killer lantern or fixing up a delicate ornament, finding the right glue is key.

But fear not, my friends. Today, we’re diving headfirst into the mesmerizing world of adhesives and uncovering the secret formula for creating an unbreakable bond between metal and glass.

We’ll tackle everything from durability and temperature resistance to ease of application, exploring the top contenders in the glue market. So grab your safety glasses and brew yourself a cup of joe – because we’re about to embark on a journey to discover the absolute best glue for sticking metal to glass.

Factors to Consider When Choosing Adhesive for Bonding Metal to Glass

Contents

When it comes to bonding metal to glass, selecting the right adhesive is crucial for achieving a strong and durable bond. With numerous options available in the market, it can be overwhelming to determine which adhesive is best suited for your specific needs. In this comprehensive guide, we will explore the key factors to consider when choosing an adhesive for bonding metal to glass.

Compatibility:

To ensure optimal adhesion and a long-lasting bond, it is essential to select an adhesive specifically designed for bonding metal and glass surfaces. Compatibility is the foundation of a successful bond, so be sure to choose an adhesive that is formulated for this purpose.

Strength:

Consider the weight and stress that will be placed on the bond. Look for adhesives with high tensile and shear strength, as they provide the necessary support for heavy materials like metal and glass. A strong adhesive ensures that your bond remains intact under various conditions.

Temperature Resistance:

Evaluate the temperature conditions the bonded assembly will be exposed to. Select an adhesive that can withstand extremes in temperature without compromising its strength or becoming brittle. This factor ensures that your bond remains stable and reliable, even in challenging environments.

Flexibility:

Metal and glass have different rates of expansion and contraction when exposed to temperature changes. This difference can strain the bond over time, potentially leading to failure. Opt for an adhesive with good flexibility to accommodate these differences and maintain bond integrity. A flexible adhesive helps prevent stress on the bond and enhances its longevity.

Transparency:

If aesthetics are important, choose an adhesive that dries clear or has minimal visible residue. This ensures that the bond line remains virtually invisible, enhancing the overall appearance of the metal and glass assembly. A transparent bond enhances the visual appeal of your project.

Chemical Resistance:

Consider the potential exposure to chemicals and select an adhesive that is resistant to them. Chemical resistance ensures that your bond remains unaffected even when exposed to cleaning agents or solvents. This factor is particularly crucial in applications where the bonded assembly encounters harsh chemical environments.

Application Method:

Evaluate the ease of application and ensure you have the necessary tools or equipment for effective adhesive application. Consider whether a liquid adhesive that requires mixing or a pre-mixed/solid adhesive would be more suitable for your project. Choosing the right application method simplifies the bonding process and ensures proper adhesive coverage.

Epoxy Adhesive

You need epoxy adhesive, the ultimate adhesive for this task. With its exceptional bonding strength, resistance to temperature fluctuations, and ability to withstand moisture and chemicals, epoxy adhesive is the go-to choice for various applications.

Let’s start with the incredible bonding strength of epoxy adhesive. When you need a bond that can withstand pulling forces without breaking or coming apart, epoxy adhesive delivers. From attaching metal brackets to glass shelves to affixing decorative metal accents to glass surfaces, epoxy adhesive keeps everything securely in place.

But that’s not all – epoxy adhesive also triumphs over temperature fluctuations. When metal and glass expand and contract at different rates due to heat or cold, epoxy adhesive remains unfazed. It can handle scorching kitchen environments or freezing cold workshops with ease, maintaining its strength regardless of the temperature.

And there’s more. Epoxy adhesive boasts excellent resistance to moisture and chemicals. No need to worry about water, oils, solvents, or other substances compromising your bond when using epoxy adhesive. It stands up to these elements, ensuring a reliable bond that won’t be weakened by exposure.

To achieve optimal results with epoxy adhesive, proper application techniques are crucial. Start by ensuring the surfaces being bonded are clean and free from dirt, oils, or contaminants. This paves the way for a strong and lasting bond. Additionally, follow the manufacturer’s instructions regarding the mixing ratio and curing time specific to your chosen epoxy adhesive.

Cyanoacrylate Glue (Super Glue)

If you’re seeking an adhesive that can bond metal to glass effortlessly, look no further than the remarkable cyanoacrylate glue, also known as Super Glue. In this guide, we’ll explore the incredible properties and uses of this adhesive powerhouse, as well as provide you with step-by-step instructions and safety precautions. So grab your safety goggles and get ready to discover the world of Super Glue.

Properties of Cyanoacrylate Glue:

- Strong Bonding: Cyanoacrylate glue forms an incredibly strong bond between various materials, including metal and glass. Its ability to create a secure connection in a matter of seconds is simply astounding.

- Quick Drying: One of the standout features of Super Glue is its rapid drying time. Once applied, it dries within seconds, allowing you to proceed with your project without delay.

- Versatility: Whether you’re working with metals, glass, plastics, or ceramics, cyanoacrylate glue is a versatile adhesive that can handle it all. Its effectiveness across different materials makes it a go-to choice for various DIY projects.

Using Cyanoacrylate Glue:

Step 1: Prepare the Surfaces

To ensure optimal bonding, clean both the metal and glass surfaces thoroughly using a mild detergent and water solution or a clean cloth. Removing dirt and debris is crucial for a successful bond.

Step 2: Apply with Precision

Less is more when it comes to applying Super Glue. Use a precision applicator or toothpick to apply a small amount of glue to one of the surfaces. Avoid excessive amounts that may result in messiness or overflow.

Step 3: Press and Hold

Align the metal and glass surfaces, pressing them together firmly. Maintain pressure for a few seconds to allow the glue to bond effectively. This patience will reward you with a sturdy and long-lasting connection.

Step 4: Smoothness Boosts Strength

For an extra-strong bond, ensure that both surfaces are smooth. If either the metal or glass has roughness or texture, consider sanding or polishing it beforehand. This step creates an ideal surface for the glue to adhere to, enhancing its strength.

Safety Precautions:

When using cyanoacrylate glue, prioritize safety with these precautions:

- Protect Your Skin: Super Glue bonds skin together almost instantly. Avoid any bare skin contact. If accidental bonding occurs, soak the affected area in warm soapy water or use an acetone-based nail polish remover to dissolve the glue.

- Proper Ventilation: Work in a well-ventilated area to avoid inhaling the fumes from Super Glue. Open windows or use a fan to circulate the air, ensuring a comfortable and safe working environment.

Eye Protection: Shield your eyes from accidental splashes by wearing safety goggles or glasses.

Silicone Adhesive

Today, we will delve into the realm of silicone adhesive and its remarkable ability to bond metal to glass. Whether you are a DIY enthusiast or a professional craftsman, understanding the advantages of silicone adhesive can elevate your projects to new heights. So hold on tight as we explore the enchanting properties of this extraordinary glue.

Flexibility that Endures:

Imagine a glue that can stand the test of time, never losing its grip despite movement and vibrations. Enter silicone adhesive, the ultimate bonding agent. Unlike other adhesives that become brittle with age, silicone adhesive remains flexible, making it perfect for projects where metal and glass need to expand or contract together. From automotive projects to awe-inspiring construction marvels, this adhesive has your back.

Weather Warrior:

Mother Nature can be unpredictable, but silicone adhesive laughs in the face of extreme temperatures. Whether faced with scorching heat or bone-chilling cold, this glue stands strong. So, if you are working on an outdoor project involving metal and glass bonding, rest assured that silicone adhesive will keep its bond firm and unwavering.

Waterproof Wonder:

Isn’t it frustrating when water seeps through your carefully crafted bond? Fear not. Silicone adhesive forms an impenetrable waterproof seal that repels moisture like a superhero protecting its territory. Bid farewell to worries about water damage or leaks because this trusty glue has got your back.

Chemical Resistant Champion:

If you are dealing with corrosive substances or working in an environment where chemicals abound, silicone adhesive is your go-to companion. It resists the harmful effects of many chemicals, enabling you to tackle projects worry-free. From industrial settings to cutting-edge laboratories, this adhesive is a true champion in the face of chemical challenges.

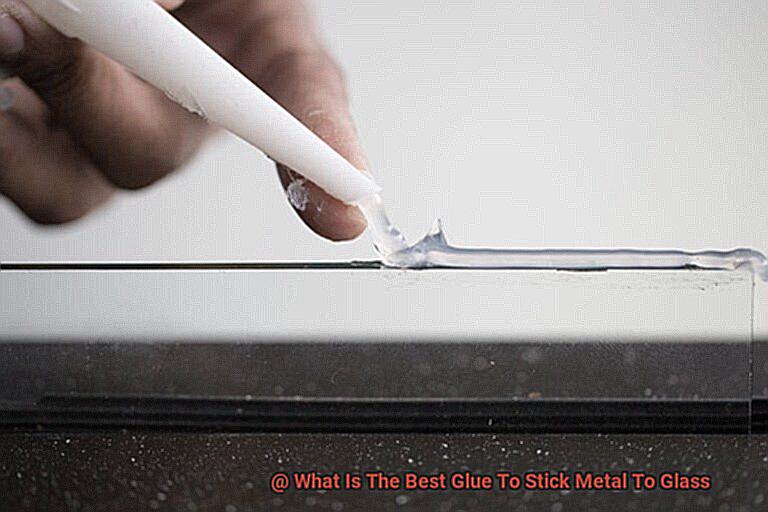

Application Tips:

To ensure a flawless bond between metal and glass, proper surface preparation is essential. Cleanliness is key. Use a degreaser or alcohol-based cleaner to remove any dirt, grease, or oils from both surfaces. Once clean and dry, apply a small amount of silicone adhesive and spread it evenly using a brush or spatula. Press the metal and glass together firmly, holding them in place for a few minutes to allow the adhesive to set. Consider using clamps or tape to secure the bond during the curing process.

UV-Curing Adhesives

In this blog post, we will explore the advantages and key considerations of using these magical glues for metal-to-glass bonding applications. Prepare to be amazed by their fast curing time, excellent bond strength, and versatile nature.

Advantages:

UV-curing adhesives offer several advantages that make them an ideal choice for metal-to-glass bonding applications.

Lightning-Fast Curing Time:

Say goodbye to long waiting periods. UV-curing adhesives work their magic in mere seconds when exposed to UV light. This rapid curing time allows for accelerated production processes, increasing efficiency and productivity.

Unbreakable Bonds:

UV-curing adhesives are known for their exceptional bond strength. They form robust and durable bonds between metal and glass surfaces, ensuring that assemblies withstand high levels of stress and temperature variations without compromising integrity.

Versatility at its Finest:

UV-curing adhesives are true chameleons. They can bond various types of metals, including stainless steel, aluminum, and copper, to different glass substrates such as borosilicate, soda-lime, and tempered glass. This versatility makes them ideal for a wide range of applications.

Key Considerations:

While UV-curing adhesives offer many benefits, it is important to consider certain factors when selecting the right adhesive for your metal-to-glass bonding needs.

Compatibility is Key:

Not all UV-curing adhesives are created equal. It is crucial to select an adhesive that is compatible with the specific metals and glass substrates you’re working with. Some adhesives may not adhere well to certain surfaces or may even cause damage.

Strength Matters:

Consider the required bond strength for your application. Some UV-curing adhesives offer higher bond strengths than others, which may be necessary for applications subjected to significant stress or load.

Resistance is Vital:

Evaluate the adhesive’s resistance to environmental factors such as temperature, moisture, and chemicals. This is particularly important for applications exposed to harsh conditions. Ensure that the adhesive can withstand the elements and maintain its bond integrity over time.

Time is Money:

Assess the curing time of the adhesive and determine if it aligns with your production requirements. Some adhesives cure faster than others, allowing for increased productivity and shorter cycle times.

Surface Preparation for Bonding Metal to Glass

Achieving a strong and durable bond between metal and glass may seem like a mystery, but fear not. I’m about to reveal the secrets of surface preparation for bonding metal to glass using glue. Get ready to dive into the captivating world of adhesion.

First and foremost, cleanliness is absolutely crucial. Before applying any adhesive, it is imperative to thoroughly clean the surfaces of both the metal and glass. We don’t want any dirt, dust, or grease getting in the way of a perfect bond, do we? So grab a mild detergent or solvent, roll up your sleeves, and give those surfaces a good scrub. Once they’re squeaky clean, rinse them off with water to remove any residue.

Now that we’ve got cleanliness covered, let’s talk about removing any existing coatings. If there are any finishes or coatings on either the metal or glass, they have got to go. These sneaky coatings can prevent proper adhesion between the two materials. But worry not. We have some tricks up our sleeves. You can use sanding, chemical stripping, or even abrasive blasting methods to strip away those barriers.

Now comes the fun part – roughening the surfaces. Both the metal and glass surfaces need a bit of texture to enhance adhesion. It’s like giving them a little grip to hold onto each other tightly. For the metal, grab some fine-grit sandpaper or a wire brush and lightly sand away to create a slightly rough texture. But be careful not to go overboard and damage the metal surface. As for the glass, you can use a glass etching solution or sandblasting to create that roughened surface.

Once your surfaces are cleaned and roughened, it’s time to let them dry. Moisture is not your friend when it comes to bonding metal to glass, so make sure those surfaces are bone dry before proceeding. You can either let them air dry or use a clean, lint-free cloth to speed up the process.

Now, here’s a little bonus step – applying a primer. Depending on the adhesive you’re using, applying a primer can further enhance adhesion and improve overall bond strength. It’s like giving your bond an extra boost of strength. Just make sure to follow the manufacturer’s instructions for applying the primer and let it dry completely before moving on to the next step.

Following Manufacturer’s Instructions

When it comes to sticking metal to glass, following the manufacturer’s instructions is nothing short of a game-changer. Imagine this: you have a shiny piece of metal and a sleek glass surface, ready to create a bond that will stand the test of time. Well, my friend, the key to success lies in those tiny instructions that accompany your glue.

Let’s start with the basics. Different glues have different formulas and play by their own rules. Some may require a thin layer on both surfaces, while others demand a generous slather on just one side. And don’t even get me started on drying times. Following these instructions ensures that you’re using the glue in the best possible way, giving you maximum bonding strength and durability.

But hold on tight, because there’s more. Safety first. Some glues contain chemicals that demand proper ventilation or protective gear during application. By following those manufacturer’s instructions, you’ll know exactly what precautions to take to keep yourself safe. After all, nobody wants to end up with glue stuck to their fingers or, even worse, something much more serious.

Oh, and let’s not forget about storage and handling. Did you know that some glues have specific storage conditions? Yep, they need to be kept in a cool and dry place or away from extreme temperatures to prolong their shelf life. Following those instructions means your glue will always be ready for action when you need it, ensuring its effectiveness for future projects.

Also Read: How to Glue Metal to Glass?

Conclusion

In conclusion, there are a plethora of exceptional glue options available for sticking metal to glass. Each adhesive brings its own unique properties and advantages to the table, making it suitable for a variety of applications.

One top contender is epoxy adhesive, renowned for its exceptional bonding strength, ability to withstand extreme temperatures, and resistance to moisture and chemicals. It’s the perfect choice when you need a strong and durable bond between metal and glass that can stand up to any challenge.

For those who value speed and efficiency, cyanoacrylate glue, also known as Super Glue, is a popular go-to. This remarkable adhesive forms an incredibly strong bond in mere seconds and dries quickly, allowing you to forge ahead with your project without delay. Its versatility extends beyond metal and glass, making it a reliable choice for various materials.

When flexibility is key, silicone adhesive reigns supreme. This adhesive offers enduring flexibility over time, making it ideal for projects where metal and glass need room to expand or contract together. Not only is it weatherproof, but it also boasts impressive resistance against harsh chemicals – ensuring a steadfast bond even in the most challenging environments.

If speed is of the essence and lightning-fast curing time is crucial, UV-curing adhesives are the way to go. With their rapid curing capabilities and excellent bond strength, these adhesives are versatile enough to bond different types of metals to various glass substrates. However, be sure to consider compatibility with specific surfaces and the required bond strength for your application.

Regardless of which adhesive you choose from this impressive lineup, proper surface preparation remains paramount in achieving an unbreakable bond between metal and glass. Thoroughly cleaning the surfaces, removing any existing coatings, roughening them up – all while diligently following the manufacturer’s instructions – are essential steps towards optimal adhesion.

So whether you’re crafting a dazzling lantern or restoring a cherished ornament back to its former glory, selecting the right glue will ensure that your metal-to-glass bond remains unyielding.