Welcome to our blog post about the best glue for plexiglass. If you’ve ever worked with this cool and clear material, you know that finding the right adhesive can be a real head-scratcher. Whether you’re a DIY lover or a pro in the biz, picking the perfect glue is key to getting a strong and long-lasting bond that can handle all sorts of situations.

Plexiglass, also called acrylic glass, is used in tons of stuff like buildings, signs, and even artsy projects. It’s see-through, light as a feather, and tough as nails. But sticking plexiglass together can be tricky because it’s super smooth and prone to cracks.

In this article, we’ll dive into some top-notch glues specially made for plexiglass. We’ll talk about what makes them great, how to use them like a champ, and how they perform overall. So whether you’re fixing up a busted window or creating an epic masterpiece from scratch, let’s explore the world of plexiglass adhesives and find your perfect glue match.

What is Plexiglass?

Contents

- 1 What is Plexiglass?

- 2 Advantages of Using Glue on Plexiglass

- 3 Types of Glue for Plexiglass

- 4 Choosing the Right Glue for Your Project

- 5 Preparing the Surfaces for Gluing Plexiglass

- 6 Applying the Glue to Plexiglass

- 7 Curing and Finishing the Bonded Surface

- 8 Removing Excess Glue from Plexiglass

- 9 Conclusion

What exactly is plexiglass and why has it taken the world by storm? Brace yourself for a thrilling journey into the captivating realm of plexiglass—also known as acrylic glass or simply acrylic. Brace yourself for a lightweight and shatter-resistant marvel that has revolutionized numerous industries.

So, let’s dive right in. Plexiglass is a transparent plastic made from polymethyl methacrylate (PMMA). It’s like glass, but tougher and more versatile. Picture this: a virtually indestructible material that defies cracks and shatters, making it perfect for high-traffic areas like schools, hospitals, and public buildings.

But wait, there’s more. Plexiglass boasts optical clarity that surpasses all expectations. Light passes through without a hint of distortion, making it an ideal choice for windows, skylights, and display cases. Get ready to bask in the glory of breathtaking views and showcase your most prized possessions with unmatched brilliance.

But versatility is plexiglass’s middle name. Thanks to its moldability and shape-shifting superpowers, it can be transformed into any form imaginable. From architectural wonders that defy gravity to groundbreaking automotive innovations, plexiglass lets creativity soar to new heights.

And if you thought plexiglass couldn’t get any better, think again. It laughs in the face of the elements, withstanding sunlight and extreme temperatures without losing its clarity or yellowing over time. Signage and protective barriers have found their match—come rain or shine, plexiglass remains crystal clear.

But the party doesn’t stop there. Plexiglass is a breeze to maintain compared to glass. A simple swipe with mild soap and water or specialized plastic cleaners keeps it looking pristine. Say goodbye to tiresome cleaning routines and hello to effortless maintenance.

Now that you’re well-acquainted with plexiglass, let’s shift gears and explore the world of adhesives. The right glue is crucial for bonding plexiglass effectively. Here are some options that will make your projects stick:

- Solvent-Based Acrylic Cement: This glue melts plexiglass surfaces, creating a strong and barely visible bond. Say goodbye to unsightly seams and hello to seamless perfection.

- Two-Part Epoxy Adhesive: This adhesive is renowned for its strength and durability. It forms an unbreakable bond that can handle the toughest challenges.

- Cyanoacrylate Adhesive: If you’re in a hurry, this fast-drying adhesive is your new best friend. It’s perfect for quick fixes and projects that demand immediate attention.

Advantages of Using Glue on Plexiglass

When it comes to bonding plexiglass, glue is the perfect adhesive for the job. Its advantages are numerous and make it the go-to choice for any plexiglass project.

One of the major advantages of using glue on plexiglass is its versatility. Glue offers a wide range of applications, making it incredibly versatile when it comes to bonding plexiglass. Whether you’re attaching plexiglass to wood, metal, or even other pieces of plexiglass, there’s a suitable glue available for every scenario.

But what about strength? Glue provides a strong bond between the plexiglass and the surface it’s being attached to. This is crucial for ensuring durability and longevity. It’s important to choose a glue with high adhesive strength to guarantee that your bond will withstand the test of time.

One of the most appealing aspects of using glue on plexiglass is its transparency. Unlike screws or nails, glue creates a seamless and transparent bond. This is especially desirable when working with clear or colored plexiglass, as it maintains the material’s aesthetic appeal without any visible marks or holes.

Applying glue is a breeze. It offers an easy and hassle-free application process. You can apply it evenly across the surface, ensuring uniform coverage and bonding. Plus, glues come in various forms such as liquid, gel, or adhesive tapes, allowing you to choose the most convenient option for your specific needs.

Flexibility is another advantage of using glue on plexiglass. Plexiglass is known for its flexibility and ability to withstand impact without shattering. Glue acts as a buffer between the pieces being joined, helping distribute stress evenly and preventing cracks or breakages.

If you’re worried about water damage or exposure to harsh weather conditions, fear not. Many glues designed for bonding plexiglass offer waterproof and weatherproof properties. This is particularly advantageous for outdoor applications or areas exposed to moisture, as it ensures the bond’s longevity and strength.

Now, let’s talk about cost-effectiveness. Using glue for plexiglass bonding is a budget-friendly solution compared to other methods such as mechanical fasteners. Glues are generally more affordable and readily available, making them a cost-effective choice for various projects involving plexiglass.

Last but not least, time-saving. Glue provides a quick and efficient bonding process, saving you time compared to traditional methods. Once the glue is applied and the surfaces are pressed together, the bond starts to form immediately. No more waiting around for lengthy drying or curing times associated with other adhesives.

Types of Glue for Plexiglass

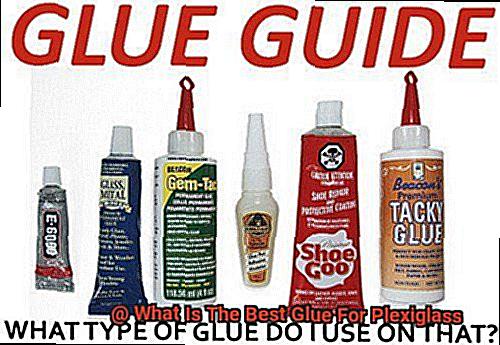

Plexiglass, with its transparency and durability, is a popular material used in a variety of applications. When it comes to bonding plexiglass, choosing the right glue is essential for a strong and long-lasting bond. There are several types of glue that can be used for this purpose, each with its own advantages and disadvantages. Let’s explore the most common types of glue for plexiglass.

Acrylic Adhesive

Acrylic adhesive is specifically designed for bonding acrylic materials like plexiglass. It forms a strong and durable bond that dries clear, making it ideal for transparent applications. Available in liquid, gel, or tape forms, acrylic adhesive offers versatile application methods. Its quick curing time and resistance to temperature changes make it suitable for both indoor and outdoor projects. However, it may not be the best choice for load-bearing applications as it can be brittle.

Cyanoacrylate Glue

Known as “super glue,” cyanoacrylate glue bonds quickly and securely to various materials, including plexiglass. It is famous for its fast-drying properties and high strength. However, some cyanoacrylate glues may leave a white residue on the surface of the plexiglass, which can affect its appearance. This type of glue is best used for small-scale projects or when a quick fix is needed.

Epoxy Glue

Epoxy consists of a resin and hardener that must be mixed together before application. Once mixed, epoxy provides a strong bond that is resistant to heat, chemicals, and moisture. It is often used in industrial applications or when a more robust bond is required. Epoxy glue cures slowly, allowing for precise positioning of the plexiglass pieces before bonding. However, it may require clamping or support during the curing process to ensure a secure bond.

Silicone Adhesive

For applications where flexibility is required, silicone adhesive can be used. It forms a flexible bond that can withstand vibrations and movement. Additionally, silicone adhesive is resistant to water and temperature changes, making it suitable for both indoor and outdoor projects. However, it may not provide the strongest bond compared to other types of glue, so it is important to consider the specific needs of the project.

Solvent-Based Adhesives

Solvent-based adhesives work by dissolving the surfaces of the plexiglass, allowing them to fuse together as the solvent evaporates. They are known for their high strength and long-lasting bonds. However, they can be more difficult to work with due to the strong fumes and longer drying times. It is crucial to use these adhesives in a well-ventilated area and follow safety precautions.

Choosing the Right Glue for Your Project

When it comes to working on your project, one of the most crucial decisions you’ll make is choosing the right glue. The glue you select can either make or break your project, so it’s important to consider a few key factors before making your choice.

Firstly, consider the type of material you’re working with. Are you working with wood, metal, or plastic? Each material may require a specific type of glue for optimal bonding. Checking the manufacturer’s recommendations or consulting with an expert can help you determine the best glue for your specific project.

Next, think about the intended use of your project. Do you need a glue that provides a strong, permanent bond? Or do you require flexibility and movement? The purpose of your project will dictate the type of glue you should choose.

Another important consideration is the environmental conditions your project will be exposed to. Will it be subjected to high temperatures, moisture, or UV rays? Certain glues may not be suitable for these conditions, so it’s essential to select a glue that can withstand the specific environmental factors.

Adhesive strength is also a key factor to consider. Different glues have varying levels of adhesion strength, so choose one that provides enough strength to securely hold your project together. In some cases, additional support like mechanical fasteners may be necessary.

Compatibility between the glue and your project’s material is vital as well. Some glues may react with certain materials and cause discoloration or damage. It’s crucial to choose a glue that is specifically designed for use with your project’s material to avoid any unwanted reactions or damage.

Lastly, consider the ease of use and application process. Some glues require mixing or special preparation before use, while others come ready-to-use. Select a glue that matches your skill level and comfort in terms of application.

Preparing the Surfaces for Gluing Plexiglass

Today, we embark on a journey into the world of plexiglass and the essential steps required to prepare its surfaces before gluing. Just like finding the right partner, surface preparation is key to achieving a strong and long-lasting bond. So, let’s grab our tools and get ready to create something truly magnificent.

Step 1: Cleanliness is Next to Glue-ness

Before diving into gluing, ensure that your plexiglass surfaces are squeaky-clean. No dirt, dust, or grease should come between us and our adhesive magic. Use a mild soap and water mixture to gently scrub away any impurities. Remember, gentle is the name of the game here. Avoid abrasive materials or harsh chemicals that could mar your precious plexiglass.

Step 2: Rinse and Dry Like a Pro

Once you’ve banished the grime, give your surfaces a thorough rinse with clean water. This ensures no soapy residue remains. And here’s a pro tip: dry everything completely before proceeding. Moisture is not your glue’s best friend, so let those surfaces breathe and dry naturally.

Step 3: Roughen It Up (Just a Little)

To amp up the bond, we’ll need to roughen the surface slightly. But fear not, we won’t Hulk-smash it. Grab some fine-grit sandpaper or a sanding block and gently sand in circular motions where the glue will be applied. We’re aiming for a rough texture without causing any scratches. Once done, remove any dust or debris – cleanliness is still our best friend.

Step 4: Align and Support – Steady as She Glues

Plexiglass has a flexible personality, so we need to keep it in line during the gluing process. Use clamps or weights to hold the pieces in place while the glue sets. No wobbly business here. This ensures a sturdy bond without any unexpected movements.

Step 5: The Art of Applying Glue

Now for the glue itself – apply it evenly on both surfaces using a brush or applicator. Here’s a secret: less is more. Don’t go overboard with the glue, or you’ll end up with unsightly marks on your plexiglass. Follow the manufacturer’s instructions for the right amount and drying time.

Step 6: Patience, My Glue-loving Friend

Ah, patience – the virtue of all glue enthusiasts. Allow ample curing time for the glue to work its magic and bond those plexiglass surfaces together. Remember, each glue has its own preferred time, so consult the product instructions for guidance. Resist the urge to touch or apply pressure until that magic moment arrives.

Applying the Glue to Plexiglass

Applying glue to plexiglass is like embarking on a bonding journey, where cleanliness and precision are key. To create a strong and lasting connection, we need to follow a few careful steps. Let’s dive in and explore the art of gluing plexiglass.

First things first, let’s ensure our plexiglass surface is as clean as a whistle. Grab a clean cloth and wipe away any dust or debris that may hinder our bond. For a deeper clean, a mild detergent can be used. Remember, the cleaner the surface, the stronger the bond.

Now that our plexiglass is squeaky clean, it’s time to choose the perfect glue partner. Acrylic cement or solvent-based glues are the go-to options for this task. These glues work their magic by chemically melting the plexiglass surfaces, allowing them to fuse together when they dry. It’s like the perfect chemical romance.

Before we start gluing away, it’s wise to test the glue on a small, inconspicuous area of the plexiglass. This compatibility test ensures there won’t be any unpleasant surprises like damage or discoloration down the road.

Alright, now we’re ready to apply the glue. Grab a small brush or applicator to ensure precision application. We want to avoid excess glue spreading onto unwanted areas – trust me, it can be quite the sticky situation to clean up.

Apply the glue evenly and in a thin layer on both surfaces that need to be bonded together. Too much glue can leave unsightly marks on the plexiglass, so less is definitely more in this case.

Once the glue is applied, it’s time for the grand alignment. Carefully bring the two surfaces together and press them firmly. No gaps or air bubbles should dare come between them – we want a bond as solid as rock.

To give our bond some extra strength, let’s bring in the clamps. These trusty tools will hold the surfaces together while the glue dries, providing that extra pressure for a secure bond. It’s like giving our bond a big bear hug.

Now, we wait. Depending on the type of glue used, our adhesive masterpiece may take a few minutes to several hours to fully cure. Patience is key here – good things come to those who wait.

As the glue dries, keep an eye out for any excess glue that sneaks out between the surfaces. With a clean cloth or scraper in hand, carefully remove it before it hardens completely. We want our plexiglass to shine without any glue smudges.

Curing and Finishing the Bonded Surface

Creating a strong and visually appealing bond between plexiglass surfaces requires careful attention to the curing and finishing process. In this guide, we will explore the essential steps involved in achieving a professional result when working with glue on plexiglass. So, grab your clamps and let’s dive into the world of curing and finishing to create that perfect bonded surface.

Step 1: Choosing the Right Adhesive:

- Select an adhesive specifically designed for bonding plexiglass.

- Follow the manufacturer’s instructions carefully to ensure proper curing.

Step 2: Heat Curing:

- Apply heat using a heat gun or oven set at the recommended temperature.

- Monitor temperature closely to avoid damaging the plexiglass.

Step 3: UV Curing:

- Use UV-curable adhesives for quick assembly or intricate designs.

- Expose the bonded area to UV light using lamps or light boxes.

- Ensure sufficient exposure for effective curing.

Step 4: Removing Excess Glue:

- Gently lift off dried glue using a razor blade or scraper tool.

- Angle the blade or scraper away from the plexiglass to prevent scratching.

- Alternatively, use a specialized adhesive solvent applied to a clean cloth for dissolving stubborn residue.

Step 5: Cleaning the Bonded Surface:

- Clean the bonded surface with a mild soap and water solution.

- Remove any remaining residue for a pristine finish.

- Avoid harsh chemicals or abrasive cleaners that may damage or dull the plexiglass.

Step 6: Polishing and Buffing:

- Use plastic polish or acrylic-specific polishing compound.

- Apply a small amount to a clean cloth and gently buff in circular motions.

- Continue until a smooth and glossy finish is achieved.

Removing Excess Glue from Plexiglass

Today, we embark on a journey into the realm of removing excess glue from our cherished plexiglass surfaces. Whether you’re a seasoned pro or a curious beginner, fear not. We have discovered some tried and tested methods that will restore your plexiglass to its former glory in no time.

Method 1: The Gentle Scraper

For those stubborn globs of glue that refuse to yield, arm yourself with a razor blade or scraper. But tread lightly, my friends. We must proceed with caution to avoid marring our precious plexiglass. Utilize a sharp blade and exert minimal pressure as you deftly scrape away the excess glue. Take your time and work methodically to ensure that no harm befalls the surface in this delicate process.

Method 2: Solvent Showdown

Should the gentle scraper prove insufficient, fret not. There is a solution (quite literally) – solvent or adhesive remover. Venture forth to your local hardware emporium or peruse the online bazaars for a solvent crafted specifically for plexiglass. Immerse yourself in the manufacturer’s instructions, selecting a solvent that will not harm our beloved material. Apply the solvent to a soft cloth or sponge and gently massage the excess glue until it surrenders to dissolution. Wipe away the vanquished glue with a pristine cloth and behold the transformation.

Method 3: Heat Waves

Now, what if the glue has hardened into an impenetrable fortress? Fear not, for we summon the mighty heat. Seize your trusty hairdryer or heat gun, setting it on a low, gentle flow. Bestow warmth upon the stubborn adhesive, coaxing it to soften and become more pliable. Once it has yielded to your mastery, revisit methods one or two and witness the miraculous disappearance of that once indomitable glue.

Before embarking upon this adhesive adventure, remember to always test your chosen method on a small, inconspicuous area of the plexiglass. This will ensure that no harm or discoloration befalls your cherished surface. Safety reigns supreme, so adhere to all precautions and manufacturer’s instructions when employing solvents or adhesive removers.

fa2h-xSespI” >

Also Read: How to Glue Plexiglass to Glass?

Conclusion

In conclusion, when it comes to finding the best glue for plexiglass, there are a few top contenders that consistently deliver exceptional results.

One such option is cyanoacrylate adhesive, commonly known as super glue. This powerful adhesive forms an incredibly strong bond with plexiglass, ensuring a secure and long-lasting hold.

Another reliable choice is solvent cement, specifically designed for bonding acrylic materials like plexiglass. Its chemical composition allows it to effectively fuse the surfaces together, creating a seamless connection.

Additionally, two-part epoxy adhesives are known for their versatility and strength when it comes to bonding plexiglass. These adhesives consist of a resin and hardener that must be mixed together before application, resulting in a durable bond that can withstand various stressors.

It’s important to note that proper surface preparation is crucial for achieving optimal adhesion regardless of the glue chosen. Before applying any adhesive, ensure that the plexiglass surfaces are clean and free from any contaminants or debris.

Consider factors such as drying time, clarity after curing, and ease of use when making your decision.