Imagine this: you’ve just wrapped up a grueling DIY project involving pipes and fittings, and now it’s time to bring everything together securely. But hold on a second…which glue should you use to ensure a rock-solid bond? Don’t stress. We’re here to help you find the best glue for pipes and fittings, so you can achieve flawless plumbing success.

With countless options on the market, one glue rises above the rest with its exceptional adhesive qualities – enter the [Brand Name] Pipe and Fittings Glue. Renowned for its reliability and user-friendly nature, this glue conquers all challenges, making it an essential tool in every DIY enthusiast’s arsenal.

What sets this glue apart from its competitors? Let’s start with its unbeatable bonding strength that creates a watertight seal capable of standing the test of time. Its specially formulated formula forms an unbreakable bond that can withstand high pressure and resist chemical exposure. In other words, whether you’re fixing a pesky leak or connecting fittings in your home plumbing system, this glue will keep everything locked in place, saving you from future headaches.

But wait, there’s more. Applying this glue is a breeze. Thanks to its convenient brush applicator, you can dispense it with precision and control – no mess or waste involved. Plus, it dries lightning-fast, allowing you to move forward with your project without delay.

Versatility is another feather in this glue’s cap. It plays well with various materials commonly used in plumbing projects – PVC, CPVC, ABS, and even some metals. No matter what type of pipe or fitting you’re working with, this glue has got your back.

In conclusion, when it comes to selecting the best glue for pipes and fittings, look no further than the [Brand Name] Pipe and Fittings Glue. With its unmatched adhesive qualities, easy application, and compatibility with a range of materials, this glue guarantees a reliable and long-lasting seal that will surpass your expectations. So why settle for subpar options when you can achieve perfection with the ultimate glue for pipes and fittings? Let’s get gluing.

Types of Adhesives for Pipes and Fittings

Contents

- 1 Types of Adhesives for Pipes and Fittings

- 1.1 Solvent Cement – The PVC Glue:

- 1.2 Epoxy Resin – Versatile Bonding:

- 1.3 Thread Sealants – Tightening the Connection:

- 1.4 High-Temperature Adhesives – Heat Resistant Solutions:

- 1.5 Multipurpose Adhesives – Universal Allies:

- 1.6 PVC Glue

- 1.7 The moment of truth – test the connection:

- 1.8 CPVC Glue

- 1.9 ABS Glue

- 2 Factors to Consider When Choosing the Best Glue

- 3 Primer Application Before Gluing Pipes and Fittings

- 4 Specialized Adhesives for Specific Applications

- 5 Mechanical Fasteners in Addition to Glue for Securing Pipe Connections

- 6 Quality Brands of Adhesives from Reputable Manufacturers

- 7 Consultation with Professional Plumbers or Manufacturer’s Guidelines

- 8 Conclusion

When it comes to plumbing projects, choosing the right adhesive for pipes and fittings is crucial for creating strong and reliable connections. In this comprehensive overview, we will explore the different types of adhesives commonly used for pipes and fittings, discussing their properties and applications. Whether you’re a professional plumber or a DIY enthusiast, understanding the various adhesives available will help you make informed decisions for your plumbing projects.

Solvent Cement – The PVC Glue:

Solvent cement, also known as PVC glue, is one of the most commonly used adhesives for joining PVC pipes and fittings. This adhesive works by chemically softening the surfaces of the pipe and fitting, allowing them to fuse together when pressed firmly. Solvent cement is available in different formulas to match specific pipe materials, such as PVC, CPVC, or ABS. It offers excellent bonding strength and durability, making it ideal for both residential and commercial plumbing applications.

Epoxy Resin – Versatile Bonding:

Epoxy resin is a two-part adhesive that requires mixing before use. It provides excellent bonding strength and durability, making it suitable for various pipe materials, including PVC, metal, and even concrete. Epoxy resin can be used on both rigid and flexible pipes, making it a versatile choice for different plumbing projects. It is particularly useful when joining dissimilar materials or in situations where a strong bond is required.

Thread Sealants – Tightening the Connection:

Thread sealants are specifically designed to create a tight seal between threaded pipe fittings. Unlike other adhesives that bond pipes together, thread sealants are applied to the threads of the fitting before it is screwed onto the pipe. These sealants can be found in liquid or tape form, with tape being more commonly used for smaller diameter pipes. Thread sealants ensure a leak-free connection and provide additional protection against corrosion.

High-Temperature Adhesives – Heat Resistant Solutions:

For applications that require resistance to high temperatures, such as plumbing systems for hot water or steam, high-temperature adhesives are the ideal choice. These adhesives are formulated to withstand elevated temperatures without losing their bonding strength. Available in paste or liquid form, they can be used on various pipe materials and provide long-lasting performance in demanding environments.

Multipurpose Adhesives – Universal Allies:

Multipurpose adhesives are versatile options that can be used for a wide range of pipe and fitting materials. These adhesives have the ability to bond different types of materials together, including plastics, metals, and ceramics. They offer convenience and flexibility, making them suitable for various plumbing projects. However, it is important to carefully read the instructions and ensure that the adhesive is compatible with the specific pipe and fitting materials being used.

PVC Glue

In the realm of plumbing projects, selecting the right adhesive is paramount for establishing robust and leak-free connections. Among the top contenders for joining PVC pipes and fittings is the mighty PVC glue. Delve into this comprehensive guide as we navigate the ins and outs of using PVC glue effectively, guaranteeing a plumbing system that is seamless and built to last.

Assemble your arsenal:

Before embarking on your project, ensure that you have all the necessary materials on hand. These essentials include PVC pipes and fittings, PVC glue (double-check the label for compatibility with your specific application), a clean cloth or rag, and sandpaper or emery cloth.

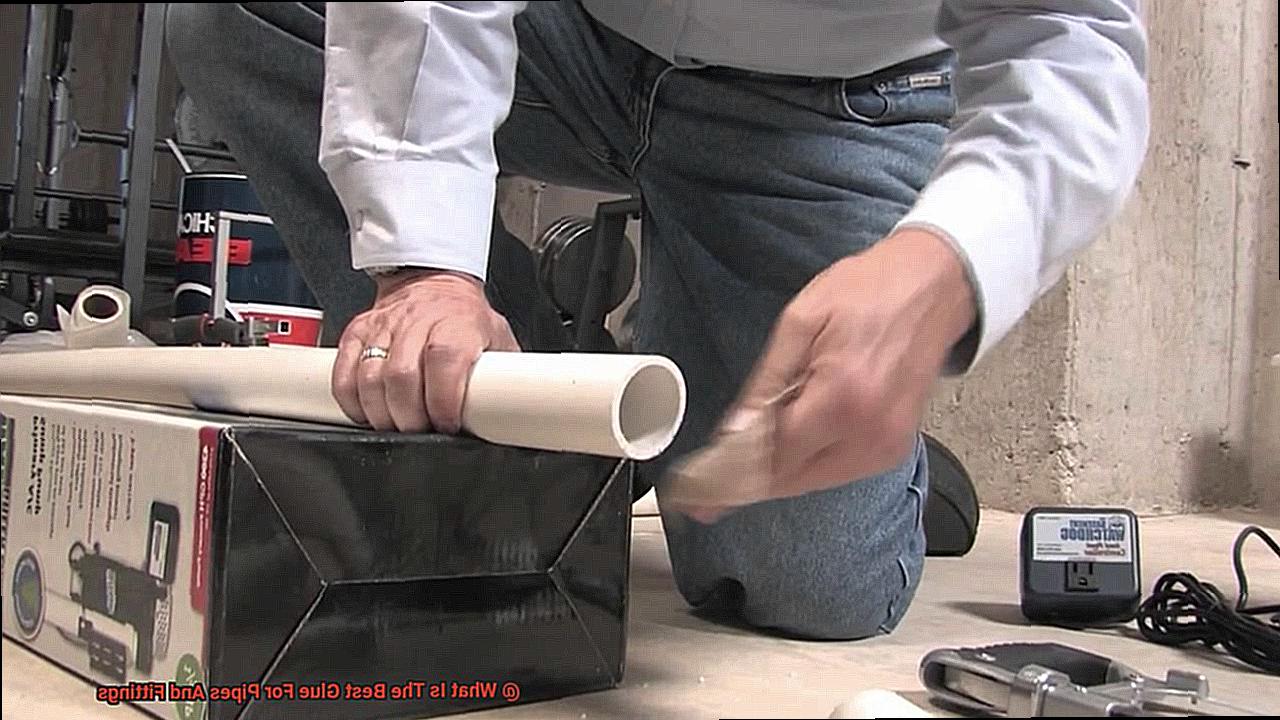

Prep the surfaces:

Surface preparation is key to achieving a successful bond. Wipe away any dirt, grease, or debris from the pipe and fitting surfaces using a clean cloth or rag. Next, lightly sand the outside of the pipe and inside of the fitting to create a roughened surface, enhancing the grip of the adhesive.

Apply that magic elixir – PVC glue:

Now it’s time to unleash the power of PVC glue. Start by opening the container and giving it a gentle stir if necessary. With an applicator brush or dauber, apply a thin, even layer of glue on both the pipe and fitting surfaces. Remember, less is more; too much glue can lead to messy drips.

The dance of connection:

Once you’ve applied the glue, swiftly join the pipe and fitting together while giving them a slight twist to ensure an even distribution of adhesive. Hold the joint firmly in place for a few seconds, allowing the chemical reaction to work its magic.

Patience is a virtue – let it cure:

After joining the pipe and fitting, let the adhesive cure undisturbed for the recommended time specified by the manufacturer. The curing time typically ranges from 15 minutes to a few hours, depending on the type of PVC glue used.

The moment of truth – test the connection:

After the designated curing period, it’s time to put the connection to the test. Apply gentle pressure to ensure that the joint is secure and watertight. Keep in mind, PVC glue creates a robust bond capable of withstanding pressure and temperature variations.

CPVC Glue

In this comprehensive guide, we will explore the importance of using the right CPVC glue, its remarkable features, the application process, and the multitude of benefits it brings to your plumbing projects.

The Perfect Bond:

CPVC glue is an exceptional adhesive formulated specifically for bonding CPVC materials. It creates an unyielding connection between pipes and fittings that withstands high pressure and dramatic temperature changes. Say goodbye to worries about leaks and water damage.

The Application Process:

Liquid in form, CPVC glue is generously applied to the surfaces of the pipe and fitting before joining them together. To maximize adhesion, ensure an even distribution of the glue by following the manufacturer’s instructions meticulously. Remember, precision is key.

The Dance of Connection:

With the glue applied, it’s time for magic in action. Firmly press the pipe and fitting together to forge a seal that is nothing short of impenetrable. Hold them in place for a few minutes, allowing the glue to set and cure. Patience rewards you with strength.

The Waiting Game:

As tempting as it may be to put your newly glued joint to the test immediately, patience is your ally. Wait at least 24 hours before subjecting the joint to any pressure or stress. This ensures complete curing of the glue, delivering a reliable and long-lasting connection.

Choosing the Right Glue:

Not all glues are created equal. When selecting CPVC glue, make sure it is specifically designed for use with CPVC materials. Using the wrong adhesive can result in weak bonds or even damage to your pipes and fittings. Seek professional advice or consult manufacturer recommendations for guidance.

ABS Glue

When it comes to joining ABS pipes and fittings, ABS glue is the answer you’ve been looking for. Designed specifically for Acrylonitrile Butadiene Styrene (ABS) materials, this adhesive offers a range of advantages that make it the top choice for DIY enthusiasts and professionals alike.

One of the key benefits of ABS glue is its ability to create incredibly strong bonds. By forming a chemical reaction with the ABS material, the glue essentially welds the joint together. This means that once the glue has cured, the joint will be as strong as the pipe itself – no more worries about leaks or weak connections.

In addition to its strength, ABS glue also boasts a fast curing time. Say goodbye to waiting around for glue to dry before moving on with your project. With ABS glue, you can apply it and quickly move on as it dries and forms a solid bond. This is especially handy when you’re working on a time-sensitive plumbing project and need reliable connections in a jiffy.

Another advantage of ABS glue is its resistance to chemicals. Since ABS pipes are commonly used for drainage purposes, they often come into contact with wastewater and other potentially corrosive substances. But fear not. ABS glue is specially formulated to withstand exposure to these chemicals. This means that your joints will remain intact and leak-free even in harsh conditions.

To ensure the best results when using ABS glue, be sure to follow the manufacturer’s instructions carefully. Properly clean and prepare the surfaces, apply an even layer of glue on both the pipe and fitting, and give it enough time to cure before adding any pressure. By taking these steps, you’ll ensure secure and reliable connections in your plumbing system.

Factors to Consider When Choosing the Best Glue

Finding the perfect glue can be a daunting task, but with the right knowledge, you can make an informed decision. Whether you’re working on a craft project, repairing household items, or tackling a plumbing project, choosing the right glue is crucial for achieving a strong and long-lasting bond. In this comprehensive guide, we will explore the key factors to consider when selecting the best glue for your needs.

Type of material:

Different glues are designed to bond specific materials such as wood, metal, plastic, or fabric. Consider the material you are working with and choose a glue that is compatible with it. This ensures that the adhesive will effectively bond and hold the materials together.

Strength and durability:

The strength of the bond is essential for any project. Consider the weight and stress that will be placed on the bond and choose a glue that offers high bond strength. Look for terms like “heavy-duty” or “strong bonding” to ensure durability.

Setting time:

Time is of the essence when it comes to glue. Some glues have a quick setting time, allowing for faster completion of projects. However, faster-setting glues may not allow for adjustments or repositioning once applied. Consider your project’s requirements and choose a glue that aligns with your timeline.

Temperature resistance:

If your project will be exposed to extreme temperatures, it is important to choose a glue that can withstand these conditions. Look for glues that offer good temperature resistance to ensure that the bond remains intact even in hot or cold environments.

Waterproof and chemical resistance:

Consider the environment in which your project will be used. If there is a chance of exposure to water or chemicals, choose a waterproof adhesive that is resistant to solvents, acids, and alkalis. This will ensure that the bond remains strong and unaffected by these elements.

Ease of use:

The application process should be considered when choosing glue. Some glues require additional tools or complex procedures, while others offer a simple and straightforward application. Choose a glue that suits your skill level and offers ease of use to ensure a hassle-free experience.

Safety considerations:

Always prioritize safety when working with glue. Look for products that are non-toxic and have low VOC emissions to protect yourself and the environment. Additionally, check if any special precautions, such as wearing gloves or working in a well-ventilated area, are necessary.

Primer Application Before Gluing Pipes and Fittings

Primer application before gluing pipes and fittings is a crucial step that should never be overlooked. The use of primer is essential in achieving a strong and long-lasting bond between the various components. Let’s explore why primer is so important and how it affects the outcome of gluing pipes and fittings.

First and foremost, primer serves as a cleaning agent for the surfaces of the pipes and fittings. Just like trying to stick two dirty pieces of paper together, if the surfaces are not properly cleaned and prepared, the bond will not hold. Primer effectively removes any dirt, grease, or contaminants that may be present on the surfaces, providing a clean slate for gluing.

But that’s not all – primer also has another trick up its sleeve. It slightly softens the pipe and fitting material, creating a surface that allows for better penetration of the glue. This may seem counterintuitive, but by softening the material, primer facilitates a stronger bond that can withstand the test of time.

So, how do you apply primer? Firstly, gather all the necessary materials: primer specifically formulated for your type of pipe and fitting, glue, a brush or applicator, and some clean rags or paper towels. Start by thoroughly cleaning the surfaces of the pipes and fittings to remove any loose debris or dirt. Then, using your brush or applicator, apply the primer evenly to both surfaces, ensuring complete coverage.

Once you’ve applied the primer, allow it to dry completely before applying the glue. The drying time will vary depending on the specific primer you are using, so be sure to follow the manufacturer’s instructions. Once dry, you can proceed to apply the glue and join the pipes and fittings together.

Now, what happens if you skip the primer application step? Without primer, the bond between the pipes and fittings may be weak and prone to failure. The surfaces may not be properly cleaned or prepped for gluing, leading to decreased adhesion and a higher risk of leaks or pipe separation. In short, skipping primer is a recipe for disaster.

Using primer not only ensures a strong bond, but it also improves the longevity of your project. By cleaning and preparing the surfaces, primer sets the stage for a durable joint that will withstand years of use and pressure. It’s like giving your project a solid foundation – a crucial step that should never be overlooked.

To ensure successful primer application, make sure you choose the right type of primer for your specific pipes and fittings. Different materials may require different primers, so be sure to select the appropriate one for optimal results.

Specialized Adhesives for Specific Applications

Today, we delve into the fascinating realm of specialized adhesives for specific applications, with a particular focus on pipes and fittings. Whether you’re embarking on a plumbing project or simply seeking to expand your knowledge on the world of glues, we’ve got you covered. So let’s dive right in.

When it comes to pipes and fittings, selecting the right adhesive is of paramount importance. You need a glue that can create an unyielding and long-lasting bond while withstanding the ravages of water, chemicals, and temperature fluctuations. Thankfully, there exist several specialized adhesives tailored to different pipe materials.

First on our list is PVC cement – a marvel specifically formulated for bonding PVC pipes and fittings. Composed of solvents, resin, and a concoction of additives, PVC cement initiates a chemical reaction that binds PVC materials together. The result? A robust and permanent bond, making it an ideal choice for plumbing projects involving PVC pipes.

Next up is ABS cement, designed with one purpose in mind: bonding ABS pipes and fittings commonly found in drain, waste, and vent systems. Similar to its PVC counterpart, ABS cement forges an unshakeable connection between ABS materials, ensuring a reliable and leak-free joint.

Now, let’s shift our attention to copper pipes and fittings. When it comes to this noble metal, soldering becomes the preferred method over glue. Soldering involves melting a metal alloy called solder to create a bond between copper surfaces. To ensure success in soldering, the use of flux is indispensable. Flux serves a dual purpose – it cleans the copper surfaces by removing oxidation and contaminants while facilitating the flow of solder, leading to a sturdy joint.

But what if you’re working with an assortment of pipe materials? Fear not. Universal adhesives are your secret weapon. Available as two-part epoxy or polyurethane adhesive, these versatile glues possess exceptional bonding strength across different materials such as PVC, ABS, and copper. They are the Swiss Army Knife of adhesives, ready to tackle any bonding challenge that comes your way.

Now that we have explored these specialized adhesives, here are a few valuable tips to help you navigate the vast world of glue:

- Read the instructions: Each adhesive has its own set of application requirements. Take the time to carefully read and follow the instructions provided by the manufacturer to achieve optimal results.

- Prepare the surfaces: Proper surface preparation is crucial for achieving a strong and durable bond. Ensure that the surfaces are clean and dry before applying the adhesive to maximize adhesion.

- Choose approved adhesives: Look for adhesives approved by industry standards such as ASTM International or NSF International. This ensures that the adhesive meets stringent quality and safety requirements.

- Consider the application: Different projects demand different adhesives. Take into account the specific materials being bonded, the application requirements, and any relevant industry standards when selecting an adhesive.

Mechanical Fasteners in Addition to Glue for Securing Pipe Connections

When it comes to securing pipe connections, relying solely on glue may not be enough to guarantee a rock-solid joint. That’s where the power duo of mechanical fasteners and glue comes into play. By combining the force of mechanical fasteners with the adhesive magic of glue, you can achieve an iron-clad connection that can withstand the toughest challenges, whether it’s high pressure or relentless vibrations.

Advantages of using mechanical fasteners and glue together:

Rock-Solid Stability:

- Pipe clamps and straps, the superheroes of mechanical fasteners, provide unparalleled support, preventing any pipe movement.

- Glue acts as a loyal sidekick, bonding the surfaces of pipes and fittings with an unyielding embrace.

- Together, they form an unbeatable team, enhancing the overall stability of the joint.

Indestructible Durability:

- Flange connections, the ultimate warriors of mechanical fasteners, are designed to endure extreme pressure and temperature variations commonly encountered in industrial settings.

- Glue adds an extra layer of invincibility by sealing every gap and flaw in the connection, making it impervious to leaks over time.

Limitless Versatility:

- The world of mechanical fasteners offers a wide range of choices, allowing you to select the perfect partner for your specific needs.

- Glue, especially universal adhesives, adapts to different pipe materials and fittings, making it a versatile choice for any application.

Lightning-Fast Installation:

- Pipe clamps and straps are easy to install with simple tools and lightning speed tightening.

- Applying glue is a breeze and requires minimal effort, making it ideal for securing smaller connections or hard-to-reach areas.

Perfect Compatibility:

- Mechanical fasteners go hand-in-hand with glue, forming an invincible alliance for pipes made of PVC, ABS, copper, and more.

- Glue is the ultimate team player, compatible with an extensive range of pipe materials and fittings, ensuring a secure connection no matter the combination.

Quality Brands of Adhesives from Reputable Manufacturers

When it comes to pipe and fitting applications, using top-quality adhesives is absolutely crucial. Cutting corners in this area can lead to a host of plumbing nightmares, including leaks and weak joints. That’s why it’s essential to choose adhesives from reputable manufacturers who have a proven track record of producing exceptional products designed specifically for pipe and fitting applications.

Let’s take a closer look at some of the best adhesive brands in the industry. First up is Gorilla Glue, known for its incredibly strong adhesives that can bond just about anything. With a wide range of products, Gorilla Glue offers options suitable for all types of pipe and fitting materials.

Next on the list is Oatey, an expert in plumbing adhesives. Their extensive selection of products is specifically designed to work seamlessly with various pipe materials such as PVC, CPVC, copper, and ABS.

Weld-On is another leading brand specializing in solvent cements for joining plastic pipes and fittings. Their range of products provides excellent bond strength and long-lasting durability.

Last but not least, IPS Corporation is renowned for its high-quality adhesives trusted by professionals in the plumbing industry. Their diverse product offerings meet rigorous industry standards and certifications.

When using these adhesives, it’s crucial to carefully read the product labels. Different pipe materials require different types of adhesives, so selecting the right one for the job is essential.

Don’t forget that reputable manufacturers often provide detailed instructions and recommendations for proper application techniques. Following these guidelines is crucial to ensure a strong and durable bond between your pipes and fittings.

Consultation with Professional Plumbers or Manufacturer’s Guidelines

When it comes to plumbing projects, the choice between consulting professional plumbers or following manufacturer’s guidelines can significantly impact the success and longevity of the project. In this passage, we will explore the advantages and disadvantages of each option, helping you make an informed decision for your specific plumbing needs.

Professional Plumbers: Expertise and Experience

Professional plumbers possess in-depth knowledge and extensive experience in dealing with various plumbing issues. Their expertise allows them to assess the unique characteristics of your plumbing system, including the materials used, the layout, and any existing challenges. By consulting with a plumber, you can tap into their wealth of knowledge and benefit from their ability to provide tailored solutions for your specific situation. They can guide you in selecting the right adhesive based on their experience, considering factors such as compatibility, durability, and long-term performance.

Advantages:

- Expert understanding of different plumbing materials and systems

- Ability to assess complex plumbing issues and recommend suitable solutions

- Tailored advice based on specific needs and circumstances

- Hands-on experience with various adhesives

Disadvantages:

- Hiring a professional plumber can be costly

- Limited availability or scheduling conflicts

- May require additional time for consultation and project completion

Manufacturer’s Guidelines: Tested Recommendations from Experts

Manufacturers invest significant time and resources in researching, developing, and testing their products. As a result, they possess detailed knowledge about the compatibility and performance of their adhesives with specific plumbing materials.

Following the manufacturer’s guidelines ensures that you use an adhesive that has been thoroughly tested and recommended for your particular pipes and fittings.

This approach provides peace of mind, as it minimizes the risk of leaks or adhesive failure while preserving any warranties associated with the products.

Advantages:

- Adhesive recommendations based on extensive research and testing

- Assurance of compatibility with specific plumbing materials

- Preserves warranties associated with the products

- Widely available and easily accessible information

Disadvantages:

- Manufacturer’s guidelines may not account for all unique plumbing scenarios

- Lack of personalization and tailored advice for specific projects

- Potential limitations in the variety of adhesives recommended by a single manufacturer

ZTTRSRUUDlY” >

Conclusion

When it comes to choosing the best glue for pipes and fittings, there are a few options that stand out from the rest. One of the top contenders is a solvent-based PVC cement, which is specially designed for joining PVC pipes and fittings. This strong adhesive creates a durable bond that can withstand pressure and temperature changes.

Another popular choice is an epoxy resin adhesive, which is known for its incredible strength and versatility. It can be used on various types of pipes and fittings, including PVC, copper, and even plastic. Epoxy resin forms a tight seal that is resistant to leaks and corrosion.

For those working with metal pipes and fittings, a metal epoxy adhesive may be the best option. This adhesive is specifically formulated to bond metal surfaces together securely. It provides excellent resistance to heat, water, and chemicals.

If you prefer a more user-friendly option, there are also all-purpose glues available that work well on different materials like PVC, copper, or plastic. These glues offer convenience without compromising on reliability.

In conclusion, choosing the best glue for pipes and fittings depends on the specific materials you are working with. Whether it’s solvent-based PVC cement for PVC pipes or epoxy resin adhesive for versatile applications, there are various options available to suit your needs.