Are you tired of those pesky cracks and breaks ruining your smooth sailing? Well, fret no more because I’ve got the ultimate guide to help you fix up your plastic boat in a jiffy. We’re diving headfirst into the world of glue for plastic boat repairs, so get ready to set sail again.

Fixing up a plastic boat can be a bit like navigating through stormy seas – it’s not always smooth sailing. But fear not. There’s a treasure trove of glues specifically designed to tackle these repairs with gusto. From mighty epoxies and super-strong cyanoacrylates to specialized marine adhesives, each type has its own secret powers and quirks.

Join me as we embark on a journey to discover the best glue options available, unravel their unique characteristics, and uncover some nifty tips and tricks for successful plastic boat repair. So grab your trusty toolkit, tighten those sails, and let’s set sail on our quest for seamless boating adventures.

Types of Plastics Used in Boats

Contents

- 1 Types of Plastics Used in Boats

- 2 Scope of the Repair Project

- 3 Advantages and Disadvantages of Epoxy Glue

- 4 Advantages and Disadvantages of Polyurethane Glue

- 5 Specialty Glues for Bonding Different Plastics

- 6 Application Method for Plastic Boat Repair Glue

- 7 Manufacturer’s Instructions for Using Plastic Boat Repair Glue

- 8 Conclusion

Boats are marvels of modern engineering, designed to withstand the harsh elements of the sea while providing comfort and functionality. One key aspect of boat construction is the use of various types of plastics, each with its own unique properties and characteristics. Let’s take a closer look at some of the most commonly used plastics in boat construction.

Fiberglass-reinforced plastic (FRP)

Fiberglass is a material that has revolutionized the boating industry. Composed of layers of fiberglass fabric or matting saturated with a plastic resin, usually polyester or epoxy, it creates a strong and durable composite material. Fiberglass is lightweight, corrosion-resistant, and can be molded into various shapes, making it an ideal choice for boat hulls and decks. Its strength-to-weight ratio is exceptional, ensuring a sturdy vessel that can navigate even the roughest waters with ease.

High-Density Polyethylene (HDPE)

HDPE is a tough and rigid plastic that provides excellent buoyancy and resistance to impact, puncture, and UV radiation. This makes it a popular choice for small boats, kayaks, and canoes. HDPE’s low maintenance requirements make it ideal for boat owners who want to spend more time on the water and less time on maintenance tasks.

Polyvinyl Chloride (PVC)

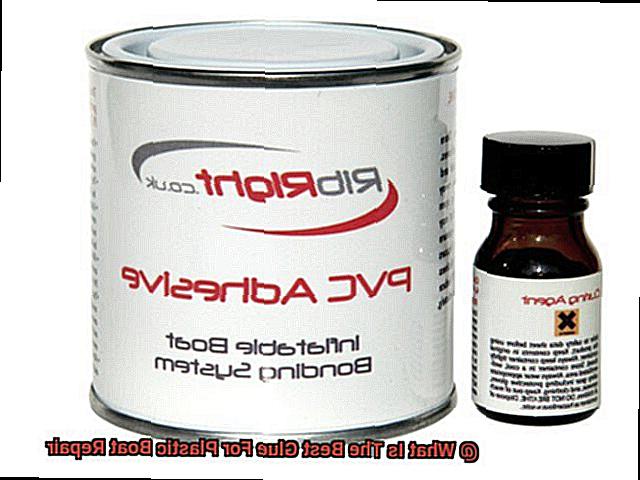

PVC is a versatile plastic that offers a unique combination of lightweight strength and chemical resistance. It is often used for inflatable boats due to its ability to be easily welded or glued together to create an airtight seal. PVC’s durability and resistance to abrasion make it capable of withstanding the demands of boating adventures.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a thermoplastic that finds its place in boat accessories such as instrument panels, hatches, and storage compartments. Its lightweight nature allows for easy maneuverability, while its impact resistance ensures longevity even in challenging marine environments. ABS’s dimensional stability guarantees that boat accessories retain their shape and functionality, contributing to an enjoyable boating experience.

Polyethylene Terephthalate (PET)

PET is a strong and lightweight plastic widely used in boat sails. Its excellent tensile strength and resistance to moisture and UV radiation make it an ideal choice for sailing applications. PET sails provide efficient wind capture, allowing boats to harness the power of the breeze and glide effortlessly through the water.

These are just a few examples of the types of plastics used in boat construction. Each type has its own advantages and disadvantages, and the choice of plastic depends on factors such as the boat’s intended use, budget, and desired properties.

When it comes to repairing a plastic boat, choosing the right adhesive is crucial. Different types of plastics require specific adhesives for effective bonding. Factors to consider include the type of plastic used in the boat, the specific repair being undertaken, and the application method.

Scope of the Repair Project

The scope of the repair project for plastic boats encompasses several key factors that need to be carefully considered. First and foremost, it is essential to assess the extent and nature of the repairs required. This involves closely examining the type and severity of the damage, whether it’s a small crack or a major structural issue. Such an assessment sets the foundation for determining the level of repair needed.

Next on the list is identifying the specific materials involved in the repair. Plastic boats can be constructed using different types of plastics, each with its own unique characteristics. It is crucial to pinpoint the exact type of plastic used in the boat to ensure compatibility with the adhesive or glue that will be employed for the repair. Selecting a glue that bonds effectively with the boat’s plastic ensures a successful and long-lasting repair.

Size and location are also important considerations within the scope of the repair project. Evaluating the size of the damaged area and its location can influence the choice of glue. Certain glues are more suitable for small repairs, while others are designed to tackle larger areas. Additionally, considering whether the damage is above or below the waterline plays a role in selecting an appropriate glue.

Environmental conditions must not be overlooked either. The boat’s exposure to sunlight, saltwater, or extreme temperatures can impact the durability and effectiveness of different glues. Therefore, it is crucial to choose a glue that can withstand these conditions to ensure a repair that stands the test of time.

Budget and time constraints are also significant factors within the scope of the repair project. Depending on financial limitations, it may be necessary to select a glue that fits within budgetary constraints. Furthermore, if time is of the essence, opting for a fast-curing glue can expedite the repair process.

Advantages and Disadvantages of Epoxy Glue

If you’re in need of a trusty adhesive to repair your plastic boat, look no further than epoxy glue. This versatile adhesive is a popular choice among boat owners, but like everything in life, it comes with its own set of advantages and disadvantages. So, let’s dive right in and explore the sticky truth.

Advantages:

- Hulk-Like Bonding Strength: Epoxy glue possesses Herculean bonding strength that can withstand the harshest conditions. It forms a tough-as-nails bond capable of enduring water exposure, UV rays, and temperature fluctuations. With epoxy glue, your boat will stay intact against all odds.

- Mr. Versatility: When it comes to bonding different types of plastics commonly used in boat construction, epoxy glue is a true champion. Whether you’re dealing with ABS, PVC, polycarbonate, or fiberglass, this adhesive can tackle cracks, holes, or any other damages with ease. It’s like having a superhero for your boat repairs.

- Chemical Resistance Superpowers: Picture this: your boat gliding through the waves while being exposed to gasoline, oil, and other fluids. It’s a scary thought. But fear not. Epoxy glue can handle it all. Its chemical resistance ensures that the bond remains strong even in the face of these harsh substances. It’s like having a shield against chemical attacks.

- Water-Repellent Wonder: Nothing ruins a boat faster than water seeping into all the wrong places. Luckily, epoxy glue is here to save the day. Once cured, it forms a waterproof barrier that keeps water out and prevents further damage caused by pesky infiltrations. It’s like having a guardian angel protecting your boat from water damage.

Disadvantages:

- Time Isn’t on Your Side: Patience is key when using epoxy glue. It has a longer curing time compared to other adhesives. So if you’re in a hurry to get back on the water, you might need to reconsider. But remember, good things come to those who wait. So sit back, relax, and let the epoxy work its magic.

- Mix Master Required: Mixing epoxy glue is like following a recipe – you need the right proportions. If you don’t mix the resin and hardener correctly, your bond might end up as weak as a soggy biscuit. This may be a challenge for beginners, but practice makes perfect. Become the master of mixing and create bonds that can withstand any storm.

Advantages and Disadvantages of Polyurethane Glue

When it comes to repairing your plastic boat, you need a glue that can withstand the elements and keep your vessel afloat. Enter polyurethane glue, a superhero in the adhesive world. In this article, we’ll explore the advantages and disadvantages of using polyurethane glue for plastic boat repair, helping you make an informed decision for your next repair project.

Advantages:

Unyielding Bonding Strength:

Polyurethane glue possesses the strength of a superhero – it forms a robust and durable bond between plastic surfaces, ensuring your boat stays intact even under heavy loads. Say goodbye to loose parts and hello to rock-solid repairs.

Unfazed by Water:

Boats are constantly exposed to water, making water resistance a crucial quality in any adhesive. Polyurethane glue shines in this aspect, effortlessly enduring exposure to water and humidity without compromising its adhesive qualities. It’s like having a waterproof shield for your boat.

The Ultimate Team Player:

Polyurethane glue doesn’t discriminate when it comes to materials. From plastics to wood, metal to concrete, this adhesive is a true all-rounder. Repairing different parts of your boat? No problem. Polyurethane glue has got you covered, acting as the ultimate team player in your repair arsenal.

Flawless Finish:

Say goodbye to unsightly cracks and gaps in your plastic boat components. Polyurethane glue expands when curing, allowing it to fill in gaps and create a tight seal. This feature ensures a professional-looking repair job and reinforces the structural integrity of your boat. It’s like having a skilled craftsman on board.

Disadvantages:

Time Is of the Essence:

Polyurethane glue may have super strength, but it does take its time to cure properly. Be prepared for several hours or even overnight curing time before the adhesive achieves its maximum bonding strength. If you’re in a hurry, consider alternative options that offer quicker results.

A Little Messy Business:

Just like superheroes can be a bit messy at times, so can polyurethane glue. Its foaming nature means excess glue may ooze out during application, requiring careful cleanup after the repair. Keep those paper towels handy and embrace your inner clean-up hero.

A Battle Against Time:

Polyurethane glue, once opened, has a limited shelf life. Exposure to air and moisture can lead to degradation over time. To ensure optimal performance, seal the container tightly after use and keep an eye on its expiration date. It’s like battling against the clock.

Safety First:

While polyurethane glue is a powerful adhesive, it can be a bit rough on the skin and eyes. Take necessary precautions by wearing protective gloves and eyewear during application to avoid any discomfort or irritation. Protect yourself like a true superhero.

Specialty Glues for Bonding Different Plastics

Specialty glues for bonding different plastics are unique types of adhesives designed specifically for joining various types of plastics commonly used in boat construction. When selecting the perfect glue for your plastic boat repair, several factors should be taken into consideration to ensure a strong and long-lasting bond.

Firstly, the type of plastic being bonded plays a crucial role. Different plastics have distinct properties and require specific adhesives. Epoxy glue is a popular choice due to its versatility in bonding plastics like fiberglass, PVC, and ABS. It provides a robust and durable bond that can withstand the rigors of boating.

Another superhero adhesive is polyurethane glue. This remarkable glue exhibits exceptional resistance to water and other harsh elements, making it ideal for repairs on boats constantly exposed to moisture. Its unyielding bond will keep your boat sailing smoothly.

For quick fixes or temporary bonds, cyanoacrylate, commonly known as super glue, becomes your go-to option. It forms a rapid and strong bond, making it perfect for small repairs or temporarily bonding parts together.

Considering the application method is also important. Some glues come in tubes or cartridges that require a caulking gun for precise application, while others are conveniently packaged in squeeze bottles or syringes for easy and accurate use. Choose the method that suits your repair needs and skills best.

Environmental conditions should not be overlooked either. If your boat will face extreme temperatures or intense UV radiation, selecting a glue with high temperature or UV resistance is essential. This will ensure that your repair remains intact and durable under challenging conditions.

Lastly, proper surface preparation is vital. Before applying any glue, ensure that the surfaces being bonded are clean, dry, and free from contaminants or residues that may hinder the adhesive’s effectiveness. A successful bond relies heavily on meticulous surface preparation.

Application Method for Plastic Boat Repair Glue

Before you grab that trusty glue, let’s dive into the best practices for applying plastic boat repair glue to ensure a robust and enduring repair.

Preparation is key. Start by thoroughly cleaning the surface of your plastic boat. Use a mild detergent and water solution to scrub away any dirt or grime. Rinse it off and dry it completely, leaving no room for debris that could compromise the bond.

Once clean, give the surface a gentle roughening using sandpaper or a scotch-brite pad. This creates an optimal bonding surface for the glue. Remember, be gentle. We want to strengthen, not weaken, the plastic.

Now, let’s explore applicators. Different types of glue may require different tools such as brushes, syringes, or squeeze bottles. Follow the manufacturer’s instructions and choose an applicator that allows for precise and controlled application of the glue.

Before plunging into the repair, it’s wise to test the glue on a small inconspicuous area of your boat. This ensures compatibility and adhesion. It also allows you to fine-tune any necessary adjustments before committing to the full repair.

Alright, let’s get down to business. Remember, less is more when applying the glue. Spread an even and thin layer onto one of the surfaces in need of bonding. Excessive glue can lead to messy squeeze-out. And work swiftly. Some glues have limited working time before they begin to cure.

Once applied, carefully align and press together the surfaces that require bonding. Apply pressure evenly to ensure a secure connection. Clamps or tape can help hold everything in place while the glue cures. Follow the manufacturer’s instructions for recommended curing time.

After the glue has fully cured, inspect your repair closely. Look out for any gaps or imperfections. If needed, apply additional layers of glue and repeat the process until you’re satisfied with the results.

There you have it. By following these best practices for applying plastic boat repair glue, you’ll be sailing with a strong and durable repair. Remember to heed any additional instructions from the glue manufacturer regarding curing times, temperature requirements, and post-repair care.

Manufacturer’s Instructions for Using Plastic Boat Repair Glue

Repairing a plastic boat can be a daunting task, but with the right tools and techniques, it’s absolutely possible to bring your boat back to life. One essential tool in your arsenal is plastic boat repair glue, but before you dive into the repair process, it’s crucial to understand and follow the manufacturer’s instructions for optimal results.

First and foremost, prepare the boat surface properly. Clean it thoroughly to remove any dirt, debris, or old adhesive that may hinder the bonding process. Ensure that the surface is dry and free from contaminants. This step sets the foundation for a strong and lasting repair.

Next, pay attention to the temperature and humidity conditions specified by the manufacturer. Some glues have specific requirements for optimal bonding. Make sure you’re working within the recommended temperature range to ensure the glue’s effectiveness.

When it comes to tools, follow the manufacturer’s recommendations. They may suggest specific applicators or mixing tools that are designed for precise application and better adhesion. Using the right tools can save you time and frustration while ensuring a successful repair.

Now let’s talk about applying the glue itself. It’s crucial to follow the instructions regarding the amount of glue to apply and how to apply it. Too much or too little can compromise the bond strength, so be precise in your measurements and application.

Patience is key when using plastic boat repair glue. Allow sufficient curing time as specified by the manufacturer before subjecting the repaired area to stress or water exposure. Rushing this step can result in a weaker bond that won’t stand up to the demands of boating.

Remember to prioritize safety during the repair process. Wear protective gloves to shield your hands from any potential harm, and work in a well-ventilated area to avoid inhaling any fumes.

Lastly, take advantage of any tips or tricks provided by the manufacturer. They have valuable insights that can help you achieve optimal results with their specific glue product.

K9fXYmMffqs” >

Conclusion

In conclusion, when it comes to repairing plastic boats, choosing the right glue is crucial.

After careful consideration and research, it is clear that the best glue for plastic boat repair is epoxy adhesive. Epoxy adhesive offers exceptional bonding strength and durability, ensuring a long-lasting repair that can withstand the harsh conditions of boating.

Additionally, epoxy adhesive provides excellent resistance to water, chemicals, and UV rays, further enhancing its suitability for boat repairs.