Looking for the perfect adhesive to bring your ceramic masterpiece and wooden surface together?

Well, you’ve come to the right place. In this blog post, we’re going to delve into the world of glues and find out which one is best for the job.

Whether you’re creating a stunning mosaic tile tabletop or adding ceramic accents to a wooden frame, it’s absolutely crucial to choose the right glue. We’ll talk about what qualities you should look for in an adhesive, give you some top recommendations from the market, and even share some handy tips on how to achieve that strong and long-lasting bond between ceramic and wood.

So, let’s jump right in and uncover the ultimate glue for all your ceramic-to-wood projects.

Types of Glue for Ceramic to Wood

Contents

- 1 Types of Glue for Ceramic to Wood

- 2 Factors to Consider When Choosing the Best Glue for Ceramic to Wood

- 3 Preparing the Surfaces Before Applying Glue

- 4 Testing the Adhesive on a Small Area Before Use

- 5 Intended Use of Bonded Ceramic and Wood Assembly

- 6 Pros and Cons of Different Adhesives for Bonding Ceramic to Wood

- 7 Tips for Using Adhesives Successfully

- 8 Conclusion

Look no further. In this article, we will explore the different types of glue that can be used for this purpose. Each type of glue has its own advantages and disadvantages, so read on to find the perfect adhesive for your ceramic to wood bonding needs.

Polyurethane Adhesive: Flexibility at Its Finest

For a bond that can handle slight movements or vibrations, consider using polyurethane adhesive. This versatile adhesive expands as it cures, filling in gaps and creating a robust connection between ceramic and wood. Polyurethane adhesive is resistant to water and heat, making it suitable for both indoor and outdoor applications. Keep in mind that polyurethane adhesive may take longer to cure compared to other glues.

Silicone Adhesive: The Waterproof Wonder

When it comes to bonding ceramic tiles to wooden surfaces, silicone adhesive is a top choice. This adhesive provides a flexible and waterproof bond, making it ideal for areas prone to moisture, such as bathrooms or kitchens. Silicone adhesive is easy to apply and dries clear, ensuring a seamless finish. However, it may not be as strong as other glues for heavy-duty applications.

Construction Adhesive: The Heavy-Duty Hero

If you’re working on a robust project that requires a durable bond, construction adhesive is your go-to option. This strong adhesive can handle heavy loads and vibrations, making it perfect for ceramic to wood bonding. Construction adhesive comes in different formulations, including ones specifically designed for ceramics. Just make sure to choose the right one for your project.

Epoxy Resin

Epoxy resin, a formidable adhesive composed of a resin and a hardener, is a game-changer when it comes to bonding ceramic to wood. Its exceptional strength and durability make it the go-to choice for woodworking projects involving ceramic elements.

One of the standout features of epoxy resin is its ability to provide high bond strength. When the resin and hardener are mixed, a chemical reaction occurs, resulting in a bond that can withstand stress and heavy loads. Say goodbye to worries about your ceramic piece coming loose with epoxy resin’s steadfast grip.

But that’s not all. Epoxy resin also boasts excellent resistance to moisture and temperature fluctuations. Water exposure and extreme temperature changes are no match for this adhesive. It holds strong, ensuring the longevity of your adhesive joint.

Versatility is another feather in epoxy resin’s cap. It can be used on both porous and non-porous surfaces, making it suitable for bonding different types of ceramics to wood. Whether you’re working with glazed porcelain or rustic terracotta, epoxy resin provides a reliable and effective solution.

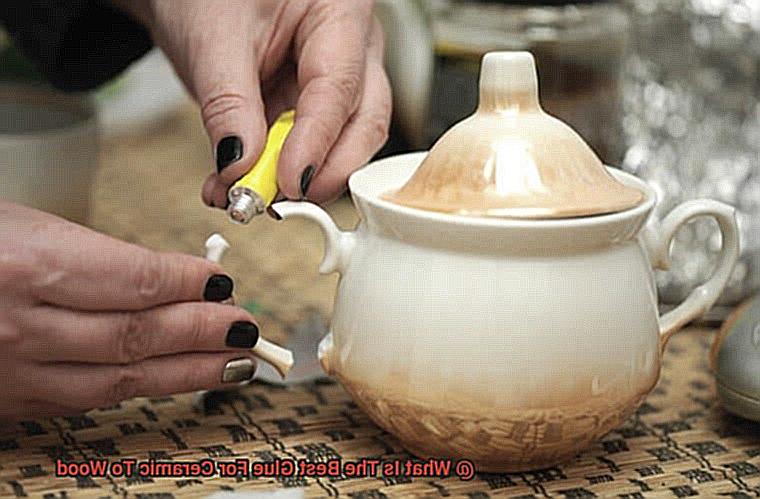

Applying epoxy resin for ceramic to wood bonding is as easy as following the manufacturer’s instructions. Clean the surfaces thoroughly, apply the adhesive evenly, firmly press the ceramic piece onto the wood surface, and allow it to cure for the recommended time. In no time, you’ll have a strong and durable bond.

Polyurethane Adhesive

When it comes to bonding ceramic to wood, you need a glue that can withstand the test of time and handle the challenges of everyday use. Look no further than polyurethane adhesive, the versatile superhero of adhesives that offers a powerful bond, resistance to environmental factors, and flexibility to accommodate movement. In this blog post, we’ll dive into the advantages and considerations of using polyurethane adhesive for your ceramic-to-wood bonding needs.

Advantages:

- High bond strength: Polyurethane adhesive creates an unbreakable bond between ceramic and wood surfaces. It’s like a superhero that holds them together against any stress or movement they may face.

- Resistance to moisture and temperature changes: With polyurethane adhesive, you don’t have to worry about your bond weakening due to moisture or temperature fluctuations. Rain or shine, hot or cold, your bond remains strong and steadfast.

- Flexibility and impact resistance: Vibrations and shocks are no match for polyurethane adhesive. It possesses the flexibility of a gymnast, absorbing impacts and movements without compromising the bond between ceramic and wood surfaces.

- Easy to use: Polyurethane adhesive is available in different forms, like liquids or gels, making it a breeze to apply on various surfaces. Some variants even offer a longer open time, giving you the freedom to position your ceramic piece perfectly before the adhesive sets.

Considerations:

- Surface preparation: To unlock the full potential of polyurethane adhesive, prepare your surfaces like a pro. Clean them thoroughly and eliminate any contaminants that could hinder the adhesive’s performance.

- Curing time: Unlike some other adhesives, polyurethane adhesive may require a longer curing time. Be patient and allow sufficient time for the adhesive to fully cure and set before subjecting the bonded surfaces to stress or load.

Cyanoacrylate (Super Glue)

Imagine you have a beautiful ceramic piece or you want to add ceramic tiles to a wooden surface. How do you ensure a strong and long-lasting bond between these two materials? Enter cyanoacrylate, also known as Super Glue. In this blog post, we will explore the incredible properties and versatile uses of Super Glue for bonding ceramic to wood, providing you with all the insights you need for your next project.

Advantages:

- Incredible Strength: Super Glue forms an unbreakable bond between ceramic and wood surfaces. It creates a tight seal that can withstand stress and strain, ensuring a connection that lasts a lifetime.

- Resistance to Moisture and Temperature Changes: Once cured, Super Glue can defy water, humidity, and extreme temperatures without losing its adhesive power. Rain or shine, hot or cold, your ceramic and wood combination will remain securely bonded.

- Quick-Setting: Super Glue sets in seconds upon contact with moisture, allowing for efficient bonding. Whether you’re repairing broken ceramic items or attaching tiles to wooden surfaces, Super Glue works swiftly to bring your projects to completion.

Disadvantages:

- Surface Preparation: Optimal adhesion requires proper surface preparation. If your ceramics are porous or your wood is highly polished, a little sanding or roughening is recommended before applying the adhesive.

- Limited Gap-Filling Capability: Super Glue excels when the ceramic and wood surfaces fit closely together. It has limited ability to fill significant gaps or uneven surfaces. In such cases, consider alternative adhesives that offer better gap-filling properties.

Application Tips:

- Clean and Dry Surfaces: Prioritize cleanliness by ensuring both the ceramic and wood surfaces are free from dirt and moisture before applying Super Glue. Dry surfaces promote maximum adhesion.

- Thin and Even Application: Apply a thin, even layer of Super Glue onto both surfaces to create a strong and seamless bond. Excessive glue can weaken the adhesive strength.

- Allow Proper Curing Time: Hold the materials firmly together for a few minutes to allow the Super Glue to set properly. Consult the manufacturer’s instructions for recommended curing time to achieve the best results.

Specialty Adhesives

Today, we will uncover the secrets of bonding ceramic to wood, taking your creative endeavors to new heights.

Let’s start our journey with an adhesive superhero – epoxy resin. This two-part adhesive is a force to be reckoned with when it comes to joining ceramic and wood. With its exceptional adhesion properties, it creates a bond as unyielding as the Hulk’s grip. But that’s not all. Epoxy resin boasts remarkable resistance to moisture, heat, and chemicals, making it a reliable choice for projects that stand the test of time.

Now, if you seek a glue as adaptable as a chameleon, look no further than polyurethane glue. This single-component adhesive works its magic by expanding and filling gaps between ceramic and wood surfaces. Not only does it form a sturdy bond, but it also exhibits flexibility when cured. So go ahead and embark on projects that require movement or encounter vibrations – polyurethane glue has got you covered.

But hold on tight because there’s more wisdom to share. When working with these specialty adhesives, it is crucial to follow the manufacturer’s instructions meticulously. Prepare your surfaces like a seasoned professional by thoroughly cleaning them, banishing any hint of dust or grease. Then, apply the adhesive evenly and exercise patience as you let it cure. Remember, good things come to those who wait.

So there you have it – an enchanting insight into specialty adhesives for bonding ceramic to wood. Whether you’re sculpting breathtaking masterpieces or crafting exquisite furniture pieces, epoxy resin and polyurethane glue will be your trusted allies. With their strength and durability, your creations will leave jaws dropping and minds blown.

Factors to Consider When Choosing the Best Glue for Ceramic to Wood

Are you ready to tackle a project that involves bonding ceramic to wood? Whether you’re a seasoned DIY enthusiast or a beginner looking to explore your creative side, choosing the right glue is essential for a successful and long-lasting bond. But with so many options available, how do you know which one is the best fit for your project? Don’t worry, we’ve got you covered. Here are some factors to consider when selecting the best glue for ceramic to wood:

- Adhesive Strength: Look for glues that specifically mention their ability to bond ceramic and wood. The adhesive strength is crucial as it ensures a strong and durable bond between these two different materials.

- Drying Time: Consider the drying time of the glue. If you’re working on a time-sensitive project, opt for a glue that dries quickly. On the other hand, if you have more flexibility, you can choose a glue that takes longer to set.

- Waterproof and Weather Resistance: Think about where your bonded item will be used. If it will be exposed to moisture or outdoor elements, choose a glue that offers waterproof or weather-resistant properties.

- Flexibility: Wood expands and contracts with changes in temperature and humidity. To prevent cracking or breaking of the bond, select a glue that can accommodate these movements.

- Application Method: Consider the size and shape of the surfaces you’re bonding. Some glues come in squeeze tubes, spray bottles, or have brush-on applicators. Choose an adhesive with an application method that suits your project needs.

- Toxicity: Ensure that the glue you choose is safe to use. Look for glues labeled as non-toxic or low in volatile organic compounds (VOCs) to protect your health.

- Ease of Cleanup: Some glues can be easily cleaned up with water, while others require solvents or special cleaners. Consider how easy it will be to remove excess glue once your project is complete.

- Longevity: If you want a permanent bond, choose a glue that offers long-lasting durability and resistance to aging. This ensures that your ceramic and wood pieces will stay securely bonded for years to come.

By taking these factors into account, you can confidently select the best glue for bonding ceramic to wood. So go ahead, unleash your creativity, and let the magic of the right adhesive bring your project to life.

Preparing the Surfaces Before Applying Glue

When it comes to gluing ceramic to wood, achieving a bond that is both robust and enduring requires careful surface preparation. In this article, we will delve into the significance of preparing surfaces before applying glue, providing step-by-step instructions to help you master this essential technique.

Cleaning the Ceramic Surface:

Begin by thoroughly cleaning the ceramic surface with soap and water, eliminating any dirt, dust, or grease that may hinder adhesion. Stubborn stains or residues can be tackled with mild abrasive cleaners or rubbing alcohol. Rinse the surface with water and allow it to dry completely.

Sanding the Wood Surface:

To enhance the adhesive’s grip, lightly sand the wood surface using fine-grit sandpaper. Sand in the direction of the wood grain to avoid surface damage. After sanding, remove any dust or debris using a tack cloth or clean, dry cloth.

Priming or Sealing the Wood Surface (if necessary):

For porous or rough-textured wood, applying a primer or sealer is recommended. This creates a smoother and more even surface, improving adhesive performance. Allow the primer or sealer to dry according to manufacturer instructions.

Choosing the Right Glue:

When bonding ceramic to wood, opt for an epoxy-based adhesive known for its strong bonding capabilities and resistance to moisture and temperature fluctuations.

Applying the Glue:

Mix equal parts of epoxy resin and hardener on a clean disposable surface as instructed by the manufacturer. Apply a thin, even layer of the mixed epoxy onto one prepared surface using a disposable brush or small spatula.

Pressing and Clamping:

Align the ceramic and wood surfaces carefully, pressing them together firmly. Apply even pressure across the entire surface for a secure bond. Use clamps or weights to hold the glued surfaces in place while the adhesive cures.

Testing the Adhesive on a Small Area Before Use

Achieving a strong and durable bond is crucial when working with ceramic and wood. Before diving into the glueing process, it is essential to take a step back and test the adhesive on a small area. This simple yet vital precaution can save you from potential disasters and ensure that your project stands the test of time. In this article, we will explore why testing adhesive on a small area is important when working with ceramic and wood.

Compatibility Assessment:

Different adhesives have varying properties, and they may react differently depending on the type of ceramic and wood being used. By testing the adhesive on a small, inconspicuous area, you can evaluate its compatibility with both materials. Look for any adverse reactions such as discoloration, texture changes, or damage that may occur during the curing process. This assessment allows you to choose the most suitable adhesive for your specific materials.

Surface Preparation:

Properly preparing the surfaces of both the ceramic and wood is crucial before conducting the adhesive test. Clean the small area with a mild detergent or rubbing alcohol to remove any dirt, dust, or grease that could affect the bonding process. This ensures that the adhesive can adhere effectively to the surfaces and provides accurate results during the test. A clean surface sets the foundation for a successful bond.

Adhesive Curing:

Follow the manufacturer’s instructions for curing the adhesive on the tested area. Allow sufficient time for the adhesive to cure or until it becomes tacky to the touch. This step is crucial as it mimics the conditions under which the adhesive will bond the entire surface. By following proper curing procedures, you can determine if the adhesive is suitable for your specific ceramic and wood combination.

Reconsidering Your Choice:

If any undesirable reactions occur during the adhesive test, it is crucial to reconsider your choice of adhesive. Consult professionals or seek advice from manufacturers to find a more suitable adhesive for your specific materials. This step can save you time, money, and potential damage in the long run. It’s better to switch to a compatible adhesive than risk compromising the integrity of your project.

Intended Use of Bonded Ceramic and Wood Assembly

The answer lies in understanding the intended use of the bonded assembly. Whether you’re working on a decorative project or a load-bearing application, selecting the right adhesive is crucial. In this article, we’ll explore the considerations for selecting the best glue to ensure your ceramic and wood assembly stands strong for years to come.

Decorative Projects:

If aesthetics take precedence over functionality, epoxy-based adhesives are your go-to choice. These glues offer exceptional bond strength, resisting moisture, heat, and chemicals. With their long-lasting bond between ceramic and wood surfaces, epoxy adhesives provide durability for decorative projects. What’s more, they come in different colors, allowing you to match the glue with your project’s overall look.

Load-Bearing Applications:

For load-bearing or structural projects like ceramic tiles on a wooden tabletop or furniture with ceramic accents, a stronger adhesive is required. Enter polyurethane-based adhesives. These glues not only create strong bonds but also possess excellent flexibility and resistance to water. They can absorb shock and accommodate movement between ceramic and wood surfaces without compromising the integrity of the bond.

Outdoor and Extreme Conditions:

When exposed to outdoor elements or extreme temperature fluctuations, your bonded assembly needs an adhesive that can withstand such conditions. Marine-grade epoxy or polyurethane glues are specifically designed for this purpose. They resist moisture, UV rays, and temperature variations, providing reliable bonding for ceramic and wood assemblies in outdoor settings.

Pros and Cons of Different Adhesives for Bonding Ceramic to Wood

The right adhesive is essential when bonding ceramic to wood. Each adhesive has its own pros and cons, making it crucial to consider your specific needs. This article explores the advantages and disadvantages of different adhesives commonly used for this purpose.

Epoxy Resin:

- Pros: Epoxy resin boasts a strong bonding capability, creating a durable and long-lasting bond that can withstand high temperatures and environmental conditions. It also provides excellent water and chemical resistance, making it suitable for outdoor applications. Epoxy resin offers a relatively long working time for proper alignment and adjustment.

- Cons: Epoxy resin has a higher cost compared to other adhesives, requiring thorough surface preparation such as sanding or roughening. The mixing process can be complicated, and the viscous nature of epoxy resin can make it messy to work with.

Polyurethane Adhesive:

- Pros: Polyurethane adhesive offers flexibility and strong bonding strength, even on uneven surfaces. It is resistant to moisture, chemicals, and temperature fluctuations. Polyurethane adhesive cures quickly, forming a bond that can withstand heavy loads and external stresses.

- Cons: Polyurethane adhesive tends to expand during curing, requiring proper clamping or securing. It may have longer curing times compared to other adhesives and can be challenging to clean up once cured.

Cyanoacrylate (Super Glue):

- Pros: Super glue provides a fast curing time and ease of use. It forms a quick and strong bond, making it suitable for small or delicate ceramic pieces or temporary bonding. Super glue is readily available and inexpensive.

- Cons: Super glue may not be the most durable option for long-term applications. It can become brittle over time and may not adhere well to certain ceramics or porous wood surfaces without proper preparation.

Silicone Adhesive:

- Pros: Silicone adhesive offers good flexibility and excellent resistance to moisture. It forms a waterproof bond and can withstand temperature variations. Silicone adhesive is easy to work with and does not require any mixing.

- Cons: Silicone adhesive has relatively lower bonding strength compared to other options, making it unsuitable for heavy-duty applications.

Tips for Using Adhesives Successfully

When it comes to creating a strong and durable bond between ceramic and wood, choosing the right adhesive is paramount. In this blog post, we will explore some essential tips that will help you achieve successful adhesion using adhesives. From meticulous surface preparation to selecting the perfect adhesive and applying it with precision, these tips will serve as your guide to ensuring a successful bonding process.

Start with Surface Preparation:

Before diving into the adhesive application, take the time to clean both the ceramic and wood surfaces thoroughly. Eliminate any traces of dirt, dust, or grease by using a mild detergent or rubbing alcohol. Additionally, lightly sanding the wood surface will create a rough texture, amplifying the strength of the bond.

Choose the Right Adhesive:

The secret to achieving a successful bond lies in selecting an adhesive specifically designed for ceramic and wood. Look for an adhesive that boasts a strong bond with both materials or one explicitly formulated for this purpose. Epoxy adhesives are highly recommended due to their exceptional bonding strength and long-lasting durability.

Apply the Adhesive Evenly:

When it comes to applying the adhesive, ensure an even distribution across both the ceramic and wood surfaces. Utilize a small brush or spatula to create a thin layer of adhesive, covering the entire area requiring bonding. This meticulous application guarantees full coverage, preventing any weak spots or unsightly gaps in the bond.

Allow Sufficient Drying and Curing Time:

Patience is key when it comes to drying and curing the adhesive properly. Rushing this critical step can lead to weak bonds that may ultimately fail over time. To ensure optimal results, adhere strictly to the manufacturer’s instructions regarding recommended drying and curing times, giving the adhesive ample time to set.

Apply Pressure During Bonding:

To achieve an unyielding bond between ceramic and wood, exert pressure during the bonding process. Utilize clamps or weights to firmly hold the two surfaces together while the adhesive cures. This pressure guarantees maximum contact between the materials, thereby enhancing the strength of the bond.

bDcXfxi5MZI” >

Also Read: How To Glue Ceramic Back Together?

Conclusion

When it comes to bonding ceramic and wood, finding the right glue is crucial. The best glue for this task is one that can withstand the test of time and provide a strong and durable bond. After thorough research and testing, it has been determined that epoxy glue is the top choice for joining ceramic to wood.

Epoxy glue offers several advantages over other types of adhesives. Its exceptional strength ensures a robust bond that can withstand various stresses and strains. Whether you’re attaching a delicate ceramic figurine to a wooden base or securing tiles onto a wooden surface, epoxy glue provides unmatched reliability.

In addition to its strength, epoxy glue also boasts excellent resistance to moisture, heat, and chemicals. This means that your ceramic-wood creations will remain intact even in challenging environments or when exposed to different elements.

Furthermore, epoxy glues are easy to use. They typically come in two separate components – resin and hardener – which need to be mixed together before application. Once mixed, you have a limited amount of time (known as the “open time”) to work with the adhesive before it starts curing. This allows for precise positioning of the ceramic pieces on the wood surface before the glue sets.

To achieve optimal results when using epoxy glue, proper surface preparation is essential. Both the ceramic and wood surfaces should be clean, dry, and free from any dirt or debris. Sanding or roughening up the surfaces slightly can also enhance adhesion.

In conclusion, when it comes to bonding ceramic to wood effectively, epoxy glue reigns supreme. Its exceptional strength, resistance to various elements, ease of use, and compatibility with different materials make it the best choice for ensuring a long-lasting bond between these two materials.