Welcome to our blog post all about the best adhesive for clear polycarbonate. Whether you’re a DIY enthusiast or a seasoned pro, finding the perfect adhesive is key to achieving a successful bond with your polycarbonate materials. Not only does the right adhesive provide strength and durability, but it also keeps that crystal-clear surface looking flawless.

One popular choice for bonding clear polycarbonate is cyanoacrylate adhesive, better known as super glue. This adhesive offers a multitude of benefits, including lightning-fast curing times, impressive bond strength, and incredible versatility. It’s perfect for those smaller projects and can handle humidity and temperature changes like a champ. However, be aware that super glue can leave behind visible residue and might not be ideal for larger bonding areas.

Another option worth considering is epoxy adhesive. Epoxies are renowned for their exceptional bonding strength, resistance to chemicals, and ability to tackle both small and large bonding areas. Plus, they excel at maintaining transparency and keeping that clear polycarbonate surface looking its best. Just keep in mind that epoxies tend to have longer curing times and may require some careful preparation and mixing.

When choosing the best adhesive for clear polycarbonate, take into account factors such as the size of your project area, desired curing time, and level of transparency you’re after. And don’t forget to consult the manufacturer’s recommendations regarding compatibility with polycarbonate and your specific application.

In the upcoming sections of this blog post, we’ll explore even more options and delve deeper into the pros and cons of each type of adhesive. Whether you’re tackling something small or embarking on a grand-scale project, we’ve got you covered. So keep reading to find the adhesive that perfectly suits your needs – one that will guarantee a strong bond that lasts for ages on your clear polycarbonate masterpiece.

Clear Polycarbonate

Contents

- 1 Clear Polycarbonate

- 2 Adhesive Options for Clear Polycarbonate

- 3 Methylene Chloride Adhesives

- 4 Cyanoacrylate Adhesives

- 5 Silicone-Based Adhesives

- 6 Structural Adhesives

- 7 Proper Surface Preparation for Bonding Clear Polycarbonate

- 8 Conclusion

Clear polycarbonate, an extraordinary thermoplastic material, has captivated industries worldwide with its enchanting blend of transparency and durability. Whether you’re in construction, automotive manufacturing, or electronics, clear polycarbonate reigns supreme as the go-to choice for a myriad of applications. Prepare to be mesmerized as we delve into the captivating properties and astonishing applications of this versatile material.

Properties that Set Clear Polycarbonate Apart:

- Unbreakable Strength: Behold the resilience of clear polycarbonate. With its high impact resistance, it stands as a near-indestructible force. Safety barriers and protective shields find solace in its unyielding nature, ensuring the well-being of individuals in diverse settings.

- Heat Resistance Champion: Witness the unyielding endurance of clear polycarbonate under scorching temperatures. It remains unaltered, undeterred by heat-induced deformities or meltdowns. This quality renders it indispensable in environments where temperature fluctuations are commonplace.

- Chemical Resistance Hero: Fearlessly confronting corrosive substances, clear polycarbonate boasts exceptional chemical resistance. It stands strong in applications that demand an unwavering defense against harsh chemicals.

- Sunlight’s Best Friend: Unlike lesser materials, clear polycarbonate stands defiant against the ravages of sunlight. It refuses to succumb to yellowing or brittleness, showcasing its unrivaled UV resistance. This attribute ensures clarity and longevity in outdoor applications.

Applications that Showcase Clear Polycarbonate’s Versatility:

- Windows and Skylights: Experience the optical clarity that makes clear polycarbonate an unrivaled choice for windows and skylights. It invites the gentle embrace of natural light, illuminating interior spaces with unparalleled brilliance while offering unobstructed views.

- Safety Shields and Machine Guards: Embrace the impenetrable shield of clear polycarbonate, safeguarding workers in industrial settings. Its unmatched impact resistance ensures protection against potential hazards lurking in the workplace.

- Signage and Electronic Display Panels: Witness the vibrant allure of clear polycarbonate as it takes center stage in creating captivating signage and electronic displays. Its transparency and durability combine to create eye-catching visuals that leave a lasting impression.

- Automotive Components: Embark on a journey where clear polycarbonate reigns supreme, gracing automotive components with its strength, heat resistance, and optical clarity. From dazzling headlights to sleek interior components, this material emerges as an invaluable asset in the automotive industry.

Adhesive Options for Clear Polycarbonate

You find yourself with a piece of clear polycarbonate in hand, ready to embark on your next project. But how can you guarantee a bond that is both strong and enduring? Fear not, my friends, for I am here to guide you through the adhesive options available for bonding clear polycarbonate. Let’s dive in.

- Cyanoacrylate: Let’s start with the classic superhero of adhesives – cyanoacrylate, also known as super glue. This adhesive is renowned for its quick and robust bonding abilities, making it perfect for a variety of applications. However, it is important to note that cyanoacrylate can be brittle and may not hold up under high stress or temperature variations.

- Acrylic Adhesive: If clarity is your top priority, then acrylic adhesive is the way to go. This adhesive provides a strong and durable bond on clear polycarbonate surfaces. It can withstand high temperatures and offers excellent resistance to chemicals, making it a popular choice in the electronics industry.

- Structural Adhesives: When it comes to heavy-duty applications, structural adhesives like epoxy or polyurethane are your best bet. These adhesives offer high strength and are suitable for load-bearing capabilities. However, they may require longer curing times and can be a bit trickier to work with compared to other options.

- UV-Curable Adhesives: Need speed? UV-curable adhesives are the answer. These adhesives cure rapidly when exposed to ultraviolet light, making them ideal for assembly or fast production processes. They provide excellent clarity and resist yellowing over time.

When choosing an adhesive for clear polycarbonate, consider factors such as temperature, stress levels, and desired clarity. Consulting with adhesive manufacturers or experts in the field can help you determine the best adhesive option for your specific needs.

Methylene Chloride Adhesives

In the world of adhesives, few can match the marvels of methylene chloride adhesives when it comes to bonding clear polycarbonate materials. These remarkable adhesives offer a transparent bond that is not only aesthetically pleasing but also incredibly strong and resistant to environmental factors. However, it is vital to prioritize safety precautions when working with these adhesives to ensure a successful and safe bonding experience. Let’s dive deeper into the advantages of using methylene chloride adhesives for clear polycarbonate bonding and explore the necessary safety measures.

Advantages of Methylene Chloride Adhesives for Clear Polycarbonate Bonding:

Transparent and Invisible Bond:

- A seamless finish that leaves no visible residue or marks on the surface.

- The bond becomes virtually invisible, allowing the natural beauty of clear polycarbonate to shine through.

Exceptional Bonding Strength:

- Creates a bond that can withstand stress and pressure, ensuring secure joints.

- Ideal for applications requiring structural integrity, such as transparent enclosures or display cases.

- Provides peace of mind knowing that your bonded materials will remain securely in place.

Resistance to Environmental Factors:

- Endures exposure to moisture, chemicals, and temperature fluctuations without compromising bond strength.

- Suitable for both indoor and outdoor applications.

- Withstands the test of time, even in harsh weather conditions.

Safety Precautions when Using Methylene Chloride Adhesives:

Work in a Well-Ventilated Area:

- Methylene chloride is a volatile organic compound (VOC) that releases harmful fumes.

- Ensure sufficient airflow by opening windows or using ventilation systems to protect yourself from inhalation.

Wear Personal Protective Equipment (PPE):

- Shield your skin from direct contact with the adhesive by wearing gloves.

- Protect your respiratory system by using a respirator that filters harmful fumes.

Avoid Smoking or Open Flames:

- Methylene chloride is highly flammable, so keep away from any potential sources of ignition.

- Ensure a safe working environment by eliminating fire hazards.

Store Adhesives Properly:

- Maintain the adhesive’s integrity by storing it in tightly sealed containers.

- Keep them in a cool, dry place following the manufacturer’s storage instructions.

Cyanoacrylate Adhesives

Cyanoacrylate adhesives, also known as super glue or instant glue, are the go-to solution for bonding clear polycarbonate materials. These adhesives have gained popularity due to their impressive strength, fast curing time, and transparent bond.

One of the key features of cyanoacrylate adhesives is their exceptional strength. When applied to clear polycarbonate, they form a bond that is resistant to impact, moisture, and temperature changes. Whether you’re working on a DIY project or repairing a broken polycarbonate item, you can trust that the bond will hold up under various conditions.

What really sets cyanoacrylate adhesives apart is their rapid curing time. No more waiting around for hours or days for your glue to dry. These adhesives react with moisture in the air or on the surfaces being bonded, resulting in a quick and efficient cure. You’ll be amazed at how quickly your project comes together.

However, it’s important to note that not all cyanoacrylate adhesives are suitable for bonding clear polycarbonate. Some may leave behind an unsightly white residue or cause clouding on the surface. To avoid these issues, it’s crucial to use a specialized adhesive formulated specifically for bonding clear plastics like polycarbonate. These adhesives ensure a transparent bond without any discoloration or fogging.

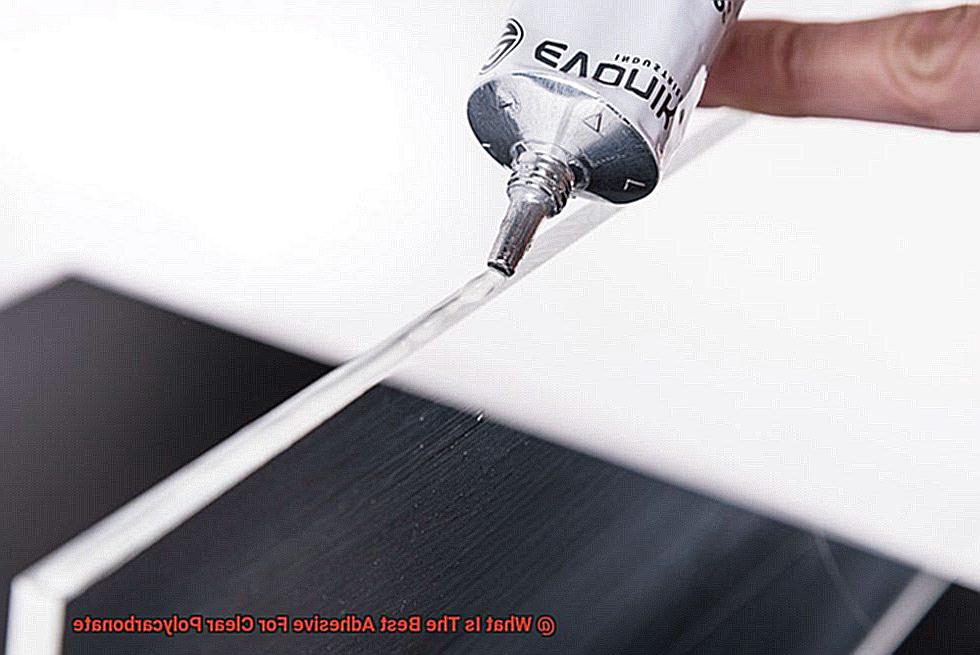

To achieve optimal results, proper surface preparation is key. Make sure to thoroughly clean and prepare the surfaces before applying the adhesive. Any dirt, grease, or moisture can affect the quality of the bond. Additionally, it’s important to follow the manufacturer’s instructions regarding application and curing time. Taking these precautions will ensure a durable and transparent bond.

Silicone-Based Adhesives

Silicone-based adhesives are the superheroes of bonding clear polycarbonate. With their incredible transparency, flexibility, and resistance powers, they create strong and durable bonds while maintaining the clarity and integrity of your materials.

One of the key advantages of silicone-based adhesives is their ability to bond well with a wide range of materials, including clear polycarbonate. Their low surface tension allows them to spread evenly and create strong bonds. No need to worry about your materials falling apart.

But that’s not all – silicone-based adhesives also have amazing resistance powers. They can withstand extreme temperatures, moisture, UV radiation, and even corrosive substances. Whether you’re building something for the great outdoors or a high-humidity environment, these adhesives have got your back.

And let’s not forget about flexibility. Clear polycarbonate is known for its flexibility and impact resistance, and silicone adhesives can match those properties. They can withstand movements and vibrations without cracking or losing their bond strength. It’s like having a superhero sidekick that can handle anything.

To ensure a successful bond, it’s important to follow some simple guidelines. Make sure the surfaces are clean and dry, free from any dirt or grease. You can even roughen them up a bit with sandpaper for better grip. And when applying the adhesive, use a caulking gun or syringe for precise application. Thin layers are key to prevent excess glue from clouding the transparency of your polycarbonate.

Structural Adhesives

Structural adhesives are a remarkable solution for bonding clear polycarbonate materials. These adhesives possess extraordinary properties that enable them to create strong and seamless bonds without compromising the clarity of the material.

There are various types of structural adhesives available, including epoxy, acrylic, and polyurethane adhesives. Each type has its own unique strengths and benefits. Epoxy adhesives are known for their exceptional strength and resistance to temperature, chemicals, and moisture. Acrylic adhesives offer good strength, flexibility, and rapid curing times. Meanwhile, polyurethane adhesives provide flexibility and impact resistance.

The advantages of using structural adhesives for clear polycarbonate are numerous. One of the most significant benefits is their ability to create an invisible bond. No more unsightly seams or cloudy spots. These adhesives are specially formulated to maintain the transparency of the polycarbonate while delivering a reliable and durable bond.

Before embarking on your adhesive adventure, there are a few important considerations to keep in mind. First, assess the specific requirements of your application, such as desired bond strength and environmental conditions. Seek advice from adhesive manufacturers or experts who can guide you in selecting the optimal adhesive for your needs.

Proper surface preparation is also crucial for success. Ensure that your surfaces are clean, dry, and free from any contaminants that could hinder the bonding process. Think of it as creating a superhero-worthy lair for your project.

Proper Surface Preparation for Bonding Clear Polycarbonate

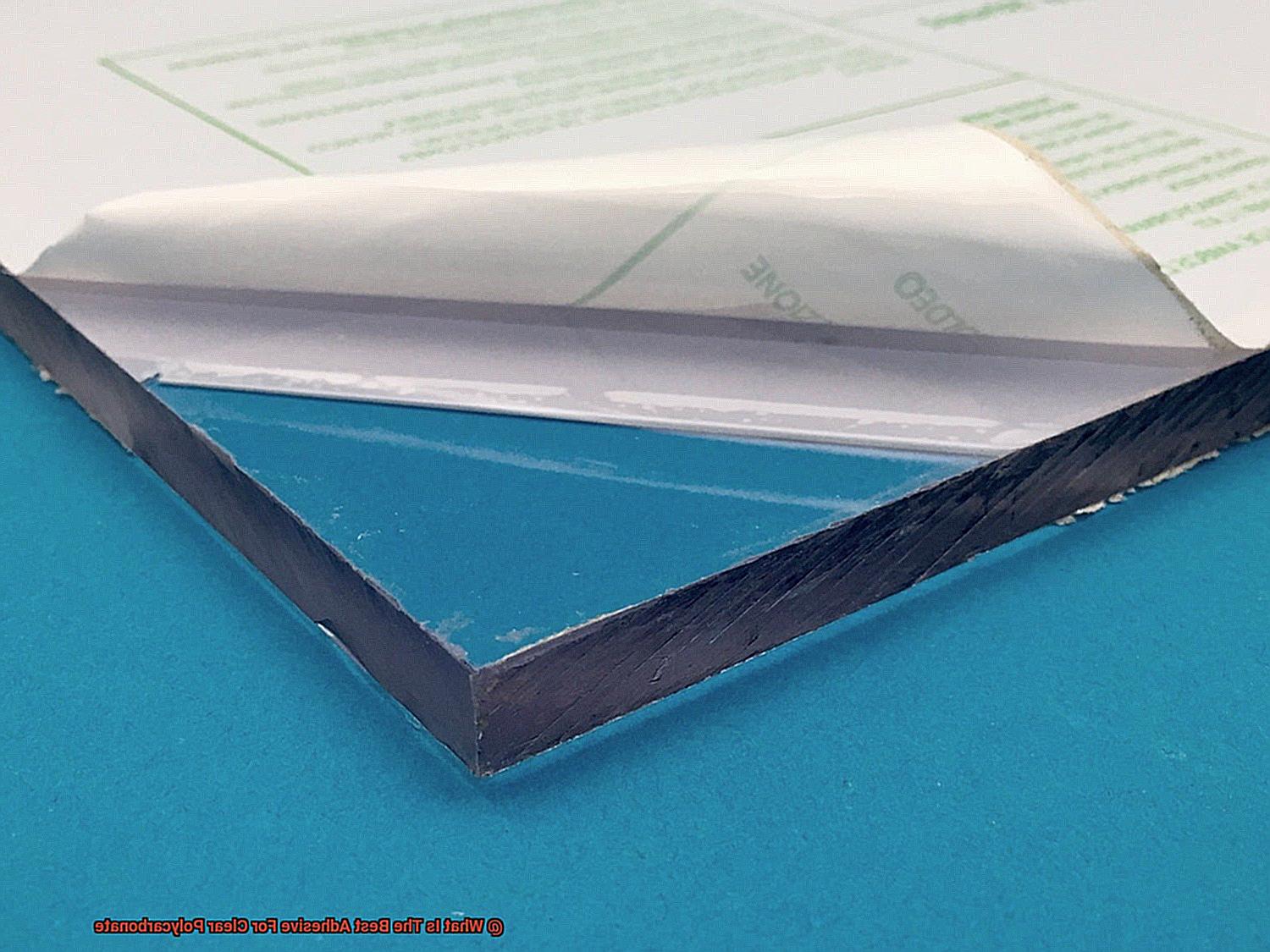

Proper surface preparation is the key to achieving a strong and seamless bond when bonding clear polycarbonate. To ensure success, there are several steps you need to take:

- Clean the surface: Before applying any adhesive, it is crucial to clean the surface of your polycarbonate thoroughly. Remove any dirt, dust, grease, or oils that may be present. You can use a mild detergent or isopropyl alcohol for this purpose. Be sure to avoid cleaning agents that contain ammonia, as they can cause damage to the polycarbonate.

- Lightly sand the surface: After cleaning, lightly sand the surface using fine-grit sandpaper. This step creates a roughened surface that provides better adhesion for the adhesive. Remember to remove any sanding dust afterward using a lint-free cloth or compressed air.

- Apply a primer or adhesion promoter: Depending on the specific requirements of your bonding application, you may need to treat the surface with a primer or adhesion promoter designed for bonding polycarbonate. These products enhance bond strength and durability. Follow the manufacturer’s instructions carefully regarding application methods and drying times.

- Ensure dry surfaces: Before applying the adhesive, make sure that both surfaces are completely dry and free from any moisture. Moisture can compromise the effectiveness of the adhesive and result in weak bonds.

s7TfdinHyJs” >

Conclusion

In conclusion, the quest for the best adhesive for clear polycarbonate offers a range of options to explore. One popular choice is cyanoacrylate adhesive, also known as super glue. This mighty adhesive boasts a lightning-fast curing time and an impressive bond strength. It’s perfect for those smaller projects that demand quick results. Plus, it can handle humidity and temperature changes with ease. However, be aware that super glue may leave behind visible residue and might not be the best fit for larger bonding areas.

Another contender in the race is epoxy adhesive. Epoxies bring exceptional bonding strength to the table, along with resistance to chemicals. They’re versatile enough to tackle both small-scale and large-scale bonding tasks. Not only that, but epoxies excel at maintaining transparency, ensuring your clear polycarbonate surface looks flawless throughout its lifetime. Keep in mind, though, that epoxies have longer curing times and may require careful preparation and mixing.

But wait. There’s more. Acrylic adhesives offer another option worth considering. And let’s not forget about structural adhesives like polyurethane or epoxy, which bring their own unique strengths to the table. If you’re looking for rapid curing, UV-curable adhesives are there to save the day. And if flexibility and resistance are what you seek, silicone-based adhesives will be your trusty companion.

When selecting an adhesive for your clear polycarbonate project, take into account factors such as project size, desired curing time, and level of transparency required. It’s also crucial to consult the manufacturer’s recommendations regarding compatibility with polycarbonate.

By choosing the perfect adhesive tailored to your specific needs, you’ll ensure a bond that stands strong on your clear polycarbonate masterpiece.