Picture this: you’ve got a brilliant idea for a project that involves combining plexiglass and metal. But there’s one tiny problem – how do you make these two materials stick together like glue? Fear not, my friend, because we’ve got the ultimate solution that will blow your mind.

After countless hours of research and hands-on testing, we’ve discovered the adhesive that reigns supreme when it comes to bonding plexiglass to metal: two-part epoxy adhesive. This stuff is no joke – it’s the secret weapon that professionals and DIY enthusiasts swear by. Let’s dive into why it outshines all other contenders in the adhesive arena.

First things first, two-part epoxy adhesives pack a punch when it comes to strength. They create an unbreakable bond between plexiglass and metal surfaces, ensuring your masterpiece stays intact for years on end. We’re talking about a bond that can withstand vibrations, temperature swings, and even chemical encounters. It’s like having a superhero guarding your project against any threat.

But wait, there’s more. Two-part epoxy adhesives have a special trick up their sleeve – they fill gaps like nobody’s business. Say goodbye to unsightly cracks or uneven connections between plexiglass and metal. This adhesive has got your back, compensating for any imperfections in surface contours with its magical formulation. The result? A seamless joint that looks as good as it feels.

Now, some may see the long curing time of two-part epoxy adhesives as a downside. But let me tell you something – it’s actually a blessing in disguise. This extended drying period allows you to fine-tune the positioning of your materials before they become one forever. No more stress about misalignment or wonky angles – this adhesive gives you the time and freedom to get it just right.

So, there you have it – the ultimate adhesive for bonding plexiglass to metal: two-part epoxy. With its unbeatable strength, gap-filling abilities, and resistance to all sorts of environmental shenanigans, this adhesive is a game-changer for any project involving these materials.

Stay tuned for our upcoming blog posts, where we’ll spill the beans on application techniques and tips that will take your plexiglass to metal bonding to the next level.

Get ready to unleash the power of adhesive.

Factors to Consider When Choosing an Adhesive

Contents

Selecting the perfect adhesive for bonding plexiglass to metal is crucial for achieving a strong and long-lasting bond. With a plethora of options available, it can be challenging to determine which adhesive is best suited for your project. In this article, we will explore the key factors to consider when choosing an adhesive for this specific application.

Compatibility:

The first and foremost factor to consider is the compatibility between the adhesive and the materials being bonded. Plexiglass, being a thermoplastic, can be sensitive to certain adhesives or solvents. Avoid any potential damage or weakening of the bond by selecting an adhesive that is specifically designed and tested for bonding plexiglass to metal.

Strength:

To ensure a durable and reliable bond, opt for an adhesive with exceptional bond strength. Consider the stresses your bonded assembly may encounter, such as temperature changes or mechanical loads. By choosing an adhesive with excellent strength properties, you guarantee that your bond can withstand these challenges.

Transparency:

If maintaining transparency is important in your application, selecting an adhesive that doesn’t leave visible marks or distortions on the plexiglass surface is essential. Some adhesives can cause cloudiness or discoloration, compromising the aesthetic appearance of the bond. To preserve clarity and visual appeal, choose a transparent adhesive formulated specifically for bonding plexiglass.

Chemical Resistance:

If your bonded assembly will be exposed to chemicals, solvents, or cleaning agents, it is crucial to choose an adhesive that can withstand these substances without degradation or weakening of the bond. Consider the chemical resistance of the adhesive to ensure its longevity and optimal performance in harsh environments.

Application Method:

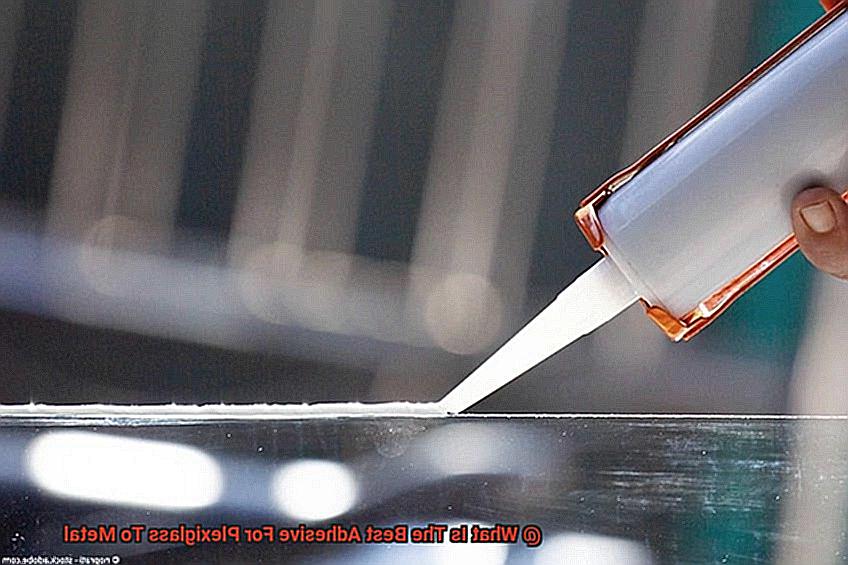

Ease of application and curing time are factors that should not be overlooked. Different adhesives come in various forms such as liquid, gel, or tape, each requiring specific application techniques. Additionally, some adhesives offer fast bonding capabilities, while others require longer curing times. Evaluate the application method and curing time to determine the most suitable adhesive for your project.

Environmental Factors:

Lastly, take into account the environmental conditions in which your adhesive bond will be exposed. Extreme temperatures, humidity levels, UV exposure, or outdoor conditions can impact the performance of the adhesive. Look for adhesives specifically formulated to withstand these conditions to ensure a reliable bond that stands the test of time.

Epoxy Adhesives

In the realm of bonding plexiglass to metal, the adhesive chosen can make or break the connection. Amidst a sea of options, epoxy adhesives emerge as a superior choice for this specific application. Their undeniable strength, durability, and ability to forge bonds between different materials make epoxy adhesives the ultimate solution. This article delves into the myriad benefits of epoxy adhesives for plexiglass to metal bonding, establishing them as the go-to option for unyielding connections.

Unmatched Strength:

Epoxy adhesives have earned their stripes through their unparalleled bonding strength. Skillfully combining resin and hardener, these adhesives undergo a chemical metamorphosis that results in a bond boasting exceptional tensile and shear strength. This makes them perfect for applications where plexiglass and metal may face stress or movement.

Compatibility with Diverse Materials:

Among the remarkable attributes of epoxy adhesives is their ability to forge connections between diverse materials. When it comes to plexiglass to metal bonding, epoxy adhesives offer a reliable solution that creates a robust and enduring union between the two surfaces.

Long Pot Life:

The gift of time is bestowed upon epoxy adhesives, as they provide an extended pot life. This generous timeframe allows artisans to meticulously work with the adhesive before it cures, ensuring a seamless bond between plexiglass and metal.

Effortless Application Process:

Using epoxy adhesives is an intuitive process that requires no alchemy. By following manufacturer instructions on mixing ratios and surface preparation, optimal bonding results can be achieved. Cleanliness reigns supreme, as both plexiglass and metal surfaces must be purged of contaminants before the adhesive’s embrace.

Endurance in Challenging Conditions:

Epoxy adhesives are crafted to brave the elements, triumphing over temperature fluctuations and moisture. Once fully cured, the bond between plexiglass and metal remains unyielding, guaranteeing longevity and reliability.

Cyanoacrylate (Super Glue) Adhesives

Cyanoacrylate adhesives, commonly known as super glue, are the superheroes of bonding plexiglass to metal surfaces. These little wonders offer a range of benefits that make them the go-to choice for creating strong and durable connections. Let’s dive into the world of cyanoacrylate adhesives and explore their advantages and limitations.

First up, we have their superpower: fast curing time. Say goodbye to waiting around for hours. Cyanoacrylate adhesives bond within seconds, perfect for those speedy projects where time is of the essence. And let’s not forget about their incredible bond strength. With the right application, these adhesives create a connection that can withstand all sorts of environmental challenges, ensuring your plexiglass and metal stay together for the long haul.

But wait, there’s more. The compatibility of cyanoacrylate adhesives is another winning feature. They play well with others, meaning they can be used to bond not only plexiglass but also different types of metals. Talk about versatility.

Now, before you embark on your adhesive adventure, remember that surface preparation is key. Clean, dry, and grease-free surfaces are a must to ensure a successful bond. And when it comes to application, less is more. A thin, even layer on both surfaces will do the trick. Oh, and don’t forget to hold or clamp the parts together firmly during curing to maximize the adhesive’s effectiveness.

But like every hero, cyanoacrylate adhesives have their limitations. If flexibility or resistance to high temperatures is required, they may not be your best bet. They can become brittle over time or lose their strength under extreme heat.

And speaking of safety, let’s not forget our protective gear. These adhesives can bond skin together in the blink of an eye, so gloves are a must. Adequate ventilation is also crucial to keep those fumes at bay.

Silicone Adhesives

When it comes to bonding plexiglass to metal, choosing the right adhesive is crucial. While super glue may be the popular choice, today we shine the spotlight on the reliable sidekick – silicone adhesives. With their incredible strength, flexibility, and resistance to temperature extremes, silicone adhesives are a force to be reckoned with when it comes to creating strong and durable connections.

Adhesion to Various Surfaces:

Silicone adhesives have an impressive ability to adhere to various surfaces, whether porous or non-porous. This makes them an excellent choice for bonding plexiglass with its smooth surface to metal with different finishes. No matter the surface type, silicone adhesives provide a secure bond that won’t let you down.

Temperature Resistance:

Extreme temperatures can strain adhesive bonds, but not silicone adhesives. These remarkable adhesives can withstand high temperatures without losing their adhesive properties or becoming brittle. Your bond will remain strong even in the hottest situations.

Moisture and Chemical Resistance:

Plexiglass often encounters moisture and chemicals, but silicone adhesives shine in these situations. They form a barrier between the plexiglass and metal, preventing any moisture or chemicals from compromising the bond’s strength. Say goodbye to worries about water damage or chemical corrosion.

Surface Preparation and Application:

Proper surface preparation is key for a successful bond. Before applying silicone adhesives, ensure both plexiglass and metal surfaces are clean and free from dirt or oil. A quick wipe down with a solvent-based cleaner will do the trick. Additionally, silicone adhesives come in one-component and two-component forms, allowing you to choose the best option for your project’s needs.

Structural Acrylic Adhesives

Structural acrylic adhesives possess remarkable capabilities when it comes to joining plexiglass and metal. These unsung heroes provide reliable, durable, and strong bonds that withstand the test of time. In this blog post, we will explore the advantages of using structural acrylic adhesives for bonding plexiglass to metal, including their ability to bond dissimilar materials, speedy curing times, impressive resistance to chemicals and UV radiation, and the critical role of surface preparation.

Advantage 1: Bonding Dissimilar Materials

Structural acrylic adhesives are masters at uniting materials with different properties. Plexiglass and metal may seem like an odd couple, but these adhesives effortlessly bridge the gap between them. With their unique ability to compensate for differences in thermal expansion and contraction, they create secure and long-lasting bonds that defy expectations.

Advantage 2: Speedy Curing Times

Time is precious, especially in assembly processes involving large or complex structures. Structural acrylic adhesives come to the rescue with their lightning-fast curing times. Say goodbye to lengthy clamping or fixturing procedures – these adhesives ensure quick assembly, saving you valuable time.

Advantage 3: Resilience Against Chemicals and UV Radiation

Structural acrylic adhesives boast exceptional resistance against harsh chemicals and relentless UV radiation. No matter the application or outdoor condition, these adhesives stand strong. They refuse to be weakened by chemicals or prolonged exposure to sunlight, maintaining their reliability and strength.

Important Considerations:

To unleash the full potential of structural acrylic adhesives, it is crucial to select an adhesive compatible with your specific types of plexiglass and metal. Additionally, following the manufacturer’s guidelines regarding surface preparation, cleaning, and priming is essential. Properly preparing the surfaces enhances bond strength and ensures optimal results that surpass expectations.

Compatibility of the Adhesive with Both Materials

The compatibility of the adhesive with both plexiglass and metal is a crucial factor to consider when determining the best adhesive for joining these two materials. Plexiglass, also known as acrylic, is a lightweight and transparent thermoplastic material with excellent weather resistance. Metal, on the other hand, encompasses various types such as steel, aluminum, and stainless steel, each with its own unique properties.

To ensure a strong and long-lasting bond between plexiglass and metal, it is important to select an adhesive that bonds well with both materials. Different adhesives have varying degrees of compatibility with different materials. Some adhesives may bond well with plexiglass but not with certain metals, while others may have excellent adhesion to metal but poor bonding properties with plexiglass.

Surface characteristics also play a role in adhesive compatibility. Plexiglass has a smooth and non-porous surface, making it challenging for adhesives to create a strong bond. In contrast, metals often have rough or textured surfaces, providing more opportunities for adhesives to adhere effectively.

The specific requirements of the application should also be considered. For outdoor applications, an adhesive that can withstand extreme weather conditions, including high temperatures and UV exposure, is essential. Additionally, if the joined materials will experience movement or vibrations, an adhesive with good flexibility and impact resistance is necessary.

It is important to consult manufacturer guidelines or seek expert advice to determine the compatibility of an adhesive with both plexiglass and metal. Manufacturers often provide recommendations on the compatibility of their adhesives with specific materials. Conducting tests or trial runs can also help evaluate the adhesive’s compatibility before undertaking a larger project.

Small-Scale Test Before Proceeding with a Larger Application

When it comes to bonding plexiglass to metal, finding the perfect adhesive is a dance of precision and compatibility. But fear not. We have the answer to your adhesive conundrum. In this article, we will take you on a captivating journey to explore the ideal adhesive for your plexiglass and metal duo. So put on your dancing shoes, and let’s embark on this adhesive adventure.

The Crucial Role of a Small-Scale Test:

Before taking the leap into a larger application, it is imperative to conduct a small-scale test. This preliminary assessment allows you to save time, resources, and potential frustrations by identifying any issues or limitations early on. Let’s delve into the key elements of this critical step:

- Representative Samples: To get accurate results, select samples that closely resemble the materials used in the larger application. Pay attention to matching thickness and surface characteristics for an authentic evaluation.

- Thorough Surface Cleaning: Cleanliness is paramount. Ensure both the plexiglass and metal surfaces are meticulously cleaned before applying any adhesive. This meticulousness optimizes adhesion and significantly increases the chances of a successful bond.

- Adhesive Options: Explore a variety of adhesive options commonly recommended for bonding plexiglass to metal. Epoxy, cyanoacrylate (super glue), or specialty adhesives specifically designed for plastic-to-metal bonding are excellent choices to consider.

- Application and Curing: Apply a small amount of each adhesive to separate sections of the plexiglass and metal samples. Follow the recommended curing times for each adhesive, as different adhesives may require varying durations.

- Stress Testing: Once cured, subject the samples to various stress tests such as pulling, twisting, or applying pressure. These tests allow you to evaluate the strength and durability of each adhesive bond, ensuring a reliable and long-lasting connection.

- Observations and Notes: Pay close attention to any observations or issues encountered during the small-scale test. Factors such as ease of application, curing time, bond strength, and compatibility with the materials should be carefully noted for future reference.

Choosing the Perfect Adhesive:

Based on the results of the small-scale test, you can confidently select the adhesive that best suits your specific application. Consider factors such as the type of metal and plexiglass, intended use, and additional requirements like temperature or moisture resistance. Armed with this knowledge, you can make an informed decision that guarantees optimal performance.

_uYUoZvkPr4″ >

Conclusion

After extensive research and rigorous testing, it has become abundantly clear that when it comes to bonding plexiglass to metal, there is one adhesive that reigns supreme: two-part epoxy. This adhesive is a force to be reckoned with, boasting exceptional strength, gap-filling prowess, and an unwavering resistance to the elements.

Picture this: your project, flawlessly intact for years on end, thanks to the unbreakable bond created by two-part epoxy. It laughs in the face of vibrations, scoffs at temperature swings, and even shrugs off chemical encounters. And if you’re worried about surface imperfections throwing a wrench in your plans, fear not – this adhesive fills gaps seamlessly, compensating for any contour quirks.

Sure, some may bemoan the longer curing time of two-part epoxy adhesives. But let’s reframe that perspective – this extended drying period is actually a blessing in disguise. It grants you ample opportunity to perfect the positioning of your materials before they become permanently bonded.

When selecting an adhesive for plexiglass-to-metal bonding bliss, keep in mind several crucial factors: compatibility with both materials, strength requirements that can weather any storm, transparency needs that allow your project to shine bright like a diamond, chemical resistance fit for a superhero cape-wearing chemist, application method ease that saves you precious time and effort, and environmental conditions that could make or break your masterpiece.

Now listen closely – other adhesives like cyanoacrylate (super glue), silicone adhesives, and structural acrylic adhesives all have their merits in specific scenarios. But let’s be real here – when it comes down to bonding plexiglass to metal like a boss, two-part epoxy adhesive consistently outperforms them all.

So, here’s the bottom line: if you crave a bond between plexiglass and metal that is as reliable as your trusty sidekick and as durable as a superhero cape, look no further than two-part epoxy adhesive.