Ready to infuse your space with a touch of rustic allure by melding wood and brick together? Whether you’re dreaming of a floating shelf that exudes charm, a handcrafted mantel that steals the show, or a captivating piece of reclaimed wood art that tells its own story, finding the perfect adhesive is key.

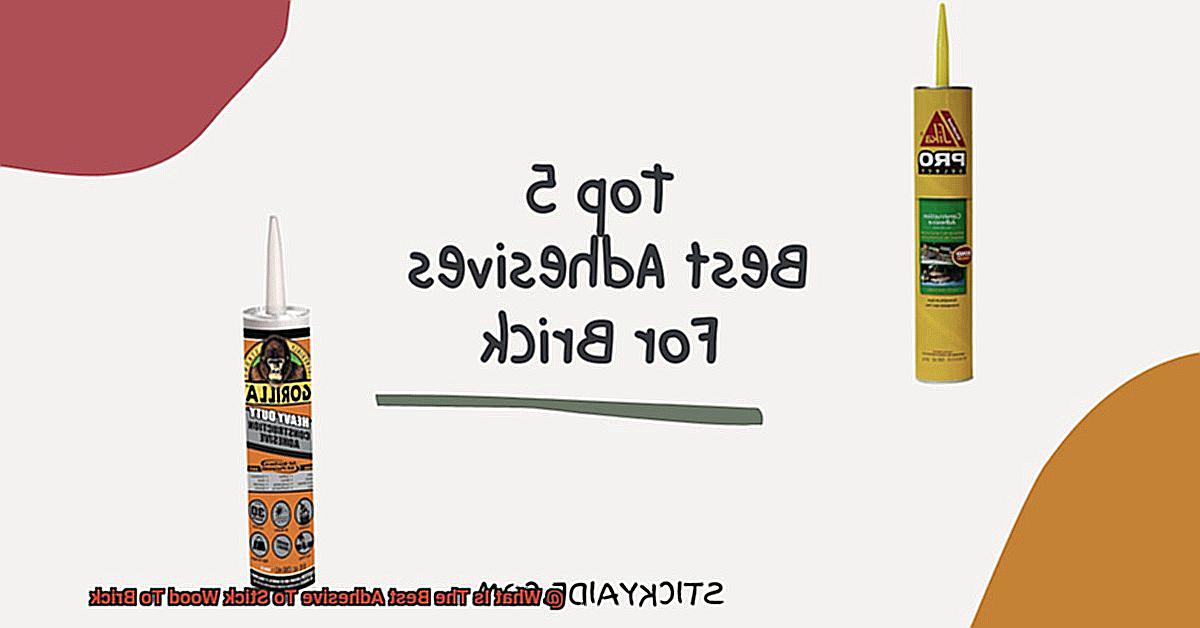

With an overwhelming array of options at your fingertips, it’s vital to select a product that not only boasts Herculean strength and unwavering reliability but also guarantees an unbreakable bond. In this blog post, we’ll embark on an adventure into the enchanting realm of wood-to-brick adhesives and unveil the reigning champion for your project.

Bid farewell to fretting over your wooden masterpiece tumbling off the wall – rest assured, we’ve got you covered with the ultimate adhesive solution.

Types of Adhesives for Wood-to-Brick Applications

Contents

Whether you’re building a cozy outdoor bench or sprucing up your backyard with a wooden pergola, choosing the right adhesive is crucial for a strong and long-lasting bond. In this blog post, we’ll explore the different types of adhesives available for wood-to-brick applications, so you can confidently tackle your next DIY adventure.

Construction Adhesive:

When it comes to sticking wood to brick, construction adhesive is your go-to superhero. This mighty adhesive is specially designed for construction projects and packs a powerful punch. With its incredible bonding strength and durability, it’s perfect for wood-to-brick applications. No matter the weather conditions or moisture levels, construction adhesive will hold your project together. Its versatility allows it to be used both indoors and outdoors, making it an ideal choice for any wood-to-brick project.

Epoxy Adhesive:

Looking for an adhesive that’s as tough as nails? Look no further than epoxy adhesive. This two-part adhesive consists of a resin and a hardener that combine to create an unbreakable bond between wood and brick. Once cured, epoxy adhesive can withstand any challenge thrown its way. It’s impervious to moisture, chemicals, and temperature changes, ensuring a bond that will stand the test of time. Just make sure to mix the two parts together thoroughly before applying for a super-strong result.

Polyurethane Adhesive:

Flexibility is the name of the game when it comes to polyurethane adhesive. This adhesive is like a gymnast, bending and stretching to keep your bond intact. It’s perfect for wood-to-brick applications where there might be some movement or expansion between the surfaces. Polyurethane adhesive also excels at filling in gaps and irregularities in the surfaces, ensuring a secure connection. Plus, it’s resistant to moisture and can be used both indoors and outdoors, making it a versatile choice for any wood-to-brick project.

Silicone Adhesive:

If your wood-to-brick project needs some extra flexibility and moisture resistance, silicone adhesive has got your back. This superhero adhesive can handle both indoor and outdoor environments with ease. Rain or shine, it won’t let you down. Silicone adhesive is known for its excellent resistance to moisture and temperature changes, making it perfect for applications where the bond will be exposed to the elements. It’s also easy to apply and clean up, saving you time and effort on your project.

Liquid Nails:

When it comes to adhesives, Liquid Nails is a trusted brand that offers a range of products specifically designed for wood-to-brick bonding. From heavy-duty to fast-drying options, they’ve got you covered. Just choose the right one for your project’s needs, and let Liquid Nails work its magic. With their reliable performance and excellent bond strength, you can trust Liquid Nails to get the job done right.

Conclusion:

With the right adhesive in your toolbox, you’re well-equipped to tackle any wood-to-brick project that comes your way.

Whether you choose construction adhesive for its strength, epoxy adhesive for its durability, polyurethane adhesive for its flexibility, silicone adhesive for its moisture resistance, or Liquid Nails for its reliable performance – each type of adhesive has its own superpowers. Remember to prepare your surfaces properly and follow the manufacturer’s instructions for the best results.

Construction Adhesive

Construction adhesive, also known as construction glue or construction sealant, is a superhero in the world of bonding materials. With its strong and durable bond, it can withstand the toughest construction applications.

From wood to brick, this versatile adhesive does not disappoint.

One of the key advantages of using construction adhesive for wood-to-brick bonding is its ability to fill gaps and voids between the surfaces. No more worrying about uneven or irregular surfaces. This adhesive ensures a secure and unbreakable bond.

But that’s not all. Construction adhesive is also resistant to moisture and weathering. Rain, snow, extreme temperatures – it can handle it all. Whether you’re building an outdoor deck or fixing a broken fence, this adhesive will keep everything together no matter what Mother Nature throws its way.

Using construction adhesive for wood-to-brick bonding is as easy as pie. First, make sure both surfaces are clean and free from debris. Then, apply a generous amount of adhesive onto the wood surface using a notched trowel or caulk gun. Spread it evenly across the surface, covering every inch that will come into contact with the brick. Finally, firmly press the wood onto the brick surface and hold it in place while the adhesive cures.

Polyurethane Adhesive

Polyurethane adhesive is the ultimate solution for bonding wood to brick, offering a reliable and strong connection that can withstand the toughest conditions. This versatile adhesive boasts several advantages that make it an unbeatable choice for construction and woodworking projects.

First and foremost, polyurethane adhesive is known for its exceptional bond strength. It forms a bond that is not only strong but also permanent, ensuring that wood and brick surfaces stay securely attached even under heavy loads or extreme conditions. Whether you’re working on a small DIY project or a large construction job, polyurethane adhesive guarantees a reliable and long-lasting bond.

But that’s not all. Polyurethane adhesive also offers excellent resistance to moisture and temperature fluctuations. Unlike other adhesives that may weaken or deteriorate when exposed to water or high temperatures, polyurethane adhesive stands its ground. It can withstand exposure to water, humidity, and even extreme temperatures without compromising its bond strength. So, no matter the climate or environment, you can trust polyurethane adhesive to keep your materials firmly bonded.

Another advantage of polyurethane adhesive is its flexibility. Even after curing, it remains flexible, allowing the bonded surfaces to move slightly without causing stress or damage to the bond. This flexibility not only enhances the durability of the bond but also helps absorb vibrations, reducing the risk of breakage under dynamic loads. So, you can have peace of mind knowing that your bonded materials can withstand movement and vibrations without compromising their integrity.

Polyurethane adhesive also excels in gap-filling capabilities. It effectively fills small gaps or irregularities between wood and brick surfaces, creating a tight and seamless bond. This is particularly valuable if you’re working with uneven or irregular surfaces, as it helps create a uniform bond line. Say goodbye to unsightly gaps and hello to a smooth and professional-looking finish.

To achieve the best results when using polyurethane adhesive, make sure to follow the manufacturer’s instructions carefully. Properly preparing the surfaces by cleaning them and removing any dirt or loose particles is essential. Applying the adhesive evenly and in the correct amount will ensure a strong and reliable bond. So, take the time to read the instructions and follow them diligently for optimal results.

Epoxy Adhesive

When it comes to securely bonding wood to brick, there’s one adhesive that reigns supreme: epoxy adhesive. In this comprehensive guide, we’ll unravel the secrets behind effectively using epoxy adhesive to create a strong and long-lasting bond between these two materials. Get ready to discover the key steps and expert tips that will ensure your wood-to-brick project stands the test of time.

Step 1: Preparing for Success

Before diving into the application process, it’s crucial to prepare both the wood and brick surfaces. Cleanliness is key, so remove any dirt, dust, or grease that could compromise the adhesive’s performance. A gentle cleanser or degreaser should do the trick. Additionally, lightly sanding the wood surface creates a rough texture, enhancing the adhesive’s grip.

Step 2: Mastering the Mix

Epoxy adhesive consists of two components: resin and hardener. Follow the manufacturer’s instructions diligently when mixing them together. This delicate dance ensures optimal chemical reactions and a powerful bond. Choose a clean container and stir vigorously until the two components are fully combined.

Step 3: Applying with Precision

Using a brush or spatula, apply the mixed epoxy adhesive evenly onto both the wood and brick surfaces. Strive for an even layer on each surface, avoiding excessive or insufficient application. Remember, balance is key for achieving optimal bond strength.

Step 4: The Power of Pressure

Once the adhesive is applied, it’s time to bring wood and brick together. Firmly press the surfaces together to ensure proper contact and enhance bond strength. If necessary, use clamps or weights to hold them in place during curing. This step sets the foundation for a secure and reliable bond.

Step 5: Patience Rewarded

Epoxy adhesive requires adequate time to set and cure. The specific setting time varies depending on the product, so carefully follow the manufacturer’s instructions. During the curing process, avoid exposing the bonded area to excessive moisture or extreme temperatures.

Factors to Consider When Selecting an Adhesive

When it comes to selecting an adhesive, there are several factors to consider to ensure a strong and reliable bond. Whether you’re working on a DIY project or a professional construction job, choosing the right adhesive can make all the difference. In this comprehensive guide, we will explore the key factors to consider when selecting an adhesive. Let’s dive in.

Factor 1: Bond Strength:

The strength of the bond is crucial for any adhesive application. Consider the materials you are bonding and select an adhesive that provides the necessary strength to withstand stress and movement. Epoxy adhesives are known for their exceptional bond strength, making them ideal for heavy-duty applications.

Factor 2: Compatibility:

Different adhesives work best with specific materials. It is important to choose an adhesive that is compatible with the surfaces you are bonding. Consider the properties of both materials and select an adhesive that ensures proper adhesion and longevity. Epoxy adhesives are versatile and compatible with various materials, making them a reliable choice.

Factor 3: Application Method:

The application method of the adhesive should align with your project requirements and personal preference. Some adhesives come in tubes or cartridges, requiring a caulking gun for precise application. Others may be available in tape or liquid form, allowing for easy direct application. Choose an application method that suits your needs and ensures efficient and accurate bonding.

Factor 4: Setting Time:

Consider the setting time of the adhesive. Some projects may require quick bonding to expedite the process, while others may allow for longer curing times. Choose an adhesive that aligns with your project timeline and requirements to ensure efficient completion.

Factor 5: Weather Resistance:

If your bonded materials will be exposed to outdoor elements, selecting an adhesive with good weather resistance is essential. Look for adhesives that can withstand rain, extreme temperatures, and UV exposure to maintain a strong bond even in harsh conditions.

Factor 6: Flexibility:

In applications where there may be movement or expansion between the bonded materials, selecting a flexible adhesive is vital. This flexibility allows the adhesive to accommodate these movements without compromising the bond. Epoxy adhesives are known for their excellent flexibility, making them a popular choice in such scenarios.

Factor 7: Safety:

Always prioritize safety when working with adhesives. Consider factors such as toxicity, flammability, and ventilation requirements. Choose an adhesive that is safe to use in your intended environment and follow proper handling precautions.

Preparing the Surfaces Before Applying an Adhesive

To ensure a secure and long-lasting bond when sticking wood to brick, proper surface preparation is crucial. This step-by-step guide will walk you through the essential steps of preparing the surfaces before applying adhesive. By following these steps, you can guarantee that your wood adheres firmly to the brick, creating a connection that will withstand the test of time.

Step 1: Thoroughly Clean the Surfaces

Remove dirt, dust, and loose particles from both the wood and brick surfaces using a stiff brush or wire brush. Eliminate any traces of paint, grease, or other contaminants that could hinder the adhesive’s effectiveness.

Step 2: Roughen Up the Surfaces

Enhance adhesion by sanding the wood surface with coarse-grit sandpaper. This creates a rough texture that allows the adhesive to penetrate and grip the wood fibers better. Use a wire brush or sandpaper to roughen up the smooth or painted brick surface as well.

Step 3: Apply Primer or Bonding Agent

Improve adhesion and bond strength by applying a primer or bonding agent to both surfaces. Follow the manufacturer’s instructions and allow it to dry completely before proceeding with the adhesive.

Step 4: Consider Using a Wood Conditioner

For particularly smooth or non-porous wood surfaces, applying a wood conditioner is beneficial. This opens up the wood pores, allowing for better penetration of the adhesive and improved adhesion.

Step 5: Ensure Surfaces Are Dry

Before applying the adhesive, ensure that both surfaces are completely dry. Moisture weakens bonding and compromises adhesive strength. Allow sufficient time for cleaning agents or primers to dry before proceeding.

Step 6: Test the Adhesive

Before committing to the full application, test the adhesive on a small, inconspicuous area of both surfaces. Check compatibility and assess the bond strength to ensure optimal results.

Different Types of Primers for Bonding Wood and Brick

Look no further. In this comprehensive guide, we will unveil the different types of primers specifically designed for this task. By exploring their unique advantages and disadvantages, you can make an informed decision and create a bond that withstands the test of time.

Epoxy Primers: Unleashing the Powerhouses

Epoxy primers reign supreme when it comes to adhesion properties. These powerhouses create a chemical bond that leads to unparalleled strength between wood and brick, making them ideal for heavy-duty projects. However, it’s important to note that epoxy primers can come with a higher price tag compared to other options.

Polyurethane Primers: Flexibility Redefined

For outdoor projects or high humidity environments, polyurethane primers are the unmatched champions. Their exceptional flexibility and resistance to moisture ensure a durable bond that can brave the elements. Say goodbye to worries about your creation crumbling under nature’s might.

Acrylic Primers: Quick, Easy, and Reliable

When time is of the essence, acrylic primers come to the rescue. With their lightning-fast drying time, they are perfect for projects with tight deadlines. Additionally, they provide reliable adhesion both indoors and outdoors, bringing efficiency to your bonding journey.

Construction Adhesives: Versatility Meets Reliability

Construction adhesives are the go-to choice for bonding wood to brick due to their incredible versatility. Available in both solvent-based and water-based formulations, they offer different strengths and drying times. Solvent-based adhesives deliver an ironclad bond, while water-based adhesives ensure safety during application.

Surface Preparation: The Key to Mastery

Regardless of the primer or adhesive chosen, proper surface preparation is the key to success. Ensure that both the wood and brick surfaces are pristine, free from contaminants that could hinder adhesion. Only then can your masterpiece reach its full potential.

iuv3toSPMhc” >

Conclusion

In conclusion, there are a plethora of outstanding adhesive options available for sticking wood to brick. Each adhesive type brings its own unique advantages and strengths, guaranteeing a robust and dependable bond between these two materials.

When it comes to wood-to-brick applications, construction adhesive is the ultimate superhero. With its exceptional bonding strength and durability, it fearlessly endures any weather conditions or moisture levels. This versatile adhesive can be utilized indoors or outdoors, making it the ideal choice for any wood-to-brick project.

Epoxy adhesive is tough as nails, forging an unbreakable connection between wood and brick. It effortlessly withstands moisture, chemicals, and temperature changes, ensuring a bond that will stand the test of time. Just remember to thoroughly mix the two parts before application for optimal results.

For flexibility and remarkable gap-filling capabilities, look no further than polyurethane adhesive. It gracefully accommodates movement or expansion between surfaces while maintaining a secure linkage. Whether you’re working inside or outside, this adhesive is resistant to moisture and ready to impress.

If your bond will face exposure to the elements, silicone adhesive is your go-to option. Offering additional flexibility and unbeatable moisture resistance, this adhesive thrives in outdoor applications. Count on its excellent resistance to moisture and temperature changes.

Liquid Nails is a trusted brand that offers an array of products specifically tailored for wood-to-brick bonding. With reliable performance and exceptional bond strength, they have earned their reputation as a top choice in the industry.

When selecting an adhesive, consider crucial factors such as bond strength, material compatibility, application method, setting time, weather resistance flexibility, and safety precautions.

Remember that proper surface preparation is paramount before applying any adhesive. Thoroughly clean the surfaces, eliminating dirt or loose particles. If necessary, roughen up smooth surfaces with sandpaper to ensure optimal adhesion. Applying primer or bonding agent can further enhance the bond strength. And always ensure that the surfaces are dry before applying the adhesive.