Looking for the perfect adhesive for your FRP (Fiber Reinforced Plastic) panels?

In this blog post, we’ll unveil the top adhesive options to take your FRP panel projects to the next level.

Strengthening and ensuring long-lasting bonds are essential, and choosing the right adhesive is key. With so many options out there, it can be overwhelming.

But fear not. We’ve done the research for you and compiled a list of the most effective adhesives for FRP panels.

So let’s dive in and discover the ideal adhesive to make your FRP projects a success.

What are FRP Panels?

Contents

- 1 What are FRP Panels?

- 2 Adhesive Options for Bonding FRP Panels

- 3 Epoxy Adhesives

- 4 Polyurethane Adhesives

- 5 Construction Adhesives

- 6 Factors to Consider When Choosing an Adhesive for FRP Panels

- 7 Preparing the Surface Before Applying the Adhesive

- 8 Following Manufacturer Instructions for Application and Curing Time

- 9 Conclusion

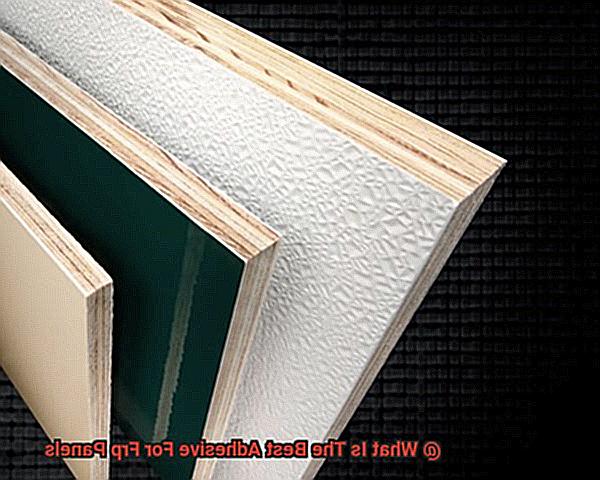

FRP panels, also known as Fiberglass Reinforced Plastic panels, have emerged as a game-changer in the construction and industrial world. With their exceptional durability, moisture resistance, chemical resistance, and ease of installation, these panels have become the go-to choice for professionals in various industries. In this article, we will delve deeper into the world of FRP panels, exploring their diverse applications and shedding light on the best adhesive options for effective installation.

Applications of FRP Panels:

- Construction: FRP panels are widely utilized as wall and ceiling coverings due to their moisture resistance and seamless installation process. Whether applied to drywall or other substrates using adhesives or mechanical fasteners, they provide a durable and visually appealing solution. Additionally, their excellent performance in environments that demand high cleanliness levels, such as hospitals or laboratories, makes them highly sought after.

- Transportation: The lightweight nature of FRP panels makes them an ideal material for reducing overall vehicle weight without compromising strength. These panels are commonly used for interior walls in vehicles like buses and trains, ensuring durability and longevity while maintaining a sleek and modern appearance.

- Industrial Applications: FRP panels’ resistance to corrosion and chemical damage makes them suitable for use in harsh environments where exposure to corrosive substances is common. Industries like wastewater treatment plants, chemical processing facilities, and food processing plants greatly benefit from these panels’ exceptional properties.

Choosing the Best Adhesive for FRP Panels:

When it comes to installing FRP panels effectively, selecting the right adhesive is crucial. Here are three adhesive options commonly used:

- Epoxy Adhesives: Renowned for their high strength and excellent bonding properties, epoxy adhesives create a robust bond between FRP panels and various substrates like wood, metal, or concrete. They offer exceptional resistance to moisture and chemicals, ensuring long-lasting performance.

- Polyurethane Adhesives: Providing a flexible bond that can withstand movement and vibration, polyurethane adhesives are an excellent choice for bonding FRP panels. They offer good resistance to moisture and chemicals and are commonly used in applications where flexibility is necessary.

- Construction Adhesives: Popular options for bonding FRP panels in construction applications include polyvinyl acetate (PVA) or polyurethane-based adhesives. These adhesives provide a strong bond and are easy to apply.

Installation Techniques:

To ensure a successful bond between FRP panels and the substrate, proper surface preparation is essential. This may involve cleaning the surfaces, roughening them for better adhesion, and removing any contaminants. Following the manufacturer’s instructions regarding the application and curing time of the adhesive is crucial. Proper curing allows for a strong bond to form.

Adhesive Options for Bonding FRP Panels

Choosing the right adhesive is crucial for achieving a strong and durable bond when bonding FRP panels. There are various adhesive options available in the market, each with its own unique properties and benefits. Let’s explore some common adhesive options for bonding FRP panels and important factors to consider when selecting an adhesive.

Epoxy Adhesives:

- Widely used for their excellent bonding strength and durability.

- Consist of two components that need to be mixed together before application.

- Provide a strong and long-lasting bond between the FRP panel and the substrate.

- Ideal for applications requiring high strength.

Polyurethane Adhesives:

- Offer flexibility and resistance to moisture, making them suitable for varying environmental conditions.

- Provide good bonding strength and can withstand thermal expansion and contraction.

- Known for their versatility and compatibility with different substrates.

Acrylic Adhesives:

- Offer fast curing times and high bond strength.

- Easy to apply and bond well with various substrates, including FRP panels.

- Provide resistance to temperature extremes and UV radiation, suitable for indoor and outdoor applications.

Structural Adhesives:

- Include methacrylate or cyanoacrylate adhesives, known for high bond strength and fast curing times.

- Often used in applications requiring immediate handling or assembly.

When selecting an adhesive, consider the specific project requirements, substrate type, and environmental conditions. Consult with adhesive manufacturers or suppliers for expert guidance in choosing the most appropriate adhesive.

Proper surface preparation is essential for achieving a strong bond. Ensure surfaces are clean, dry, and free from contaminants that can hinder adhesion. Roughening the FRP panels and substrate surfaces can increase bonding area and enhance adhesion.

Follow the manufacturer’s instructions for adhesive mixing and application to achieve optimal bonding results. Allow sufficient curing time before subjecting bonded panels to stress or load.

Epoxy Adhesives

Step into the world of adhesives and prepare to be amazed by the superhero of bonding – epoxy adhesives. These mighty glues are the ultimate choice when it comes to bonding FRP (Fiber Reinforced Polymer) panels, and it’s not hard to see why.

Let’s start with their incredible strength. Epoxy adhesives create a bond that can withstand the test of time, making them the go-to option for applications where structural integrity is paramount. Whether you’re in construction, automotive, aerospace, or marine industries, epoxy adhesives have got your back like a loyal sidekick.

But that’s not all – these adhesives have more tricks up their sleeve. They possess an impressive resistance to chemicals and extreme temperatures. Imagine your FRP panels being exposed to harsh environments or nasty chemicals, yet the bond remains unscathed. Talk about reliability in the face of adversity.

Flexibility is yet another superpower of epoxy adhesives. FRP panels can expand or contract due to temperature changes or other external factors, but epoxy adhesives can handle it with ease. Their flexibility allows for some movement between bonded surfaces, preventing cracks and delamination. It’s like having a yoga instructor for your glue – keeping it nimble and adaptable.

Before you embark on your epic bonding journey with epoxy adhesives, remember to prepare the surfaces properly by cleaning them and removing any contaminants. Follow the manufacturer’s instructions closely to ensure a flawless bond that would make any villain jealous.

And here’s a little secret – not all epoxy adhesives are created equal. There are different formulations available for different applications, each with its own set of powers. So be sure to consult with adhesive manufacturers or experts to choose the perfect one for your FRP panel bonding needs. It’s like assembling a team of Avengers specifically tailored for your mission.

Polyurethane Adhesives

Polyurethane adhesives are the superheroes of the adhesive world, especially when it comes to bonding FRP (Fiber Reinforced Plastic) panels. These incredible adhesives offer a multitude of benefits that make them the top choice for industries like construction, automotive, marine, and aerospace.

First and foremost, polyurethane adhesives possess exceptional bonding properties. They have the power to create strong and long-lasting bonds between different materials, including FRP panels. This is crucial for applications where the adhesive needs to withstand high levels of stress, such as in structural bonding.

But that’s not all – polyurethane adhesives also possess an extraordinary resistance to water, chemicals, and temperature variations. This makes them perfect for applications that require the adhesive to perform well in harsh environments or under extreme conditions. Imagine FRP panels bonded with polyurethane adhesives in a car that can withstand constant exposure to moisture, heat, and chemicals without losing their grip – it’s like having a superhero protecting your panels.

Flexibility and elasticity are two more superpowers possessed by polyurethane adhesives. They have the ability to absorb vibrations and movements, adding an extra layer of strength and durability to the bonded joint. This is especially important for applications where the FRP panels may be subject to impact or dynamic loads.

But wait, there’s more. Polyurethane adhesives are also known for their ease of use. They typically come in two-component formulations that need to be mixed before application, ensuring proper curing and bonding. Plus, they have a relatively long open time, allowing for adjustments and repositioning of the panels before the adhesive sets. It’s like having a glue that gives you time to get things just right.

Of course, even superheroes have their limitations. Using polyurethane adhesives may require some surface preparation before application. This might involve cleaning and roughening the surfaces to be bonded to ensure optimal adhesion. Additionally, certain polyurethane adhesives may require the use of primers or activators for specific applications or substrates. It’s like having a secret weapon to ensure the best bond possible.

Construction Adhesives

Installing FRP (Fiber Reinforced Plastic) panels requires the right construction adhesive for a successful and durable bond. But with countless options available, how do you choose the perfect sidekick? In this article, we’ll explore the key factors to consider when selecting the best construction adhesive for FRP panel installation. Get ready to unleash the superhero strength of your project.

Material Compatibility:

To ensure a strong bond, consider material compatibility. FRP panels are made of fiberglass and resin, requiring an adhesive that can effectively bond these materials. Epoxy adhesives are a popular choice thanks to their excellent bonding strength and resistance to moisture, chemicals, and temperature changes. With this superpower, your bond will withstand the test of time.

Application Method and Working Conditions:

Consider the application method and working conditions. Two-part epoxy systems provide better control over the curing process, resulting in a stronger bond. Pre-mixed cartridges or tubes offer convenience and ease of use.

Choose an adhesive that suits your preferred application method and working environment, whether it’s a fast-paced construction site or a DIY project in your garage.

Specific Installation Requirements:

Every installation has unique requirements. Think about moisture levels, humidity, extreme temperatures, and exposure to harsh chemicals. For high moisture or humidity levels, opt for an adhesive with water resistance properties.

Extreme temperatures or chemical exposure require an adhesive with excellent chemical resistance and temperature stability. These superpowers ensure your FRP panels can handle any challenge.

Surface Preparation:

Even superheroes need preparation before their missions, and so do construction adhesives. Proper surface preparation is vital for a strong bond. Ensure surfaces are clean, dry, and free from debris or contaminants.

Depending on the adhesive manufacturer’s recommendations, roughen the surface or apply a primer. This sets the stage for successful adhesion.

Factors to Consider When Choosing an Adhesive for FRP Panels

Choosing the right adhesive for bonding FRP (Fiber Reinforced Plastic) panels is crucial for a successful installation. Just like a superhero needs a reliable sidekick, your FRP panel installation requires an adhesive that can withstand various challenges.

In this article, we will explore the key factors to consider when selecting an adhesive for FRP panels, ensuring that you find the perfect partner for your project.

Compatibility:

Select an adhesive specifically designed for bonding FRP panels. These adhesives are formulated to adhere to the unique composition of FRP materials, providing a strong and durable bond.

Strength:

Opt for an adhesive with high bond strength to ensure that your installation can withstand significant loads and stresses.

Flexibility:

Choose a flexible adhesive that allows FRP panels to expand and contract with temperature changes, preventing cracks or delamination.

Chemical Resistance:

Consider the environment in which your FRP panels will be installed. Choose an adhesive with excellent chemical resistance to ensure long-term durability, even when exposed to acids, solvents, or cleaning agents.

Moisture Resistance:

For wet or damp environments, such as bathrooms or industrial settings, select an adhesive with exceptional moisture resistance. This prevents water penetration and safeguards against mold growth, delamination, or structural damage.

Application Method:

Take into account the available application methods and choose an adhesive that aligns with your installation process. Consider whether you prefer pre-mixed forms or if you’re comfortable with mixing before application.

Cure Time:

Consider project requirements and time constraints. Some adhesives offer fast curing options, reducing downtime and allowing for quicker installation. Others may require longer curing times but provide superior bond strength once fully cured.

Environmental Impact:

Be environmentally responsible by choosing an adhesive with low VOC content and environmentally friendly characteristics. This not only benefits the environment but also ensures a healthier indoor air quality.

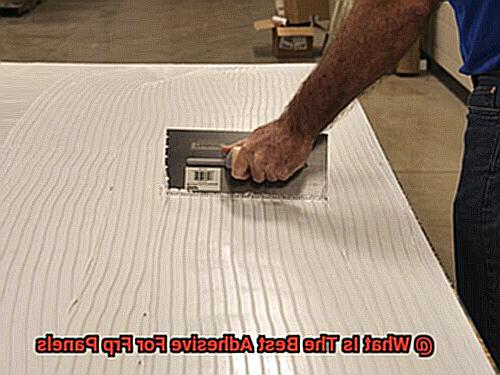

Preparing the Surface Before Applying the Adhesive

Surface preparation is a critical step when it comes to applying adhesive to ensure a strong and durable bond between FRP panels and the surface they will be bonded to. It’s like setting the stage for a masterpiece – you want to create the perfect canvas for the adhesive to work its magic. So let’s dive into the important steps of preparing the surface before applying the adhesive.

- Cleanliness is crucial: Before applying any adhesive, it’s essential to thoroughly clean the surface. Dust, dirt, grease, and other contaminants can create a barrier that prevents a strong bond from forming between the adhesive and FRP panels. Use a mild detergent or a cleaning solution recommended by the adhesive manufacturer to scrub away all those pesky particles. A soft brush or sponge will do the trick.

- Rinse away residue: Once the surface is clean, don’t forget to rinse it thoroughly with clean water. This step ensures that no traces of cleaning agents are left behind, which can interfere with the adhesive’s performance and weaken the bond. So give it a good rinse and say goodbye to any lingering residue.

- Embrace rough love: Now that your surface is clean and dry, it’s time to roughen it up a bit. Gently sanding the surface with sandpaper or a sanding block creates a slightly rough texture that enhances adhesion. Be careful not to go overboard and damage the FRP panels in the process.

- Banish dust and debris: After sanding, take a moment to remove any dust or debris left behind. A clean cloth or compressed air can help ensure that your surface is smooth and ready for adhesive application.

- Prime for success: Some adhesive manufacturers recommend using a primer before applying the adhesive. This extra step can significantly improve adhesion by creating a better bond between the adhesive and FRP panels. Follow the manufacturer’s instructions on the type of primer to use and how to apply it.

- Temperature and humidity matter: Adhesives often have specific temperature requirements for optimal bonding. Ensure that both the FRP panels and the surface they will be bonded to are at room temperature. Additionally, keep an eye on the humidity level. High humidity can disrupt the adhesion process and result in weaker bonds. Consider using dehumidifiers or waiting for ideal weather conditions before applying the adhesive.

- Follow instructions diligently: Last but not least, read and follow the instructions provided by the adhesive manufacturer. Different adhesives may have specific requirements, such as application methods, curing times, and recommended tools or equipment. Treat these instructions like a GPS guiding you towards a successful bond.

Following Manufacturer Instructions for Application and Curing Time

In this blog post, we’ll delve into the specific reasons why these instructions are crucial when using adhesives for FRP (Fiber Reinforced Plastic) panels. So, let’s dive in.

Surface Preparation: The Foundation of Strong Bonding

Proper surface preparation is key to achieving a strong bond between FRP panels. Before applying any adhesive, it’s vital to clean the surface thoroughly, removing any existing adhesives or coatings that could hinder bonding. Creating a rough texture through gentle sanding enhances adhesion. By following the manufacturer’s instructions, you ensure that your adhesive has a clean, dry, and contaminant-free surface to bond with. This step sets the stage for a durable and reliable connection between your FRP panels.

Application Techniques: The Art of Even Coverage

Applying the adhesive correctly is crucial for achieving optimal bonding strength. Manufacturer instructions will guide you on the specific techniques and tools required for proper application. From choosing the right applicator or tool to applying the adhesive in a particular pattern or thickness, following these instructions ensures even coverage across the entire bonding area. This uniformity will result in a stronger bond and enhance the overall structural integrity of your FRP panels.

Curing Time: Patience is Key

Patience becomes your best friend after applying the adhesive. Curing time refers to the duration required for the adhesive to dry and reach its maximum strength. Different adhesives have varying curing times based on factors such as temperature, humidity, and the adhesive formulation itself. By following the recommended curing time provided by the manufacturer, you allow the adhesive to fully develop its bonding potential. Rushing this process could compromise the strength and longevity of your bond.

Optimal Bonding Conditions: Creating the Perfect Environment

During the curing process, it’s crucial to provide the right conditions for bonding. Following manufacturer instructions will guide you on maintaining appropriate temperature ranges, humidity levels, and ventilation requirements. These conditions ensure that the adhesive cures optimally, allowing it to achieve its maximum strength. Avoid disturbances or movements that could disrupt the bonding process, and create a stable environment for your panels to bond flawlessly.

Additional Steps: Unveiling the Secrets

Some adhesive formulations may require additional steps or precautions during the curing process. This could include applying pressure or using curing agents to accelerate drying time. By carefully following these additional instructions, you unlock the full potential of your adhesive, ensuring a strong and reliable bond between your FRP panels.

GqrD_G1W4-4″ >

Conclusion

After careful research and analysis, it is clear that when it comes to finding the best adhesive for FRP panels, there is one standout choice: epoxy adhesive. Epoxy adhesive offers exceptional bonding strength, durability, and resistance to moisture, making it the ideal option for securing FRP panels in place.

Not only does epoxy adhesive provide a strong bond between the FRP panel and the substrate, but it also ensures long-lasting adhesion that can withstand various environmental conditions. Whether you are installing FRP panels in a bathroom, kitchen, or any other high-moisture area, epoxy adhesive will deliver reliable results.

One of the key advantages of using epoxy adhesive for FRP panels is its ability to fill gaps and irregularities on surfaces. This feature ensures a seamless installation and enhances the overall appearance of the panels. With epoxy adhesive, you can achieve a professional finish that will impress even the most discerning eye.

Furthermore, epoxy adhesive offers excellent chemical resistance, making it suitable for applications where exposure to chemicals is likely. This characteristic adds an extra layer of protection to your FRP panels and extends their lifespan.

In terms of application, epoxy adhesive is easy to work with. It typically comes in two parts – resin and hardener – which need to be mixed together before use. Once mixed, you have a limited working time before the adhesive sets, so it’s important to plan your installation accordingly.

When it comes to choosing an epoxy adhesive for FRP panels, opt for one specifically designed for this purpose. Look for products that offer high bond strength and are recommended by manufacturers of FRP panels.

In conclusion, if you want the best adhesive for FRP panels that provides exceptional bonding strength, durability, moisture resistance, and ease of application – look no further than epoxy adhesive. Its ability to fill gaps and its chemical resistance make it a top choice for professionals and DIY enthusiasts alike.