Ready to give your car’s interior a fresh new look? Well, buckle up because we’ve got the inside scoop on the best adhesive for the job. After diving headfirst into the world of car interior adhesives, we can confidently say that 3M Super 77 Multipurpose Adhesive takes the trophy. This bad boy is like a superhero for your car’s insides – with its unbeatable bonding powers and incredible versatility.

No need to wait around for hours, twiddling your thumbs while your adhesive dries. The 3M Super 77 is lightning fast, ensuring a quick installation without sacrificing strength. It’s like having a pit crew in your back pocket. Plus, this adhesive isn’t picky when it comes to surfaces – it’ll stick to fabric, leather, vinyl, and even those pesky plastics that never seem to cooperate.

But wait, there’s more. The 3M Super 77 can handle the heat – literally. With its high-temperature resistance, you won’t have to worry about your newly glued masterpiece melting away in the summer sun. And let’s not forget about moisture – this adhesive laughs in the face of water damage with its excellent resistance.

So whether you’re reupholstering your seats or giving your dashboard a facelift, trust us when we say that the 3M Super 77 Multipurpose Adhesive is the glue you’ve been searching for. Say goodbye to shoddy repairs and hello to a professional finish that will last mile after mile.

The Benefits of Using Adhesives in Car Interiors

Contents

- 1 The Benefits of Using Adhesives in Car Interiors

- 2 Different Types of Adhesives for Automotive Use

- 3 Epoxy Adhesive

- 4 Polyurethane Adhesive

- 5 Silicone Adhesive

- 6 Contact Adhesive

- 7 Considerations When Selecting the Best Adhesive for Car Interior Applications

- 8 Test the Adhesive Before Applying It to the Entire Surface

- 9 Conclusion

Adhesives play a vital role in the manufacturing and assembly of car interiors, providing a secure and durable bond between different materials. The use of adhesives offers numerous advantages, including seamless finishes, improved acoustic insulation, even stress distribution, flexibility in bonding dissimilar materials, sealing and moisture resistance, weight savings, and cost efficiency. This article explores these benefits in detail, highlighting the specific types of adhesives commonly used in automotive applications.

Seamless Finishes:

Unlike traditional fasteners like screws or rivets, adhesives create a bond that is invisible to the eye, resulting in a clean and smooth surface in car interiors. This seamless finish enhances the overall aesthetic appeal of the cabin.

Improved Acoustic Insulation:

Adhesives contribute to reducing noise and vibration in car interiors by creating a strong bond between components. This prevents rattling or vibrating, ensuring a quieter and more comfortable cabin environment.

Even Distribution of Stress:

Adhesives distribute stress evenly across the bonded area, improving the structural integrity of car interiors. Components stay securely in place even under harsh conditions or during accidents.

Flexibility in Bonding Dissimilar Materials:

Adhesives have the unique ability to bond different materials together, such as fabric to plastic or metal. This flexibility is particularly valuable in car interiors where various materials with different properties need to be joined.

Sealing and Moisture Resistance:

Adhesives can seal gaps or joints in car interiors, preventing water or moisture from entering. This protects sensitive electronic components and inhibits the growth of mold or mildew.

Weight Savings:

Using adhesives eliminates the need for additional hardware like screws or clips, resulting in reduced weight and improved fuel efficiency.

Cost Efficiency:

Adhesive application is often faster and more efficient compared to traditional assembly methods, leading to reduced labor costs and increased production rates.

Types of Adhesives for Car Interiors:

- Epoxy adhesives: Exceptional bonding strength, heat resistance, and chemical resistance.

- Polyurethane adhesives: Strong bonding capabilities and flexibility, suitable for harsh conditions.

- Silicone adhesives: Excellent flexibility, heat resistance, and moisture resistance, ideal for vibration damping and sealing.

- Contact adhesives: Strong and instant bond, commonly used for fabric, foam, vinyl, and leather in car interiors.

Different Types of Adhesives for Automotive Use

Adhesives play a crucial role in the automotive industry, especially when it comes to keeping various components together in car interiors. From providing strength and durability to flexibility and resistance, different types of adhesives are used for specific applications.

In this article, we will explore four main types of adhesives commonly used in automotive applications: epoxy, polyurethane, acrylic, and silicone.

Epoxy Adhesives – The Unbreakable Bond:

Epoxy adhesives are known for their exceptional strength and durability. They can bond metal, plastic, or composite materials with ease, making them ideal for a wide range of automotive applications.

Whether it’s repairing cracks or holes in components or bonding various parts together, epoxy adhesives offer an unbreakable bond that can withstand heat and chemicals. With their ability to provide structural integrity, epoxy adhesives ensure the longevity and reliability of car interiors.

Polyurethane Adhesives – Flexibility at Its Finest:

When it comes to attaching upholstery materials like fabric, leather, or vinyl to different surfaces in car interiors, polyurethane adhesives are the go-to choice. These adhesives not only provide a strong bond but also offer flexibility.

As cars experience vibrations and movement on the road, polyurethane adhesives can handle the stress without compromising the integrity of the bond. With their ability to withstand constant use and wear, polyurethane adhesives ensure a long-lasting and comfortable interior.

Acrylic Adhesives – Fast and Furious:

For quick and efficient bonding in automotive applications, acrylic adhesives are the perfect solution. They have fast curing times and high bond strength, making them ideal for bonding plastic trim pieces such as dashboard panels or interior trims. With acrylic adhesives, car interiors achieve a sleek and polished look in no time. Their ability to provide a strong and durable bond ensures that trim pieces stay in place, even under demanding conditions.

Silicone Adhesives – Defying Extreme Conditions:

When it comes to sealing and bonding components in automotive applications, silicone adhesives are a reliable choice. These adhesives excel in extreme conditions, withstanding scorching heat, freezing cold, and pouring rain. As car windows need effective sealing or weatherstripping requires secure bonding, silicone adhesives perform with style and grace. Their excellent resistance to temperature extremes and harsh environmental conditions ensures the longevity and functionality of car interiors.

Epoxy Adhesive

Epoxy adhesive is the superhero of the adhesive world, ready to save the day when your car’s interior starts falling apart. With its incredible bonding strength, temperature resistance, chemical resistance, and gap-filling magic, epoxy adhesive is the perfect choice for keeping everything in place.

First and foremost, epoxy adhesive boasts incredible bonding strength. It’s like a super glue on steroids, capable of bonding different materials together with ease. Whether it’s metal, plastic, fabric, or leather, epoxy adhesive can handle it all. This versatility makes it ideal for a wide range of applications in your car, from repairing upholstery to securing trim panels.

But that’s not all – epoxy adhesive is also tough when it comes to temperature changes. Car interiors experience extreme heat and cold, especially in harsh weather conditions. However, epoxy adhesives are tough cookies that can handle it all. They won’t let you down no matter how hot or cold it gets.

Chemical resistance is another superpower of epoxy adhesive. Your car interior is constantly exposed to substances like cleaning agents, oils, and fuels. But fear not. Epoxy adhesive can handle it all. It’s resistant to chemicals, ensuring that it won’t break down or deteriorate when in contact with these substances.

And let’s not forget about the gap-filling magic of epoxy adhesive. Bonding two uneven surfaces together can be a real headache, but with epoxy adhesive, it’s a breeze. It has excellent gap-filling properties, meaning it can fill in small gaps or uneven surfaces between bonded materials. Say goodbye to those annoying gaps and hello to a seamless bond.

To unleash the full power of epoxy adhesive, remember to follow the right steps. Ensure that the surfaces you’re bonding are clean and free from any dirt or grease. Apply the adhesive evenly and give it enough time to cure. And most importantly, follow the manufacturer’s instructions to ensure a strong and long-lasting bond.

Polyurethane Adhesive

When it comes to preserving the integrity of your car’s interior, one adhesive reigns supreme – polyurethane adhesive. This powerful and adaptable glue offers a multitude of advantages that make it the go-to choice for automotive applications. In this article, we will delve into the benefits of using polyurethane adhesive and explore why it is the superhero of the adhesive world.

Unparalleled Bonding Strength:

Polyurethane adhesive is renowned for its exceptional strength. It creates a resilient bond that can withstand the daily wear and tear experienced by car interiors. From securing trim pieces to attaching upholstery, this adhesive ensures that everything stays firmly in place for years to come.

Flexibility in Extreme Conditions:

Car interiors face constant temperature fluctuations and vibrations, which can stress bonded materials. Luckily, polyurethane adhesive rises to the challenge. Its flexibility allows it to endure these conditions without compromising the bond. So whether you’re driving through scorching heat or freezing cold, your car’s interior will remain intact.

Resistant to Moisture and Chemicals:

Spills, cleaning agents, and condensation are all part of life inside a car. Fortunately, polyurethane adhesive provides excellent resistance to moisture and chemicals. It acts as an impermeable barrier, preventing damage to bonded materials and ensuring that your car’s interior remains immaculate.

Versatility in Formulations:

Polyurethane adhesive is available in various formulations tailored to specific bonding needs. Whether you require rapid curing times or enhanced flexibility, there is a polyurethane adhesive out there for you. This versatility makes it ideal for efficient production processes in the automotive industry.

Silicone Adhesive

Silicone Adhesive: The Ultimate Game-Changer for Your Car Interior

Calling all car enthusiasts and DIYers. Are you searching for the perfect adhesive to tackle your car interior repairs and modifications? Look no further than silicone adhesive. This exceptional glue is a true superhero when it comes to bonding different materials together. Let’s dive into why silicone adhesive is the ultimate solution for all your car interior needs.

First up, let’s talk about temperature resistance. We all know that car interiors can experience extreme temperature changes, whether it’s the blistering heat of the summer sun or the freezing cold of winter. But fear not, because silicone adhesive can handle these fluctuations like a true champ. It remains steadfast, retaining its adhesive properties and keeping your repairs intact even in the harshest conditions. So, whether you’re cruising under scorching sunlight or braving a snowstorm, your repairs will stay put.

But that’s not all – flexibility is another superpower of silicone adhesive. Car interiors often have curved surfaces that require an adhesive with exceptional flexibility to ensure a strong and durable hold. Well, silicone adhesive is as flexible as a yoga master. It effortlessly conforms to those tricky curves without cracking or breaking. And not only that, it also absorbs vibrations and shocks like a boss, ensuring that your repairs stay firmly in place even on the bumpiest of roads.

But wait, there’s more. Silicone adhesive also boasts excellent water resistance properties. Spills and moisture are no match for this mighty glue. When applied correctly, silicone adhesive forms a watertight seal that shields your bonded surfaces from water damage, mold, and pesky mildew growth. So, whether you accidentally spill your morning coffee or get caught in an unexpected rainstorm, your repairs will stay dry and secure.

Now let’s talk about versatility. Silicone adhesive is like a chameleon – it can bond fabric to plastic, leather to metal, rubber to vinyl, and more. Its remarkable bonding strength works wonders on various materials commonly found in car interiors. So, whether you’re fixing a torn seat cover or adding a touch of glam to your dashboard, silicone adhesive has got your back.

But remember, using silicone adhesive requires some tender loving care. Always follow the manufacturer’s instructions to the letter, including proper surface preparation and drying time. And don’t forget to choose a high-quality silicone adhesive specifically formulated for automotive use. Trust me, these products are specially designed to meet the unique demands of car interiors.

So, there you have it, folks. Silicone adhesive is the go-to choice for all your car interior bonding needs. Its temperature resistance, flexibility, water resistance, and strong bonding strength make it a real lifesaver. With silicone adhesive in your toolbox, you can confidently tackle any car interior repair or modification, knowing that your hard work will stand the test of time.

Contact Adhesive

Look no further than contact adhesive, also known as contact cement. This adhesive is a true superhero when it comes to bonding various materials together. Let’s explore the advantages of using contact adhesive for your car interiors.

Versatility at Its Finest:

Contact adhesive is a true multi-tasker, capable of bonding a wide range of materials commonly found in car interiors. Whether you’re working with fabric, leather, vinyl, plastic, or metal, this adhesive has got your back. Say goodbye to compatibility issues – contact adhesive saves the day.

Strength and Durability:

Car interiors demand an adhesive that can withstand the test of time, stress, and vibrations. Contact adhesive is up for the challenge. Once it forms a bond, it won’t let go – even under extreme conditions like heat, moisture, and chemicals. It’s a reliable sidekick you can count on.

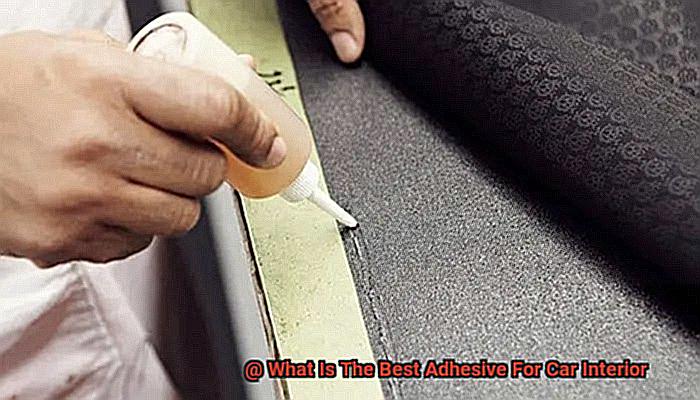

Easy Application:

Using contact adhesive is a breeze. Available in liquid or spray form, you can choose your preferred method. Simply brush or roll on the liquid form or spray it directly onto the surfaces you want to bond. Quick and easy – just the way we like it.

Proper Preparation is Key:

To ensure a strong and lasting bond, proper surface preparation is essential. Cleanliness is next to stickiness in this case. Make sure the surfaces you’re bonding are clean, dry, and free from grease or contaminants. This maximizes adhesion and prevents hiccups along the way.

Choose Wisely:

With countless brands and types of contact adhesives out there, it’s important to choose a high-quality adhesive that suits your car interior project. Some popular brands include 3M Super 77 Multipurpose Adhesive, Permatex Body Shop Heavy Duty Headliner Adhesive, and 3M Hi-Strength 90 Spray Adhesive. Don’t settle for anything less than the best.

Considerations When Selecting the Best Adhesive for Car Interior Applications

When it comes to selecting the best adhesive for car interior applications, there are several key factors that need to be considered. From the type of adhesive to the drying and curing time, each factor plays a crucial role in ensuring a strong and durable bond that can withstand the demanding conditions of a car interior.

First and foremost, the type of adhesive is essential. There are various types available, such as epoxy, cyanoacrylate, polyurethane, and acrylic adhesives. It’s important to choose an adhesive that is specifically designed for automotive use and is suitable for bonding the materials commonly found in car interiors, including plastic, leather, fabric, and metal.

Next, the bonding strength of the adhesive is crucial. Car interiors are subjected to various forces and stresses, such as temperature changes, vibrations, and constant use. Therefore, it’s important to select an adhesive that offers a strong and durable bond that can withstand these conditions. Look for adhesives with high shear and peel strength for optimal performance.

Compatibility with materials is another factor to consider. Car interiors are made up of a wide range of materials, and not all adhesives may adhere properly to all materials. It’s important to choose an adhesive that is compatible with the specific materials you are bonding. Check the adhesive manufacturer’s guidelines or consult with an expert to determine compatibility.

The application method of the adhesive should also be considered. Some adhesives come in aerosol cans or tubes, while others require mixing before application. Choose an adhesive that suits your preferred application method and ensures precise and controlled application without any mess or waste.

Drying and curing time is another important consideration, especially when working on car interiors. Faster drying and curing times can save time during installation or repair tasks. However, it’s important to strike a balance between quick drying time and sufficient curing time to ensure a strong and durable bond.

Lastly, consider the resistance of the adhesive to environmental factors. Car interiors are exposed to temperature changes, humidity, UV radiation, and chemical exposure. Choose an adhesive that can withstand these environmental conditions without deteriorating or losing its bonding properties.

Test the Adhesive Before Applying It to the Entire Surface

When it comes to customizing your car’s interior, using adhesive is a common practice. However, applying adhesive to the entire surface without testing it first can lead to disastrous consequences. In this comprehensive guide, we will explore the importance of testing adhesive before application, providing you with step-by-step instructions and expert advice to ensure a successful and safe outcome.

Step 1: Choose the Test Area:

Selecting a small, inconspicuous area on the car interior is crucial for testing the adhesive’s compatibility. Opt for a hidden spot under a seat or on the backside of a panel to minimize any visible damage or discoloration.

Step 2: Prepare the Surface:

To guarantee accurate results, thoroughly clean and prepare the test area. Remove any dirt, dust, or grease that may hinder the adhesive’s adhesion. A pristine surface will allow you to assess how well the adhesive bonds.

Step 3: Apply and Dry:

Apply a small amount of adhesive to the test area using a brush or applicator. Ensure even distribution and follow the manufacturer’s instructions regarding drying time. Patience is key during this phase.

Step 4: Inspect for Issues:

After the adhesive has dried, carefully inspect the test area for any signs of discoloration, damage, or poor adhesion. Pay close attention to changes in texture or appearance that could indicate compatibility issues with the material.

Step 5: Test Durability:

If the adhesive passes the initial test, it’s time to evaluate its durability. Subject it to extreme temperatures, moisture, or physical stress to assess its ability to withstand real-world conditions.

Step 6: Seek Expert Advice:

Each adhesive has specific properties and suitability for different car interior materials. It is advisable to consult professionals or experts in car interior materials before making a final decision. Their guidance will ensure you choose the most appropriate adhesive for your specific application.

Juh39LHkFus” >

Conclusion

In conclusion, when it comes to finding the best adhesive for your car interior, there are a few key factors to consider.

Firstly, you want an adhesive that is strong and durable, capable of withstanding the wear and tear of daily use. Secondly, it should be easy to apply and provide a secure bond without leaving any residue or damage behind.

Lastly, consider the drying time and flexibility of the adhesive, as these aspects can greatly impact its effectiveness.