Ready to dive into a DIY project but stuck on the glue?

With so many options out there, it’s tough to find a glue that works on all surfaces.

But fear not. In this blog post, we’ll unravel the mysteries of adhesive and show you which ones work best for different materials.

So grab your tools and get ready for some expert advice that’ll make your projects stick like glue, no matter what you’re working with.

Different Types of Glues and Their Uses

Contents

- 1 Different Types of Glues and Their Uses

- 2 PVA Glue: Ideal for Wood, Paper, or Fabric

- 3 Epoxy Glue: Suitable for Bonding a Variety of Materials

- 4 Super Glue: Perfect for Quick Fixes and Non-Porous Surfaces

- 5 Silicone Adhesive: Best for Flexible Materials

- 6 Specialized Adhesives: For Specific Materials

- 7 Reading the Instructions and Recommendations Provided by the Manufacturer

- 8 Tips for Choosing the Right Glue for Your Project

- 9 Conclusion

Glue, glue, glue. There are so many different types of glue out there, each with its own special uses. Let’s dive into the fascinating world of adhesives and explore the various types and their specific applications.

First on our list is super glue, also known as cyanoacrylate adhesive. True to its name, super glue is incredibly fast-drying and forms an ultra-strong bond. This adhesive is perfect for bonding materials such as metal, plastic, rubber, ceramics, and wood. However, it’s important to exercise caution when using super glue as it can stick your fingers together in no time.

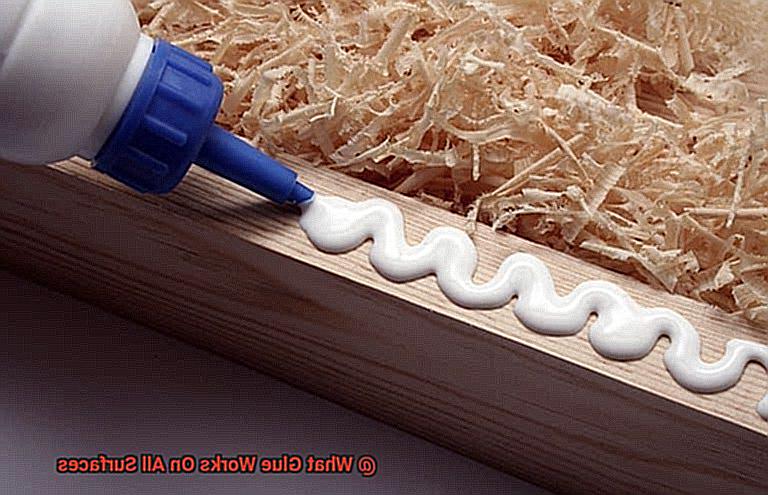

Next up is wood glue, a true hero for all your woodworking projects. Wood glue is specifically formulated to bond wood surfaces securely. Whether you’re building a birdhouse or fixing a chair, wood glue is your go-to adhesive. There are different types of wood glue available, such as white glue and yellow glue, but they all share the same high strength and resistance to heat and moisture that are essential for woodworking projects.

Now let’s talk about epoxy glue – a real game-changer in the world of adhesives. Epoxy consists of two parts

a resin and a hardener that must be mixed together before use. Once combined, epoxy creates an incredibly strong bond that can withstand high temperatures. It’s the perfect choice for sticking metal, glass, ceramics, and some plastics together.

If you’re an arts and crafts enthusiast, then craft glue is your best friend. Craft glues come in various forms like liquid glue, glue sticks, and even little dots of glue. They are designed to bond materials such as paper, fabric, leather, plastic, and foam. So whether you’re making a collage or decorating a picture frame, craft glue is the way to go.

Lastly, let’s talk about construction adhesive – the heavyweight champion of glues. This adhesive is specifically designed for heavy-duty projects such as building houses or fixing broken concrete. Construction adhesive is exceptionally strong and can handle heavy loads and extreme weather conditions. It’s perfect for sticking materials like concrete, stone, brick, metal, and wood together.

So there you have it – a quick guide to the different types of glues and their specific uses. Each type of glue has its own set of properties that make it ideal for certain applications. When choosing the right glue for your project, consider factors such as the materials being bonded, the desired strength of the bond, and any environmental factors that may affect the adhesive’s performance.

PVA Glue: Ideal for Wood, Paper, or Fabric

Well, get ready to discover the ultimate adhesive for all your creative endeavors – PVA glue. No matter if you’re working with wood, paper, or fabric, PVA glue is the perfect choice to achieve a strong and reliable bond. Let’s delve into the advantages of using PVA glue and why it should be a staple in your crafting arsenal.

Let’s start with wood. PVA glue creates a solid bond that can withstand the test of time. Whether you’re building a small wooden masterpiece or repairing furniture, PVA glue has got your back. Research has shown that it works best on porous surfaces like unfinished or rough-textured wood. So, before you start gluing, make sure to give those wooden surfaces a thorough cleaning to ensure optimal adhesion.

Now, let’s move on to paper crafts. PVA glue is a classroom and art studio favorite for a reason. It bonds paper quickly and securely like no other. Whether you’re designing greeting cards, scrapbooking, or mastering the art of origami, PVA glue provides a strong hold without damaging the paper. Plus, its water-based formula guarantees a clear and residue-free finish.

But wait, there’s more. PVA glue isn’t just limited to wood and paper. It’s also perfect for fabric projects. Whether you need to adhere fabric to other materials or create fabric-based crafts, PVA glue does it all. It forms a sturdy bond that can withstand washing and regular use. However, keep in mind that not all fabrics may be suitable for PVA glue. Always test it on a small area before applying it to the entire fabric surface.

What makes PVA glue so great is its ease of use. It typically comes in a squeeze bottle or container with an applicator brush, making it super convenient to apply directly onto your desired surface. Plus, it dries relatively fast, allowing you to complete your projects efficiently. Just remember to give it enough time to fully dry and cure for maximum bond strength.

However, it’s important to note that while PVA glue is ideal for wood, paper, and fabric, there may be instances where other types of adhesives are more suitable. Non-porous materials like metal or plastic might require a different adhesive such as epoxy or super glue.

Epoxy Glue: Suitable for Bonding a Variety of Materials

Are you tired of juggling multiple adhesives for different materials? Look no further – epoxy glue is here to save the day. With its remarkable ability to bond a wide range of materials, epoxy glue reigns supreme as the ultimate adhesive for all your bonding needs. Let’s explore the benefits and advantages of using epoxy glue, backed by thorough research.

- Versatility: Epoxy glue is a true jack-of-all-trades when it comes to bonding. It can securely bond metal, glass, ceramics, wood, plastic, and even stone. This means you can confidently use it for a variety of applications, from repairing household items to creating intricate crafts. Say goodbye to the hassle of stocking up on multiple adhesives.

- Exceptional Adhesive Properties: Epoxy glue goes beyond surface-level bonding. It forms an unbreakable bond by penetrating the materials and creating a tight connection between them. This makes it particularly effective for bonding porous materials like wood or concrete. The epoxy seeps into the pores, ensuring an incredibly secure attachment.

- Unparalleled Strength: Once fully cured, epoxy bonds often surpass the strength of the materials they join together. This makes epoxy glue perfect for load-bearing applications or situations where durability is crucial. Rest assured that your wobbly chair leg will be firmly repaired and your favorite piece of jewelry will receive the reinforcement it deserves.

- Resistant to the Elements: Epoxy glue doesn’t back down in the face of moisture, heat, or chemicals. It can withstand exposure to water without weakening or deteriorating over time. This makes it suitable for both indoor and outdoor applications. Additionally, epoxy glue can handle high temperatures without compromising its adhesive properties.

It’s important to note that following the manufacturer’s instructions is essential when using epoxy glue. The correct mixing ratio of resin and hardener is crucial for achieving optimal bonding strength. Additionally, ensure that the surfaces to be bonded are clean, dry, and free from contaminants that may interfere with the adhesive properties of the epoxy.

Super Glue: Perfect for Quick Fixes and Non-Porous Surfaces

When it comes to quick fixes and bonding non-porous surfaces, there is one adhesive that stands above the rest: super glue. Also known as cyanoacrylate adhesive, super glue is renowned for its exceptional fast-drying nature and its ability to create strong bonds that last. But what exactly makes it the ideal option for these specific applications?

One of the key advantages of super glue is its effortless bonding on non-porous surfaces. These are surfaces like glass, metal, and plastic that do not absorb liquids or allow them to pass through. Super glue forms an incredibly strong bond on these surfaces, ensuring durability and strength in any application.

Using super glue on non-porous surfaces is a breeze. Simply make sure that the surfaces are clean, free from any dirt, dust, or moisture. Then, apply a small amount of the adhesive onto one surface. Press the two surfaces together firmly, and within seconds, voila. You have a secure bond. The adhesive reaches its maximum strength within a few hours, providing peace of mind that your repair or project will hold up over time.

However, it’s important to note that super glue may not be as effective on porous materials like wood or fabric. These materials have the ability to absorb the adhesive, making it less efficient in creating a strong bond. In such cases, multiple layers of super glue or specialized adhesives designed specifically for porous materials may be necessary.

Another factor to consider when using super glue is its reaction with moisture in the air. Super glue cures by reacting with moisture to form a strong bond. To prevent premature curing, make sure to tightly seal the container when not in use.

Super glue is available in different viscosities, ranging from thin to gel-like consistencies. The viscosity you choose depends on your specific application and desired flow and control of the adhesive. Whether you need a thin adhesive for precision or a thicker gel for vertical applications, there is a super glue formulation to meet your needs.

Silicone Adhesive: Best for Flexible Materials

When it comes to bonding flexible materials, finding a glue that can withstand constant movement and stress is crucial. Silicone adhesive is the answer. In this article, we will explore why silicone adhesive is the best choice for bonding flexible materials, highlighting its unmatched flexibility, resistance to moisture and temperature extremes, exceptional durability, and chemical resistance.

Flexibility:

Silicone adhesive sets itself apart with its unparalleled flexibility. Unlike other glues that become brittle and crack under pressure, silicone adhesive remains pliable and resilient. It can effortlessly endure the expansion and contraction common with flexible materials, ensuring a long-lasting bond that won’t disappoint.

Resistance to Moisture and Temperature Extremes:

Whether you’re working on an outdoor project or in an environment with extreme temperature fluctuations, silicone adhesive has got your back. Its high resistance to water makes it perfect for applications where exposure to moisture is unavoidable. Additionally, it can withstand both scorching heat and freezing cold without losing its adhesive properties or stability. Take on challenging projects with confidence, knowing your glue won’t let you down.

Durability:

Strength is essential when bonding flexible materials, and silicone adhesive delivers just that. It forms a robust bond capable of withstanding significant strain and pulling forces. Whether you’re bonding fabric or attaching a rubber sole to a shoe, silicone adhesive offers a reliable and long-lasting solution that won’t fail you.

Chemical Resistance:

Some glues deteriorate when exposed to harsh chemicals or sunlight, leading to degradation and loss of bond over time. Silicone adhesive stands strong against these challenges. It boasts excellent resistance to chemicals and UV radiation, ensuring your bond remains intact even in harsh conditions.

Surface Preparation:

To achieve optimal results when using silicone adhesive on flexible materials, proper surface preparation is crucial. Ensure the surfaces are clean, dry, and free from debris or contaminants that could hinder the bonding process. For improved adhesion, lightly roughen the surface with sandpaper.

Specialized Adhesives: For Specific Materials

In the world of adhesive bonding, there is no one-size-fits-all solution. The secret to achieving a strong and durable connection lies in the realm of specialized adhesives. These unsung heroes are formulated with unique properties that cater to the specific characteristics of the materials they are designed to bond. Let’s delve into the fascinating world of specialized adhesives and explore their applications for specific materials.

Epoxy Adhesives: The Workhorses of Bonding

Epoxy adhesives reign supreme in the adhesive world, boasting exceptional strength and versatility. They form unbreakable bonds between various materials like metal, glass, wood, and plastic. Comprising a resin and a hardener, epoxy adhesives create a chemical reaction upon mixing, resulting in a rock-solid connection that withstands the test of time.

Cyanoacrylate Adhesives: The Speedy Super Glue

Known as super glue, cyanoacrylate adhesives are ideal for non-porous materials such as metal and plastic. Their fast curing times and high bond strength make them a go-to choice for quick fixes. However, their moisture-activated curing process may not work as effectively on porous surfaces.

Rubber Cement: Flexibility at Its Finest

For bonding rubber or flexible materials, rubber cement takes center stage. Remaining flexible even after drying, this adhesive forms secure bonds that are commonly used in shoe repair or craft projects involving rubber materials.

Fabric Glue: Seamlessly Stitching Textiles Together

Designed specifically for fabric and textiles, fabric glue is washable and flexible. It ensures that the bond remains intact even after repeated washing or stretching, making it an ideal choice for clothing repairs or DIY projects.

Ceramic Glue: A Pottery Lover’s Best Friend

When it comes to ceramics or pottery, ceramic glue steals the spotlight. With its heat-resistant properties and formidable bond strength, it is perfect for repairing broken ceramic or porcelain items that can withstand high temperatures.

Glass Adhesive: A Clear Connection

Glass materials require a specialized adhesive that is transparent and creates an invisible bond. These adhesives are commonly used for glassware or mirror repairs, ensuring that the appearance of the glass remains unaffected.

Reading the Instructions and Recommendations Provided by the Manufacturer

When it comes to using glue, reading and following the instructions and recommendations provided by the manufacturer is more than just a mundane task. It’s the key to unlocking the full potential of your adhesive. So, let’s dive into what these instructions and recommendations entail.

First and foremost, different glues are formulated for specific purposes and surfaces. So before you start sticking things together, take a moment to read the instructions. This will help you determine if the glue is suitable for your intended application and if it can be used on all surfaces. It’s like finding a match made in heaven.

But it doesn’t stop there. The instructions also include valuable information on prepping your surfaces before applying the glue. Whether it’s cleaning, sanding, or priming – these steps are crucial to ensure a strong bond. Don’t skip them. Surface preparation is the key to success.

Now, let’s talk about the art of application. Ever wondered why your glue didn’t perform as expected? Well, chances are you didn’t follow the recommended application technique or conditions. Temperature range, humidity levels, and curing times – these factors can make or break your bonding success. Pay attention to the details.

And let’s not forget about safety. Glue may seem harmless, but manufacturers are here to remind us otherwise. Read those safety precautions and handling instructions carefully. They’re designed to protect you from any potential health hazards associated with the glue’s ingredients or application process. Your well-being matters.

By following these instructions and recommendations, you’ll ensure that you’re using the glue correctly, maximizing its effectiveness on all surfaces, and avoiding any potential pitfalls or risks associated with improper usage.

Tips for Choosing the Right Glue for Your Project

With numerous options available, it can be overwhelming to find the perfect adhesive for your specific needs. This comprehensive guide will provide you with tips and tricks to help you select the right glue for any project.

Consider Your Materials:

Start by considering the materials you’ll be working with. Different glues are formulated for specific surfaces, so it’s crucial to match the adhesive to your materials. If you’re working with porous surfaces like wood or fabric, opt for a glue designed specifically for them. For non-porous surfaces like glass or metal, choose a glue that can create a strong bond without being absorbed.

Strength Matters:

Think about the strength of the bond you need. Some glues are designed for temporary fixes or light-duty applications, while others are formulated for heavy-duty use. Ensure that you choose an adhesive that matches the level of durability required for your project.

Drying Time:

Consider the drying time of your chosen glue. Quick-drying glues allow you to move forward with your project faster, while slower-drying options may require more patience. Take into account your schedule and how long you’re willing to wait for the glue to set before proceeding.

Application Method:

The application method of the glue is another important factor to consider. Squeeze bottles or tubes are ideal for precise and controlled application, while brushes or applicators work well for larger surface areas. Choose a glue with an application method that suits your needs and preferences.

Manufacturer Recommendations:

Always check the manufacturer’s recommendations for the materials you’re working with. Some materials may have specific requirements or restrictions on the type of glue that can be used. Following these guidelines will ensure optimal bonding and prevent any potential damage.

1hY1jyGNzIo” >

Also Read: Glue Types

Conclusion

Finding a glue that works on all surfaces can be a daunting task. With so many options available, it’s easy to get overwhelmed. However, there is one glue that stands out from the rest – the ultimate adhesive solution for any project. This remarkable glue has the power to bond materials together with ease, regardless of the surface type. Whether you’re working with wood, metal, plastic, or even glass, this glue has got you covered. Its versatility knows no bounds, making it a must-have in any DIY enthusiast’s toolkit.

But what makes this glue so special? It’s all about its unique formulation. This adhesive is designed to create an incredibly strong bond that can withstand even the toughest conditions. No matter if it’s extreme temperatures or heavy-duty wear and tear, this glue will hold everything together like magic.

Not only does this adhesive excel in strength and durability, but it also boasts exceptional versatility. It effortlessly adheres to various surfaces without compromising its effectiveness. From smooth and shiny glass to rough and porous wood, this glue seamlessly bonds them all.

Furthermore, this remarkable glue dries quickly and clear, leaving behind a flawless finish that won’t detract from your project’s aesthetics. Say goodbye to unsightly residue or messy application processes – this adhesive ensures a clean and professional look every time.

In addition to its impressive performance, this glue is also user-friendly. Its easy-to-use applicator allows for precise and controlled application, minimizing waste and ensuring optimal results. Whether you’re an experienced craftsman or a novice DIYer, using this glue is a breeze.

So next time you find yourself in need of an adhesive that works on all surfaces, don’t settle for anything less than perfection. Choose the ultimate glue that combines strength, versatility, and ease of use into one extraordinary package.