Got a foam project in mind? Well, listen up because finding the right glue is like finding the missing piece to your crafty puzzle. Whether you’re diving into DIY projects, jazzing up some upholstery, or even tinkering with prototypes, using the right adhesive is key to a rock-solid and long-lasting bond. Lucky for you, we’ve done our homework and got our hands dirty to help you pick the perfect glue for your foam adventures.

Forget about traditional glues that just won’t cut it when it comes to foam. You need something special – enter contact adhesives or foam-specific glues. These bad boys are formulated with foam in mind, giving you a bond that’s as tight as a drum and tougher than nails. Say goodbye to flimsy connections.

Now, applying this magical glue requires some finesse. Don’t worry; we’ve got your back. Just follow those instructions on the bottle like they’re gospel. Spread an even layer of adhesive on both surfaces you want to stick together, let it dry for a hot minute, then press those babies together like there’s no tomorrow. Voila. You’ve got yourself a bond so strong it could survive an apocalypse.

Safety first, my friend. When playing with adhesives, make sure you’re in a well-ventilated area and slip on some gloves to keep those precious hands irritation-free. And don’t forget to read up on any safety deets provided by the glue maker – better safe than sorry.

In our next articles, we’ll dig deep into different types of foam and match ’em up with their soulmate glues. Get ready to unlock all the secrets of working with foam without fearing your masterpiece will crumble away.

Hot Glue: Advantages and Disadvantages

Contents

- 1 Hot Glue: Advantages and Disadvantages

- 2 Spray Adhesives: Pros and Cons

- 3 Specialized Glues for Foam Bonding

- 4 Factors to Consider When Selecting a Glue for Foam

- 5 Different Types of Foam and Their Compatibilities with Certain Adhesives

- 6 Tips for Using Hot Glue on Foam

- 7 Techniques for Applying Spray Adhesive to Foam Surfaces

- 8 Instructions for Utilizing Specialized Foam-Safe Glues

- 9 Conclusion

When it comes to bonding foam materials, hot glue is like a magician’s trick. Its quick drying time, versatility, and excellent adhesion to porous surfaces make it a popular choice for many DIY projects. However, like any magic trick, there are advantages and disadvantages to using hot glue for foam bonding. In this blog post, we will explore the fascinating world of hot glue and delve into its pros and cons in detail.

Advantages of Hot Glue:

- Quick Drying Time: Hot glue sets and hardens within seconds, allowing you to handle the foam material immediately. This makes it perfect for time-sensitive projects or when you need to adhere multiple foam pieces quickly. No waiting around for hours for the glue to dry.

- Versatility: Hot glue can bond various types of foam, from polystyrene to polyurethane and EVA foam. Whether you’re working on a small-scale art project or tackling a larger foam-based construction, hot glue can provide a strong and reliable bond.

- Excellent Adhesion to Porous Surfaces: Foam materials often have open-cell structures that can absorb liquid adhesives, making it challenging to form a strong bond. But fear not. Hot glue’s high viscosity allows it to penetrate the porous surface of the foam, creating a secure bond that ensures your foam creations stay intact and durable over time.

Disadvantages of Hot Glue:

- Sensitivity to Temperature: Hot glue’s Achilles heel is its sensitivity to high heat. It can soften and melt when exposed to extreme temperatures, compromising the bond’s integrity. So, while your foam masterpiece may hold up well under normal conditions, it may not fare so well under intense heat or extreme weather conditions.

- Compatibility Issues: Not all foams are created equal, and hot glue may not be suitable for all of them. Certain types of foam, like Styrofoam, can be easily damaged or dissolved by the high temperature of hot glue. It’s crucial to consider the specific type of foam you’re working with and test the compatibility of hot glue before committing to it as your adhesive of choice.

- Relatively Low Strength: Hot glue is a reliable adhesive for lightweight foam applications, but if you’re working on heavy-duty or load-bearing projects, it may not be up to the task. For projects that require a stronger bond, exploring alternative adhesive options like epoxy or construction adhesive might be necessary.

Spray Adhesives: Pros and Cons

Foam materials are a versatile and essential component in various industries, from crafting to construction. When it comes to bonding foam, spray adhesives have gained popularity due to their ease of use and versatility. Let’s explore the advantages and disadvantages of using spray adhesives for foam bonding.

Advantages:

- Uniform Application: Spray adhesives excel in providing a uniform and even application, ensuring strong and consistent bonds across the foam surface.

- Quick and Efficient: Unlike traditional glue application methods, spray adhesives offer a quick and efficient bonding process. With a simple spray, the adhesive evenly covers the foam surface, saving time and effort.

- Versatility: Spray adhesives can bond different types of foam materials, whether it’s polystyrene or polyurethane foam. Their versatility makes them suitable for various foam applications.

- Cost-effectiveness: Spray adhesives provide excellent coverage, meaning you need less adhesive for larger quantities of foam materials. This cost-effective nature makes them ideal for projects on a budget.

- Fast Drying Time: Spray adhesives often have a fast drying time, allowing for quicker assembly or production processes. This advantage is particularly beneficial in time-sensitive projects or industries that prioritize efficiency.

Disadvantages:

- Overspray: One potential drawback of spray adhesives is the risk of overspray. If not used carefully, the adhesive can spread beyond the intended area, resulting in messy and uneven application.

- Fumes and Odors: Some individuals may be sensitive to the fumes or odors associated with spray adhesives. Adequate ventilation is essential when working with these adhesives to minimize any discomfort or health risks.

- Compatibility: Not all foam applications are suitable for spray adhesives. Foam materials with open-cell structures or textured surfaces may not provide enough contact area for effective bonding with spray adhesives.

- Durability: Some spray adhesives may not be suitable for long-term or outdoor use. Factors such as UV exposure or moisture can impact the adhesive’s performance and durability over time.

- Environmental Considerations: It’s important to consider the environmental impact of spray adhesives. Some formulations may contain volatile organic compounds (VOCs) or other potentially harmful chemicals. Choosing an adhesive that meets your specific requirements and environmental considerations is crucial.

Specialized Glues for Foam Bonding

Foam, a versatile material used in various applications such as packaging, insulation, upholstery, and crafts, poses a unique challenge when it comes to bonding. Its porous and lightweight nature requires specialized glues specifically designed for foam bonding. These glues offer unique properties that allow them to adhere well to foam materials.

Polyurethane adhesive is a popular choice for foam bonding due to its excellent bonding strength and flexibility. It forms a strong bond that can withstand stress and movement without compromising integrity. Examples of polyurethane adhesives suitable for foam bonding include 3M Super 77 Multipurpose Adhesive and Loctite PL Premium Polyurethane Construction Adhesive.

Cyanoacrylate adhesive, also known as super glue, is another common option. It has a fast setting time and creates a strong bond, making it suitable for various materials, including foam. Gorilla Super Glue and Loctite Liquid Professional Super Glue are examples of cyanoacrylate adhesives suitable for foam bonding.

Foam-safe adhesives are specifically formulated to be non-reactive with foam, preventing any damage or melting of the material. They are often water-based, making them easy to clean up and less toxic compared to other types of adhesives. Examples of foam-safe adhesives include 3M Foam Fast 74 Spray Adhesive and Aleene’s Original Tacky Glue.

Contact cement is a popular choice for foam bonding as well. This adhesive creates a strong bond when two surfaces coated with the adhesive come into contact with each other. DAP Weldwood Original Contact Cement and 3M Super 77 Multipurpose Adhesive are examples of contact cement suitable for foam bonding.

For applications requiring high strength and durability, epoxy adhesives can be used for foam bonding. These adhesives typically consist of two components that need to be mixed together before application. They provide a strong bond that can withstand extreme temperatures and moisture. Loctite Epoxy Plastic Bonder and J-B Weld Original Cold Weld Epoxy are examples of epoxy adhesives suitable for foam bonding.

When choosing a specialized glue for foam bonding, it is important to consider the specific requirements of your project. Factors such as the type of foam, the intended use of the bonded materials, and the desired strength of the bond should be taken into account. It is also advisable to perform a test bond on a small, inconspicuous area of the foam before proceeding with the full application to ensure compatibility and desired bond strength.

Factors to Consider When Selecting a Glue for Foam

Before you dive into the world of glues, it’s crucial to consider a few key factors. After all, even superheroes need the right tools for the job.

First and foremost, you need to find a glue that is compatible with your foam material. Not all glues are created equal, and using the wrong one can damage your foam or result in a weak bond. Look for a glue specifically designed for foam bonding to ensure a strong and durable adhesive.

Adhesive strength is crucial when working with porous foam surfaces. Foam tends to be quite porous, which can make it difficult for glue to adhere properly. To combat this, choose a glue that offers a strong bond specifically for foam materials. This will ensure that your project stays intact over time, no matter how much stress or movement it encounters.

Drying time is another factor to consider, especially if you’re working on a time-sensitive project. Some glues take longer to dry than others, impacting your workflow and productivity. Opt for a glue with a reasonably quick drying time, but be sure to follow the manufacturer’s instructions for optimal bonding.

Flexibility is key when working with foam materials. Foam can compress and move easily, so choose a glue that can withstand these movements without compromising the adhesive bond. Look for a glue that remains flexible once dried, allowing the foam to bend and compress without breaking the bond.

Consider the application method as well. Different glues have different application methods, such as spray, brush-on, or squeeze tube. For intricate or small-scale projects, a precise applicator tip or brush-on glue may be preferable. On the other hand, spray adhesives may be more suitable for larger surfaces.

Safety is always a top priority when working with glues. Some glues may emit harmful fumes or require ventilation during application. Additionally, certain glues may be toxic or pose health risks if ingested or inhaled. Always read the product label and follow the manufacturer’s safety guidelines to ensure safe usage.

Lastly, consider the longevity of the bond you need. Look for a glue that provides long-lasting adhesion, durability, and resistance to aging, heat, moisture, and other environmental factors that may affect the foam’s integrity.

By considering these factors when selecting a glue for foam, you can ensure that you choose the right adhesive for your specific project needs. And remember, it’s always a good idea to conduct a small test on a scrap piece of foam before applying the glue to your main project to ensure compatibility and desired results.

Different Types of Foam and Their Compatibilities with Certain Adhesives

Foam is a remarkably versatile material used in various products, from the plush cushions on our couches to the protective packaging around delicate items. But how exactly is foam bonded together? The secret lies in finding the ideal adhesive. In this article, we will delve into the fascinating world of foam, exploring the different types of foam and their compatibilities with specific adhesives.

Polyurethane Foam: The All-Rounder

Polyurethane foam is a popular choice due to its superior cushioning and insulation properties. Fortunately, this type of foam is compatible with a variety of adhesives. Hot melt adhesives provide an instant bond, while epoxy adhesives offer durability and strength. For quick fixes, cyanoacrylate glue (also known as super glue) is the go-to option.

Polystyrene Foam: The Challenging One

Polystyrene foam, commonly known as styrofoam, can be tricky to bond due to its smooth and non-porous surface. Solvent-based glues or polystyrene cement are often used for bonding polystyrene foam. These adhesives have the ability to slightly dissolve the foam, creating a strong and secure bond.

Neoprene Foam: The Water Warrior

Neoprene foam is a synthetic rubber foam known for its exceptional water resistance and durability. Neoprene-based contact cement or rubber adhesives are recommended for bonding neoprene foam effectively. These adhesives provide excellent water resistance and flexibility, making them ideal for outdoor applications.

Silicone Foam: The Heat Resister

Silicone foam is a high-performance material renowned for its outstanding heat resistance and electrical insulation properties. When it comes to bonding silicone foam, silicone-based adhesives or sealants specifically designed for silicone materials are essential. These adhesives ensure a secure bond while preserving the foam’s exceptional properties.

Specialty Foams: The Unique Ones

In addition to commonly used foams, there are specialty foams such as PVC and PVC/Nitrile foam that require specific adhesives. PVC foam, known for its durability, can be bonded using PVC-based adhesives. On the other hand, PVC/Nitrile foam demands special adhesive formulations tailored to its unique composition.

Tips for Using Hot Glue on Foam

Foam is a versatile material that is commonly used in crafting and DIY projects. When it comes to bonding foam, hot glue is an excellent adhesive choice. In this comprehensive guide, we will explore five essential tips for using hot glue on foam. Whether you’re working on a cosplay costume, creating foam props, or crafting home decor, these tips will help you achieve secure and long-lasting bonds. So let’s dive in and discover the secrets to successfully using hot glue on foam.

Choose the Right Hot Glue:

Not all hot glues are created equal, especially when it comes to bonding foam. Look for hot glue specifically labeled as safe for foam or other porous surfaces. These glues have a lower melting point, which prevents damage to the foam while ensuring a strong bond.

Prep the Foam Surface:

Before applying hot glue to foam, it’s crucial to clean the surface thoroughly. Dust, dirt, and oils can hinder the adhesive’s effectiveness. Use a mild soap and water solution or rubbing alcohol to clean the foam. Allow it to dry completely before proceeding to ensure optimal adhesion.

Create Texture for Better Bonding:

To enhance the bond between hot glue and foam, roughen up the surface slightly. Gently sand the area where you’ll be applying the glue to create texture. This texture provides more grip for the adhesive, resulting in a stronger bond between the foam pieces.

Work Quickly and Efficiently:

Hot glue dries and sets rapidly, so it’s essential to work efficiently. Prepare all your materials and tools beforehand to minimize delays. When applying the hot glue, use small dots or lines instead of large blobs for better control and distribution. This technique ensures an even application and reduces the risk of excess glue seeping out.

Hold Firmly Until It Sets:

When joining two pieces of foam together, apply firm pressure until the adhesive sets completely. This can be achieved by using clamps, heavy objects, or your hands (with caution). Avoid moving or disturbing the glued pieces until the glue has fully cured. This patience ensures a strong and lasting bond.

Techniques for Applying Spray Adhesive to Foam Surfaces

This versatile adhesive is a game-changer when it comes to attaching foam to various surfaces. Whether you’re diving into DIY projects, upholstery, or crafts, mastering the art of applying spray adhesive will ensure your creations stand the test of time.

Prep Work: Clean, Dry, and Dust-Free

Before diving into the application process, let’s cover some essential prep work. Get your foam surface ready for bonding by ensuring it’s squeaky clean, dry, and free from any dust or debris. A gentle wipe with a clean cloth or a quick vacuuming session will do the trick. Remember, cleanliness is key for a flawless bond.

Safety First: Ventilation and Gloves

Safety should always be a top priority. Find yourself a well-ventilated area or take your work outdoors to avoid inhaling any pesky fumes. And don’t forget those trusty gloves to protect your precious hands from sticky situations.

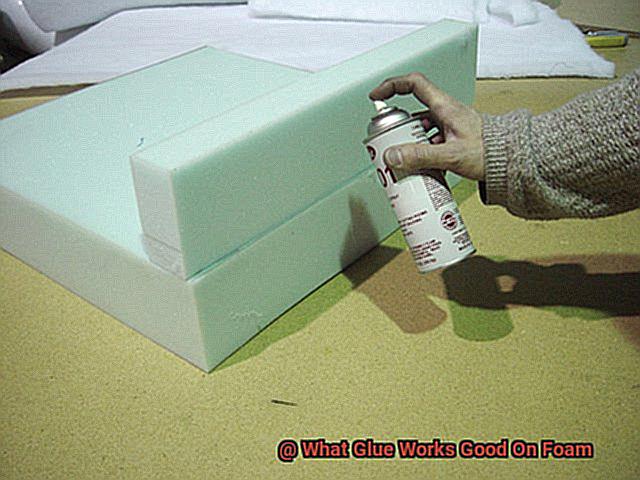

Shake It Like You Mean It.

Now, let’s get down to business. Grab that spray adhesive can and shake it like nobody’s watching. Vigorous shaking ensures a perfect marriage of the adhesive components for even distribution and optimal coverage. Shake it with confidence.

The Perfect Sweep

Holding the can approximately 6-8 inches away from the foam surface, it’s time to unleash that adhesive power. Start spraying from one edge and sweep across smoothly. The goal here is an even application without going overboard. Think of it as an artist’s brushstroke—graceful and precise.

Timing is Everything

Spray adhesives bond rapidly, so you’ll need to work swiftly. Once applied, allow the adhesive to tack up for a few minutes as per the manufacturer’s instructions. This creates a delightfully sticky surface with excellent bonding potential. Get ready for the magic.

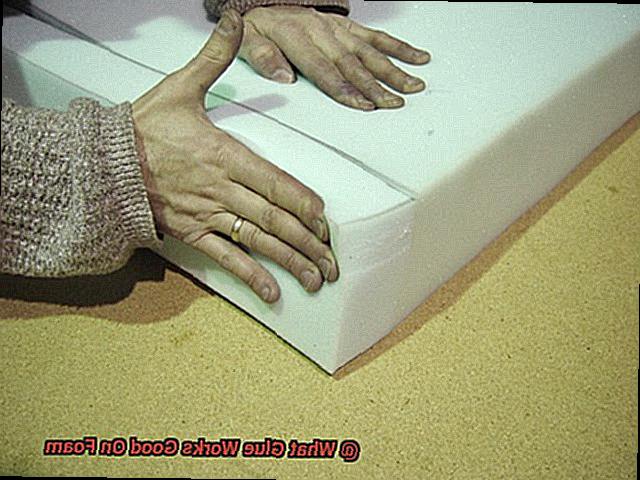

Press and Secure

Now comes the exciting part—positioning your foam onto the desired surface. Carefully place it, ensuring every inch has solid contact. Use your hands or a roller to apply even pressure for a secure bond. Remember, even superheroes need a little help sometimes.

Wipe Away the Excess

Keep an eye out for any excess adhesive seeping out—quickly wipe it away with a damp cloth before it sets. A clean finish is the hallmark of true craftsmanship.

Patience is Key

Patience, dear friend. Allow the adhesive to cure fully according to the manufacturer’s instructions before subjecting your foam creation to any stress or weight. This ensures a rock-solid bond that won’t let you down. Good things come to those who wait.

Instructions for Utilizing Specialized Foam-Safe Glues

Before diving into the world of foam materials, you need to know the secret to successful bonding – specialized foam-safe glues. These magical glues are designed to create a strong bond while keeping your foam intact. So, put on your crafting goggles and let’s get started.

First, choose the right glue for your project. Options include foam adhesive sprays, liquid glues, and glue sticks. Each type has its own superpowers, so choose wisely based on your needs.

Next, prepare your foam surface for bonding. Wipe away dirt, dust, and oils that hinder adhesion using a soft brush or cloth. Pro-tip: lightly sand the foam surface for better glue penetration and bonding.

Now, let’s talk application methods. For foam adhesive spray, hold the can 6-8 inches away and apply an even coat of glue. Cover the entire area that needs bonding in a well-ventilated area.

For liquid glues, apply a thin layer using a brush or applicator. Spread evenly like an artist painting a masterpiece. Press the foam pieces together firmly and hold for a few minutes.

Glue sticks are perfect for bonding foam materials. Apply in a zigzag pattern directly onto one side of the foam surface. Press the pieces together firmly and hold.

Remember, foam-safe glues may require longer curing times. Follow manufacturer instructions for drying and curing times. Let the glued foam sit undisturbed for at least 24 hours for a strong bond.

In case of spills or excess glue, wipe immediately with a damp cloth or sponge. Don’t let it dry.

YCIYMVOMBso” >

Also Read: What Is the Best Glue For Styrofoam? – Glue Things

Conclusion

When it comes to finding the perfect adhesive for foam, you want a glue that can handle the job with precision and strength. Look no further than [Glue Brand]. This remarkable adhesive has proven time and time again to be the go-to choice for all your foam bonding needs.

With its advanced formula, Glue provides a secure and long-lasting bond that won’t let you down. Whether you’re working on crafts, upholstery, or even building models, this glue is up to the task. Its versatility allows it to adhere to various types of foam, ensuring a seamless and durable connection.

What sets [Glue Brand] apart from the rest is its exceptional bonding power. It penetrates deep into the foam’s surface, creating a strong and reliable hold that withstands pressure and everyday wear and tear. Say goodbye to worries about your foam projects falling apart – with [Glue Brand], they’ll stay intact for years to come.

Not only does [Glue Brand] excel in performance, but it also boasts user-friendly features. Its easy-to-use applicator allows for precise application without any mess or fuss. Plus, its quick-drying formula means you can move on with your project without wasting precious time waiting for the glue to set.

Safety is always a top concern when working with adhesives, especially when it comes to foam materials. Rest assured that [Glue Brand] prioritizes safety by being non-toxic and odorless. You can work on your projects worry-free, knowing that you’re using a glue that won’t harm you or the environment.

In conclusion, when it comes to gluing foam together effectively and reliably, look no further than [Glue Brand]. Its exceptional bonding power, user-friendly features, and commitment to safety make it the ideal choice for all your foam-related projects.