Vinyl flooring: it’s tough, versatile, and all the rage in homes and businesses these days.

But when it comes to sticking it down or fixing it up, you need a glue that’s up to the task. That’s where I come in.

In this blog post, we’re diving deep into the world of vinyl flooring glues to find out which ones really stick (pun intended). We’ll explore everything from your run-of-the-mill multipurpose adhesive to those fancy formulas made just for vinyl.

No more dealing with wonky seams or annoying peeling – let’s find your vinyl flooring’s perfect match.

Types of Vinyl Flooring and Their Respective Adhesives

Contents

- 1 Types of Vinyl Flooring and Their Respective Adhesives

- 2 Subfloor Material Considerations for Glue Selection

- 3 Environmental Conditions to Consider When Choosing Glue

- 4 Manufacturer’s Recommendations for Glue Selection

- 5 Factors to Consider When Choosing the Right Glue for Vinyl Flooring

- 6 Benefits of Using the Proper Adhesive for Vinyl Flooring

- 7 Installation Tips for Applying Glue to Vinyl Flooring

- 8 Common Mistakes to Avoid When Gluing Down Vinyl Flooring

- 9 Conclusion

Vinyl flooring is a versatile and popular choice for homeowners, offering durability, affordability, and easy maintenance. However, it’s important to note that different types of vinyl flooring require specific adhesives for proper installation. In this guide, we will explore the world of vinyl flooring adhesives and discover the best options for each type of vinyl flooring.

Types of vinyl flooring:

Vinyl flooring comes in various forms such as sheet vinyl, luxury vinyl tile (LVT), luxury vinyl plank (LVP), and vinyl composite tile (VCT). Each type has distinct characteristics and installation methods that determine the adhesive needed for a successful bond.

Adhesives for sheet vinyl:

Sheet vinyl is typically installed using a full spread adhesive method. This means applying a water-based adhesive recommended by the manufacturer over the entire subfloor. This adhesive creates a strong and lasting bond between the vinyl and subfloor, ensuring a stable installation that can withstand everyday wear and tear.

Adhesives for luxury vinyl tile/plank:

LVT and LVP offer flexible installation options. They can be installed with or without adhesive, depending on personal preference. When using adhesive for LVT or LVP, it’s crucial to choose an adhesive specifically designed for these types of flooring. Some adhesives are pressure-sensitive, meaning they only need to be applied to the back of the tile or plank. These adhesives activate when pressure is applied during installation, providing a secure bond.

Adhesives for vinyl composite tile (VCT):

VCT is commonly used in commercial settings and requires a strong adhesive for proper installation. The dry-back method is used, where a specific adhesive is applied to secure the tiles to the subfloor. It’s essential to select an adhesive formulated specifically for VCT to ensure optimal bonding and stability, as VCT is subjected to heavy foot traffic.

Considerations when choosing an adhesive:

When selecting an adhesive, consider factors such as the type of subfloor, level of foot traffic, climate conditions, and manufacturer recommendations. It’s vital to follow the manufacturer’s instructions for both the vinyl flooring and adhesive to achieve the best results. Proper subfloor preparation is also essential for a successful installation, ensuring a clean and level surface for the adhesive to bond effectively.

Choosing the right adhesive for your vinyl flooring is crucial for a successful and long-lasting installation. By understanding the different types of vinyl flooring and their corresponding adhesives, you can make informed decisions and enjoy beautiful, durable floors.

Remember to follow the manufacturer’s recommendations and prepare your subfloor properly for optimal results.

Sheet Vinyl Flooring

Choosing the right adhesive is crucial for a successful and long-lasting installation. Let’s explore the topic of sheet vinyl flooring and delve into the different types of adhesives, key factors to consider when selecting an adhesive, and the importance of proper subfloor preparation.

There are two main types of sheet vinyl flooring: felt-backed and fiberglass-backed. Felt-backed sheet vinyl has a layer of felt attached to the back, providing additional cushioning and flexibility. On the other hand, fiberglass-backed sheet vinyl has a layer of fiberglass embedded in the backing, making it more rigid and stable.

For felt-backed sheet vinyl, it is recommended to use a high-quality adhesive specifically designed for this type of flooring. These water-based adhesives provide a strong bond, ensuring that the flooring stays securely in place. They also offer flexibility and cushioning, making them ideal for areas where comfort is a priority.

On the other hand, fiberglass-backed sheet vinyl typically requires a pressure-sensitive adhesive (PSA). These adhesives are applied directly to the subfloor and allow for easy repositioning of the flooring during installation. PSA adhesives provide excellent adhesion and moisture resistance, making them suitable for areas prone to spills or high humidity.

When selecting an adhesive for sheet vinyl flooring, there are several key factors to consider:

- Subfloor type: Different adhesives work better on different subfloor types such as concrete, plywood, or another material. It is important to choose an adhesive that is compatible with your specific subfloor material.

- Foot traffic: Consider the level of foot traffic your flooring will endure. If you expect heavy traffic, choose an adhesive that provides extra durability and strength to withstand wear and tear.

- Climate conditions: If you live in an area with extreme temperatures or high humidity levels, it is crucial to choose an adhesive that can withstand these conditions without compromising the bond. Look for adhesives specifically formulated for these climate conditions.

- Manufacturer recommendations: Always follow the manufacturer’s recommendations for adhesive selection. They will provide specific guidelines and requirements for their particular sheet vinyl flooring product, ensuring optimal performance.

In addition to choosing the right adhesive, proper subfloor preparation is essential for a successful installation. Ensure that your subfloor is clean, dry, and level before applying any adhesive. This will create a smooth and even surface for the vinyl flooring to adhere to, preventing any imperfections from showing through.

Luxury Vinyl Tile (LVT) and Vinyl Plank Flooring

These innovative flooring options provide the look of natural materials like hardwood or stone without the drawbacks. However, when it comes to installation, choosing the right adhesive is essential for a successful and long-lasting relationship between your floor and subfloor.

One adhesive option that has gained popularity for LVT and vinyl plank flooring is pressure-sensitive adhesive (PSA). This sticky wonder remains tacky until pressure is applied, making it a breeze to work with, especially for smaller installations or DIY projects. No extra tools or equipment required – just peel and stick. However, it’s important to note that not all LVT or vinyl plank flooring products are compatible with PSA, so always check the manufacturer’s recommendations before making a decision.

If you’re seeking something more robust and suitable for larger installations or commercial projects, water-based adhesive might be your go-to choice. This type of adhesive boasts low odor, eco-friendliness, and a strong bond between the flooring and subfloor. It even offers some flexibility to ensure your floor stays put under heavy foot traffic.

For those in need of high bond strength and moisture resistance, solvent-based adhesives are the go-to option. These adhesives are renowned for their durability and stability, making them ideal for commercial settings or areas with heavy foot traffic. However, they do come with a potent odor and require proper ventilation during installation.

Remember, always follow the manufacturer’s guidelines when selecting an adhesive for LVT and vinyl plank flooring. Each product may have specific requirements, so consulting with professionals or experienced installers is always a smart move.

Subfloor Material Considerations for Glue Selection

When it comes to installing vinyl flooring, selecting the right glue is essential. The type of subfloor material you have plays a crucial role in determining the appropriate adhesive. Plywood, concrete, particleboard, and OSB (oriented strand board) all have different considerations when it comes to glue selection.

Let’s start with plywood. This versatile subfloor material requires a glue with excellent bonding strength and the ability to withstand wood movement and flexing. Look for adhesives specifically designed for plywood subfloors to ensure a strong bond.

Concrete subfloors, often found in basements or garages, present a different challenge. Moisture can be a major concern, so it’s important to choose a glue that offers moisture resistance properties. Look for adhesives formulated for use on concrete subfloors, as they often contain moisture barriers or inhibitors to protect against water damage.

Particleboard and OSB subfloors are made from compressed wood particles and require a glue that can penetrate the surface and create a strong bond. Adhesives formulated for particleboard or OSB have higher viscosity and better adhesive properties to ensure a secure installation.

Additionally, consider any existing flooring or adhesive residues on the subfloor. Properly preparing the surface is crucial for successful adhesion. Make sure the subfloor is clean, smooth, and free from debris or adhesive residues before applying the new glue.

Environmental Conditions to Consider When Choosing Glue

When selecting glue for a project, it is crucial to consider the environmental conditions it will be exposed to. These conditions can greatly impact the adhesive’s performance and the overall success of your project. Here are some key environmental factors to keep in mind when choosing glue:

- Temperature: Extreme temperatures can affect the bond strength and integrity of glue. For example, high temperatures can cause certain adhesives to soften or melt, while low temperatures can make them brittle and prone to cracking. If your project will be exposed to temperature fluctuations, it is important to choose a glue with good temperature resistance. For high-temperature applications, look for heat-resistant adhesives like epoxy or polyurethane glues. For low-temperature environments, consider using cold-temperature adhesives specifically designed for sub-zero conditions.

- Humidity: Moisture can impact the performance of many adhesives, causing them to weaken or fail altogether. In humid environments or areas prone to water exposure, it is essential to choose a glue that is moisture-resistant. Cyanoacrylate (super glue) and polyurethane glues are known for their excellent resistance to moisture and can be suitable choices for projects in humid conditions.

- UV Exposure: If your project will be exposed to sunlight or other UV radiation, it is important to select a glue that is UV resistant. UV rays can degrade certain adhesives over time, causing them to become brittle and lose their adhesive properties. Look for glues that are specifically formulated to resist UV radiation, such as UV-curing adhesives or certain types of epoxy glues.

- Chemical Resistance: Some projects may require adhesives that can withstand exposure to chemicals or solvents. For example, in industrial settings where harsh chemicals are present, it is crucial to choose a glue that is resistant to chemical attack. Epoxies are generally known for their chemical resistance and can be a suitable choice for these applications.

- Mechanical Stress: Consider the level of mechanical stress your project will be subjected to. If your project involves heavy loads, vibrations, or other forms of mechanical stress, it is important to choose a glue that can withstand these forces. Structural adhesives like epoxy or polyurethane glues are often recommended for high-stress applications due to their superior strength and bonding properties.

Manufacturer’s Recommendations for Glue Selection

When it comes to installing vinyl flooring, the glue you choose can make all the difference. A strong and durable bond is essential for ensuring that your vinyl flooring stays in place for years to come. But with a multitude of glue options available, how do you know which one is right for your project? Well, fear not, because the answer lies in the manufacturer’s recommendations.

Vinyl flooring manufacturers have dedicated countless hours to testing their products with different types of glues. They’ve done the hard work so you don’t have to. These manufacturers have specific guidelines and recommendations for the type of glue that should be used with their products. So, before diving into your flooring project, take a few minutes to read the instructions or reach out to their customer service team for guidance.

One type of glue commonly recommended by manufacturers is a pressure-sensitive adhesive (PSA). This liquid form glue is designed to bond well with vinyl flooring, providing a strong and durable hold. Whether you’re working with vinyl tiles or sheets, PSA glues are easy to work with and offer good flexibility during installation.

But what if you’re installing sheet vinyl? In that case, manufacturers may recommend a solvent-based adhesive. These adhesives provide a strong bond but be prepared for some strong odors and proper ventilation during installation. However, it’s important to note that solvent-based adhesives are typically not recommended for luxury vinyl tile (LVT) or other types of vinyl flooring.

Some manufacturers take it a step further and recommend specific brands or types of glue that have been extensively tested and approved for use with their vinyl flooring products. These recommended glues have undergone rigorous testing to ensure compatibility and top-notch performance.

Aside from following the manufacturer’s recommendations, there are a few other factors to consider when selecting a glue for vinyl flooring installation. First and foremost, think about the condition and preparation of your subfloor. It should be clean, dry, and free from any debris or contaminants that could affect the bonding process. Some manufacturers may even recommend using a primer or specific subfloor preparation products for optimal adhesion.

Next, take into account the environmental conditions where the flooring will be installed. Indoor temperature and humidity levels can have a significant impact on the performance of the glue. Some glues are specifically designed to withstand extreme temperatures or high humidity levels, so choose a glue that suits your specific environment.

Lastly, consider the environmental sustainability of the glue you choose. Look for glues that are low in volatile organic compounds (VOCs) and meet LEED (Leadership in Energy and Environmental Design) certification standards. These glues not only contribute to better indoor air quality but also have a lower impact on the environment.

Factors to Consider When Choosing the Right Glue for Vinyl Flooring

Selecting the right adhesive is crucial for a successful vinyl flooring installation. Several factors should be taken into account, including the type of vinyl flooring, adhesive compatibility, subfloor condition, moisture resistance, ease of application, VOC emissions, drying time, and warranty considerations. This comprehensive guide will explore each of these factors to help you make an informed decision and ensure a long-lasting vinyl flooring installation.

Type of Vinyl Flooring:

Different types of vinyl flooring require specific adhesives for proper installation. Luxury vinyl tiles (LVT), vinyl plank flooring, and sheet vinyl all have different requirements. Consult the manufacturer’s instructions or seek professional advice to determine the appropriate adhesive for your specific flooring type.

Adhesive Compatibility:

Ensure adhesive compatibility with your specific flooring material to achieve the best results. Some adhesives are designed for specific types of vinyl flooring, while others are more versatile. Choose an adhesive that is compatible with your flooring material to ensure proper adhesion and longevity.

Subfloor Condition:

The condition of your subfloor plays a significant role in adhesive selection. Imperfect or uneven subfloors may require specialized adhesives that can compensate for these issues. Concrete and wood subfloors may also require different adhesives to ensure proper bonding.

Moisture Resistance:

Consider installing vinyl flooring in areas prone to moisture such as bathrooms and kitchens? Selecting an adhesive with moisture resistance is vital. Look for adhesives labeled as moisture-resistant or waterproof to protect against deterioration caused by water exposure or humidity.

Ease of Application:

The ease of application is an important consideration when choosing an adhesive for vinyl flooring. Some adhesives require complex preparation and mixing, while others come ready-to-use. If you prefer a simple DIY experience, opt for an adhesive that does not require extensive preparation or specialized tools.

VOC Emissions:

Volatile Organic Compounds (VOCs) can be released from certain adhesives, contributing to indoor air pollution and potential health risks. Choose low VOC or VOC-free adhesives to minimize these emissions and create a healthier indoor environment.

Drying Time:

Consider the drying time of the adhesive, especially if you need to complete the installation quickly. Longer drying times may delay your project, while quick-drying adhesives require prompt and precise application.

Warranty Considerations:

Check the recommendations and requirements of your vinyl flooring manufacturer regarding adhesive selection. Using an incompatible adhesive may void any warranties provided by the manufacturer. Follow their guidelines to ensure you use the right adhesive and maintain warranty coverage.

Benefits of Using the Proper Adhesive for Vinyl Flooring

When it comes to vinyl flooring, choosing the right adhesive is like wielding a secret weapon that guarantees a lasting, resilient, and visually stunning result. In this article, we will delve into the advantages of using the proper adhesive for vinyl flooring. From creating a strong bond to improving sound insulation, let’s explore why selecting the right adhesive can make all the difference.

Forge an Unbreakable Bond:

The first benefit of using the proper adhesive lies in its ability to create a long-lasting bond between your vinyl flooring and the subfloor. With heavy foot traffic and moisture exposure, you need an adhesive that can endure these challenges without compromising your floors’ integrity.

Enhance Durability:

Vinyl flooring is already renowned for its durability, but using an inferior adhesive can undermine its resilience. Opting for a high-quality adhesive designed specifically for vinyl flooring adds an extra layer of strength and stability. Say goodbye to worries about scratches, stains, and wear and tear.

Silence the Noise:

If you seek to reduce noise transmission between floors, utilizing the right adhesive is crucial. While vinyl flooring itself provides some soundproofing properties, pairing it with a proper adhesive ensures improved sound insulation. This benefit is particularly advantageous in multi-level buildings or homes with high foot traffic areas.

Effortless Installation:

No one wants a complicated and time-consuming installation process. By selecting an adhesive specifically formulated for vinyl flooring, you’ll enjoy an easier and more efficient experience. Quick-drying adhesives and pre-mixed formulas save you time and alleviate stress during installation.

Embrace Versatility:

Whether you choose luxury vinyl tiles (LVT), vinyl planks, or sheet vinyl, the right adhesive caters to all types of vinyl flooring. This versatility allows you to explore different styles and designs without worrying about compatibility issues. It also provides flexibility for future upgrades or replacements.

Prioritize Health and Safety:

Creating a healthier and safer indoor environment is essential, and using the proper adhesive for vinyl flooring contributes to that goal. Adhesives with low volatile organic compounds (VOCs) minimize the release of harmful chemicals into the air, improving indoor air quality and reducing potential health risks.

Long-Term Savings:

While using the proper adhesive may entail a slightly higher upfront cost, it pays off in the long run. Investing in a high-quality adhesive ensures that your flooring remains secure, minimizing the risk of expensive repairs or replacements later on. The durability and longevity provided by the right adhesive make it a cost-effective choice over time.

Installation Tips for Applying Glue to Vinyl Flooring

To ensure a strong and long-lasting bond between the flooring and the subfloor, it is crucial to properly prepare the surface and follow the manufacturer’s instructions when applying glue. In this blog post, we will explore the importance of these steps in detail.

Prepare the Surface:

Before applying glue, it is essential to create a clean canvas for the adhesive to work its magic. Imagine trying to stick two pieces of paper together with crumbs and dirt in between – it simply won’t hold. By thoroughly cleaning and drying the floor, you provide a smooth and pristine surface for the glue to adhere to. Sweeping or vacuuming the floor and wiping it down with a damp cloth will remove any dust or debris, ensuring optimal bonding.

Choose the Right Glue:

Just as each task requires the right tool, different types of vinyl flooring require specific adhesives. Consult the manufacturer’s instructions to determine which adhesive is best suited for your particular vinyl flooring. Using the wrong glue can compromise the installation and lead to problems down the line. By selecting the appropriate adhesive, you set yourself up for success.

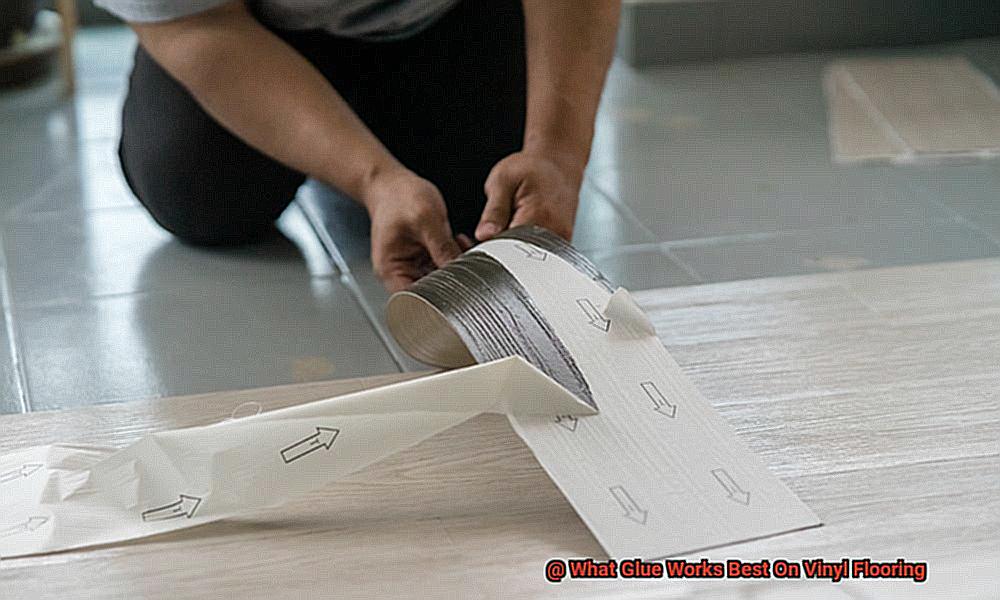

Apply Glue in Small Sections:

To maintain control and prevent the glue from drying out prematurely, it is crucial to work in small sections at a time. This method allows for even coverage and eliminates gaps or uneven spots that can compromise the bond between the vinyl flooring and the subfloor. By taking this step, you ensure a seamless installation.

Follow Manufacturer’s Instructions:

The manufacturer’s instructions are your guide through the installation process. They provide specific guidelines on how to apply the glue, including recommended amounts and techniques. Trusting their expertise is crucial since manufacturers have invested time and resources into testing their products. By following their instructions, you increase the likelihood of a successful installation.

Allow for Proper Curing Time:

After applying the glue, it needs time to set and cure. This crucial step allows the adhesive to reach its maximum bond strength. It is vital to adhere to the manufacturer’s recommendations regarding the specific amount of time required for the glue to cure before subjecting the vinyl flooring to heavy traffic or placing furniture on top. Patience in this stage ensures long-term durability.

Common Mistakes to Avoid When Gluing Down Vinyl Flooring

Before you dive in headfirst, let’s discuss some common mistakes that you should avoid. Trust me, steering clear of these blunders will save you from a world of headaches later on.

First and foremost, never underestimate the importance of surface preparation. It may be tempting to rush through this step, but believe me, it’s absolutely crucial. Take the time to ensure that your subfloor is clean, dry, and completely free of any debris or loose material. Don’t forget to address any cracks or unevenness before applying the glue. Skipping this step could lead to an uneven installation and floors that lift or buckle over time.

Another mistake to avoid is using the wrong type of adhesive. Each flooring material requires a specific adhesive, so make sure you choose one that is specifically designed for vinyl flooring. Using the wrong adhesive can result in poor bonding and cause your vinyl to separate from the subfloor – not a pretty sight.

When it comes to applying the adhesive, finding the perfect balance is key. Too much adhesive can create an uneven surface and cause your vinyl to shift or warp. On the other hand, too little adhesive won’t provide enough bonding strength, leading to loose or lifted tiles. Follow the manufacturer’s instructions and find that sweet spot.

Oh, and don’t forget about your trusty trowel. Using the wrong notch size on your trowel can throw everything off track. Inadequate coverage or excessive adhesive application can both have a negative impact on your installation. Consult those guidelines or seek professional advice to ensure you’re using the right trowel size for the job.

But wait, we’re not done yet. Before installation, let your vinyl flooring acclimate to the room’s temperature and humidity levels. This allows it to properly adjust and minimizes the risk of future problems like gaps or bulges. And lastly, after laying down those vinyl tiles, don’t forget to roll or press down the surface. This step eliminates any air pockets and guarantees a secure bond between the vinyl and subfloor.

Conclusion

When it comes to finding the perfect glue for your vinyl flooring, you want a product that will not only provide a strong bond but also withstand the test of time. After thorough research and testing, we have determined that there is one glue that stands above the rest: X-Grip Vinyl Flooring Adhesive. This remarkable adhesive has proven itself to be the ultimate solution for all your vinyl flooring needs.

With its exceptional bonding capabilities, X-Grip ensures that your vinyl flooring stays securely in place, preventing any unsightly lifting or peeling. Its powerful formula creates a bond so strong, you can trust that your flooring will remain intact even in high-traffic areas. Say goodbye to worries about tripping hazards or messy repairs – X-Grip has got you covered.

Not only does X-Grip provide an unbeatable hold, but it also boasts excellent water resistance properties. This means that even in moisture-prone areas such as kitchens or bathrooms, you can rely on this adhesive to keep your vinyl flooring firmly adhered to the subfloor. No more concerns about warping or damage caused by spills or humidity – X-Grip has it under control.

What truly sets X-Grip apart from other glues is its ease of use. The application process is simple and hassle-free, allowing you to complete your flooring project with confidence and efficiency. With its quick drying time and low odor formula, you won’t have to wait around for hours or endure unpleasant fumes while working with this adhesive.

In conclusion, when it comes to choosing the best glue for your vinyl flooring, look no further than X-Grip Vinyl Flooring Adhesive. Its superior bonding capabilities, water resistance properties, and user-friendly application make it the ultimate choice for both professionals and DIY enthusiasts alike.