Whether you’re a DIY enthusiast or a design aficionado, knowing how to glue acrylic to acrylic is an invaluable skill. Acrylic, with its remarkable clarity, durability, and impact resistance, has become a favorite material for various projects.

But achieving a strong and long-lasting bond requires specific adhesive materials and techniques. In this blog post, we’ll dive deep into the world of acrylic bonding, exploring the top adhesive options and sharing application tips that will make your acrylic pieces stick together like a pro.

So get ready to discover the secrets of flawless connections.

What is Acrylic?

Contents

- 1 What is Acrylic?

- 2 Types of Adhesive for Glueing Acrylic to Acrylic

- 3 Solvent-Based Cement or Adhesive

- 4 Methyl Methacrylate (MMA) Adhesive

- 5 Cyanoacrylate Adhesives (Super Glue/Instant Glue)

- 6 Different Forms of Acrylic Adhesives

- 7 Preparing the Surfaces for Bonding

- 8 Applying the Adhesive Properly

- 9 Conclusion

When it comes to materials that combine functionality and beauty, few can match the remarkable versatility of acrylic. This extraordinary plastic has found its way into a multitude of industries, ranging from construction and automotive to art and design. In this blog post, we will delve into the fascinating history, unique properties, diverse applications, and numerous benefits of acrylic, shedding light on why it has become such a popular choice in today’s world.

A Brief History:

Acrylic had its genesis in the early 20th century, with commercial production commencing in the 1930s. Originally developed as an alternative to glass due to its clarity and lightweight nature, acrylic has evolved over time into an immensely sought-after material with an ever-expanding range of applications.

Properties that Set Acrylic Apart:

One of the standout features of acrylic is its exceptional durability. Unlike glass, which can shatter upon impact, acrylic is renowned for its resistance to breakage. This property makes it the preferred choice for safety barriers, protective equipment, and even aircraft windows.

In addition to its strength, acrylic offers outstanding optical clarity. Its transparency allows for maximum light transmission, making it perfect for applications that require clear visibility, such as display cases, signage, and architectural elements.

Moreover, the lightweight nature of acrylic makes it easy to handle and transport compared to glass or other materials. This advantage has made it the go-to option in industries where weight plays a crucial role, such as automotive manufacturing and aerospace engineering.

Versatile Applications:

The applications of acrylic are virtually limitless. In construction, it is used for windows, skylights, and roofing materials due to its weather resistance and UV stability. In the automotive industry, acrylic finds its way into headlights, taillights, and interior components because of its exceptional clarity and impact resistance.

Artists and designers have also wholeheartedly embraced acrylic for its versatility. It serves as a canvas for painters, a sculpting medium for 3D artists, and a material for creating modern furniture or decorative items. Its ability to be easily cut, shaped, and bonded together using adhesives specifically designed for acrylic makes it an artist’s dream material.

Benefits Galore:

The benefits of acrylic are manifold. Its weather resistance ensures that it won’t yellow or deteriorate when exposed to sunlight, making it perfect for outdoor applications. Furthermore, its light weight and ease of fabrication contribute to cost savings during installation and transportation.

Acrylic’s eco-friendliness is another notable advantage. Unlike certain plastics, it can be recycled, reducing its environmental impact and promoting sustainability.

Types of Adhesive for Glueing Acrylic to Acrylic

The secret lies in the power of adhesives. In this article, we will explore the diverse range of adhesives that can be used to glue acrylic to acrylic. So, let us embark on a journey to uncover the enchantment behind this magical bonding process.

Solvent Cement – The Mighty Powerhouse:

Amongst the most commonly used adhesives for gluing acrylic to acrylic is solvent cement. This superhero adhesive works its wonders through a chemical reaction that binds the two pieces of acrylic together. It is akin to a secret handshake that forges an eternal connection between them. Solvent cement is ideal for heavy-duty applications, such as construction or industrial projects. Simply brush it on, firmly press the pieces together, and witness the magic unfold before your eyes.

Super Glue – The Speedster Extraordinaire:

For those moments when time is of the essence, super glue emerges as your trusted ally. Also known as cyanoacrylate glue, this speedy superhero forms an instant and secure bond between acrylic surfaces. It comes in various viscosities, allowing you to choose the perfect consistency for your project. From intricate crafts to swift repairs, super glue is always there to save the day.

Acrylic Adhesive Tapes – The Invisible Heroes:

Yearning for a seamless appearance without any visible traces of glue? Look no further than acrylic adhesive tapes. These invisible heroes possess a robust adhesive backing that securely bonds acrylic surfaces together. They are perfect for projects where aesthetics are paramount. Simply peel off the backing, adhere the pieces together, and behold. Your project will exude flawlessness.

UV-Curing Adhesives – The Rapid Reactors:

When time is of the essence, UV-curing adhesives swoop in to save you. These mystical adhesives are liquid superheroes that instantaneously cure when exposed to ultraviolet light. They are perfect for applications that demand rapid bonding and exceptional strength. Apply the adhesive, shine the UV light, and witness the bond materialize within seconds.

Epoxy Adhesives – The Unbreakables:

If you crave a bond that can endure extreme conditions, epoxy adhesives are your ultimate heroes. These indomitable adhesives exhibit resistance to high temperatures, chemicals, and moisture. They are ideal for heavy-duty applications where strength and durability reign supreme. Mix the components, apply the adhesive, and let it work its magic.

Solvent-Based Cement or Adhesive

Gluing acrylic materials together is a crucial skill, and one of the most commonly used adhesives in this field is solvent-based cement. This glue is specifically designed for bonding acrylic materials, providing a bond that is not only strong but also durable, standing the test of time.

One of the standout features of solvent-based cement is its ability to create an almost invisible bond. When applied correctly, the glue seeps into the microscopic gaps between the acrylic pieces, resulting in a seamless connection. No visible lines or marks are left behind, giving your project a clean and professional finish.

But it doesn’t stop there. Solvent-based cement also creates a bond that can withstand stress and load, making it suitable for both small-scale projects and larger constructions. It forms a structural bond that ensures your creations stay intact.

However, it’s important to heed the manufacturer’s instructions when using solvent-based cement. Apply the glue sparingly and evenly to ensure proper bonding. Also, give it enough time to dry and cure fully before subjecting the bonded pieces to any stress or load.

One thing to keep in mind is the strong odor and potential health hazards associated with solvent-based cement. The solvents used in these glues can emit powerful fumes that could be harmful if inhaled excessively or over an extended period. To protect yourself, work in a well-ventilated area or wear appropriate respiratory protection when using this type of adhesive.

Methyl Methacrylate (MMA) Adhesive

Methyl Methacrylate (MMA) adhesive, also known as the superhero of bonding acrylic materials, is a remarkable structural adhesive that creates invisible and powerful bonds. With its fast cure time, high bond strength, and versatility in bonding various materials, MMA adhesive is a go-to choice for industries such as automotive, construction, and mixed media projects.

One of the standout features of MMA adhesive is its lightning-fast cure time. Within minutes, your project is ready to go. This rapid curing process allows for quick assembly and reduces production time, making it ideal for industries where speed is crucial. Whether you’re constructing a vehicle or building a structure, MMA adhesive has got your back.

But it doesn’t stop there. MMA adhesive also offers exceptional bond strength. It creates strong and durable bonds that can withstand diverse environmental conditions, including temperature changes, moisture, and UV exposure. From indoor applications to outdoor projects braving the elements, MMA adhesive ensures reliable and long-lasting bonds.

Versatility is another key advantage of MMA adhesive. It can bond not only acrylic to acrylic but also other materials like metal, wood, and composites. Whether you’re working on a mixed media project or need to join different components together, MMA adhesive rises to the challenge.

When it comes to application, MMA adhesive typically comes in two parts – the adhesive and the catalyst. These two components are mixed together just before use to initiate the curing process. Apply the adhesive to the surfaces you want to bond, apply pressure for good contact, and watch as the magic happens.

However, proper surface preparation is essential for successful bonding with MMA adhesive. Surfaces should be clean, dry, and free from any contaminants like dust or grease. You can even lightly roughen the surfaces with sandpaper for enhanced adhesion. Safety precautions are equally important when working with MMA adhesive. Protective gloves, goggles, and a respirator should be worn to ensure a safe and successful application.

Cyanoacrylate Adhesives (Super Glue/Instant Glue)

Step into the world of cyanoacrylate adhesives, also known as super glue or instant glue, and prepare to be amazed by their extraordinary properties. These adhesives possess a unique combination of fast-drying capabilities and exceptional bonding strength, making them the ultimate heroes for joining acrylic materials. Let’s delve into the fascinating process of how this adhesive works and explore its wide range of applications.

At its core, cyanoacrylate adhesive functions by polymerizing in the presence of moisture, resulting in a robust bond between acrylic surfaces. However, before embarking on your bonding journey, ensure that the surfaces are meticulously cleaned, free from any dust, dirt, or grease. Just like any good superhero, super glue needs a clean canvas to showcase its powers.

Once your surfaces are pristine, it’s time to unleash the adhesive. Apply it sparingly and evenly on one of the acrylic surfaces. Remember, less is more. Excessive glue can lead to messy and uneven bonding, which we definitely want to avoid. We want our superheroes to look flawless.

Now comes the moment of truth – bringing the acrylic pieces together. Press them firmly and hold them in place for a few minutes to allow the glue to set. This is where the magic happens. The super glue will weave its spell, creating an unbreakable bond that even villains would envy.

However, patience is a virtue when working with cyanoacrylate adhesives. Leave your masterpiece undisturbed for at least 24 hours. This period ensures that the bond fully cures and reaches its maximum strength. Our heroes need time to gather their energy and become invincible.

While super glue is a formidable ally for most projects involving acrylic materials, it does have its limitations. For larger or heavier acrylic pieces, consider using stronger adhesives or mechanical fasteners. And remember that once super glue bonds have formed, they cannot be easily reversed. So be confident in your placement before committing to the bond.

But don’t despair. Should you encounter any spills or excess glue, our trusty companion acetone will come to the rescue. Just exercise caution, as acetone can cause damage to certain types of acrylic materials. Use it sparingly and with care to avoid any unintended consequences.

Different Forms of Acrylic Adhesives

In this comprehensive guide, we will explore the various forms of acrylic adhesives and their remarkable properties. Get ready to embark on a journey to discover the superheroes of adhesive bonding.

Liquid Solvent Cement:

Our first superhero is liquid solvent cement, a powerful adhesive that chemically melts the surfaces of acrylic, enabling them to fuse together upon drying. This quick-drying adhesive creates a robust bond between acrylic pieces. Application is a breeze with a brush or applicator.

Acrylic Tape:

Next up is acrylic tape, a user-friendly adhesive in the form of a thin strip or sheet with adhesive properties on both sides. Simply apply it between the two acrylic surfaces and press firmly for a strong, permanent bond. Acrylic tape is particularly ideal for bonding acrylic sheets.

Acrylic Glue:

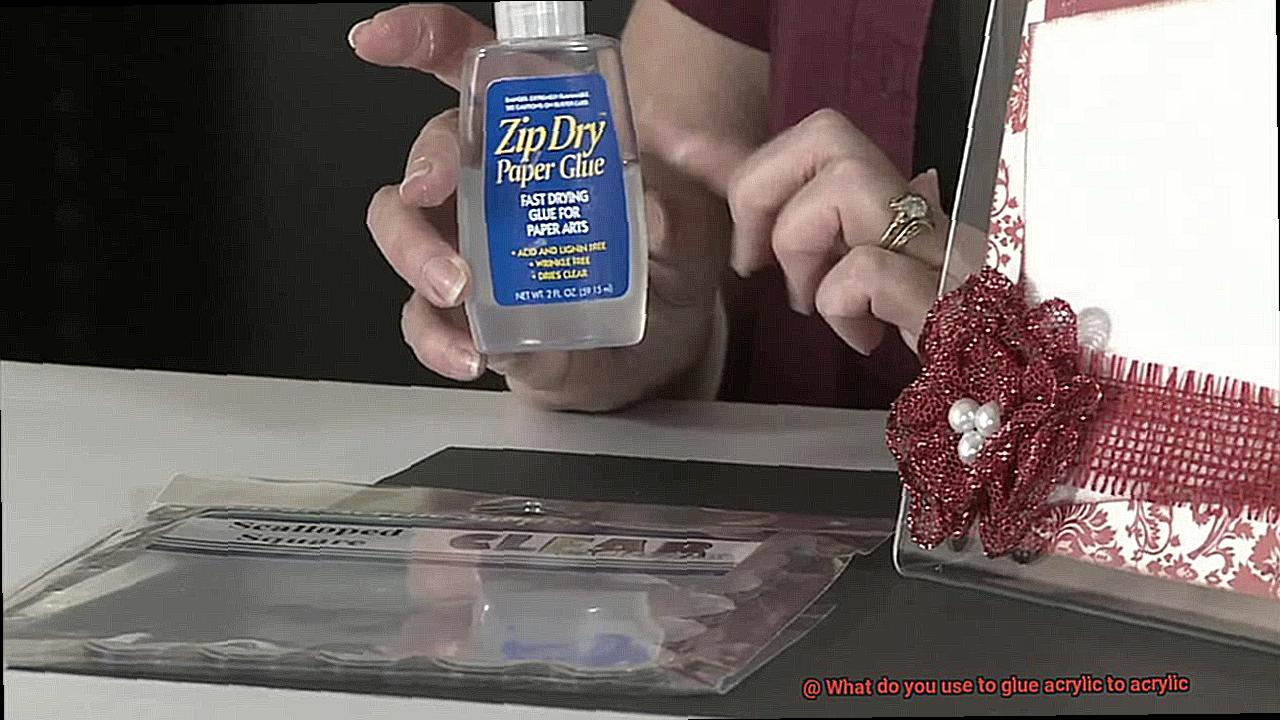

Acrylic glue, available in tubes or bottles, is another formidable ally in bonding acrylic to acrylic. Applied with a brush or nozzle, this adhesive initiates a chemical reaction that forms an enduring bond between the acrylic surfaces. Opting for an adhesive specifically designed for bonding acrylic is crucial for optimal results.

UV-Curing Adhesives:

Our final superhero is UV-curing adhesives. These adhesives are applied to the acrylic surfaces and then exposed to UV light, triggering rapid hardening and creating an exceptionally strong bond. Renowned for their fast curing time and high strength, UV-curing adhesives are perfect for time-sensitive projects.

Specialty Adhesives:

There are also specialty adhesives tailored for specific applications. For instance, adhesives designed exclusively for bonding colored or transparent acrylic, as well as those with high temperature resistance for heat-exposed projects. These adhesives ensure the perfect bond, catering to your unique needs.

Conclusion:

With an array of acrylic adhesives at your disposal, bonding acrylic to acrylic has never been easier. Whether you choose the melting powers of liquid solvent cement, the simplicity of acrylic tape, the chemical reaction of acrylic glue, or the speed of UV-curing adhesives, you can rest assured knowing that these superheroes will create a strong and durable bond. So, gear up and let these extraordinary adhesives unleash their true potential in creating unbreakable bonds between acrylic surfaces.

Preparing the Surfaces for Bonding

Today, we’re going to dive into the world of gluing acrylic to acrylic and learn how to properly prepare the surfaces for a strong and durable bond. Trust me, with these tips, your adhesive will stick like glue.

Step 1: Clean, clean, clean.

Before you even think about applying any adhesive, it’s crucial to clean the surfaces that will be bonded. Grab a mild soap or detergent, mix it with warm water, and give those acrylic surfaces a good scrub with a soft cloth or sponge. Pay special attention to any areas that may have accumulated dirt or oils. Rinse the acrylic thoroughly with clean water and make sure it’s bone dry before moving on.

Step 2: Peel off the protective films

Acrylic surfaces often come with protective films or coatings to prevent scratches during manufacturing or shipping. But guess what? These films can interfere with the bonding process. Carefully peel them off, making sure not to scratch or damage the acrylic.

Step 3: Sand it down

Now it’s time to create a rough surface texture for better adhesion. Grab some fine-grit sandpaper (around 220-400 grit) and gently sand the surfaces in a circular motion. Don’t press too hard or you might damage or warp the acrylic. After sanding, wipe away any dust or debris with a clean, lint-free cloth.

Step 4: Optional but recommended – use a solvent-based cleaner or primer

If you want to take your bonding game to the next level, consider using a solvent-based cleaner or primer specifically designed for acrylic bonding. These products help remove any residual oils or contaminants that may be present on the surface, further improving adhesion. Just follow the instructions carefully and make sure you have proper ventilation.

Step 5: Dry it like a pro

Last but definitely not least, make sure those surfaces are completely dry before applying the adhesive. Moisture can weaken the bond over time, and we don’t want that. Let the acrylic air dry or use a clean, lint-free cloth to dry it thoroughly.

And there you have it. By following these steps, you’ll be well on your way to creating unbreakable bonds between acrylic surfaces. So go ahead, unleash your inner bonding superhero and take on any gluing challenge that comes your way.

Preparing the surfaces for bonding is a crucial step when it comes to gluing acrylic to acrylic. This step ensures that the adhesive has a clean and well-prepared surface to adhere to, maximizing the bond strength and durability of the joint.

Applying the Adhesive Properly

If you’ve ever wondered how to properly apply adhesive when gluing acrylic to acrylic, then you’ve come to the right place. In this article, we’ll walk you through the steps to ensure a strong and durable bond that will stick like glue (pun intended.).

- Cleanliness is Key: Before applying the adhesive, it’s crucial to clean the surfaces thoroughly. Any dirt, dust, or grease can hinder the adhesive from bonding properly. Grab a mild detergent or soap and water solution, give those surfaces a good scrub, and make sure to dry them completely before moving on.

- Choose the Right Adhesive: Now that your surfaces are squeaky clean, it’s time to choose the right adhesive for the job. There are various types available, such as solvent-based adhesives, UV-curing adhesives, and two-part epoxy adhesives. Each has its own advantages and considerations, so be sure to select one that suits your specific needs.

- Get Sticky: With the right adhesive in hand, it’s time to get sticky. Follow the manufacturer’s instructions carefully, applying the adhesive in the recommended amount and spreading it evenly on both surfaces. Make sure every nook and cranny is covered for a strong and durable bond.

- Join Immediately: Once the adhesive is applied, join the two pieces of acrylic together immediately. This helps prevent any air bubbles from forming and ensures a secure bond. Apply gentle pressure to hold them together firmly, but avoid excessive force that could cause damage.

- Patience is a Virtue: Now comes the waiting game. Give the adhesive sufficient time to cure or set. The curing time can vary depending on the type of adhesive used, so refer to the manufacturer’s instructions for specific guidelines. During this period, avoid any movement or stress on the glued area for optimal results.

- Consider Temperature and Humidity: Temperature and humidity are also factors to consider. It’s best to work in a well-ventilated area with moderate temperature and humidity levels for optimal bonding.

- Handle With Care: Lastly, handle your glued acrylic pieces with care once the adhesive has fully cured. While the bond may be strong, excessive force or stress can still cause damage. Treat them gently and avoid subjecting them to heavy loads or impacts.

3KzZDi-aXD4″ >

Conclusion

When it comes to bonding acrylic to acrylic, there are a few options you can consider.

One popular choice is using a solvent-based adhesive specifically designed for acrylics. These adhesives work by chemically melting the surfaces of the acrylic, creating a strong and durable bond.

Another option is using a two-part epoxy adhesive, which involves mixing two components together to create a strong adhesive that can securely bond acrylics. Additionally, there are also acrylic cements available that provide a quick and efficient way to glue acrylic to acrylic.

Whichever method you choose, it’s important to ensure that both surfaces are clean and properly prepared before applying the adhesive.