We know that when it comes to our outdoor spaces, we want nothing but the best. Whether you’re building a dreamy patio, a rock-solid driveway, or a charming walkway with pavers, keeping those bad boys firmly in place is crucial. But with so many adhesive options out there, how do you pick the perfect glue for your project?

Well, worry not. In this blog post extravaganza, we’ve got your back. We’ll be dishing out expert advice and insider knowledge on the top-notch adhesives that can glue pavers together like nobody’s business. We’ll dig into their special powers, application techniques, and long-lasting durability, so you can make an informed decision and create an outdoor space that’s both stunning and sturdy.

So get ready to dive headfirst into the wild world of adhesives as we unlock the secrets to achieving a paver installation that’s as solid as a rock. Stick around (pun intended) because we’re about to unveil the ultimate solution for your next hardscaping adventure.

What is Glue?

Contents

Glue, a powerful substance with humble origins, has been a trusted companion for humans throughout history. It serves as the ultimate problem-solver, capable of fixing broken objects and constructing remarkable structures.

In this article, we will embark on a journey into the captivating world of glue, exploring its types, composition, properties, and vast applications.

Types of Glue:

Glue comes in various forms, each possessing unique characteristics. Solvent-based glues contain solvents that evaporate during the drying process, leaving behind a robust adhesive bond. Water-based glues utilize water as a carrier agent and dry through evaporation or absorption into the materials being glued.

Epoxy glue consists of two components that are mixed together before application, ultimately hardening into an unyielding bond.

Composition and Properties:

Glue typically consists of a combination of chemicals, polymers, or natural materials. Its primary function is to create a durable bond between different materials by adhering to their surfaces and then hardening or drying. The strength of the bond varies depending on the glue type and the materials being joined.

Some glues are designed for specific materials, while others offer versatility for use on a wide range of surfaces.

Additionally, certain glues exhibit flexibility and resistance to heat, moisture, or chemicals, making them ideal for specific applications or environments.

Applications:

Glue finds purpose in numerous industries and activities. In woodworking and construction, it is indispensable for joining wood, metal, and plastic. In arts and crafts, glue is essential for creating intricate designs using paper, fabric, or other creative mediums.

The automotive industry relies on glue for assembling parts and ensuring structural integrity. Moreover, glue plays a critical role in packaging and labeling by securing products and providing vital information.

Gluing Pavers:

When it comes to gluing pavers together, multiple options are available. Polymeric sand combines fine sand with polymer additives to create an easy-to-apply solution that hardens when exposed to moisture. Construction adhesive, specifically designed for bonding concrete, stone, and brick, offers a strong bond suitable for both outdoor and indoor applications.

For larger and heavier pavers or areas with heavy traffic, epoxy-based adhesives provide exceptional strength and durability. Mortar or concrete mix can also be used for bonding pavers together, requiring proper surface preparation and application.

Different Types of Adhesives for Gluing Pavers Together

If you’re looking to create a solid, durable path or patio, you’ll need the right adhesive to stick those pavers together. In this guide, we’ll explore five different types of adhesives that are commonly used for gluing pavers together.

From the mighty joint stabilizer to the classic choice, let’s dive in and discover the right adhesive for your paving project.

Polymeric Sand: The Mighty Joint Stabilizer

Polymeric sand is like a superhero for interlocking pavers. This special mixture of sand and a sticky ingredient works wonders in creating a strong bond between the pavers. Simply sprinkle it between the joints and give it a splash of water.

Watch as it hardens up, locking those pavers in place. Say goodbye to pesky weeds and wobbly paths – polymeric sand has got your back.

Construction Adhesive: The Tough Guy

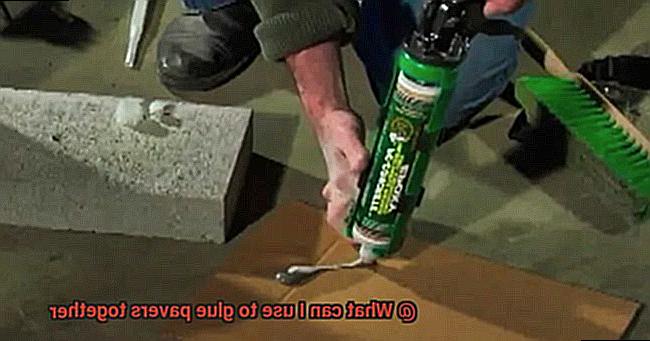

When it comes to bonding various materials, including pavers, construction adhesive means business. Available in different forms like liquid or paste, this adhesive is perfect for both indoor and outdoor projects.

Whether you’re creating a beautiful path or constructing an outdoor masterpiece, construction adhesive provides a strong and durable bond that can withstand the test of time.

Epoxy Resin: The Unbreakable Bond

If you’re looking for an adhesive that can handle heavy-duty areas or high traffic zones, epoxy resin is your go-to glue. Made up of two parts – resin and hardener – epoxy resin creates an unbreakable bond that can resist water, chemicals, and even changes in temperature. It’s like having the Hulk on your side. So if durability is what you’re after, look no further than epoxy resin.

Landscape Block Adhesive: The Flexibility Master

When it comes to vertical applications or securing capstones on retaining walls, landscape block adhesive is your secret weapon. This specially formulated adhesive is designed to be flexible, allowing it to bend and stretch with the movement of the pavers.

So go ahead and get creative with those curved designs – landscape block adhesive will keep everything in place.

Mortar: The Classic Choice

Last but not least, we have the classic choice for gluing pavers together – mortar. Made from a mix of cement, sand, and water, mortar hardens over time to create a solid and reliable bond.

While it may not be as flexible as other adhesives, mortar is still a popular option for certain applications. Just make sure to choose the right type of mortar for your project.

Polymeric Sand

Say goodbye to these problems with the superhero of paver adhesives – polymeric sand. With its incredible strength, durability, and ability to prevent weed growth, polymeric sand is the ultimate solution for gluing pavers together.

Let’s explore the advantages and installation process of this amazing product.

Advantages of Polymeric Sand:

- Erosion Resistance: Unlike traditional sand, polymeric sand forms a solid surface that resists erosion caused by wind, rain, and foot traffic. It won’t easily wash away, making it perfect for areas with high rainfall or heavy use.

- Aesthetic Appeal: Polymeric sand comes in various colors, allowing you to choose a shade that complements your pavers and enhances the overall look of your outdoor space.

Installation Process:

- Prepare the Area: Clean the joints between the pavers to provide a clean surface for the polymeric sand to bond to.

- Apply the Sand: Pour the polymeric sand over the joints, ensuring even distribution. Wait until the joints are completely dry before applying the sand for optimal results.

- Compact and Activate: Lightly compact the sand using a tamper or plate compactor to ensure a tight bond. Thoroughly water the surface to activate the polymers and allow them to solidify.

Maintenance:

Regularly check for gaps or cracks in the joints and add more sand as needed. Applying a sealant can help protect the surface from stains and maintain the integrity of the paver installation.

Construction Adhesive

Construction adhesive is a powerful and durable adhesive that is widely used in the construction industry to bond various materials together, including pavers. It is specifically designed to provide a permanent bond and withstand the harsh outdoor conditions, making it an ideal choice for gluing pavers together. There are different formulations of construction adhesive available, such as polyurethane and epoxy, each with its own unique advantages and recommended applications.

Polyurethane construction adhesive is a popular choice for bonding pavers due to its excellent adhesion and flexibility. It acts like a flexible powerhouse, capable of withstanding heavy loads and extreme weather conditions without losing its bond. Whether it’s scorching hot or freezing cold outside, your pavers will stay firmly in place.

On the other hand, epoxy construction adhesive offers an incredibly strong bond and is resistant to moisture, chemicals, and temperature fluctuations. It is the go-to option for areas with harsh weather or proximity to water, such as pools. However, it requires proper surface preparation and can be more challenging to work with compared to polyurethane.

When using construction adhesive to glue pavers together, it is crucial to follow the manufacturer’s instructions meticulously. This includes preparing the surfaces properly, applying the adhesive evenly, and allowing sufficient curing time before subjecting the pavers to any stress or weight. It is also advisable to choose a construction adhesive specifically labeled for outdoor or hardscape applications to ensure its durability and longevity.

Apart from bonding pavers together, construction adhesive has various other landscaping applications. It can be used to secure capstones or edging stones onto walls or steps, create decorative features by gluing stones or tiles onto concrete surfaces, or fix loose or cracked pavers. The versatility of construction adhesive allows homeowners to unleash their creativity and transform their outdoor spaces into stunning and stable havens.

Epoxy-Based Adhesive

Searching for a reliable and durable solution to keep your pavers securely in place? Look no further than epoxy-based adhesive. This powerful adhesive offers the strength, resilience, and weather resistance needed for gluing pavers together.

In this article, we will explore the advantages of using epoxy adhesive, the steps involved in its application, and essential tips to ensure a secure bond that stands the test of time.

Advantages of Epoxy-Based Adhesive:

Epoxy-based adhesive boasts numerous benefits that make it the ideal choice for paver installation. Its incredible strength and durability allow it to withstand heavy foot traffic and even the harshest weather conditions. Furthermore, epoxy possesses excellent adhesion properties, ensuring a secure bond between various materials commonly used for pavers, including concrete, stone, and brick.

Preparation of the Surface:

Properly preparing the surface before applying epoxy-based adhesive is crucial. Begin by thoroughly cleaning the pavers, removing any dirt or contaminants that could hinder bonding. If necessary, use sandpaper or a wire brush to gently roughen the surface, enhancing adhesion. This step creates a stronger bond between the adhesive and the pavers.

Application Techniques:

To apply epoxy-based adhesive effectively, follow the manufacturer’s instructions diligently. Mix the resin and hardener in the correct proportions within the specified working time. Once mixed, use a trowel or notched trowel to apply the adhesive evenly across the entire area. Ensure you apply enough adhesive to create a robust bond between each paver.

Tips for Ensuring a Secure Bond:

To guarantee a secure bond between your pavers, keep a few key tips in mind. Allow sufficient curing time before subjecting the glued pavers to stress or traffic. Curing times typically range from 24 hours to several days, depending on the product and environmental conditions. Additionally, ensure the adhesive is applied evenly, covering the entire surface of each paver for maximum strength and durability.

Mortar or Concrete Mix

When it comes to creating a sturdy and unyielding surface with pavers, the question arises: mortar or concrete mix? These two materials possess similar traits and are renowned for their ability to forge an unbreakable bond between pavers. So, whether you’re embarking on a driveway, patio, or walkway project, let’s delve deep into the nuances of using mortar or concrete mix as the adhesive that will hold your pavers together.

Before diving into the application process, it is imperative to prepare the surface meticulously. This involves meticulous cleaning of the pavers, eradicating any pesky dirt or debris that may impede the bonding process. Additionally, ensure that the surface is level and steadfast to achieve an even and enduring bond.

Equipped with a trusty trowel or grout bag, it’s time to apply the mortar or concrete mix. This enchanting concoction should be spread evenly between the pavers, ensuring that every nook and cranny is filled to perfection. This crucial step guarantees an unwavering bond, leaving no room for shifting or movement in the face of time. Should there be any surplus mortar or concrete mix, a simple brush or damp sponge will whisk it away.

Patience is a virtue when working with mortar or concrete mix. Allow ample time for the magic to unfold as the material cures and hardens. This captivating transformation typically takes several days, contingent upon the specific product and environmental conditions. Adhering to the manufacturer’s instructions regarding curing time is paramount in ensuring a bond between pavers that is robust and enduring.

Mortar and concrete mix boast unparalleled versatility, accommodating an array of paver materials ranging from natural stone to concrete, clay, or brick. However, caution must be exercised in selecting the appropriate mortar or concrete mix that harmonizes with your particular paver material. This careful selection guarantees optimal adhesion and a bond that defies time.

Beyond their adhesive prowess, mortar or concrete mix act as guardians against the relentless onslaught of weeds, maintaining the stability and aesthetic allure of your pavers for years on end.

It is important to note that while mortar or concrete mix may serve as the golden standard for most paver projects, alternative methods such as polymeric sand or adhesive may prove more fitting in certain cases. Consulting with a professional or conducting thorough research is always prudent before settling on the ideal method for gluing your pavers together.

Surface Preparation for a Successful Bond

Achieving a successful bond when gluing pavers together requires meticulous surface preparation. Are you ready to take your paver project to the next level? Well, get ready because I’m about to spill the secrets that will give you a rock-solid foundation that will withstand the test of time.

Cleanliness is key. Before applying any adhesive, give those pavers a good scrub down. Sweep away loose dirt, debris, and pesky vegetation. Stubborn stains or residues? No problem. Mix up a mild detergent with warm water and gently scrub them away. Rinse thoroughly to ensure no soap residue is left behind.

Now that your pavers are squeaky clean, it’s time to dry them out. Moisture is a buzzkill for bonding, so make sure they’re bone dry. Give them a little touch or use a handy-dandy moisture meter if you want to get all technical.

But wait, there’s more. Sometimes, pavers have a smooth or sealed surface that makes it tough for adhesives to stick properly. No worries though, we’ve got a solution for that too. Roughen up that surface. Break out the sandblaster or grinder and give those pavers some texture. More contact points mean a stronger bond.

Clean and dry? Check. Properly textured? Check. Now let’s make sure those pavers are aligned and leveled. Uneven surfaces can cause weak spots in the bond, and we definitely don’t want that. Grab a spirit level or laser level and check for even spacing and height. Adjust as needed by adding or removing sand or gravel underneath.

Last but not least, priming. Think of it as the cherry on top of your paver project. Primers are adhesion superheroes. They improve the bond, making it stronger. Plus, they act as a barrier against moisture seepage. Just follow the manufacturer’s instructions for the specific primer you’re using, and you’ll be good to go.

Following the Manufacturer’s Instructions and Guidelines

Brace yourself for the secret sauce behind a strong and durable outcome: following the manufacturer’s instructions and guidelines. These instructions not only hold the key to a successful application but also guarantee a long-lasting and reliable bond between those pavers.

In this enlightening blog post, we will delve into the importance of adhering to these instructions, exploring the realms of surface preparation, proper application techniques, curing time, and safety precautions.

Surface Preparation:

Picture this: a clean slate, a fresh start. The first step in achieving a solid bond between pavers lies in impeccable surface preparation. Scrub away the remnants of the past, bid farewell to dirt, debris, and previous adhesive residue.

The manufacturer’s instructions shall be your guiding light, illuminating the path towards a clean and stable base that allows the adhesive to adhere effectively.

Follow these steps religiously, and witness the magic unfold.

Proper Application Techniques:

Ah, the art of application. Here’s where precision takes center stage. The manufacturer’s guidelines may unveil secrets like specific trowels or applicators that will dance gracefully across the paver surface, ensuring an even distribution of adhesive at just the right thickness.

Deviating from these guidelines? Tread carefully, for you might invite chaos into your masterpiece. Stick to the script, dear reader, and let your adhesive prowess shine.

Curing Time:

Patience, my friend, is indeed a virtue when it comes to bonding pavers together. The adhesive needs time—a sacred period for it to fully set and embrace its destiny. The manufacturer’s instructions shall whisper sweet nothings in your ear, revealing the required curing time.

Resist the urge to rush this step; instead, grant your adhesive the serenade it deserves. A strong bond shall be your reward, impervious to the trials of regular use and weather’s whims.

Safety Precautions:

Safety first, always. As you venture into the realm of adhesives, heed the manufacturer’s warnings and precautions. Don your armor, wield your shield—gloves, goggles, masks—to protect yourself from potential harm. Some adhesives may emit fumes, demanding proper ventilation. Embrace these safety measures as your trusted companions, ensuring a harmonious symphony between you and the adhesive.

4HtjS7EiurM” >

Also Read: How To Glue Rocks Together?

Conclusion

When it comes to gluing pavers together, there are a few options that can provide a strong and durable bond. One popular choice is polymeric sand, which contains additives that activate when wet to create a solid joint between the pavers. This sand not only holds the pavers in place but also helps prevent weed growth and insect infestation.

Another option is using an adhesive specifically designed for pavers, such as a construction adhesive or landscape block adhesive. These adhesives are formulated to withstand outdoor conditions and provide a long-lasting bond between the pavers.

If you’re looking for a more natural approach, you can use mortar or concrete mix to glue the pavers together. Mortar is commonly used for larger projects or when extra strength is required, while concrete mix provides a more flexible and versatile option.

No matter which method you choose, it’s important to ensure that the surface of the pavers is clean and dry before applying any adhesive. Additionally, follow the manufacturer’s instructions carefully for best results.

In conclusion, there are several options available when it comes to gluing pavers together.