Its elegance and sophistication are simply unmatched. From stunning countertops to exquisite flooring, marble is a top choice for those who crave timeless beauty. But when it comes to repairs or DIY projects involving this precious stone, finding the right adhesive can be a bit of a head-scratcher.

You don’t want to ruin that natural allure with an adhesive that just won’t cut it.

So here we are, diving deep into the world of adhesives that stick flawlessly to marble. We’ve got all the tried-and-true options and even some hidden gems up our sleeves. But first, let’s talk about why marble is so unique and why certain adhesives work better than others.

Marble’s smooth surface demands an adhesive that can handle its non-porous nature, temperature changes, and moisture resistance. Sure, water-based glues might seem tempting at first glance, but they tend to weaken over time due to marble’s chemical composition and its unfortunate tendency to stain.

That’s where epoxy adhesives come in like knights in shining armor for your marble bonding needs. These bad boys are known for their exceptional strength, durability, and resistance to moisture, chemicals, and heat. They dive deep into the pores of your marble surfaces and create a bond so strong it’ll make your repairs or projects stand tall through the ages.

Don’t get overwhelmed by the plethora of epoxy options out there. In this guide, we’ll walk you through different epoxy formulations specially designed for marble bonding. And hey, we won’t stop there. We’ll also explore other adhesive options suitable for various marble applications.

Whether you’re fixing a broken piece or unleashing your inner artist with new marble tiles, understanding which adhesives work best is key to avoiding any sticky situations (pun intended). So buckle up, my friends, and get ready to take your marble projects to a whole new level.

Remember, it’s not just about sticking things together; it’s about preserving the timeless charm of your marble surfaces. So dive into our guide, soak up all the knowledge, and get ready to conquer your marble bonding adventures with confidence.

What is Marble?

Contents

- 1 What is Marble?

- 2 Adhesives for Marble: Epoxy Resin

- 3 Adhesives for Marble: Polyurethane Adhesive

- 4 Avoid Certain Adhesives on Marble

- 5 Preparing the Marble Surface

- 6 Applying the Adhesive Properly

- 7 Clamping or Securing Items to Marble

- 8 Color of the Adhesive

- 9 Silicone Adhesive for Decorative Items

- 10 Test the Adhesive Before Use

- 11 Conclusion

Marble, a stunning metamorphic rock formed from limestone under intense heat and pressure, has captivated humanity for centuries. With its smooth and polished surface, durability, and unique patterns, marble has become a favored material for a wide range of applications. In this article, we will delve into the world of marble, exploring its composition, characteristics, and popular sources.

Composition and Formation:

Marble is primarily composed of calcium carbonate crystals, giving it its characteristic white or light-colored appearance. However, impurities present during its formation can introduce a variety of colors and patterns. The ancient Greeks and Romans recognized the beauty of marble and extensively used it in their architecture and sculptures.

Strength and Durability:

Marble’s dense structure provides exceptional strength, making it suitable for flooring, countertops, and wall cladding. While not as hard as granite, marble can withstand heavy use and extreme weather conditions.

However, caution must be exercised with acidic substances that can cause etching or dulling of the surface finish.

Sources of Marble:

Marble is quarried from various locations worldwide, each producing distinct variations in color, veining, and texture. The Carrara region in Italy is renowned for its high-quality white marble with delicate gray veins.

Thassos in Greece offers pure white marble with a crystalline appearance. Calacatta marble from Spain showcases bold veining on a creamy white background.

Care and Maintenance:

To preserve the beauty and longevity of marble, proper care and maintenance are essential. Regular cleaning with mild soap and water is recommended to avoid damaging the surface. Acidic cleaners should be avoided, as they can etch or dull the marble’s finish. Additionally, sealing the marble periodically can protect it from stains and enhance its natural luster.

Adhesives for Marble: Epoxy Resin

Prepare to be captivated as we delve into the magical realm of epoxy resin – the ultimate solution for bonding marble.

Marble, the superstar of natural stone surfaces, demands an adhesive that matches its strength and durability. Enter epoxy resin, the game-changer in the world of marble bonding.

To embark on this journey, select an epoxy resin specifically formulated for marble. Look for labels like “marble epoxy” or those mentioning natural stone surfaces. Trust me, you don’t want to settle for any ordinary epoxy glue. Marble deserves the best.

Before applying the resin, ensure your marble surface is immaculate. Dust and debris have no place here. Once cleaned and dry, gently sand the surface to create a rough texture that enhances the bond between adhesive and marble. In this case, a little roughness goes a long way.

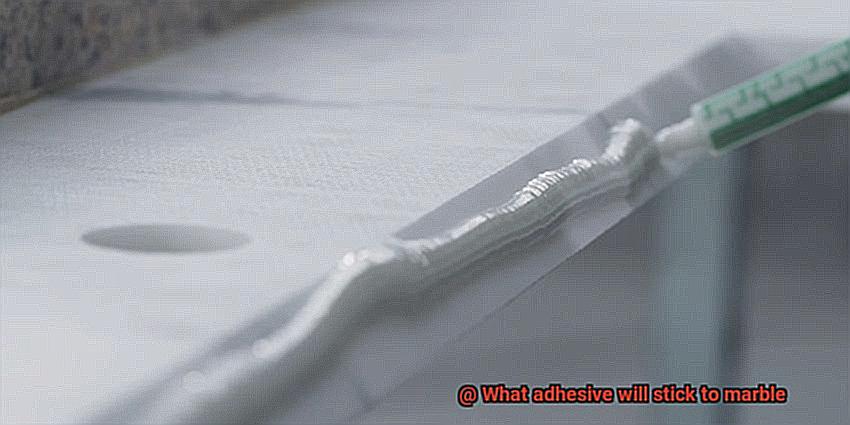

Now comes the exhilarating part – mixing and applying the epoxy resin. Armed with a brush or spatula, spread that magical glue evenly on both surfaces requiring bonding. Be wary of using too much or too little; a thin and even layer is ideal.

Remember, excess adhesive is a big no-no. Immediately wipe away any surplus with a clean cloth or sponge. Our goal is a flawless bond.

Once everything is in place, firmly press those marble surfaces together and hold them for the recommended curing time. Patience is key here, my friends. Follow the manufacturer’s instructions religiously.

After curing and achieving a formidable bond, residue may remain. Fear not. Employ a solvent designed for cleaning epoxy resin to wipe away any excess. Voilà. Your marble is ready to shine.

Bear in mind that while epoxy resin bonds are robust, they may yellow over time when exposed to direct sunlight. So, avoid using them in sun-drenched areas. We wouldn’t want a yellowed masterpiece, would we?

And here’s a little secret: should your exquisite marble creation suffer damage or detachment, don’t panic. Simply follow the same procedure and reapply the epoxy resin. It’s like granting your marble a second chance at glory.

So, my glue-loving comrades, armed with this knowledge, you are now equipped to bond marble like true professionals. Epoxy resin is your ticket to creating breathtaking marble masterpieces that will withstand the test of time. Embrace the magic and let your creativity flow.

Stay steadfast in your adhesive dreams.

Adhesives for Marble: Polyurethane Adhesive

Polyurethane adhesive: the ultimate superhero in the world of adhesives. With its incredible strength, flexibility, and resistance to moisture, this adhesive is a true champion when it comes to bonding marble.

One of its greatest advantages is its ability to bond different types of surfaces. Whether your marble is porous or non-porous, polyurethane adhesive has got your back. It forms a strong bond that can withstand the test of time, ensuring that your marble creations stay intact for years to come.

But it doesn’t stop there. This adhesive is designed to resist moisture, making it perfect for marble projects. No need to worry about your bond deteriorating or losing strength when faced with water or other liquids – polyurethane has got it covered.

Flexibility is also a key characteristic of this adhesive. Marble tends to expand and contract with changes in temperature and humidity, but polyurethane can accommodate these movements without compromising the bond. Your marble will remain securely in place, no matter what the weather throws at it.

However, it’s important to handle polyurethane adhesive with care. It may contain chemicals that can be harmful if ingested or come into contact with skin or eyes. Protect yourself by wearing gloves and goggles, and work in a well-ventilated area.

To ensure success, follow the manufacturer’s instructions carefully. Proper surface preparation, even application, and sufficient curing time are essential for a long-lasting bond. And don’t forget to test the adhesive on a small area before applying it to the entire surface.

Avoid Certain Adhesives on Marble

Marble, renowned for its elegance and luxury, requires careful consideration when selecting adhesives. Using the wrong adhesive can result in stains, discoloration, and damage to the surface. This article explores why specific adhesives should be avoided when working with marble and provides recommendations for safer alternatives.

Epoxy Resin – The Discoloration Culprit:

While epoxy resin is commonly used for various applications, it reacts negatively with marble’s calcium carbonate, leading to unsightly yellow or brown stains. This chemical reaction can ruin the appearance of your marble masterpiece.

Super Glue – A Sticky Situation:

Despite its reputation for quick and strong bonding, super glue is not suitable for marble. It leaves behind a stubborn white residue that is challenging to remove without causing harm to the delicate stone. Avoid this headache altogether.

Construction Adhesives – Not Marble’s Cup of Tea:

Construction adhesives or liquid nails are designed for wood or concrete bonding, not marble. These adhesives often contain chemicals that can harm the surface of your precious stone. It is best to keep them away from your marble projects.

The Heroes of Marble Adhesives:

When it comes to bonding marble, two adhesive champions stand out: specialized marble adhesive and clear silicone adhesive. These adhesives are specifically formulated for marble and do not cause any damage or discoloration. They ensure a secure bond that lasts.

The Importance of Surface Preparation:

Just like any successful superhero team-up, proper surface preparation is vital for effective marble bonding. Ensure that the surface is clean, dry, and free from dirt or debris. This enhances adhesion and minimizes the risk of damage.

Consult the Experts:

If you remain uncertain about which adhesive to use or have concerns about bonding marble, seek advice from professionals such as stone fabricators or marble suppliers. They possess the expertise and knowledge to guide you in selecting the appropriate adhesive for your specific marble application.

Preparing the Marble Surface

Whether it’s a new marble countertop installation or a repair for a cracked marble floor, the key to success lies in properly preparing the surface before applying any adhesive.

By following a series of necessary steps, you can ensure a bond that will withstand the test of time.

Step 1: Cleanse the Surface

Begin by giving your marble surface a meticulous cleaning. Use a mild soap or a stone-specific cleaner to banish any dirt, dust, or grime that may have accumulated. Harsh chemicals and abrasive cleaners are off-limits, as they can wreak havoc on the delicate marble.

After cleansing, rinse the surface with water and meticulously dry it with a soft cloth or towel. It is crucial to eradicate all moisture, as it can sabotage the adhesive’s ability to form a strong bond.

Step 2: Inspect and Repair

Once the surface is dry, embark on an inspection mission to identify any cracks, chips, or uneven areas. These imperfections must be addressed before applying adhesive.

Utilize a marble repair kit or seek professional guidance if necessary to mend any damages. By tending to these issues in advance, you pave the way for a seamless and flawless bond.

Step 3: Enhance Adhesion

To bolster the adhesion of the adhesive, gently roughen the surface using fine-grit sandpaper. Exercise caution to avoid inflicting further damage during this process. Afterward, meticulously wipe away any dust or debris with a damp cloth, leaving behind a clean and dry surface primed for bonding.

Step 4: Stain Removal (if needed)

If your marble surface bears any unsightly stains, it is advisable to eliminate them before applying adhesive. There are specific stain removal products available for marble that can expedite this process. Follow the instructions meticulously and ensure thorough rinsing and drying of the surface after stain removal.

Applying the Adhesive Properly

Look no further. The proper application of adhesive is paramount in creating a robust and long-lasting bond. Whether you’re embarking on a DIY project or undertaking a professional installation, we’ve compiled some expert tips to help you master the process with finesse.

First and foremost, preparing the surface is the foundation of success. Ensure that your marble surface is pristine, dry, and completely devoid of any unwanted dirt, dust, or debris. This step is critical because any impurities on the surface can impede the bonding process and compromise the adhesive’s effectiveness. So grab your favorite cleaning solution and give that marble a thorough scrub.

Next up, selecting the right adhesive for your marble is key. Marble is an exquisite material that necessitates a specialized adhesive. Epoxy-based adhesives are often the recommended choice for marble due to their remarkable bonding strength and resistance to moisture and chemicals. So be sure to have the appropriate adhesive on hand before diving in.

Now it’s time to mix things up correctly. Follow the manufacturer’s instructions meticulously when combining the components of your epoxy-based adhesive. Precisely measuring and thoroughly mixing the adhesive will ensure optimal curing and superior adhesion.

When it comes to applying the adhesive, uniformity is paramount. Utilize a notched trowel or a suitable applicator recommended by the adhesive manufacturer to distribute the adhesive evenly across the surface. This meticulous approach will prevent any unsightly gaps or irregularities in the bond.

Once you’ve applied the adhesive, exercise patience and allow ample time for proper curing. Curing times may vary depending on the specific adhesive employed, so adhere closely to the manufacturer’s instructions. And remember to apply pressure during curing. This can be achieved through the strategic use of clamps or weights, depending on the size and shape of your precious marble piece.

Finally, attend to any excess adhesive that may have oozed out during the bonding process. It’s perfectly normal for a bit of adhesive to escape, but it’s crucial to promptly clean it up using an appropriate solvent or cleaner recommended by the adhesive manufacturer.

Clamping or Securing Items to Marble

Marble, renowned for its timeless beauty and elegance, is a popular choice for countertops, flooring, and various other applications. However, when it comes to clamping or securing items to marble, finding the right adhesive and properly preparing the surface is crucial for achieving a strong and long-lasting bond.

Marble’s porous nature presents a unique challenge when it comes to adhesion. To overcome this, epoxy adhesive is often the go-to choice. With its exceptional bonding properties, epoxy can effectively adhere to marble surfaces. However, it is essential to select an epoxy specifically designed for marble to ensure compatibility and a secure bond.

Construction adhesive is another viable option for securing items to marble. Widely used for bonding different materials together, construction adhesive can also provide a strong bond on marble surfaces. Nevertheless, it is imperative to choose a construction adhesive that is suitable for use on marble.

Proper preparation of the marble surface is paramount before applying any adhesive. Thoroughly cleaning the surface eliminates dust, dirt, and debris that might hinder the bonding process. In some cases, lightly roughening the surface with sandpaper can enhance adhesion.

Following the manufacturer’s instructions when applying the adhesive is crucial. This involves ensuring even application and allowing sufficient drying or curing time before removing clamps or applying pressure to the bonded area.

For added support when securing heavy items to marble surfaces, mechanical fasteners like brackets or screws can be used in conjunction with adhesives. It is vital to select fasteners that are compatible with both the item being secured and the marble surface.

Not all adhesives are suitable for use on marble as some may contain solvents or chemicals that could damage or discolor the surface. Thus, testing the adhesive on a small, inconspicuous area of the marble before full application is highly recommended.

Considering the weight and size of the item being secured is essential. If the item is exceptionally heavy or large, seeking professional advice or consulting an expert ensures proper bonding and support.

Lastly, handling and applying adhesives in a well-ventilated area and adhering to safety precautions are crucial. Wearing gloves, eye protection, and ensuring adequate ventilation prevents inhalation of fumes or contact with the skin.

Color of the Adhesive

Marble is a stunning natural stone known for its elegance and beauty. When it comes to bonding marble, selecting the right adhesive is crucial for a strong and long-lasting bond. While it may seem like a minor detail, the color of the adhesive plays a significant role in the final appearance of your marble surface. In this blog post, we will delve into why the color of the adhesive matters when bonding marble.

The Halo Effect:

Using clear adhesives on marble can result in an unsightly halo effect. This is when a visible ring or halo forms around the edges of the bonding area, detracting from the natural beauty of the marble. Over time, this halo effect can worsen and even change color, leaving an unattractive blemish on your marble surface.

Finding a Match:

To avoid the halo effect and maintain the seamless beauty of your marble, it is crucial to choose an adhesive that closely matches the color of your marble. Manufacturers offer adhesives in various shades of white, gray, and beige specifically designed to blend seamlessly with different types of marble. By selecting an adhesive that matches your marble’s color, you can achieve a cohesive and visually appealing bond.

Unique Marble Hues:

In some cases, finding an exact match for your marble’s color may be challenging, especially if it has unique or unusual hues. In such situations, it is best to choose an adhesive that closely resembles the background color of your marble or opt for a neutral shade that complements its overall aesthetics. This way, you can achieve a harmonious blend while highlighting the unique characteristics of your marble.

Compatibility with Marble:

Beyond color considerations, it is essential to ensure that the chosen adhesive is specifically formulated for use with marble. Marble is a porous material that can react to certain chemicals present in adhesives, resulting in discoloration, staining, or damage. To avoid these issues, look for adhesives labeled as suitable for use with marble or natural stone. Always follow the manufacturer’s instructions regarding application and curing times for optimal results.

Silicone Adhesive for Decorative Items

When it comes to attaching decorative items to marble surfaces, choosing the right adhesive is crucial to ensure a secure bond without causing any damage. In this article, we will explore the benefits of using high-quality silicone adhesive for sticking decorative items to marble surfaces, highlighting its strong bond, flexibility, specific design for stone surfaces, proper surface preparation, even application, curing time, versatility for repairs, and considerations for testing.

Strong Bond and Flexibility:

Silicone adhesive stands out from other adhesives due to its exceptional bonding strength and flexibility. Unlike traditional adhesives, silicone adhesive can withstand movement and vibrations without compromising its bonding ability. This is particularly important for decorative items that may be subject to accidental bumps or slight movements.

Specifically Designed for Stone Surfaces:

Choosing a silicone adhesive specifically designed for stone surfaces is essential when adhering decorative items to marble. These high-quality adhesives are formulated to provide excellent adhesion to marble while minimizing the risk of discoloration or damage. Additionally, they are resistant to water, heat, and UV exposure, ensuring a long-lasting bond even in challenging conditions.

Proper Surface Preparation:

Achieving a strong and long-lasting bond requires proper surface preparation. Thoroughly cleaning the marble surface before applying silicone adhesive removes any dust, dirt, or oils that could interfere with the bonding process. This ensures that the adhesive can fully penetrate the surface, resulting in a secure bond.

Even Application:

To maximize bonding strength and aesthetics, it is crucial to apply silicone adhesive in small amounts and spread it evenly on both the decorative item and the marble surface. This technique eliminates gaps or air bubbles between the two surfaces, ensuring a seamless and visually appealing bond.

Curing Time:

Allowing the silicone adhesive to cure properly according to the manufacturer’s instructions is essential. This ensures that the bond reaches its maximum strength before subjecting the items to stress or pressure. Rushing the curing process can weaken the bond and lead to potential failure.

Versatility for Repairs:

In addition to sticking decorative items, silicone adhesive can also be used for repairing broken or chipped marble pieces. Its flexibility enables it to fill gaps and cracks, restoring the integrity and beauty of the marble.

Considerations and Testing:

While silicone adhesive is suitable for most decorative items on marble surfaces, certain considerations should be taken into account. Heavy-weight items or those exposed to extreme temperatures may require alternative adhesive options. It is advisable to test the adhesive on a small inconspicuous area before applying it to the entire piece or installing the decorative item permanently.

Test the Adhesive Before Use

Marble, with its timeless elegance and luxurious appeal, is a popular choice for both residential and commercial spaces. Whether you’re bonding decorative items or repairing a damaged marble surface, selecting the right adhesive is essential to maintaining its pristine appearance. Prioritizing testing the adhesive before use is a critical step in ensuring compatibility and preventing any potential damage. This blog post delves into the significance of testing adhesives on marble, providing valuable insights to safeguard your investment.

Why Test the Adhesive?

- Compatibility: Marble, a delicate and porous material, is susceptible to discoloration and staining if exposed to incompatible adhesives. Testing allows you to determine whether the adhesive will bond properly without causing adverse reactions or damage.

- Adhesion Strength: A successful bond requires an adhesive that can withstand weight and stress. Testing helps evaluate whether the adhesive adheres firmly to the marble surface, ensuring durability and longevity.

- Visual Impact: Unsuitable adhesives may cause discoloration or darkening. By testing on a small, inconspicuous area, you can assess whether the adhesive alters the marble’s appearance, enabling you to make an informed decision.

- Drying Time: Some adhesives may not dry completely or remain tacky when used on marble. Testing allows you to determine if the adhesive dries properly, ensuring a seamless bond without any sticky residue.

How to Test the Adhesive:

- Select a small, inconspicuous area of the marble surface.

- Thoroughly clean the area using a mild soap and water solution or a stone-specific cleaner.

- Apply a small amount of adhesive following manufacturer instructions.

- Allow the adhesive to dry completely within the recommended time frame.

- Check for changes in appearance or signs of poor adhesion.

- Gently touch the dried adhesive to ensure it is not sticky or tacky.

- Remove the adhesive using a mild solvent recommended for marble cleaning.

- Inspect the tested area for any damage or discoloration caused by the adhesive.

Recommended Adhesives for Marble:

- Epoxy-based adhesives: Known for their strength and durability, epoxy adhesives are often used for bonding marble.

- Polyurethane adhesives: These adhesives offer excellent flexibility, making them suitable for bonding marble that may experience slight movement or vibrations.

- Silicone adhesives: Certain types of silicone adhesives are compatible with marble and provide a strong bond without causing discoloration.

eEcaSrE2ZSA” >

Conclusion

When it comes to finding an adhesive that will stick to marble, you need a solution that is not only strong but also compatible with the unique properties of this elegant stone. Marble is smooth, polished, and often used in high-end applications such as countertops and flooring. Therefore, it requires an adhesive that can withstand the test of time and provide a secure bond.

One adhesive that is highly recommended for marble is epoxy resin. Epoxy resin is known for its exceptional bonding strength and durability. It forms a strong chemical bond with the marble surface, ensuring a long-lasting hold.

Additionally, epoxy resin has excellent resistance to moisture, heat, and chemicals, making it ideal for use in areas where marble may be exposed to these elements.

Another adhesive option for marble is polyurethane-based glue. Polyurethane glue provides a strong bond and has good flexibility, which allows it to withstand movement or vibrations without cracking or breaking. This makes it suitable for bonding marble pieces together or attaching them to other materials.

For smaller repairs or projects involving lighter objects, cyanoacrylate adhesive (commonly known as super glue) can also be used on marble. Super glue bonds quickly and securely to most surfaces, including marble.

However, it’s important to note that super glue may not be suitable for larger or load-bearing applications due to its limited strength.

In conclusion, when choosing an adhesive for marble surfaces, consider using epoxy resin for its exceptional bonding strength and resistance to various elements. Alternatively, polyurethane-based glue offers flexibility and durability for bonding or attaching marble pieces together.

And if you have smaller repairs or lightweight projects, super glue can provide a quick and secure bond.