Are you tired of your DIY projects falling apart because of weak adhesives? Do you find yourself wondering if there’s a difference between normal glue and wood glue? Look no further, because we’ve got the answers you need.

It’s simple: wood glue is stronger than normal glue. But why settle for “stronger” when you can have “the strongest”? Wood glue is specifically designed for use with wood, making it the go-to choice for carpentry, furniture repair, and other wood-based projects. Its superior bonding agent creates an unbreakable hold that your standard glue just can’t compete with.

So what sets wood glue apart from its weaker counterpart? One word: drying time. While normal glue dries quickly, it simply doesn’t have the time to penetrate the pores of the wood and create a deep bond. Wood glue, on the other hand, takes longer to dry but uses that time to seep into every crevice and create a bond that can withstand even the toughest conditions.

In this blog post, we’ll delve into the science behind these two types of adhesive and explore their pros and cons. By the end of our journey, you’ll be armed with all the knowledge you need to make informed decisions about which adhesive is right for your next project. So let’s dive in and discover why wood glue reigns supreme.

Types of Normal Glue

Contents

If you’re trying to decide on the right type of glue for your next project, it’s important to understand the properties and characteristics of each type. In this article, we’ll take a closer look at five of the most common types of normal glue available in the market.

- White Glue: Also known as PVA (polyvinyl acetate) glue, white glue is a water-based adhesive that is perfect for woodworking, paper crafts, and other DIY projects. It dries clear and is easy to clean up with water. White glue is ideal for bonding porous materials such as paper, cardboard, and fabric. However, it may not be the best choice for non-porous materials such as metal or plastic.

- Super Glue: Super glue, also known as cyanoacrylate, is a fast-drying adhesive that bonds quickly and strongly. It is perfect for small repairs and bonding non-porous materials such as metal, plastic, and rubber. However, it may not be the best choice for porous materials such as wood or fabric.

- Epoxy Glue: Epoxy glue is a two-part adhesive that consists of a resin and a hardener. When mixed together, they create a strong and durable bond that can withstand high stress and impact. Epoxy glue is commonly used for automotive repairs, boat building, and construction. It sets slowly and requires clamping during the curing process.

- Contact Cement: Contact cement is a type of adhesive that forms a strong, permanent bond when both surfaces are coated with the glue and allowed to dry before being pressed together. It is commonly used for bonding large surfaces such as laminates, veneers, and countertops. Contact cement dries quickly and provides a strong bond that can withstand high temperatures.

- Hot Glue: Hot glue, also known as hot melt adhesive, is a thermoplastic adhesive that melts when heated and solidifies when cooled. It is commonly used for bonding paper, cardboard, fabric, and other materials. Hot glue is ideal for quick fixes and temporary bonds. However, it may not be the best choice for bonding heavy or load-bearing objects.

In summary, each type of normal glue has its own set of unique characteristics and properties that make it suitable for specific applications. When choosing a type of glue, consider the surface you are bonding and the conditions it will be exposed to.

Properties of Wood Glue

That’s why it’s crucial to understand the properties of wood glue before deciding which type to use. Wood glue, also known as carpenter’s glue, is a popular adhesive specially designed for bonding wood together. However, not all wood glues are created equal, and each type has its unique set of properties that affect its performance and strength.

One of the most vital properties to consider when selecting wood glue is viscosity or thickness. Thin glue is ideal for small pieces of wood or projects requiring precision, while thicker glue is better for filling gaps and bonding larger pieces of wood. Imagine trying to fit a tiny wooden puzzle piece together with thick glue – it would be a disaster.

Drying time is another critical aspect to consider. Depending on the type of glue and the conditions in which it is applied, wood glue can take anywhere from minutes to hours to dry. Quick-drying glues are perfect for time-sensitive projects, while slow-drying glues allow more time to adjust and position the wood.

Strength is one of the most important properties of wood glue, and it can vary depending on the type of glue used and the conditions in which it is applied. Polyurethane-based glues are often stronger than traditional white or yellow glues.

Other factors that affect wood glue performance include water resistance, temperature resistance, and flexibility. Water-resistant glues are ideal for outdoor projects or those exposed to moisture, while temperature-resistant glues are better for projects exposed to extreme temperatures. Flexible glues are perfect for projects requiring movement or flexibility, such as furniture joints or musical instruments.

Why Is Wood Glue Stronger Than Normal Glue?

Wood glue, also known as carpenter’s glue or PVA glue, is made from polyvinyl acetate, a water-based polymer. When applied to two pieces of wood, the water in the glue evaporates and the polyvinyl acetate molecules bond with the wood fibers, creating a strong adhesive bond. This unique chemical makeup is specifically designed for woodworking projects and sets it apart from other types of adhesives like cyanoacrylate, epoxy or urethane which are not designed specifically for wood bonding.

But that’s not all that makes wood glue stronger. Its longer open time gives you more time to position and adjust the pieces being glued together before the bond sets. This is not always possible with normal glues like cyanoacrylate which bond quickly but can become brittle over time, making them less ideal for woodworking projects.

Another advantage of wood glue is its water solubility when wet which makes cleanup easy with just a damp cloth. This is a significant advantage over normal glues that may require harsh chemicals or solvents for clean-up.

However, it’s important to note that not all wood glues are created equal. When choosing the right wood glue for your project, viscosity, drying time, strength, water resistance, temperature resistance, and flexibility are all crucial factors to consider. Different types of wood glue have varying strengths and drying times depending on specific project needs.

Different Types of Wood Glue

When it comes to woodworking, a strong bond is essential for a successful project. Choosing the right type of wood glue can make all the difference. In this article, we will dive into the different types of wood glue available and their unique properties.

PVA Glue

Polyvinyl acetate (PVA) glue is the most popular type of wood glue. It is easy to use and creates a strong bond between wood surfaces. PVA glue dries clear, making it ideal for indoor projects like furniture and cabinets. It is also sandable and paintable once dry.

Hide Glue

Hide glue has been used for centuries in woodworking. Made from animal collagen, it has a longer open time than other glues, making it ideal for complex projects like instrument building. Hide glue also has excellent holding power and can be easily repaired if needed.

Epoxy Glue

Epoxy is a two-part adhesive with excellent strength and durability. It is perfect for bonding different types of wood together or for projects that require heavy loads and extreme temperatures. Epoxy glue is also waterproof, making it ideal for outdoor projects like decks and fences.

Cyanoacrylate (CA) Glue

Cyanoacrylate glue, or superglue, forms an instant bond between wood surfaces but is not waterproof. It is ideal for small woodworking projects where speed is essential.

Polyurethane (PU) Glue

Polyurethane (PU) glue is a waterproof adhesive that expands as it dries, filling gaps between wood surfaces and creating a tight seal. It is perfect for outdoor projects like boats and outdoor furniture because it resists water and weathering.

Factors Affecting the Strength of a Bonded Joint

Achieving a strong and durable bond is crucial in woodworking projects, and selecting the right adhesive is only part of the equation. The strength of a bonded joint is also heavily influenced by other factors such as surface preparation, adhesive type, and environmental conditions during bonding.

Surface preparation plays a vital role in ensuring a strong bond. Prior to bonding, surfaces must be completely clean, dry, and free of any contaminants like dust, oil or grease. Any impurities on the surface can weaken the bond by interfering with the adhesion of the glue to the material. To enhance adhesion, consider roughening up smooth surfaces by sanding them before applying glue.

The type of adhesive used is another critical factor affecting the strength of a bonded joint. For instance, wood glue is specifically formulated for bonding wood materials and is typically stronger than normal glue when used on a wood surface. Conversely, normal glue may be more effective than wood glue when bonding other materials like plastic or metal.

Environmental conditions during bonding are also important to consider. Temperature and humidity can significantly impact the adhesion of an adhesive to a material. Most adhesives have specific temperature and humidity requirements for optimal bonding strength. High temperatures can cause some adhesives to evaporate too quickly, while low temperatures can slow down curing time.

Proper Bonding Techniques for Maximum Strength

If you’re looking to create a strong bond between any two materials, be it wood, plastic, metal, or anything else, using the right bonding technique is absolutely essential. To achieve maximum strength in your bond, there are three key sub-topics you need to keep in mind: surface preparation, adhesive application, and curing time.

The first step in creating a strong bond is surface preparation. This is arguably the most important aspect of bonding, as any residue or contaminants left on the surface can interfere with the adhesive’s ability to properly bond. To prepare surfaces for bonding, make sure they are clean, dry, and free from any dust or debris. Sandpaper or a scraper can come in handy to remove rough spots or old adhesive, while a solvent like acetone or rubbing alcohol can be used to clean oily or greasy surfaces.

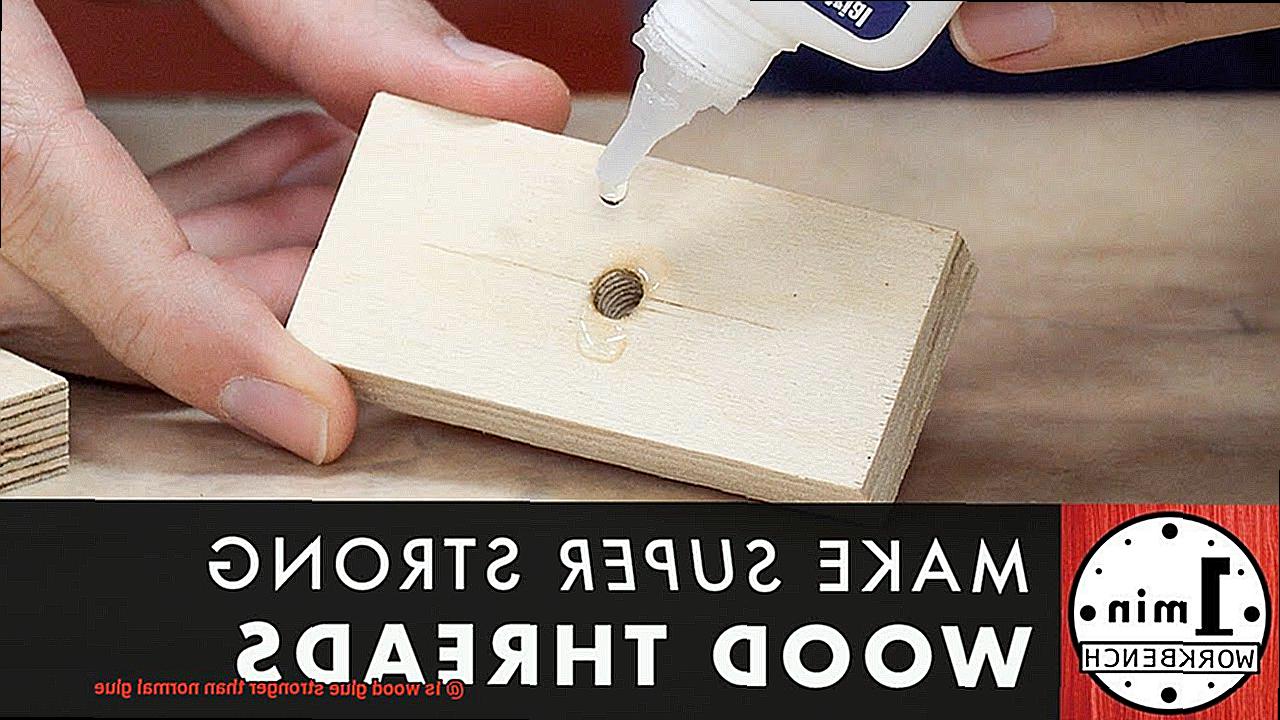

Once you’ve prepared your surfaces, it’s time to apply the adhesive. Choosing the right adhesive for your project is important, but applying it correctly is equally crucial. For wood surfaces, wood glue is a popular choice. Apply a thin and even layer of glue to both surfaces being bonded; too much glue can create gaps and weaken the bond. Use a brush or roller to apply the glue evenly.

The final step in achieving maximum strength in your bond is allowing sufficient curing time. This can vary depending on the type of adhesive used and environmental conditions like temperature and humidity. Be sure to follow the manufacturer’s instructions for curing time and avoid rushing the process. Applying pressure during curing time can also help create a stronger bond.

Advantages and Disadvantages of Wood Glue vs. Normal Glue

With various options available in the market, this decision can be overwhelming. In this blog post, we’ll delve into the advantages and disadvantages of wood glue versus normal glue to help you make an informed choice.

To begin with, let’s examine wood glue. One of its most significant advantages is its strong bond. It’s specially formulated to bond wood pieces together and creates a bond that is stronger than normal glue. Moreover, it’s perfect for rough and porous surfaces as it seeps into the pores and creates an even stronger bond. Wood glue also allows for a longer drying time, providing you with more time to adjust the pieces before the glue sets.

However, wood glue is not versatile and may not work as well on other materials. Additionally, it takes longer to cure properly, which can be challenging if you’re working on a time-sensitive project. Furthermore, due to its specialized formula, wood glue is generally more expensive than normal glue.

Now let’s turn our attention to normal glue. The most significant advantage of normal glue is its versatility. It can be used on a range of materials, including plastic, metal, and paper. Normal glue dries quickly, making it ideal for projects that require a fast bonding time. It’s also more affordable than wood glue.

However, normal glue may not create as strong a bond as wood glue on wood surfaces. It may also not work well on porous surfaces as it does not seep in like wood glue. Some normal glues can damage certain materials such as foam or fabric.

Also Read: How To Glue Pictures On Wood?

Conclusion

In conclusion, when it comes to woodworking projects or other wood-based DIY endeavors, wood glue reigns supreme. Its unique formula is specifically designed for use with wood and provides an unparalleled bonding experience that normal glue simply can’t match. With its extended drying time, wood glue is able to seep into the pores of the wood and create a deep bond that’s perfect for carpentry, furniture repair, and other similar projects.

But don’t be too quick to dismiss normal glues like white glue, superglue, epoxy glue, contact cement, and hot glue. Each type of adhesive has its own set of advantages and disadvantages depending on the surface being bonded and the conditions it will be exposed to. From surface preparation to adhesive application technique, curing time to temperature resistance and flexibility – all these factors play a crucial role in determining which adhesive is right for your project.

Ultimately, whether you choose wood glue or normal glue depends on your specific needs. While wood glue may be stronger than normal glue when used on wooden surfaces, normal glues offer versatility in bonding different materials quickly. So choose wisely based on your project requirements.