In our fast-paced, tech-driven world, finding a reliable adhesive to secure electrical connections can feel like searching for a needle in a haystack. But what if we told you there might just be a solution that bridges that gap, quite literally?

Welcome to the intriguing realm of electrical glue – a potentially groundbreaking innovation that could revolutionize how we think about electrical connections. This specially designed adhesive has the power to securely bond various conductive materials, leaving no room for uncertainty or worries about short circuits.

In this blog post, we’ll explore the promising potential of electrical glue and delve into its composition, applications, and advantages over traditional adhesives. Whether you’re an avid DIY enthusiast or an industry professional seeking reliable solutions, get ready to be captivated by the possibilities of electrical glue.

Join us as we dive deeper into the electrifying world of this adhesive, shedding light on its effectiveness, safety measures, and what sets it apart from generic adhesives dominating the market. Sound electrifying enough? Keep reading because there’s a shockingly miraculous glue that could finally bring all your electrical connections together.

What is Electrical Glue?

Contents

- 1 What is Electrical Glue?

- 2 Benefits of Electrical Glue

- 3 How to Prepare Surfaces for Bonding

- 4 Regular Household Glues vs. Electrical Glue

- 5 Choosing the Right Electrical Glue

- 6 Safety Tips When Handling Electrical Glue

- 7 Common Applications of Electrical Glue

- 8 Advantages of Using Electrical Glue over Soldering

In the vast realm of electronics, establishing strong and steadfast connections between components is paramount. And at the heart of this endeavor lies electrical glue, also known as conductive adhesive or electrically conductive adhesive (ECA). In this comprehensive guide, we will embark on a journey through the intricate world of electrical glue, exploring its multifaceted nature, its myriad applications, and the pivotal factors to consider when selecting the perfect adhesive for your specific needs.

Understanding Electrical Glue

Electrical glue is no ordinary adhesive. It is a specialized marvel that not only creates a tenacious bond but also facilitates electrical conductivity when joining electrical components. Unlike conventional adhesives, electrical glue contains conductive particles or fillers that allow it to effectively conduct electricity, making it an indispensable tool in the realm of electronics.

The Versatility of Electrical Glue

Electrical glue finds its purpose in an assortment of industries, including electronics, automotive, aerospace, and telecommunications. Its versatility shines through in various applications, such as attaching wires to circuit boards, bonding components on flexible circuits, or joining electronic components together. This adhesive’s ability to seamlessly unite diverse components makes it an invaluable asset in modern technological advancements.

Unveiling the Types of Electrical Glue

Properties and Crucial Considerations

When choosing electrical glue, several properties must be taken into account. These include electrical conductivity, adhesion strength, thermal stability, moisture absorption, and resistance to environmental factors like humidity and temperature fluctuations. The choice of filler material within the adhesive determines these crucial properties. Common fillers include silver flakes, silver-coated copper particles, carbon nanotubes, and graphene.

Selecting the Perfect Electrical Glue

To ensure optimal performance and unwavering reliability, it is imperative to consider factors such as the type of materials being bonded, the desired level of conductivity, and the prevailing operating conditions.

Adhering faithfully to the manufacturer’s instructions for proper application and curing is also paramount. By carefully evaluating these aspects, you can confidently select the ideal electrical glue that seamlessly harmonizes with your project’s requirements.

Benefits of Electrical Glue

When it comes to creating electrical connections, soldering may be the first method that comes to mind. But what if I told you there’s a glue that can do the job just as well, if not better? Enter electrical glue, also known as conductive adhesive. This specialized glue is designed to create strong and durable bonds between electrical components, without the need for high temperatures or fancy equipment.

So, what are the benefits of using electrical glue? Let’s dive in.

First and foremost, electrical glue provides a reliable and long-lasting bond between materials that can’t be easily soldered. Think plastics, glass, and ceramics. This means you can create connections that were once thought impossible, opening up a whole new world of possibilities.

But it doesn’t stop there. Electrical glue also boasts excellent electrical conductivity. The conductive particles or fibers present in the glue ensure that there is minimal resistance in the electrical connection, allowing for efficient transmission of electricity. It’s like having a superhighway for electrons.

Flexibility is another key advantage of electrical glue. It can withstand vibrations and movements without losing its bond or conductivity. This makes it perfect for applications where mechanical stress or movement is involved. Say goodbye to worrying about your delicate electronic components coming loose.

And let’s not forget about durability. Electrical glue is resistant to moisture and other environmental factors, ensuring that the electrical connection remains stable and reliable even in harsh conditions. So whether you’re working in a humid environment or dealing with extreme temperatures, rest assured that your connections will hold strong.

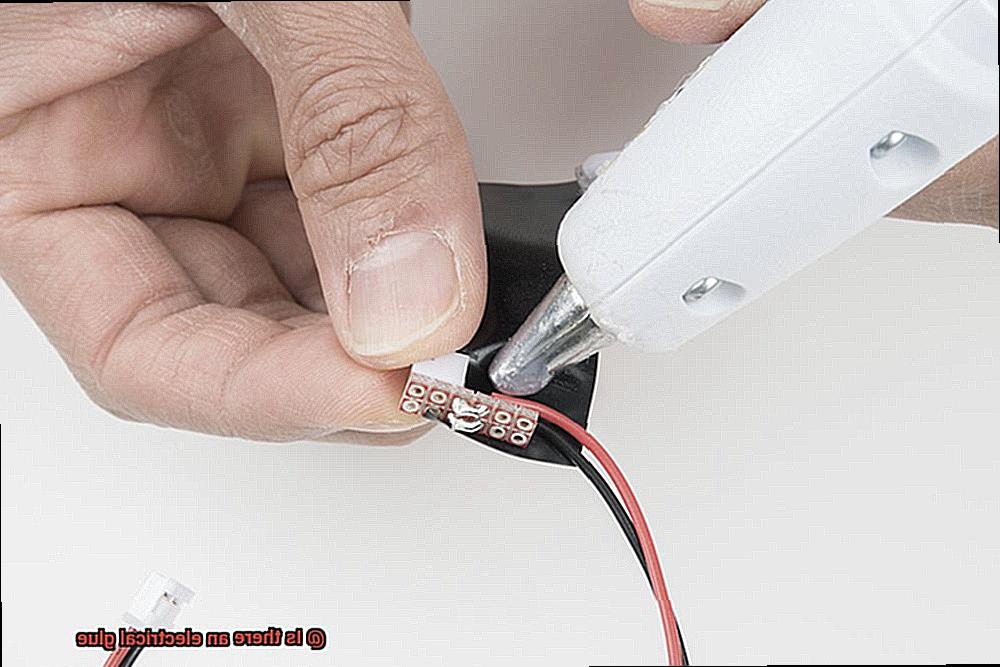

Now, here’s the icing on the cake: convenience. Electrical glue can be easily applied using various methods such as brushing, spraying, or dispensing. No need for fancy equipment or complicated processes. Just grab your glue and get to work. Plus, it can be used directly from its container, saving you time and money compared to traditional soldering.

Electrical glue is not just for creating new connections. It’s also great for repairs. Need to replace a component? No problem. With electrical glue, you can easily rework or replace components without the need for extensive desoldering or re-soldering processes. It’s like a get-out-of-jail-free card for your electronics.

How to Prepare Surfaces for Bonding

Achieving a strong and lasting bond requires proper surface preparation. Whether you’re bonding materials for a DIY project or repairing broken items, following the right steps can make all the difference. In this article, we will explore the key steps to prepare surfaces for bonding and ensure a bond that can withstand the test of time.

Cleanliness is Crucial:

Before bonding, it is essential to clean the surfaces thoroughly. Any dirt, dust, grease, or moisture on the surfaces can hinder adhesion and weaken the bond. Imagine trying to glue two pieces of paper together with sand in between – it simply wouldn’t work. To ensure cleanliness, use a mild detergent or solvent suitable for your materials and make sure to remove any residue that could affect the bond.

Roughen Up for Better Adhesion:

Smooth surfaces like glass or metal can pose a challenge when it comes to bonding. To overcome this hurdle, roughening up the surfaces is necessary. This process provides the adhesive with something to grip onto, enhancing adhesion. You can achieve this by gently sanding the surface or using abrasive materials like a wire brush. The goal is to create tiny grooves and scratches that increase the surface area and improve adhesion.

Consider Priming for Optimal Bond Strength:

In some cases, applying a primer or adhesive promoter can significantly improve bond strength. Primers create a chemical bond between the surface and adhesive, ensuring optimal adhesion. This is particularly useful when working with difficult materials such as polyethylene or polypropylene plastics. Follow the manufacturer’s instructions carefully when applying primers for best results.

Perfect Alignment for Even Bonding:

Before applying the adhesive, ensure that the surfaces are properly aligned and fit together correctly. Proper alignment guarantees an even distribution of adhesive and prevents gaps or uneven bonding. Consider using clamps or other tools to hold the surfaces in place during the bonding process. This step is crucial for achieving a strong and uniform bond.

Apply Adhesive with Precision:

Now comes the exciting part – applying the adhesive. Follow the manufacturer’s instructions and choose a suitable adhesive for your materials. Spread the adhesive evenly over the entire surface to be bonded, ensuring complete coverage. Pay attention to excess adhesive, as it can interfere with the bond and create a messy outcome. Remove any excess adhesive promptly to achieve a clean and reliable bond.

Regular Household Glues vs. Electrical Glue

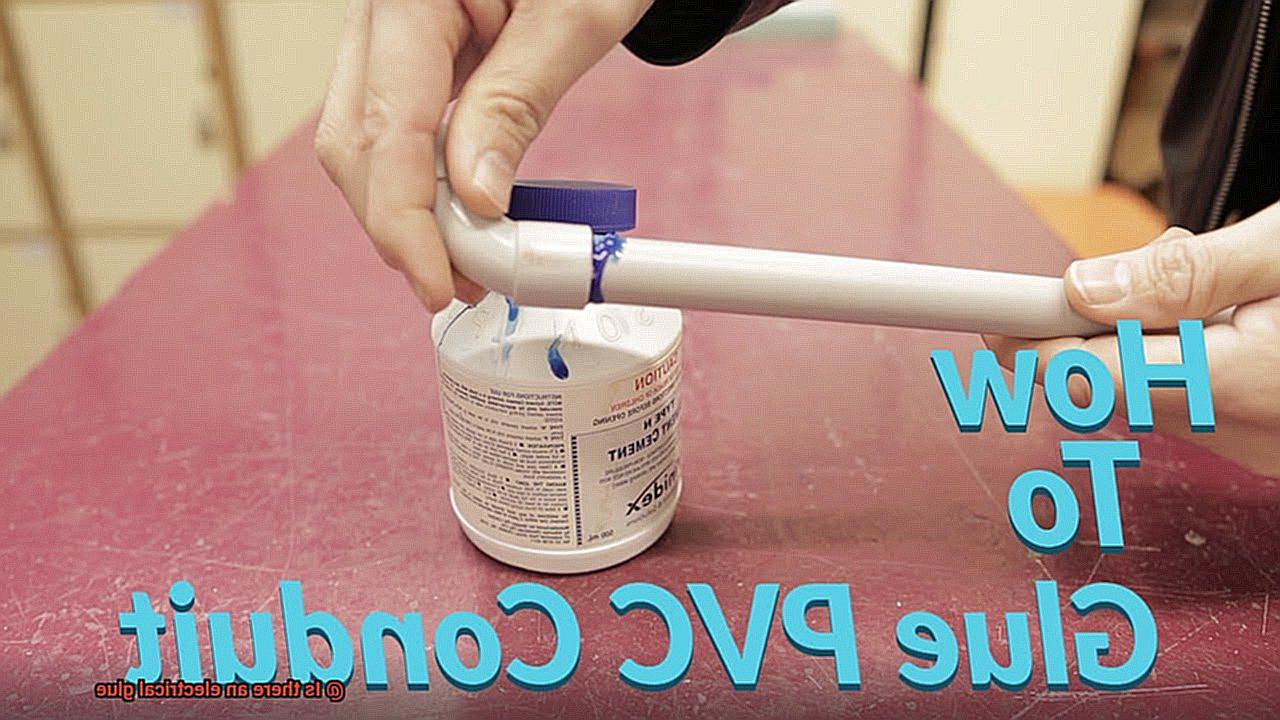

When it comes to choosing the right glue for your project, it’s important to understand the differences between regular household glues and electrical glue. Regular household glues, like multipurpose or craft glues, are the superheroes of everyday bonding. They can bond materials such as paper, cardboard, fabric, wood, and some plastics. These glues are typically water-based and non-conductive, which means they won’t conduct electricity. So if you’re working on a non-electrical project like crafting or repairs around the house, regular household glue is your go-to adhesive.

On the other hand, electrical glue is like a secret agent for bonding wires, connectors, terminals, and other electrical components. It’s specifically formulated for electrical applications. Unlike regular household glues, electrical glue is conductive, allowing it to create secure and reliable electrical connections. It’s made from special conductive materials or contains conductive additives that ensure electricity flows smoothly.

Here’s a shocking difference between regular household glues and electrical glue – their conductivity. Regular household glues are non-conductive and shouldn’t be used for electrical connections. They can interfere with the flow of electricity or even cause short circuits. Electrical glue, on the other hand, conducts electricity like a pro and ensures your circuits stay connected.

Another difference lies in their strength and durability. Regular household glues provide strong bonds for everyday applications but may not hold up under extreme temperatures or harsh conditions. Electrical glue, however, is designed to withstand high temperatures and resist moisture. So if you’re working on an electrical project where heat or moisture may be present (like fixing a broken wire in the rain), reach for that trusty electrical glue.

So how do you decide which glue to use? It’s simple. If you’re working on a non-electrical project, regular household glue is your best friend. It’ll get the job done without any shocking surprises. But if you’re dealing with electrical connections or circuits, it’s crucial to use electrical glue. Don’t let your project go up in smoke.

In conclusion, regular household glues and electrical glue are like two sides of a coin – they serve different purposes and have distinct characteristics. Regular household glues are your everyday heroes, perfect for non-electrical bonding tasks. Electrical glue, on the other hand, is a specialized agent for electrical connections, conducting electricity and withstanding high temperatures and moisture.

Choosing the Right Electrical Glue

When it comes to electrical projects, the glue you choose can make all the difference in ensuring a strong and reliable bond. With a wide range of options available, it’s important to consider several factors before making your selection. From temperature resistance to adhesive strength, curing time to material compatibility, each aspect plays a crucial role in determining the right electrical glue for your needs.

- Temperature Resistance: Electrical components generate heat during operation, so it’s vital to select a glue that can withstand high temperatures without melting or degrading. Look for glues with a high temperature rating and labels indicating heat resistance or thermal conductivity. Using a glue with low temperature resistance in a high-temperature environment can lead to bond failure over time.

- Adhesive Strength: Electrical systems often face vibrations, shocks, and other stresses that can weaken bonds. Opt for glues with high tensile strength and proven adhesive properties. This ensures that your connections stay secure even in demanding conditions.

- Curing Time: Consider your project requirements when it comes to curing time. Some glues cure quickly, allowing for instant bonding, while others require longer curing times. If you need the flexibility to make adjustments or reposition before the glue sets completely, choose one with a longer curing time. For instant bonding, look for glues that offer quick curing times.

- Electrically Insulating: It is crucial to choose an electrical glue that is electrically insulating. This means it should not conduct electricity and must provide effective insulation between different electrical components or connections. Look for glues specifically formulated to be non-conductive.

- Compatibility with Materials: Ensure that the glue you choose is compatible with the materials being bonded. Some glues are designed for specific types of materials such as metals, plastics, or rubber. Check product specifications to verify compatibility and avoid weak bonds or damage to materials by using an incompatible glue.

- Additional Features or Requirements: Consider any specific features or requirements for your application. If you need the glue to be resistant to moisture, chemicals, or UV radiation, choose a glue that offers those properties.

Safety Tips When Handling Electrical Glue

When it comes to working with electrical glue, safety should always be your number one priority. This specialized glue, also known as conductive adhesive, is used to bond electrical components together or repair electrical connections. But before you dive into your electrifying projects, let’s go over some crucial safety tips to keep you safe and sound.

Safety Gear: Gear up for the Glue Battle.

Before getting your hands sticky, make sure to gear up with proper protective equipment. Wear gloves and safety glasses to shield your skin and eyes from any potential contact with the glue or its fumes. Remember, safety gear is like a superhero cape that protects you from harm.

Breathe Easy: Ventilation is the Key.

Electrical glue can emit fumes during the curing process, which might not be good for your lungs. So, always work in a well-ventilated area. Open a window, use an exhaust fan, or work near a fume hood to ensure those pesky fumes don’t linger around.

Instruction Manual: Your Safety Bible.

Before diving into any project, take a moment to read and understand the product instructions. Each electrical glue may have specific usage instructions or precautions you need to follow to ensure optimal safety and effectiveness.

Hands Off: Keep Your Skin Happy.

Electrical glue can irritate your skin and cause allergic reactions in some people. To avoid any unpleasant surprises, always wear gloves when handling the glue. And if you do accidentally get some on your skin, wash it off immediately with soap and water.

No Tasting Allowed: Keep It Away from Your Mouth.

Electrical glue is definitely not a delicious treat. Never ever ingest it as it can be toxic. Keep the glue out of reach of children and pets to prevent any accidental ingestion. If ingestion does occur, seek immediate medical attention.

Storage Savvy: Keep It Safe and Sound.

Once you’ve finished using the electrical glue, store it properly according to the manufacturer’s instructions. Seal the container tightly and store it in a cool, dry place away from direct sunlight and heat sources. This will help maintain its effectiveness and prevent any potential accidents.

Common Applications of Electrical Glue

Electrical glue, also known as conductive adhesive, is a superhero of the adhesive world. It possesses the uncanny ability to conduct electricity, making it a vital tool in various industries and everyday situations. Let’s dive into the electrifying world of electrical glue and explore its common applications.

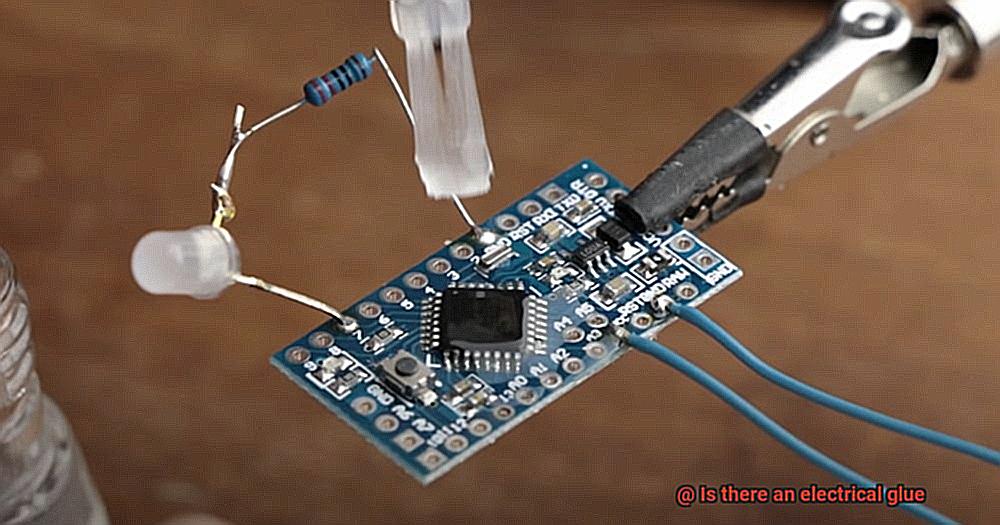

In the realm of electronics manufacturing and repair, electrical glue is the unsung hero. It bonds components together on circuit boards, creating secure electrical connections that ensure the smooth flow of electricity. Without this adhesive marvel, our beloved gadgets would be nothing but a chaotic tangle of loose wires.

But wait, there’s more. The automotive industry harnesses the magical powers of electrical glue to repair and secure wiring harnesses, connectors, and other electrical components. Its adhesive properties provide a reliable and durable connection that can withstand harsh conditions like vibrations and temperature fluctuations. So the next time you hit the road, remember to thank electrical glue for keeping your car’s electrical system running like a well-oiled machine.

Now let’s take to the skies with the aerospace industry. Electrical glue plays a crucial role in assembling and repairing aircraft electrical systems. It ensures that connections remain intact even under intense stress and extreme environmental conditions. So the next time you board a plane, rest assured that electrical glue is working behind the scenes to keep you safe and sound.

But wait, there’s even more. In the world of telecommunications, electrical glue is the unsung hero. It secures and connects wires and cables, providing a strong bond that ensures uninterrupted transmission of signals. Say goodbye to those annoying dropped calls and glitchy internet connections.

But enough about industries – let’s talk about everyday applications. Electrical glue can come to the rescue in your own home. Use it to repair or secure electrical cords, connections, and small appliances. Its adhesive properties make it the perfect tool for fixing minor electrical issues and keeping your household running smoothly.

Oh, and let’s not forget about renewable energy. Electrical glue can be a game-changer in the world of solar power. It bonds solar cells onto substrates or connects them together to form solar panels. Its conductive nature allows for efficient transfer of electricity between the cells, enhancing their overall performance. So the next time you see a solar panel, remember that electrical glue played a part in harnessing the power of the sun.

Advantages of Using Electrical Glue over Soldering

When it comes to electrical bonding, there are many advantages to using electrical glue over soldering. Whether you’re a DIY enthusiast or a professional, understanding these advantages can help you make the best choice for your electrical projects.

- Ease of Use: Electrical glue is incredibly user-friendly, making it an excellent option for beginners and experts alike. Unlike soldering, which requires specialized skills and equipment, applying electrical glue is as simple as using a brush or a syringe. No more worrying about burning yourself with a hot soldering iron or dealing with messy flux.

- Versatility: Electrical glue has the ability to bond a wide range of materials, including metals, plastics, and ceramics. This versatility makes it suitable for various applications in the electronics industry, such as repairing circuit boards, securing small components, and creating electrical connections. No matter what kind of project you’re working on, electrical glue has got you covered.

- Temperature Resistance: Soldering involves high temperatures that can be a concern in certain situations. However, electrical glue can withstand high temperatures without losing its adhesive properties. This makes it perfect for applications in high-temperature environments or when bonding heat-sensitive components. You can have peace of mind knowing that your connections will remain strong even under extreme conditions.

- Flexibility: One of the key advantages of electrical glue is its flexibility. While soldered connections can be rigid and prone to cracking under stress or vibration, electrical glue creates a more flexible bond that can withstand movement and vibrations. Say goodbye to loose connections caused by constant movement or mechanical stress. With electrical glue, you can ensure the durability and longevity of your electrical connections.

- Non-Destructive: Unlike soldering, which fuses metals together, electrical glue creates a non-destructive bond between components. This means that if you need to make changes down the line, components can be easily separated without causing any damage. No more struggling with desoldering and risking delicate electronic components. Electrical glue offers the convenience of easy repairs or modifications without the fear of ruining your work.

- Cost-Effectiveness: Soldering requires specialized equipment and materials like soldering irons, flux, and solder. On the other hand, electrical glue can be applied using simple tools and is often available in smaller quantities, reducing waste and cost. So for those on a budget or looking to save some cash, electrical glue is a wallet-friendly alternative that doesn’t compromise on quality or performance.

hFK0CIpTqsE” >