When it comes to sticking stuff together, you’ve got options. UV glue and epoxy are two adhesive powerhouses that promise to get the job done. But which one is the real deal? Which one has the strength to hold things tight? It’s time to dive into the nitty-gritty and figure out once and for all: is UV glue stronger than epoxy?

Let’s break it down, my friends. We’re going to take a deep dive into the world of adhesives and explore what sets UV glue and epoxy apart. We’ll compare their characteristics, put them through their paces, and see which one comes out on top.

Now, I don’t know about you, but when it comes to gluing stuff together, I want the best of the best. Whether you’re a DIY enthusiast looking to fix that broken lampshade or a professional craftsman working on a masterpiece, you need an adhesive that won’t let you down.

So grab your safety goggles and strap in for this adhesive adventure. By the end of this blog post, you’ll have all the knowledge you need to make an informed decision about whether UV glue or epoxy is right for your project. Let’s get sticky.

Strength Comparison

Contents

When it comes to bonding materials, UV glue and epoxy stand out as two exceptional adhesive options known for their strength and durability. Understanding the nuances between these adhesives is crucial for making an informed decision tailored to your specific project.

In this article, we will delve into a comprehensive comparison of the strength, durability, flexibility, and other properties of UV glue and epoxy. By doing so, we aim to equip you with the knowledge necessary to select the adhesive that best suits your needs.

UV Glue:

UV glue, also known as ultraviolet light-curing adhesive, boasts an impressive array of strengths. One of its primary advantages lies in its rapid curing time, enabling swift assembly and heightened productivity. While it may not rival epoxy in terms of sheer strength, UV glue excels in tensile strength, exhibiting an exceptional resistance against forces pulling it apart. This makes it an ideal choice for applications requiring resilience against tensile forces.

Furthermore, UV glue’s quick curing time ensures that the bond reaches its maximum strength in a shorter period, minimizing the risk of bond failure.

Epoxy:

Epoxy, on the other hand, represents another formidable adhesive renowned for its extraordinary bonding strength and durability. Comprised of two components – resin and hardener – that are skillfully mixed before application, epoxy’s chemical bonding mechanism contributes to its remarkable shear strength. This makes it suitable for demanding applications requiring a robust bond capable of withstanding heavy-duty usage.

Its versatility also shines through its ability to bond various materials such as wood, metal, ceramics, and plastics. Additionally, epoxy adhesives showcase excellent resistance to impact, chemicals, and temperature variations – making them indispensable in industries such as automotive, aerospace, and construction.

Choosing the Right Adhesive:

The decision between UV glue and epoxy hinges on your specific application’s needs. If you prioritize quick bonding and transparency, UV glue reigns supreme. It finds common usage in electronics manufacturing for delicate component bonding or in the medical field where rapid assembly and sterilization are critical. Conversely, if structural applications or heavy-duty bonding are your requirements, epoxy emerges as the preferred choice. Its exceptional shear strength and durability render it ideal for demanding environments.

Curing Time Comparison

When it comes to finding the perfect adhesive for your projects, curing time is a crucial factor to consider. Two popular adhesives, UV glue and epoxy, offer different curing times and properties that make them suitable for various applications.

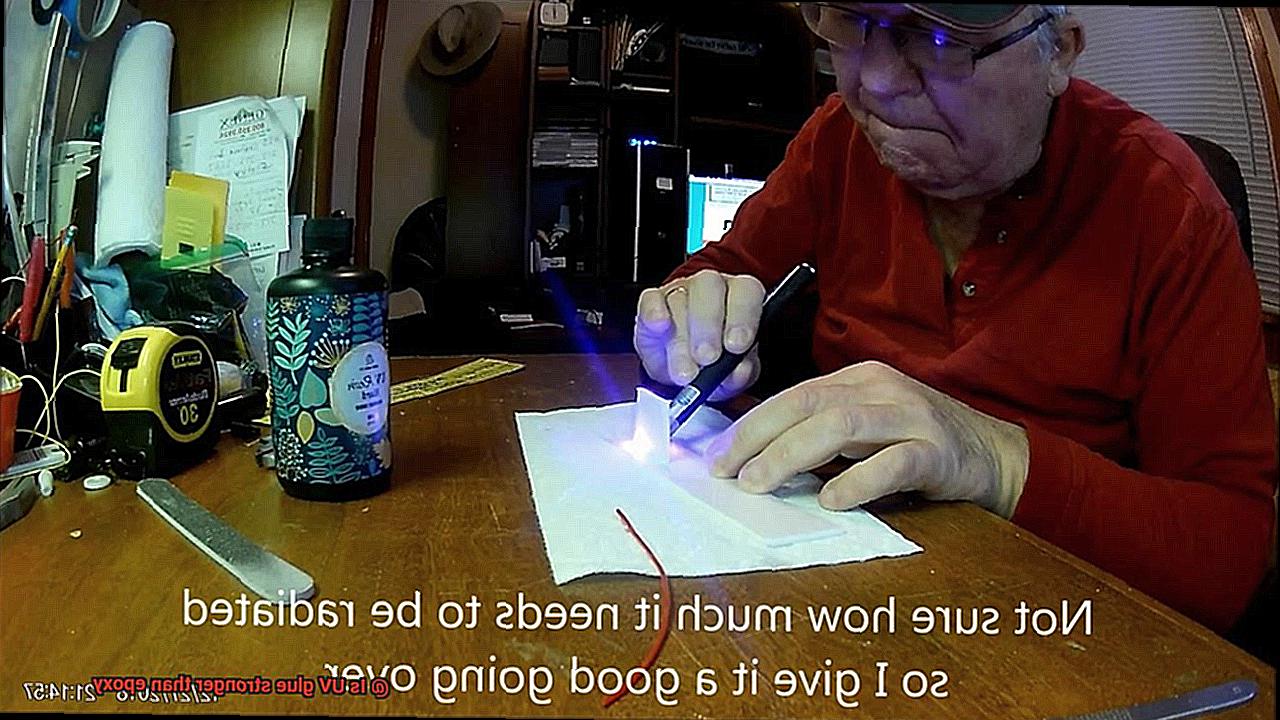

UV glue, also known as ultraviolet glue or light-curing adhesive, is a true marvel of the adhesive world. It cures when exposed to ultraviolet light, allowing for incredibly fast bonding times. The actual curing time of UV glue can vary depending on factors such as the thickness of the adhesive layer, the intensity of the UV light source, and the specific formulation of the glue. However, what’s truly exciting is that UV glue can cure within seconds or minutes when exposed to UV light. Its rapid curing time makes it perfect for quick assembly jobs or delicate components that require immediate bonding.

On the other hand, we have epoxy, a two-part adhesive consisting of a resin and a hardener. Epoxy takes a bit longer to cure compared to UV glue due to its unique chemical reaction curing process. It can take anywhere from a few minutes to several hours or even days to reach its maximum strength. This longer curing time is necessary for the chemical reaction between the resin and hardener components to complete, resulting in a strong and durable bond. If you need an adhesive that can withstand heavy-duty tasks in demanding environments, epoxy is your go-to choice.

It’s important to consider the environmental conditions that can affect the curing time of these adhesives. UV glue relies on exposure to ultraviolet light for curing, so having a reliable UV light source is essential. The intensity of the light can impact the curing time, so having the right equipment is crucial for optimal results. On the other hand, temperature plays a vital role in the epoxy curing process. Warmer temperatures generally accelerate the curing time, while colder temperatures slow it down. It’s important to follow the manufacturer’s instructions regarding temperature requirements to ensure proper curing.

Safety considerations are also important when working with these adhesives. UV glue can cause eye and skin irritation, so wearing protective goggles and gloves is essential. Epoxy, on the other hand, can emit fumes during the curing process, so proper ventilation is necessary. It’s recommended to wear gloves and work in a well-ventilated area when using epoxy.

Transparency Comparison

When it comes to transparency, different industries have varying levels of openness and disclosure. Transparency refers to the degree to which information is accessible, visible, and easily understood by stakeholders. In this comparison, we will explore the levels of transparency in three industries: finance, healthcare, and technology.

Finance:

In the finance industry, transparency is crucial for building trust and maintaining investor confidence. Key aspects of transparency in finance include:

- Disclosure of financial statements: Companies are required to provide accurate and timely financial statements that reflect their financial health and performance. This allows investors and stakeholders to make informed decisions.

- Regulatory compliance: Financial institutions must adhere to regulations and reporting standards set by regulatory bodies such as the Securities and Exchange Commission (SEC) or the Financial Conduct Authority (FCA). Compliance with these regulations ensures transparency in operations and reduces the risk of fraud or misconduct.

- Shareholder communication: Companies are expected to communicate with their shareholders regularly, providing updates on financial performance, corporate governance practices, and strategic plans. This enables shareholders to participate actively in decision-making processes.

Healthcare:

In the healthcare industry, transparency is essential for patient safety, quality improvement, and trust-building. Here are some aspects of transparency in healthcare:

- Patient access to medical records: Patients have the right to access their medical records, enabling them to make informed decisions about their care. Transparent access to medical information fosters patient engagement and empowers individuals to take control of their health.

- Reporting of adverse events: Healthcare organizations are encouraged to report adverse events or medical errors openly. This allows for learning from mistakes and implementing corrective measures to improve patient safety.

- Pricing transparency: With rising healthcare costs, there is a growing demand for pricing transparency. Patients want to know the cost of medical services upfront so they can make informed decisions about their healthcare expenses.

Technology:

In the technology industry, transparency is essential for data privacy, cybersecurity, and ethical practices. Key areas of transparency in technology include:

- Data privacy policies: Technology companies must be transparent about how they collect, use, and protect user data. Clear and concise privacy policies enable users to make informed decisions about sharing their personal information.

- Cybersecurity practices: As cyber threats continue to evolve, transparency about cybersecurity measures is critical. Companies should disclose how they protect user data from breaches and what steps they take to address security vulnerabilities.

- Ethical AI and algorithmic transparency: With the increasing use of artificial intelligence and algorithms, ensuring transparency in their decision-making processes is vital. Users should be aware of the factors influencing algorithmic decisions that impact their lives.

Structural Bonding Applications

Structural bonding applications are a crucial aspect of joining components together to create a strong and durable bond. The choice of adhesive plays a significant role in determining the success of these applications.

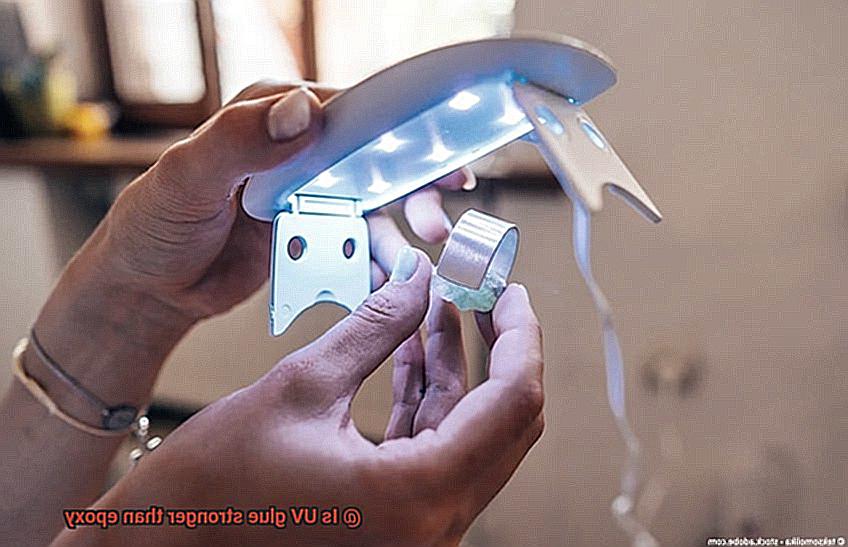

One popular option for structural bonding is UV glue, also known as UV-curable adhesive. This game-changing adhesive offers a rapid curing time, hardening and creating a strong bond in just a few seconds under a UV light. This makes it ideal for applications that require fast turnaround or high production rates. On the other hand, epoxy adhesives typically have longer cure times, allowing for better alignment and adjustment of components before hardening.

In terms of strength, epoxy adhesives are known for their exceptional bonding capabilities on a wide range of materials, including metals, plastics, ceramics, and composites. They can withstand high-stress environments and maintain bond integrity over time. UV glue, while still strong, may not have the same level of bonding strength as epoxy.

UV glue also offers the advantage of curing completely clear. This makes it ideal for bonding transparent materials like glass or acrylic where aesthetics and visibility are important. Epoxy adhesives may not offer the same level of clarity when cured.

However, epoxy adhesives are generally more versatile in terms of material compatibility. They can bond a wider range of substrates compared to UV glue. So if you’re working with different types of materials, epoxy may be the better option.

To summarize, UV glue and epoxy adhesives are both valuable options for structural bonding applications, each with their own strengths and weaknesses. UV glue offers rapid curing times and clarity for transparent materials, while epoxy adhesives provide exceptional bonding strength and versatility across different substrates. The choice between them depends on your specific needs and requirements for the project at hand.

Electronics Manufacturing Applications

When it comes to electronics manufacturing, the adhesive you choose can make or break your project. In this blog post, we will explore the advantages and applications of two popular options that have proven their worth in the industry: UV glue and epoxy. By understanding their unique characteristics and benefits, you can make an informed decision for your electronics manufacturing needs.

UV Glue: Quick, Reliable, and Aesthetically Pleasing

- Rapid Curing Power: Like a superhero, UV glue cures at the speed of light when exposed to ultraviolet radiation. This lightning-fast curing time is perfect for projects with tight deadlines or high production rates.

- Excellent Adhesion Properties: UV glue forms a bond so strong that components remain securely attached to circuit boards even under harsh conditions. Its reliability is crucial in electronics manufacturing.

- Aesthetically Appealing: UV glue cures completely clear, making it ideal for applications involving transparent materials like glass or acrylic. Say goodbye to unsightly residue or discoloration.

Epoxy: The Hulking Giant of Strength and Versatility

- Unmatched Strength and Durability: Epoxy adhesives are renowned for their exceptional strength, making them perfect for bonding heavy components or providing structural support. They can withstand physical stress, temperature extremes, and chemical exposure.

- Versatility in Bonding: From metals to plastics, epoxy adhesives can bond a wide range of materials commonly found in electronics manufacturing. Whatever substrate you’re working with, epoxy has got you covered.

- Excellent Electrical Insulation Properties: In the world of electronics, electrical insulation is crucial. Epoxy provides outstanding electrical insulation properties, ensuring the safety and performance of your electronic devices.

Choosing the Right Adhesive:

The choice between UV glue and epoxy ultimately depends on your specific project requirements. Consider factors such as curing time, bond strength, durability, aesthetics, and electrical insulation properties. If you need a quick and visually appealing bond, UV glue is your go-to. For applications that demand maximum strength, durability, and versatility, epoxy is the heavyweight champion.

Brand Variations

Brand Variations refer to the different types and formulations of adhesive materials that are available in the market. When it comes to adhesives, there are numerous brands offering a variety of UV glue and epoxy options, each with its own unique characteristics and performance qualities.

UV glue, also known as ultraviolet curing adhesive, is a popular choice for applications that require rapid curing time. By utilizing ultraviolet light, this adhesive can cure within seconds, creating a strong bond. One key advantage of UV glue is its clear finish, making it ideal for projects where aesthetics matter, such as electronics assembly, jewelry making, and glass bonding.

On the other hand, epoxy is a versatile adhesive that offers unmatched strength and durability. Comprised of two components – resin and hardener – epoxy is mixed together to create a powerful bond. It excels in electrical insulation properties and exhibits resistance to chemicals and heat. Epoxy is widely used in construction, automotive repair, and industrial applications.

In terms of strength, epoxy takes the crown. Its molecular structure and unique chemical composition provide superior bonding capabilities compared to UV glue. While UV glue may be sufficient for smaller or lighter projects, epoxy is the go-to choice for heavy-duty applications that demand maximum strength and durability.

When choosing between UV glue and epoxy brands, it’s important to consider factors such as intended use, bonding surface, and specific project requirements. Some brands may specialize in certain applications or offer features that make them more suitable for specific projects. It is recommended to read product reviews and conduct thorough research before selecting a brand.

Advantages and Disadvantages of UV Glue and Epoxy

In this article, we will discuss the advantages and disadvantages of UV glue and epoxy, giving you all the information you need to make an informed decision.

Let’s start with UV glue. This adhesive is known for its lightning-fast curing time, making it a top choice for applications that require a quick bond. In just a matter of seconds, UV glue can be cured when exposed to ultraviolet light. This means you can save precious time and increase efficiency in your production process. Additionally, UV glue dries clear, resulting in a seamless and visually appealing bond.

It forms a strong bond capable of withstanding high tensile and shear forces. It adheres well to various materials such as glass, metal, plastic, and ceramics.

Another advantage of UV glue is that it does not require any mixing prior to application, unlike epoxy. This simplifies the process and ensures consistent bonding performance. Lastly, UV glue is versatile and available in different viscosities, allowing it to be used for various applications like coatings or filling gaps and voids.

However, UV glue does have some limitations. Firstly, it requires ultraviolet light to cure properly. This means it may not be suitable for bonding in areas that are difficult to reach with the UV light source. Additionally, prolonged exposure to sunlight can cause premature curing or degradation of the adhesive.

Secondly, UV glue has limited gap-filling ability due to its low viscosity. Lastly, while UV glue offers good temperature resistance, it may not be suitable for applications exposed to extreme heat or continuous high temperatures as it can soften or degrade under such conditions.

Now let’s turn our attention to epoxy. This adhesive is known for its exceptional bonding strength, making it ideal for heavy-duty applications. It can bond various materials like wood, metal, concrete, and plastics with ease. Epoxy also excels in gap-filling properties, allowing it to bond uneven surfaces or fill gaps effectively. Additionally, epoxy adhesive is highly resistant to chemicals, including solvents, fuels, and acids. This makes it perfect for use in harsh environments or industries where exposure to chemicals is common.

Epoxy also boasts high heat resistance, remaining stable and durable even at elevated temperatures. Lastly, epoxy has a longer curing time compared to UV glue, allowing for proper positioning and adjustment of parts before the bond sets.

As with any adhesive, epoxy does have its drawbacks. Firstly, it requires mixing prior to application, which can be a hassle for some users. Secondly, epoxy can be messy to work with as it has a thicker consistency compared to UV glue. Lastly, epoxy may not dry clear like UV glue, which can be a disadvantage for applications where aesthetics are important.

DpDKTqnesMI” >

Conclusion

To sum up, UV glue and epoxy each have their own unique strengths and advantages. UV glue boasts lightning-fast curing time, impressive tensile strength, and a crystal-clear finish that adds a touch of elegance to any project. It’s perfect for those quick assembly jobs where time is of the essence and aesthetics are paramount.

On the other hand, epoxy is a force to be reckoned with when it comes to bonding power. Its exceptional strength, durability, and versatility in material compatibility make it the go-to choice for projects that demand unwavering resilience. Plus, its resistance to chemicals and heat ensures that your bonds will stand strong even under the harshest conditions.

When deciding between UV glue and epoxy, take a moment to assess your specific project requirements. If you need a bond in the blink of an eye or crave transparency like never before, UV glue is your ticket to success. It shines brightest in delicate electronics manufacturing or any application that demands rapid assembly.

However, if you’re searching for sheer might and longevity or need to unite different materials seamlessly, epoxy reigns supreme. It thrives in heavy-duty applications and offers unparalleled electrical insulation properties that keep things running smoothly.

It’s worth noting that various brands offer different formulations of both UV glue and epoxy. Each brand may cater to specific needs with tailored features designed for particular applications. So don’t forget to roll up your sleeves and dive into some thorough research while also perusing product reviews before making your final selection.

Ultimately, whether UV glue or epoxy emerges as the stronger adhesive depends on what you’re looking for on your quest for bonding greatness. Both have carved out their places in various industries and can provide reliable solutions when used correctly.