Picture this: you’re knee-deep in a DIY project, bonding everything together with trusty super glue, when disaster strikes. Maybe it’s a pot of boiling water gone rogue, a cup of scorching coffee spilling over your creation, or even an intense dishwashing session. In that moment, you can’t help but wonder, “Will my bond survive the scalding wrath of hot water?”

Today, we embark on a thrilling quest for answers. We’re diving headfirst into the world of super glue to uncover its true resilience against blistering temperatures. So grab a warm drink and join us as we unravel the science and push various super glue brands to their limits against the relentless power of hot water. Get ready to be blown away by the secrets we unearth and prepare to rethink everything you thought you knew about this miraculous adhesive.

What is Super Glue Used For?

Contents

- 1 What is Super Glue Used For?

- 2 How Does Super Glue Work?

- 3 Hot Water Resistance of Super Glue

- 4 Reasons Why Super Glue Is Not Recommended for High-Temperature Environments

- 5 Temperature at Which Super Glue Starts to Lose Its Effectiveness

- 6 Specialized Adhesives for High-Temperature Applications

- 7 Important Considerations When Using Super Glue

- 8 Alternatives to Using Super Glue in Hot Water Conditions

- 9 Conclusion

When it comes to adhesive solutions, super glue, also known as cyanoacrylate adhesive, reigns supreme. Its rapid bonding capabilities and versatility have made it an indispensable tool in both household and industrial settings. In this article, we will explore the diverse uses of super glue, from repairing broken items to medical wound closure, and everything in between.

Repairing Broken Items:

Super glue is a savior for fixing small cracks or breaks in various materials like plastic, glass, metal, ceramic, and wood. Whether it’s a shattered toy, a cracked phone screen, or a chipped piece of pottery, super glue can swiftly restore functionality and appearance.

Crafting and DIY Projects:

The quick-drying nature of super glue makes it perfect for crafting and DIY enthusiasts. From jewelry-making to model-building, super glue bonds small pieces together with ease. Attach embellishments to surfaces or create intricate designs knowing that super glue provides a reliable hold.

Medical Wound Closure:

In urgent situations or when stitches are impractical, medical-grade super glue comes to the rescue. It can effectively seal small cuts or lacerations in emergency care settings or when immediate medical attention is unavailable. This technique offers a viable alternative to traditional wound closure methods.

Automotive Repairs:

Super glue proves its worth in the automotive industry by securely bonding interior trim pieces and exterior body parts. With its strength and resilience, super glue ensures that components stay firmly in place even under the vibrations and stresses associated with driving.

Electronics Repairs:

Repairing small electronic devices like headphones, chargers, or cables becomes a breeze with super glue. Eliminating the need for specialized tools or skills, super glue provides a secure bond that can withstand daily use and handling.

How Does Super Glue Work?

This fast-acting adhesive seems almost like magic, instantly creating a strong bond between materials. But how does it work? Let’s dive into the science behind this superhero of adhesives.

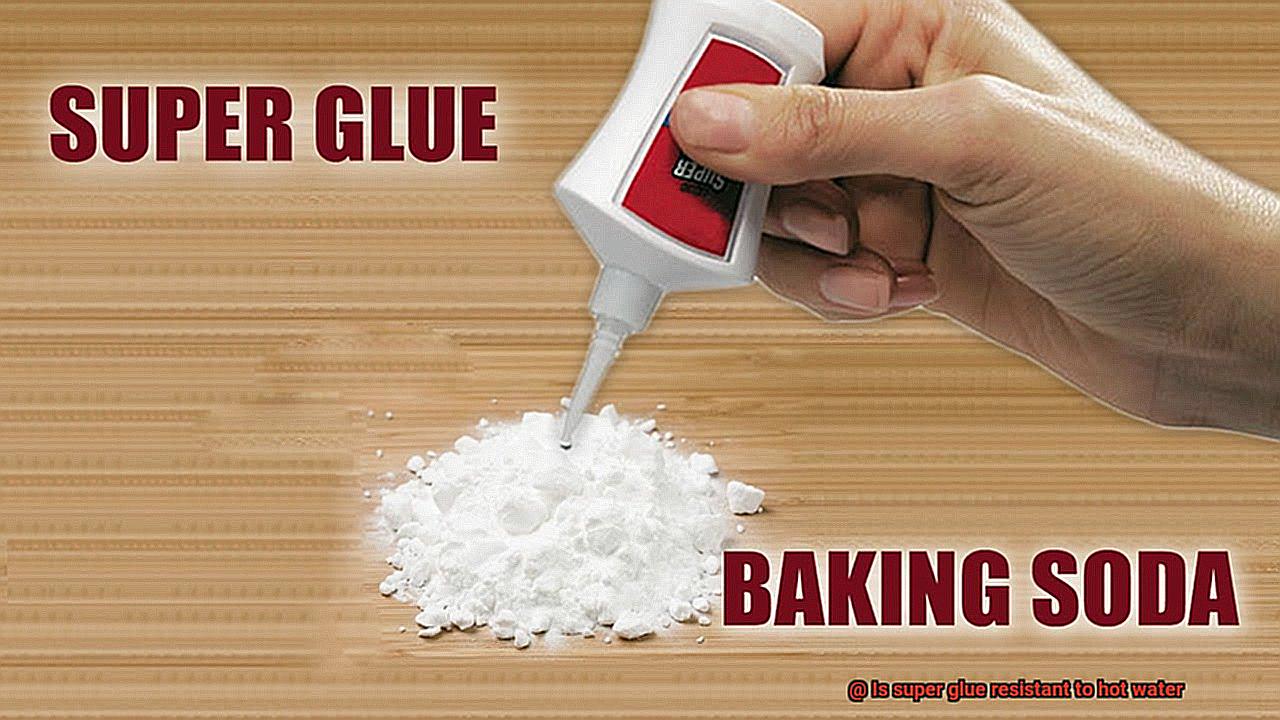

At the heart of super glue lies its secret ingredient: cyanoacrylate. This liquid monomer may sound fancy, but its true power lies in its ability to rapidly polymerize in the presence of moisture. When the super glue comes into contact with even trace amounts of water, such as the humidity in the air or the water on the surfaces being glued, a chemical reaction is initiated, causing it to solidify and form a strong bond.

This reaction occurs due to a process called polymerization. The water acts as a catalyst, speeding up the formation of long chains of molecules that connect and intertwine with each other. As a result, super glue bonds quickly and securely to a wide range of materials, including plastics, metals, ceramics, and even skin.

But what really makes super glue so incredibly strong is its ability to create intermolecular bonds between the adhesive and the surface molecules of the materials being bonded. These bonds are known as van der Waals forces or intermolecular forces. These forces arise due to temporary fluctuations in electron distribution and allow super glue to adhere to various surfaces.

In addition to its bonding prowess, super glue has another trick up its sleeve. It can fill small gaps and imperfections in materials, further enhancing its bonding strength. So even if your broken item has a few missing pieces or uneven surfaces, super glue can come to the rescue and create a solid connection.

However, it’s important to note that super glue works best on clean and dry surfaces. Any oil, dirt, or moisture present on the surfaces can hinder its bonding effectiveness. So before you embark on your next repair or crafting project, make sure to clean and dry the surfaces to ensure a strong bond.

Hot Water Resistance of Super Glue

Super glue, also known as cyanoacrylate adhesive, is renowned for its fast-setting and strong bond properties. But what about its resistance to hot water? In this article, we will dive into the world of super glue and uncover the truth about its limitations when exposed to hot water. So fasten your seatbelts, adhesive enthusiasts, as we explore the hot water resistance of super glue and its impact on various applications.

Understanding the Science Behind Super Glue:

Super glue possesses a secret power that allows it to transform from a liquid monomer to a solid bond when it encounters moisture. This adhesive forms robust intermolecular bonds with different materials, effectively sealing gaps and imperfections to create a reliable and durable bond.

The Impact of Hot Water on Super Glue:

Unfortunately, super glue is not designed to be heat resistant. When exposed to high temperatures or hot water for extended periods, it can weaken or even fail. The heat softens the adhesive, causing it to lose strength and potentially break apart. Furthermore, the presence of moisture in hot water further compromises the bond since super glue works best on dry surfaces.

Factors Affecting Hot Water Resistance:

The hot water resistance of super glue depends on its specific formulation and brand. Different brands may offer varying degrees of resistance, with some claiming enhanced heat resistance. To ensure accurate information, it is crucial to refer to the manufacturer’s instructions and specifications.

Alternatives for Hot Water Resistance:

For applications requiring hot water resistance, specialized heat-resistant adhesives explicitly designed for such conditions should be considered. These adhesives have the ability to withstand high temperatures and exposure to hot water without compromising their bonding properties.

Practical Considerations:

When using super glue in applications exposed to hot water, take into account the specific circumstances and limitations of the adhesive. For objects frequently encountering hot water, like kitchen utensils or plumbing fixtures, it is advisable to opt for adhesives labeled as heat resistant or suitable for such applications.

Reasons Why Super Glue Is Not Recommended for High-Temperature Environments

Well, let me spill the beans and explain why this sticky solution loses its grip when things get hot.

The Heat Breakdown:

Super glue, also known as cyanoacrylate adhesive, may be strong, but it’s not a fan of the heat. When exposed to high temperatures, the chemical bonds within the glue break down, causing it to lose its adhesive properties. Imagine trying to hold onto a slippery ice cube – that’s what happens to super glue when things heat up.

Super glue undergoes thermal degradation, where the chemical compounds within the glue break apart due to heat. This breakdown weakens its adhesive strength and makes it less effective in bonding surfaces together. It’s like watching a strong friendship crumble under the heat of an argument.

Threshold Temperature:

Each brand of super glue has its own breaking point, but it’s generally a good idea to avoid exposing it to temperatures above 150 degrees Fahrenheit (65 degrees Celsius). High-temperature environments like near stovetops or ovens can easily exceed this limit, resulting in the glue losing its grip and your objects falling apart.

Just like people have their limits, super glue has its temperature threshold. Exposing it to temperatures beyond this limit is like pushing someone past their breaking point – they can’t handle it anymore and start to fall apart.

Moisture Matters:

Super glue loves a dry surface for optimal adhesion. However, in high-temperature environments, hot water vapor or steam can make things moist. And guess what? Moisture is not a friend of super glue. It can interfere with the bonding process and weaken the bond or even break it entirely.

Moisture is like an unwanted third wheel in the world of super glue. It intrudes and disrupts the bonding process, creating a weak bond that can easily be broken. It’s like trying to build a sandcastle when the waves keep crashing into it – the foundation becomes weak, and everything falls apart.

Meltdown Alert:

Direct exposure to hot water can spell disaster for super glue. The heat can speed up the breakdown process, causing the glue to soften or dissolve completely. It’s like watching a popsicle melt under the sun – super glue just can’t handle the heat.

Hot water is like kryptonite to super glue. It turns its solid structure into a gooey mess, making it lose its grip and fail to hold things together. It’s like watching a superhero lose their powers when faced with their greatest weakness – it’s a meltdown waiting to happen.

Temperature at Which Super Glue Starts to Lose Its Effectiveness

Super glue, or cyanoacrylate adhesive, is a remarkable bonding agent renowned for its quick and secure adhesion. However, just like any adhesive, it has its limitations when it comes to extreme temperatures. Imagine trying to grasp onto a slippery ice cube with hands drenched in grease – a challenging feat indeed. This is precisely how super glue feels when confronted with high heat.

The precise temperature at which super glue begins to lose its effectiveness can vary slightly depending on the brand. However, as a general rule, it starts to weaken at around 180°F (82°C). This is akin to stepping into a scorching hot tub that’s just a tad too steamy for comfort. Prolonged exposure to temperatures above this threshold can cause the bond to break entirely, leaving behind a sticky mess.

Here’s the deal: super glue isn’t designed for hot water or high-temperature environments. It’s like wielding a regular umbrella in the midst of a furious hurricane – the outcome won’t be favorable. If you find yourself needing an adhesive for materials that will be subjected to heat or steam, consider specialized options tailored to those conditions. Heat-resistant adhesives exist that scoff in the face of scorching temperatures.

To summarize, super glue is exceptional for most everyday bonding needs but isn’t invincible against heat. Think of it as a superhero with a weakness for hot weather – we all have our kryptonite. So, exercise caution and opt for heat-resistant adhesives or alternative bonding methods when dealing with sizzling situations.

Specialized Adhesives for High-Temperature Applications

When it comes to holding things together, regular adhesives like super glue may not always be up to the challenge of extreme heat. Just like a superhero facing their nemesis, high temperatures can weaken and break down traditional adhesives, leaving you with nothing but a sticky mess.

There is a league of specialized adhesives designed specifically to withstand scorching temperatures. In this blog post, we will dive into the world of high-temperature adhesives and discover their secret powers.

Epoxy Adhesives:

Leading the charge against heat is the mighty epoxy adhesive. With exceptional heat resistance, these adhesives can endure temperatures reaching up to 500°F (260°C) or even higher.

Epoxy adhesives consist of two components – epoxy resin and hardener – that create a powerful chemical reaction when mixed together, forming an unyielding bond capable of standing up to extreme heat.

Silicone-Based Adhesives:

Joining the fight against high temperatures are silicone-based adhesives. With their outstanding thermal stability, these adhesives can brave temperatures ranging from -100°F (-73°C) to 500°F (260°C) or higher.

Not only do silicone adhesives resist heat, but they also offer flexibility and excellent electrical insulation properties, making them ideal for applications in electronics and automotive industries.

Polyimide Adhesives:

In the battle against scorching heat, polyimide adhesives are another formidable ally. These adhesives possess exceptional temperature resistance and can withstand continuous exposure to high temperatures without compromising their adhesive properties. They are commonly used in aerospace and automotive applications where extreme heat is encountered during operation.

Ceramic-Based Adhesives:

For those seeking an adhesive that can withstand even higher temperatures, ceramic-based adhesives come to the rescue. With their unique composition, these adhesives can endure temperatures above 1000°F (538°C). They are commonly used in applications involving high-temperature materials like glass, metal, and ceramics.

Thermosetting Adhesives:

Last but not least, thermosetting adhesives offer another solution for high-temperature applications. These adhesives undergo a chemical reaction when exposed to heat, transforming from a liquid or semi-liquid state to a solid state. Once cured, thermosetting adhesives provide excellent heat resistance and durability.

Important Considerations When Using Super Glue

Super glue, also known as cyanoacrylate adhesive, is a powerful tool for bonding. However, when using super glue in hot water environments, there are important considerations to keep in mind to ensure a strong and reliable bond.

Choose the Right Formula:

Not all super glues are created equal. Standard super glues are not designed to withstand high temperatures or prolonged water exposure. To ensure the glue can handle heat and water, look for specialty formulations labeled as “waterproof” or “heat-resistant.”

Read the Product Label:

Before purchasing any super glue, carefully read the product label and packaging information. This will provide crucial details about the adhesive’s resistance capabilities. Don’t be caught off guard with a glue that can’t handle the heat.

Exercise Caution:

Even with a heat-resistant or waterproof super glue, caution is still necessary in hot water environments. Avoid subjecting glued surfaces to extreme temperature changes as this can compromise the bond. Gradual transitions are key to maintaining a strong connection.

Consider Material Compatibility:

Different materials react differently to hot water exposure. While super glue may hold up well, the material it’s applied to could potentially weaken or degrade in high temperatures. Before relying on super glue for repairs or bonding tasks, consider the material’s compatibility with hot water.

Alternatives to Using Super Glue in Hot Water Conditions

When it comes to hot water conditions, super glue may fall short in providing a strong and reliable bond. Fortunately, there are alternative adhesives specifically designed to withstand high temperatures and water exposure. In this article, we will delve into the top alternatives to super glue for hot water applications, ensuring your projects stay intact even in challenging environments.

Epoxy Resin Adhesive:

Epoxy adhesives are champions in resisting heat and water. Withstanding temperatures of 200 degrees Fahrenheit or more, these adhesives excel in plumbing repairs and fixing items that come into contact with hot liquids. The bond created by epoxy resin adhesives is not only strong, but also durable, guaranteeing longevity in hot water conditions.

Polyurethane Adhesive:

Polyurethane adhesives are a formidable option for hot water environments. Their exceptional resistance to heat and water makes them ideal for automotive and construction applications.

Whether you’re repairing a radiator or working on a project that demands heat and water resistance, polyurethane adhesives provide a reliable bond that remains unyielding in hot water conditions.

Silicone Adhesive:

Versatile and resilient, silicone adhesives are renowned for their ability to withstand extreme temperatures. These adhesives exhibit outstanding resistance to both heat and water, making them perfect for applications requiring flexibility. With a range of -40 degrees Fahrenheit to over 400 degrees Fahrenheit, silicone adhesives ensure a strong bond even when faced with scorching hot water.

Tips for Success:

- Surface preparation is key to achieving a strong bond in hot water conditions. Ensure surfaces are clean, dry, and free from contaminants.

- Follow the manufacturer’s instructions and guidelines when using alternative adhesives. Each adhesive may have specific application requirements and curing times.

- Consider material compatibility when selecting an adhesive. Certain adhesives work better with specific materials, so choose one that is compatible with the materials you are bonding.

-bwjyPhEACk” >

Also Read: Is Super Glue Waterproof? – Glue Things

Conclusion

In conclusion, super glue’s resistance to hot water is limited. Despite its impressive ability to bond different materials together, it falls short when faced with high temperatures or prolonged water exposure.

When hot water comes into contact with super glue, its formidable strength begins to soften and weaken, leaving the bond vulnerable to breaking apart.

It’s worth noting that the exact temperature at which super glue loses effectiveness may vary slightly depending on the brand. As a general guideline, however, it starts to weaken around 180°F (82°C). Any exposure beyond this threshold can spell complete failure for the bond.

For projects demanding resilience against hot water or extreme heat, it’s crucial to consider specialized adhesives tailored for such conditions.

Epoxy adhesives, silicone-based adhesives, polyimide adhesives, ceramic-based adhesives, and thermosetting adhesives are all viable alternatives that excel in high-temperature environments and provide reliable bonding even in the presence of hot water.

When using super glue in hot water scenarios, exercising caution and ensuring material compatibility are paramount. Gradual temperature transitions and thorough surface preparation play pivotal roles in maintaining a robust bond. Moreover, reading product labels diligently and selecting formulas labeled as “waterproof” or “heat-resistant” will guarantee optimal results.

To summarize, while super glue proves invaluable for many everyday applications, it is not recommended for use in environments with elevated temperatures or prolonged exposure to water.