Want to add a unique touch to your next DIY project? Gluing brass to PVC is a fast, cost-effective way to make it happen. Brass is great for adding a bit of class and sophistication to furniture accents and artwork. But how do you glue these two materials together?

It’s easier than you think! All you need are the right tools and techniques. Start by thoroughly cleaning both surfaces of dust and debris. Then use a special adhesive made specifically for bonding metal and plastic together. Once the adhesive has been applied evenly over both surfaces, press them together until firmly adhered.

Remember to allow the project plenty of time to dry before handling or using it—this could take several minutes up to 24 hours or more depending on the adhesive brand used. Follow these simple steps for gluing brass to PVC, and you’ll have a strong bond that lasts.So go ahead and get creative with your next DIY project—just remember these guidelines!

What You Need – Tools and Materials Required for the Job

Contents

- 1 What You Need – Tools and Materials Required for the Job

- 2 Step-by-Step Guide – How to Connect Brass to PVC

- 3 Advantages of Glueing Brass to PVC

- 4 Disadvantages of Glueing Brass to PVC

- 5 Different Types of Glues for Brass and PVC

- 6 Tips and Tricks for Applying the Glue Properly

- 7 Cleanup After Gluing Brass to PVC

- 8 Troubleshooting Common Problems with Gluing Brass to PVC

- 9 Conclusion

Before you begin, there are a few essential tools and supplies that you’ll need to have on hand.

These include a PVC primer, PVC cement, a brush or roller for applying the glue, a clean cloth for wiping off any excess glue, and of course the brass and PVC components that need to be glued together.

Additionally, it may be beneficial to have some sandpaper or a file handy in order to smooth out any rough edges on the brass or PVC components before gluing them together.

Once you have all of these items ready and available, you will be able to begin your project with confidence, knowing that you have everything needed for success.

Step-by-Step Guide – How to Connect Brass to PVC

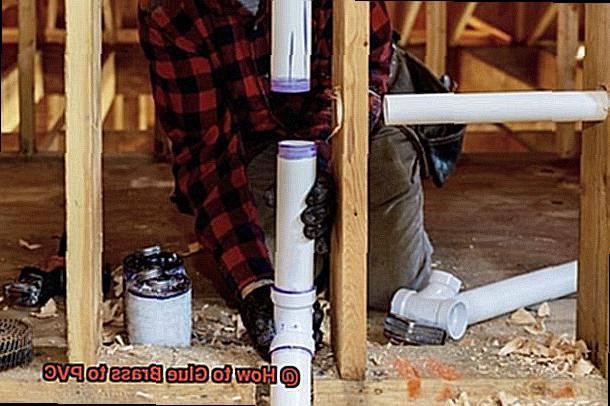

With the right tools and techniques, you can achieve this task with ease. Here is a step-by-step guide that will help you get the job done quickly and efficiently.

First, gather all of the essential items. You’ll need PVC pipe, brass fittings, glue or adhesive, and any other items necessary for the project. Once you have all of your supplies, it’s time to start connecting the pieces.

Apply a generous amount of glue or adhesive to both the brass fitting and the PVC pipe before twisting them together until they are securely fastened.

Make sure there are no gaps between them, as this could result in leaks in your system.

Allow the glue or adhesive to dry for at least 24 hours before testing your connection. Turn on the water supply and look for any leaks or weak points in your connection.If all goes well, congratulations! You have successfully attached brass to PVC!

Attaching brass to PVC may seem daunting at first, but with patience and careful attention to detail, you can easily complete this task with confidence.

Advantages of Glueing Brass to PVC

If you’re looking for a cost-effective solution to your DIY project, gluing brass to PVC is an ideal choice.

Not only is it easy to use and fast, but it also provides a strong and permanent connection between the two materials. Plus, it allows for some flexibility in the connection, so you can adjust the fit as needed.

And because the glue used is usually non-toxic and safe to use around people and pets, it’s an even better option.

Disadvantages of Glueing Brass to PVC

Gluing brass to PVC is a delicate task that requires patience, precision, and plenty of time.

The glue used in this process may not be strong enough to hold the two materials together for an extended period of time, making it unsuitable for certain applications such as plumbing or electrical work.

In addition, the adhesive used in this process can be toxic or flammable, so it is essential to take caution when working with it.

All in all, gluing brass to PVC can be a challenging job that needs additional care and attention.

Different Types of Glues for Brass and PVC

There are several types of glue available for this job, including epoxy, cyanoacrylate, and polyurethane glues.

Epoxy is a two-part adhesive that creates a strong bond when cured. It’s easy to use and works well with both brass and PVC. Cyanoacrylate glue, also known as “super glue,” is great for quick repairs.

It adheres best to metal surfaces, but it can also be used on PVC. Lastly, polyurethane glue is a versatile adhesive that bonds both metals and plastics together securely.

Plus, it creates a waterproof seal that won’t break down over time—perfect for any project.

Tips and Tricks for Applying the Glue Properly

Whether you’re gluing brass and PVC or some other type of plastic, these seven easy-to-follow tips will help you get the job done right.

Clean the Surfaces

Before gluing two surfaces together, make sure to clean them thoroughly. Use a damp cloth to remove any dirt, dust, or debris that may be on the surface. This will prevent it from interfering with the bonding process.

Apply Evenly

When applying glue to both surfaces, spread it evenly in a thin layer over both pieces. Too much glue can seep out of the joint and weaken the bond when pressed together.

Use Disposable Brushes or Cloths

To avoid contamination of the glue from other materials that may be present in your workspace, use a disposable brush or cloth when applying the glue.

Work Quickly

Once you’ve spread the glue evenly over both pieces, press them together before it starts to dry. This will ensure that they are securely bound without any air pockets between them, which could weaken their relationship over time.

Press or Clamp Firmly

After pressing both pieces together, use a clamp or heavy object to hold them in place while they dry completely for at least 30 minutes. This will also help keep them close together if they have been moved around or exposed to moisture and dirt over time.

Wipe Excess Glue

If there is excess glue coming out of the joint when it is pressed together, use a rag dampened with water to wipe it away before it dries completely, as leaving it for too long can weaken its strength and stability over time.

Screws for Extra Strength

For maximum durability and stability over time when joining brass and PVC together, use screws or bolts instead of just relying on the glue alone, as this provides extra strength and support for your projects.

Cleanup After Gluing Brass to PVC

Gluing brass to PVC is a great way to create a strong and lasting bond.

But when the job is done, you need to take the extra step of cleaning up any remaining glue residue. Start by wiping away the excess with a damp cloth and warm, soapy water, taking your time to make sure all of it is gone.

If there are any particularly stubborn areas, use a razor blade or other sharp knife to scrape them off.

Once everything is clean and dry, apply a sealant or primer to protect the brass from corrosion.

Cleaning up after gluing brass to PVC may seem like an unnecessary task, but it’s essential for keeping your project looking great for years to come.

Troubleshooting Common Problems with Gluing Brass to PVC

Gluing brass to PVC can be tricky, but with the right adhesive and a few helpful tips, you can make sure your project turns out perfect! Here are some common issues and how to solve them:

- The first issue you may face is the glue not sticking to the brass or PVC surface. This is usually due to dirt or grease on the surface, so make sure it’s clean with a degreaser or rubbing alcohol before gluing.

- Another problem that may arise is that the adhesive isn’t drying correctly. Check that you’re using an appropriate adhesive for your project and that it will work in your environment; check the manufacturer’s website for more information on your specific adhesive type.

- Finally, if your glue isn’t strong enough to hold the pieces together, try a metal-to-plastic adhesive and use a clamp or other device to hold them together while it dries. This will give your project extra strength and stability.

Conclusion

Gluing brass to PVC is an easy and cost-effective way to add a unique touch to any DIY project.

With the right products and techniques, such as PVC primer, cement, glue, or adhesive, plus other items that may be required for the job, you can create a strong and long-lasting bond between these two materials.

Make sure to clean both surfaces thoroughly before gluing them together, and use a clamp or other device to hold them together until the glue is dry for maximum strength.

Different types of glue can be used to produce a waterproof seal that won’t break down with time.