Are you looking for a safe way to bond fiberglass to metal? You’ve come to the right place. In this blog post, we will explore how to glue fiberglass to metal.

We’ll look at the types of adhesive available, how to prepare the surfaces and step-by-step instructions for successful gluing.

So, if you want to know how to stick these two materials together safely and with confidence, read on.

What You Need Before Gluing Fiberglass to Metal

Contents

- 1 What You Need Before Gluing Fiberglass to Metal

- 2 Steps for Preparing the Surface for Glue Application

- 3 Selecting the Right Glue for the Job

- 4 Applying the Glue Properly

- 5 How to Glue Fiberglass to Metal

- 6 How Long Should You Wait Before Joining the Pieces?

- 7 Tips for Joining and Securing the Pieces Together

- 8 Finishing Touches: Sealing and Cleaning Up

- 9 Common Mistakes to Avoid When Gluing Fiberglass to Metal

- 10 Conclusion

Gluing fiberglass to metal is a strong and reliable bond between two materials. But before you start, it’s important to have the right tools and materials at your disposal.

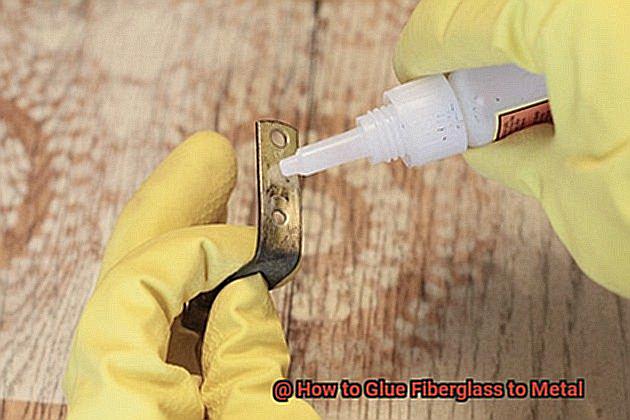

This includes safety glasses, gloves, masking tape, a clean surface, a drill and drill bit, sandpaper, a measuring tape or ruler, epoxy resin and hardener, fiberglass cloth or matting, as well as a stirring stick.

First of all, make sure the surface is squeaky clean with soap and water before drying it off. If necessary for better adhesion, use the drill to create holes in the metal.

Sandpaper can be used to roughen up its surface for extra strength. When drilling or sanding, safety glasses must always be worn. When mixing and applying epoxy resin to the metal’s surface, gloves and a mask should also be worn for protection.

When cutting fiberglass cloth or matting for application on the metal’s surface, accuracy is key; make sure you measure correctly so that it fits perfectly onto the area.

A mixing container should also be used when combining epoxy resin with its hardener to properly mix both components prior to application.

Gluing fiberglass to metal can be tricky but if you have all of the right tools and materials you can create lasting bonds that will hold up over time.

Steps for Preparing the Surface for Glue Application

Are you looking to glue fiberglass to metal? Before you begin, it’s essential to make sure the metal surface is clean, dry, and free of any dirt or debris. To get a better grip on the adhesive, lightly scuff up the metal with a wire brush or sandpaper. If there are any rust spots on the surface, use a rust remover and then wipe it down with a damp cloth.

Now it’s time to apply an adhesive primer. This will help ensure that the glue sticks properly and prevent corrosion of the metal over time. Lastly, check that both surfaces are dry and free from moisture before gluing them together.

Selecting the Right Glue for the Job

When it comes to selecting the right glue for the job, having the necessary information is key.

There are several types of glue available for fiberglass and metal bonding, each with its own set of advantages and disadvantages.

Epoxy is a strong adhesive that cures quickly and creates a permanent bond. Polyurethane glue is versatile and can be used in wet or dry situations. Contact cement creates a strong bond but requires additional clamping time.

Acrylic adhesives are best used for bonding wood and other porous materials together.

To choose the best option for your project, consider the type of bonding you need, the working environment, and how long it will take to complete the job. Once you’ve selected the right type of glue, it’s important to use it correctly in order to form a strong bond.

Read all instructions thoroughly before applying any kind of adhesive tape, and if possible, try scrap materials first before applying it to your project.

It’s also essential to take safety precautions when working with any sort of glue; some chemicals in these products can cause skin irritation or respiratory problems if not treated properly.

Applying the Glue Properly

Getting the glue application right is essential to ensure a strong bond between fiberglass and metal surfaces. To achieve this, it’s important to follow the manufacturer’s instructions and apply the glue properly.

Start by preparing the surface: make sure it is clean and dry before applying the glue. You can choose from a brush, roller or sprayer for application. With a brush or roller, spread out the glue in an even, thin layer. When using a sprayer, cover the entire surface with an even coating of glue.

To ensure that your fiberglass and metal are securely attached, allow the glue to dry completely before proceeding with attaching them.

How to Glue Fiberglass to Metal

Using Epoxy

Epoxy is an effective adhesive for bonding fiberglass to metal. It is important to prepare the surfaces before gluing.

First, clean the metal surface with a degreaser and a wire brush or sandpaper to remove any rust or dirt. Then, roughen the surface of the metal with sandpaper or a wire brush.

This will help the epoxy adhere better. Once the surfaces are prepared, mix the epoxy according to the instructions on the package.

Apply the epoxy to both surfaces and press them together firmly. Allow the epoxy to dry completely before using the bond.

Using Polyester Resin

Polyester resin is another option for gluing fiberglass to metal. Before applying the resin, clean and roughen both surfaces as described in the previous section.

Mix the polyester resin according to the instructions on the package and apply it to both surfaces.

Press them together firmly and allow the resin to dry completely before using the bond.

Using Contact Cement

Contact cement is another option for gluing fiberglass to metal. Before applying the contact cement, clean and roughen both surfaces as described in the previous sections.

Apply a thin layer of contact cement to both surfaces and allow it to dry until it becomes tacky. Then press them together firmly and allow the bond to dry completely before using it.

How Long Should You Wait Before Joining the Pieces?

Before you do, it’s important to give the glue enough time to dry and set. But how long should you wait?

The answer depends on the type of glue used, as well as the temperature and humidity of your environment.

Generally, experts suggest waiting at least 24 hours for the glue to dry before connecting the pieces. This will help ensure a strong bond between them.

For an even stronger adhesion, some experts recommend waiting up to 72 hours before joining them together.

If you’re using an epoxy glue, be sure to check the manufacturer’s instructions as they may have specific recommendations on how long you need to wait before joining the pieces.

Tips for Joining and Securing the Pieces Together

Joining and Securing Pieces Together

When joining and securing pieces together, it is essential to use the right adhesive that is suitable for both fiberglass and metal surfaces. The most efficient way to apply the glue evenly across both surfaces is with a caulking gun, followed by spreading it in an even layer with a putty knife.

Then press the pieces firmly together for at least 30 seconds, allowing them to cure for 24 hours before using them.

If possible, use clamps or weights to hold the pieces together while they cure.

Once healed, check if the pieces are securely joined and there are no gaps or air bubbles between them. Any excess glue that may have seeped out during curing should be sanded down before testing its joint strength.

Touches After Joining Pieces Together

After joining two pieces together, there are still some finishing touches that need to be done to ensure a strong bond. Sand down any rough edges after joining the pieces together so that everything looks neat and professional.

Additionally, use an appropriate sealant or coating to protect the joint from moisture and corrosion. Lastly, make sure to allow adequate time for the glue to dry before testing its joint strength.

Considerations When Joining and Securing Pieces Together

The process of joining and securing two pieces together requires careful consideration of several aspects including:

- Choosing an appropriate adhesive

- Applying generous amounts of glue on both surfaces evenly

- Pressing the two pieces together

- Using clamps or weights

- Allowing adequate time for curing

- Sanding down any rough edges after joining

- Sealing or coating your joint for protection against moisture and corrosion

Finishing Touches: Sealing and Cleaning Up

The finishing touches of any fiberglass and metal project are essential to ensure that it lasts for years to come.

Sealing the joint between the two materials is an important step in this process.

The best way to do this is with a clear silicone sealant, which will provide an extra layer of protection against moisture, dust, and other potential damage.

Before applying the sealant, make sure you clean up any excess glue or debris that may have been left behind using a damp cloth or paper towel.

Once the sealant has dried completely, you can rest assured knowing that your fiberglass/metal piece is secure and ready for use!

Common Mistakes to Avoid When Gluing Fiberglass to Metal

Gluing fiberglass to metal can be a tricky process, but with the right steps and materials, you can create a strong bond that will last. To ensure success, it’s important to avoid these common mistakes when gluing fiberglass to metal.

First, make sure both surfaces are perfectly clean and free of any dirt or debris. This is essential for the glue to adhere properly and form a reliable bond. Second, be generous with the glue.

If you don’t use enough adhesive, the two materials won’t stick together properly and won’t stand the test of time.

Thirdly, choose a glue specifically designed for this purpose; generic adhesives may not provide sufficient strength for the bond.

Lastly, give enough time for the glue to cure before putting any pressure on it.

Applying pressure too soon could weaken or break the connection between them.

By avoiding these common errors when gluing fiberglass to metal, you can create a strong and lasting bond between your materials.

Conclusion

In conclusion, gluing fiberglass to metal is a relatively simple process that can be done with the right materials and some patience.

The first step is to prepare the metal surface by cleaning it thoroughly and then roughening it up with sandpaper or a wire brush.

After the surface is ready, you can use an epoxy adhesive to bond the fiberglass to the metal.

Make sure to apply the adhesive evenly and press down firmly on the fiberglass for a secure bond. Finally, allow the adhesive to cure for 24 hours before using the item.

With these steps, you can successfully glue fiberglass to metal and create a strong bond that will last for years to come.