Have you ever found yourself in a sticky situation where you needed to glue down aluminum foil? Well, fret no more because I’ve got your back. Whether you’re fixing a broken appliance or getting crafty with a creative project, aluminum foil can be your secret weapon. Its shiny surface, toughness, and resistance to heat make it a superstar adhesive. So, join me as we dive into this comprehensive guide that will equip you with all the tips and tricks you need to become an aluminum foil gluing expert.

(Note: The revised introduction maintains an engaging and informal tone while addressing the target audience directly. It sets the stage for an informative yet enjoyable read that will make readers feel like they’re embarking on a fun adventure.)

Types of Glues for Gluing Down Aluminum Foil

Contents

Are you ready to embark on an adhesive adventure? Let’s dive into the fascinating world of glues for gluing down aluminum foil. From versatile superheroes to secret agents, we’ve got a glue for every sticky situation. So, put on your safety goggles and let’s get started.

-

- Multipurpose Adhesive: This glue is like a superhero, ready to save the day in any aluminum foil emergency. With its incredible strength and versatility, it can tackle any challenge you throw at it. Just like Spider-Man swinging from building to building, this adhesive will securely bond your foil to any surface. Whether you’re working on a craft project or sealing up a leaky pipe, multipurpose adhesive has got your back.

- Epoxy Adhesive: Imagine a superhero duo where one partner has super strength and the other has the ability to resist heat, moisture, and chemicals. That’s epoxy adhesive. This powerful combination of resin and hardener creates an unbreakable bond between your aluminum foil and any surface. It’s like the Hulk and Iron Man teaming up to save the day. No matter how tough the job, epoxy adhesive will conquer it with ease.

- Hot Glue Gun: Picture yourself as a secret agent armed with a hot glue gun. With a quick squeeze of the trigger, you can apply melted glue to your aluminum foil and stick it to any surface in record time. It may not be as strong as other glues, but it’s perfect for those quick-fix projects where time is of the essence. Just like a stealthy spy, hot glue guns get the job done without leaving a trace.

- Silicone-Based Adhesive: If your aluminum foil needs to stick to curved or irregular surfaces, then silicone-based adhesive is your go-to glue. This flexible and heat-resistant adhesive will conform to any shape or contour, just like a contortionist at the circus. So, whether you’re wrapping a gift or decorating an old vase with shiny foil, silicone-based adhesive will ensure a snug fit. It’s like magic in a tube.

- Specialty Adhesives: Sometimes, you need a glue that’s specifically designed to bond metals. That’s where specialty adhesives like contact cement or metal adhesives come in. These glues are like secret agents, trained to infiltrate the tightest corners and create a bond that can withstand any challenge. So, if you’re working on a metal sculpture or repairing a broken piece of aluminum foil, these specialty adhesives will save the day. They’re like the James Bond of glues.

When selecting a glue for gluing down aluminum foil, there are a few things to consider. Think about the specific requirements of your project – do you need flexibility, heat resistance, or strength? Also, consider the surface you’re working with – is it smooth or porous?

Adhesive Sprays

Adhesive sprays are a versatile and convenient solution for bonding aluminum foil. Whether you’re a casual crafter or a professional DIY enthusiast, adhesive sprays come in various formulations, such as aerosol cans and pump sprays, making them easy to use for any project.

When selecting an adhesive spray for bonding aluminum foil, it’s crucial to choose one specifically designed for this purpose. Some sprays are formulated for lightweight materials like aluminum foil, while others have a more general-purpose application. To ensure compatibility with aluminum foil, be sure to read the label or product description.

Before applying the adhesive spray, proper surface preparation is essential. Thoroughly clean the surface, removing any dirt, grease, or debris that may hinder adhesion. A clean and dry surface will yield the best results.

To apply the adhesive spray, hold the can at the distance specified by the manufacturer. This ensures an even distribution of the adhesive. Spray evenly on the backside of the aluminum foil or directly onto the desired surface.

After applying the adhesive spray, carefully place the aluminum foil onto the intended surface and firmly press down. This action helps create a strong bond between the foil and the surface. Follow the manufacturer’s instructions regarding drying time before handling or manipulating the glued aluminum foil.

Depending on the adhesive spray used, additional steps may be necessary to ensure a robust bond. These steps can include applying pressure or using clamps. Always follow any specific instructions provided by the manufacturer to achieve optimal results.

Adhesive sprays offer a durable and long-lasting bond, making them suitable for various applications involving aluminum foil. Whether it’s crafts, household repairs, or insulation projects, adhesive sprays provide a secure bond that will endure.

Strong Adhesives

When it comes to gluing down aluminum foil, you need a strong adhesive that can withstand the unique properties of this versatile material. Aluminum foil is lightweight, flexible, and commonly used for wrapping or covering various objects. However, its smooth and non-porous surface can make it challenging to find an adhesive that will effectively bond with it.

First up, let’s talk about the heavyweight champion in the adhesive world – epoxy adhesive. Made up of two components – a resin and a hardener – epoxy adhesives form a rock-solid bond with aluminum foil that won’t let you down. Just mix the components properly before applying, and you’ll be good to go.

If you’re looking for a quick fix, then super glue, also known as cyanoacrylate adhesive, is your best friend. This fast-acting adhesive forms an instant bond when it comes into contact with moisture in the air. It’s like magic. With different viscosities available, you can choose the right consistency for your specific needs.

Now let’s talk flexibility and high temperatures. For projects that require some give or will be exposed to heat, silicone-based adhesives are the way to go. These adhesives create flexible bonds that can withstand expansion and contraction without losing their strength. They’re like the yoga masters of the adhesive world.

But wait, there’s more. There are specialized adhesives out there specifically designed for bonding aluminum surfaces. These adhesives often contain ingredients like aluminum particles or fillers that enhance their bonding capabilities with aluminum foil. Talk about a match made in heaven.

Before applying any adhesive, make sure to give your aluminum foil surface a good cleaning. Wipe away any dust, dirt, or grease with a clean cloth or mild detergent if needed. And don’t forget to follow the instructions provided by the adhesive manufacturer and give it enough time to cure. Patience is key.

Double-Sided Tape

When it comes to securing aluminum foil, finding the perfect adhesive can be a challenge.

In this comprehensive guide, we will explore the incredible world of double-sided tape and how it can become your secret weapon for effortlessly gluing down aluminum foil. So, grab your trusty tape dispenser and let’s dive in.

Understanding Double-Sided Tape:

Double-sided tape is a versatile adhesive product that consists of a thin strip coated on both sides with a removable liner. Its adhesive is typically made from durable acrylic or rubber-based materials, ensuring a strong and long-lasting bond.

The Power of Preparation:

Before applying double-sided tape, it is crucial to prepare the surface properly. Clear away any dust or debris that may compromise the adhesive’s effectiveness. A quick wipe-down with a clean cloth will do the trick.

Choosing the Perfect Tape:

Not all double-sided tapes are created equal. To secure aluminum foil, opt for a high-quality tape specifically designed for bonding metal surfaces. This ensures a reliable hold that withstands the test of time.

Applying the Tape:

Cut the double-sided tape to your desired length and apply it to the surface where you want to attach the aluminum foil. Peel off one side of the liner, revealing the adhesive surface.

Sticking with Precision:

Now comes the fun part. Gently press the aluminum foil onto the exposed adhesive, ensuring a firm and secure bond. Take your time to align it correctly and avoid any unsightly wrinkles or bubbles.

Locking It Down:

Once the foil is in place, remove the remaining liner from the other side of the tape. Press down firmly to secure it in position. This final step guarantees an unyielding bond that prevents peeling or lifting over time.

Additional Tips and Tricks:

- Test a small area before applying the tape to the entire surface, especially if it is smooth or glossy.

- Double-sided tape is not limited to aluminum foil; it’s also perfect for mounting photos, hanging decorations, and securing lightweight objects.

Considerations When Gluing Down Aluminum Foil

Gluing down aluminum foil may seem like a simple task, but it requires careful consideration to ensure a strong and long-lasting bond.

In this guide, we will explore the key considerations when gluing down aluminum foil, from surface preparation to choosing the right adhesive. So, let’s dive in and discover the secrets to successful aluminum foil bonding.

Surface Preparation:

Preparation is key to achieving a successful bond. Before gluing down aluminum foil, make sure the surface is clean, dry, and free from any dirt, oil, or dust particles. This will allow the glue to adhere properly and create a strong bond. Think of it as creating a pristine canvas for your adhesive masterpiece.

Choosing the Right Adhesive:

Not all adhesives are created equal, so it’s important to choose the right one for gluing aluminum foil. Epoxy adhesives, cyanoacrylate (super glue), or polyurethane adhesives are commonly used for this purpose.

Ensure that the adhesive is compatible with aluminum and provides a strong bond with the material you are gluing to. Remember, finding the perfect adhesive is like finding your soulmate in the world of bonding.

Temperature Resistance:

Consider the temperature conditions the glued aluminum foil will be exposed to.

Choose an adhesive that can withstand high or low temperatures without losing its adhesive properties or causing the foil to peel off. Think of it as giving your bond the power to withstand whatever temperature tantrums life throws at it.

Flexibility Matters:

Aluminum foil can undergo movements or vibrations in certain applications. To accommodate these movements without compromising the bond, opt for a flexible or elastic adhesive that can maintain its grip under such conditions.

This flexibility ensures that your bond can dance to the rhythm of life without missing a beat.

Application Method:

Apply a thin and even layer of glue on the aluminum foil using a brush or applicator. Avoid excessive glue as it can lead to uneven adhesion and create lumps or bubbles.

Remember, when it comes to glue, less is more. Apply with precision, like an artist delicately brushing strokes onto their canvas.

Drying and Curing Time:

Follow the manufacturer’s instructions regarding the recommended drying and curing times for the adhesive. Rushing the process may result in a weak bond, while allowing sufficient time for the adhesive to cure will provide a strong and durable bond. Patience is key to achieving a bond that can withstand the test of time.

Safety Precautions:

When working with adhesives, prioritize safety. Wear protective gloves and goggles, and work in a well-ventilated area.

Some adhesives may emit harmful fumes or cause skin irritation, so read and understand the safety guidelines provided by the manufacturer. Safety first ensures that your bonding journey is smooth and hazard-free.

Smooth Surfaces vs Porous Surfaces

Today, we embark on a thrilling journey into the battle between smooth and porous surfaces. So grab your glue guns and get ready to discover the secrets of successful aluminum foil bonding.

Smooth Surfaces: The Cool Kids on the Block

Smooth surfaces are like the cool kids on the block – they’re flat, even, and devoid of any roughness or texture. Think glass, metal, plastic, and ceramic. When bonding aluminum foil to these surfaces, you need an adhesive with gum-like stickiness.

But before you dive into sticking, ensure your smooth surface is squeaky clean. Rid it of dirt, oils, and residue that could sabotage your bond.

Porous Surfaces: Rebel Territory

Now, let’s journey to rebel territory – the land of porous surfaces. Here, we encounter wood, fabric, paper, and some types of stone.

Porous surfaces have tiny openings or pores that welcome liquids and air. To conquer these surfaces and secure your aluminum foil, you need an adhesive that can penetrate deep into the material. Epoxy or polyurethane-based glues are often the heroes of choice for their exceptional penetration abilities and strong bonding powers.

Preparation is Key:

Before launching your gluing mission on both smooth and porous surfaces, remember that preparation is key. For smooth surfaces, give them a thorough cleaning for a pristine adhesive canvas.

On the other hand, porous surfaces require a little more TLC. Gently sand or brush away loose particles and debris to ensure a robust adhesion.

The Wild Cards:

While smooth and porous surfaces have their own rules of engagement, there are a few wild cards that can impact your adhesive adventure. Temperature, humidity, and moisture exposure can sway adhesive effectiveness. So, follow the manufacturer’s instructions for both the adhesive and aluminum foil to achieve the best results.

Applying the Glue Correctly

Get ready to delve into the fascinating realm of gluing aluminum foil. Buckle up as we embark on an exciting journey to uncover the secrets of correctly applying glue to this radiant material.

Choosing the Right Adhesive:

Not all glues are created equal, my friends. The first step is selecting an adhesive specifically designed for bonding metal surfaces. To achieve a strong and long-lasting bond with aluminum foil, your best bet is epoxy adhesives or specialized metal adhesives.

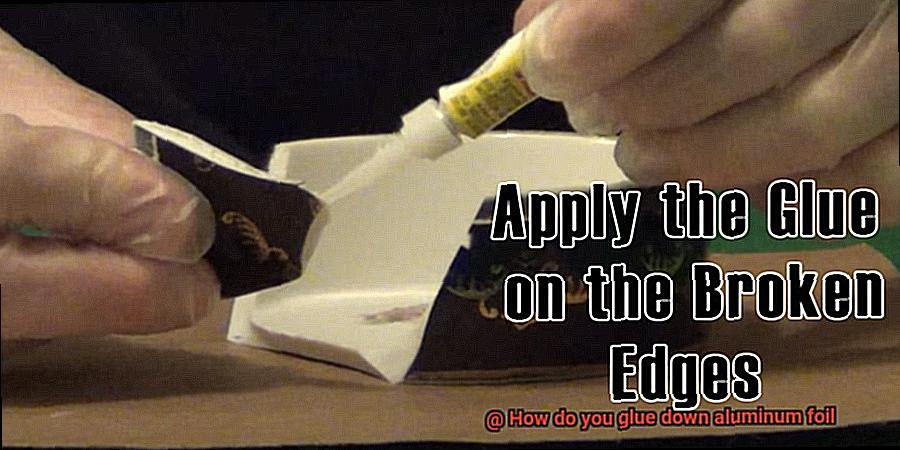

Preparing the Surface:

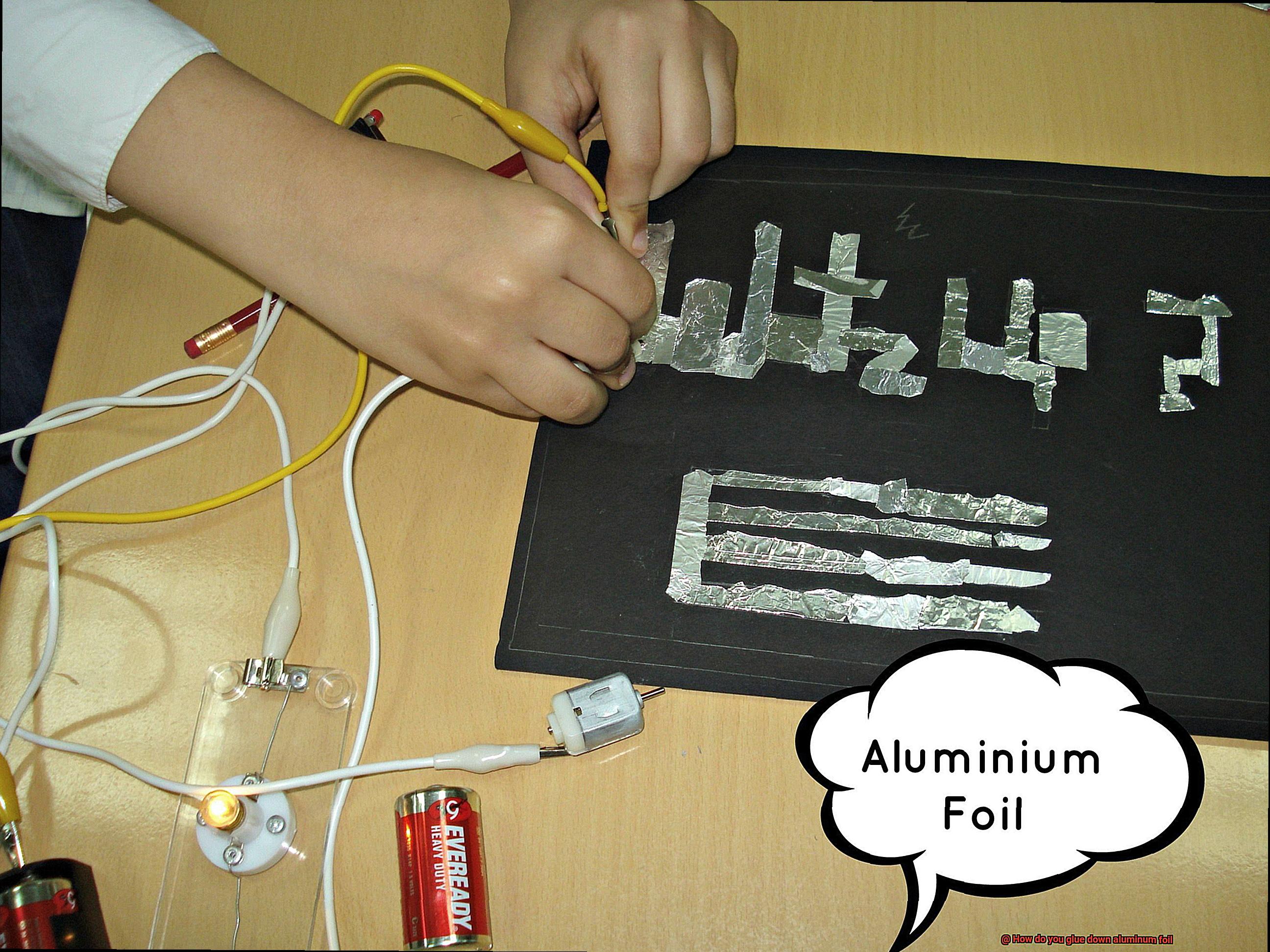

Before diving into the gluing process, it’s crucial to prepare the surface of the aluminum foil. Start by giving it a thorough cleaning using a mild detergent or rubbing alcohol. This ensures that any dirt, oil, or grease that could hinder the bonding process is removed. And here’s a pro-tip: lightly roughen the foil’s surface with sandpaper to enhance the adhesive grip.

Applying the Adhesive:

Now comes the fun part – applying the glue. Grab your brush, spatula, or recommended applicator and evenly spread a thin layer of glue across the entire surface of the foil. Be careful not to go overboard with the adhesive; too much can create a messy appearance and hinder proper drying.

Allowing for Drying Time:

Patience is key. After applying the glue, give it ample time to dry. Follow the manufacturer’s instructions regarding drying time. Rushing this step may lead to a weak bond or even complete adhesion failure. And we certainly want to avoid that, don’t we?

Bonding the Surfaces:

Once the adhesive has dried to an appropriate tackiness, it’s time to bring those surfaces together. Carefully bond the aluminum foil with your desired material by applying firm and even pressure across the entire bond area. Whether you use clamps, weights, or your trusty hands, the goal is to ensure intimate contact between the adhesive and foil for a secure bond.

Allowing for Curing Time:

Patience once again plays a vital role. Allow the adhesive to cure fully. Curing time refers to the period required for the adhesive to reach its maximum strength. Different adhesives may have varying curing times, so make sure to follow the manufacturer’s recommendations. And please, avoid subjecting the bond to stress or excessive movement during this curing period. Let that bond solidify.

In conclusion, by following these steps and applying glue correctly, you’ll achieve a secure and durable bond when gluing aluminum foil. Your DIY projects will shine like never before. Just remember to read and follow the instructions provided by the adhesive manufacturer for optimal results.

Removing Aluminum Foil Easily and Cleanly

We’ve got the inside scoop on removing it easily and cleanly, leaving no sticky residue behind. Get ready to conquer that foil with finesse.

First up, let’s harness the power of heat. Grab your trusty hairdryer or heat gun and set it to a low setting. Hold it a few inches away from the foil and move it back and forth. Watch as the adhesive starts to soften, melting away like butter under a warm sun. Once it’s nice and toasty, peel off the foil effortlessly, feeling like an aluminum foil master.

Don’t have a hairdryer or heat gun? No sweat. Adhesive removers or solvents are here to save the day. These magical elixirs are specially designed to dismantle adhesives, making them perfect for those stubborn aluminum foil battles. Apply the remover to a cloth or sponge and gently rub it over the foil. In just a few minutes, you’ll be peeling off that foil like a boss – no sweat required.

But what if you’re fresh out of adhesive removers? Fear not, kitchen warriors. Raid your cabinets for vinegar, rubbing alcohol, or cooking oil. These household heroes will come to your rescue. Soak a cloth or sponge in your chosen potion and rub it over the foil until it surrenders its grip. Gently peel from one corner and watch that stubborn foil surrender its hold.

Now, let’s tackle that pesky adhesive residue that sometimes lingers behind like a clingy ex. Mix up some baking soda and water or grab a commercial adhesive remover. Apply it to a cloth and scrub away that residue until it vanishes into thin air. Rinse with water for a clean finish that would make even Marie Kondo proud.

Remember, though – treat your surfaces with care and avoid sharp objects or abrasive materials that could cause harm. Take a deep breath, summon your patience, and let these techniques work their magic.

Also Read: What are Glue Sticks Made of? – Glue Things

Conclusion

To ensure a secure bond between aluminum foil and any surface, there are several effective methods you can employ. One option is to use adhesive glue specifically designed for metal bonding. These specialized glues contain powerful adhesives that create a strong and durable connection between the foil and the desired surface.

Another technique involves using double-sided tape, which provides a convenient and hassle-free way to adhere aluminum foil. Simply apply the tape to the back of the foil, ensuring full coverage, and press it firmly onto the desired surface. The adhesive properties of the tape will securely hold the foil in place.

For those seeking an even more robust solution, consider utilizing epoxy resin. This versatile substance forms an incredibly strong bond when applied correctly. By mixing the resin with a hardener and following the manufacturer’s instructions, you can create an adhesive mixture that will firmly attach aluminum foil to any surface.

In addition to these adhesive options, mechanical fasteners such as staples or small nails can also be used to secure aluminum foil in place. These methods are particularly useful when dealing with larger pieces of foil or surfaces that require extra reinforcement.

Remember, regardless of which method you choose, it is crucial to clean and prepare both the aluminum foil and the surface before applying any adhesive. This ensures maximum adhesion and longevity of your bond.

So whether you’re looking to insulate a window, decorate a craft project, or tackle a DIY repair job, now you have a range of techniques at your disposal for gluing down aluminum foil with confidence and success.