Have you ever been in a bind trying to fix a beloved brass ornament or appliance, only to struggle finding the right adhesive that works? Well, look no further than the trusty epoxy putty. This two-part adhesive hardens after mixing two parts together, creating a bond that’s not only strong but also durable. But here’s the million-dollar question: does epoxy putty stick to brass?

The answer is yes, epoxy putty can stick to brass, but it all depends on several factors. Brass is a metal alloy consisting of copper and zinc, which makes it tricky to bond due to its smooth surface and potential residue from corrosion or oils.

To ensure a robust bond between brass and epoxy putty, prepping the brass surface correctly is crucial. Cleaning it thoroughly with rubbing alcohol or acetone is essential. Additionally, roughening the surface with sandpaper or wire brush can increase adhesion between the brass and epoxy putty.

In this blog post, we’ll dive deeper into the science behind epoxy putty and brass adhesion. We’ll cover different types of epoxy putty and how to apply them to brass while providing tips for achieving optimal results. So if you’re looking for ways to mend your cherished brass item, read on as we discover how epoxy putty can save the day.

What is Epoxy Putty?

Contents

Epoxy putty is a remarkable adhesive that has gained immense popularity over the years. This two-part adhesive consists of a resin and a hardener that can be mixed together to create a strong and durable bond. Its versatility allows it to bond to various materials, including metal, wood, plastics, ceramics, and more.

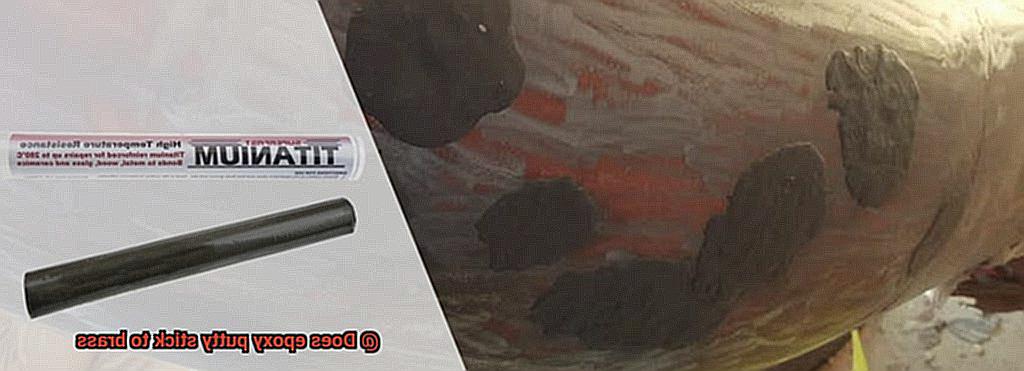

One of the most significant advantages of epoxy putty is its ability to fill gaps and cracks in surfaces. It can mold into any shape or form, making it ideal for repairing or restoring damaged objects, such as furniture, automotive parts, plumbing fixtures, and more. Additionally, once it has cured, it can be sanded or painted to match the surrounding material.

Moreover, epoxy putty is known for its strength and durability. Once it has cured, it forms a robust and rigid bond that can withstand heavy loads and vibrations, making it suitable for use in applications where strength and durability are essential, such as in the construction industry.

But can epoxy putty stick to brass? The answer is yes. However, several factors determine the success of the bond between epoxy putty and brass. To achieve a strong and durable bond, proper surface preparation, application technique, and curing time are crucial factors.

Before applying epoxy putty to brass, ensure that the surface is clean, dry, and free from dirt or grease. Any contaminants present on the surface can affect the adhesion strength of the epoxy putty. It is recommended to clean the surface with a degreaser or rubbing alcohol before applying the epoxy putty.

Once the surface is properly prepared, mix equal parts of resin and hardener until it forms a uniform paste. Then, apply the epoxy putty onto the prepared brass surface using a spatula or brush and smooth it out evenly. Allow at least 24 hours of curing time before handling or putting any stress on the bond.

What is Brass?

Brass is more than just a metal alloy – it’s an integral part of our daily lives. From musical instruments to decorative items and hardware, brass has proven itself as a versatile and durable material with many beneficial properties.

So what exactly is brass? It’s an alloy made of copper and zinc, with the ratio of copper to zinc varying based on the desired properties of the brass. Generally, brass has a yellowish-gold color that is warm and inviting. It’s easy to work with, making it ideal for molding into different shapes and sizes for various applications.

One of the most fascinating things about brass is its ability to develop a patina over time. This patina is a thin layer that forms on the surface of the brass due to exposure to air and moisture. The patina can take on a range of colors from green to brown, depending on the composition of the brass and environmental conditions.

Brass has a wide range of uses in our daily lives, including:

- Musical instruments: Brass is renowned for its acoustic properties, making it a popular material for musical instruments such as trumpets, trombones, and tubas.

- Decorative items: The warm and inviting color of brass makes it ideal for decorative items such as lamps, candlesticks, and picture frames.

- Hardware: Brass is used for many types of hardware, including locks, hinges, doorknobs, and faucets.

- Jewelry: Brass is a popular base metal for jewelry due to its affordability and durability.

Does Epoxy Putty Stick to Brass?

Epoxy putty may be the answer, but it’s not as simple as just slathering it on. As an expert in the field, I can tell you that several factors come into play when determining whether epoxy putty can bond effectively with brass.

Firstly, it’s crucial to select the correct type of epoxy putty for your needs. There are various formulations available; some are designed for metal bonding, while others are more versatile and can bond with different materials. If you’re looking to bond brass, it’s essential to choose an epoxy putty that is specifically formulated for metal bonding and can withstand high temperatures.

Next, the condition of the brass surface is paramount to achieving a robust bond with the epoxy putty. Before application, ensure that the surface is clean, dry, and free from any oil or grease residues that may hinder bonding. Sanding or roughening the surface may also help improve adhesion.

When applying the epoxy putty, follow the manufacturer’s instructions carefully to ensure maximum effectiveness. Thoroughly mix the adhesive and apply it evenly on the brass surface to achieve an effective bond. It’s also vital to give the adhesive enough time to cure and harden before subjecting it to any stress or strain.

While epoxy putty can bond successfully with brass under the right conditions, it’s crucial to note that other adhesives may be more effective for specific applications. So before reaching for your trusty tube of epoxy putty, consider your specific needs and do your research to determine which adhesive is best suited for your project.

Factors Affecting the Bond Strength between Epoxy Putty and Brass

These factors include surface preparation, temperature, humidity, and curing time. Let’s take a closer look.

Surface preparation is the foundation of a strong bond. Just like building a house requires a sturdy foundation, applying epoxy putty onto a dirty or greasy surface is doomed to fail. To ensure maximum adhesion, the surface must be free of any dirt, grease, or oil. Abrading the surface with sandpaper or a wire brush can help create more surface area for the adhesive to grip onto.

Temperature is another crucial factor in achieving a strong bond. Epoxy putty doesn’t do well in extreme temperatures as they can cause the adhesive to become brittle and lose its bonding ability. To avoid this, it’s recommended to apply epoxy putty at a temperature range between 60-90 degrees Fahrenheit.

Humidity can also affect the bond strength between epoxy putty and brass. High levels of humidity can cause moisture to build up on the surface, preventing the adhesive from properly adhering. To ensure optimal conditions for bonding, it’s essential to ensure that the surface is dry before applying the epoxy putty.

Lastly, curing time is vital for creating a strong bond that will last over time. Just like you need time to build a lasting relationship with someone, epoxy putty needs sufficient time to cure properly before it can withstand any stress or strain applied to it. It’s recommended to allow at least 24 hours for the adhesive to cure fully before subjecting it to any stress or strain.

Preparing the Surface for Application

When it comes to working with brass and epoxy putty, proper surface preparation is the key to ensuring a strong and long-lasting bond. Brass is a non-porous material that can make it difficult for the putty to adhere properly. Therefore, the surface must be prepared beforehand to ensure maximum adhesion.

To prepare the surface for application, follow these steps:

- Step 1: Clean the surface thoroughly. Any oil, dirt, or debris on the brass surface can prevent the epoxy putty from adhering properly. Use a degreaser to clean the brass surface and then rinse it with water. This will ensure that the surface is free of contaminants that could affect adhesion.

- Step 2: Roughen up the surface. Brass is a smooth material that can make it difficult for epoxy putty to stick to it. To create some texture on the surface, use sandpaper to create small scratches that will help the putty bond more effectively. This step is crucial in ensuring that the putty has something to grip onto.

- Step 3: Apply a primer. A primer creates a layer between the brass and epoxy putty, improving adhesion and filling in any small gaps or rough spots on the surface. Be sure to follow the manufacturer’s instructions carefully when applying primer, as some primers may require multiple coats or specific drying times.

Applying Epoxy Putty to Brass

Look no further than epoxy putty. However, achieving a strong and long-lasting bond requires proper preparation and application techniques. As an expert in applying epoxy putty to brass, I’m here to share some tips and tricks to help you achieve the best results possible.

First things first – prep is key. Make sure that the brass surface is spotless and free from any dirt, debris, or oil residue. A degreaser or rubbing alcohol can help achieve this. Once the surface is clean and dry, it’s time to mix your epoxy putty. Follow the manufacturer’s instructions closely and ensure that the putty is thoroughly and evenly mixed.

When it comes to applying the putty, remember that less is more. Apply a small amount at a time in small sections. This ensures that the putty adheres properly to the brass without any air pockets or gaps. Working in small sections also helps maintain control over the application process.

Curing time is another vital factor to consider. After applying the putty, allow ample time for it to cure fully before handling or using the brass object. The curing time can vary depending on the type of epoxy putty used, so consult the manufacturer’s instructions for specific guidance.

To sum it up, here are some key takeaways when working with epoxy putty and brass:

- Thoroughly clean the brass surface before applying the putty.

- Mix the epoxy putty evenly according to the manufacturer’s instructions.

- Apply a small amount of putty at a time in small sections.

- Allow ample time for curing before handling or using the brass object.

Curing Time for a Strong Bond

Epoxy putty is a two-part adhesive that requires mixing before application. Once applied to the brass surface, it begins to harden as the curing process takes place. Rushing the curing process by applying stress or load too soon can result in a weaker bond that may not hold up over time.

To ensure the best results, it’s crucial to allow enough curing time. The general rule of thumb is to let the epoxy putty dry for at least 24 hours. However, different brands and types of epoxy putty may require longer curing times, so it’s always best to follow the manufacturer’s instructions for optimal results.

In addition to allowing enough curing time, it’s essential to prepare both surfaces before bonding. Any debris or oils on the surfaces can interfere with the bonding process and weaken the bond. To improve adhesion, I recommend sanding or roughing up the surface of your brass before applying the epoxy putty.

The key to achieving a strong bond between epoxy putty and brass is patience and attention to detail during the application and curing process. By taking the time to properly prepare your surfaces, allow adequate curing time, and follow the manufacturer’s instructions, you can create a bond that can withstand various types of stress and load.

To summarize:

- Curing time is crucial in achieving a strong bond between epoxy putty and brass.

- Allow at least 24 hours for drying, but follow manufacturer’s instructions for specific curing times.

- Prepare surfaces by cleaning and sanding before bonding.

- Patience and attention to detail are key in creating a bond that can withstand stress and load over time.

3Byz_fR7iGM” >

Conclusion

In conclusion, the answer to the question of whether epoxy putty sticks to brass is a resounding yes. However, achieving a strong and lasting bond between these two materials requires attention to detail and proper technique. Brass is notoriously difficult to bond due to its smooth surface and potential residue from corrosion or oils. But fear not, with the right preparation, you can create a bond that will stand the test of time.

To ensure a robust connection between brass and epoxy putty, it’s crucial to prep the brass surface correctly. Start by cleaning it thoroughly with rubbing alcohol or acetone. Additionally, roughening the surface with sandpaper or wire brush can increase adhesion between the brass and epoxy putty. This step is essential as it creates tiny grooves in the surface for the putty to grip onto.

Epoxy putty is an incredible adhesive that has gained immense popularity over time due to its versatility in bonding various materials such as metal, wood, plastics, ceramics, and more. Its ability to fill gaps and cracks in surfaces makes it ideal for repairing or restoring damaged objects such as furniture, automotive parts, plumbing fixtures, etc.

However, when applying epoxy putty specifically to brass surfaces, selecting the correct type of epoxy putty for your needs is crucial. Proper surface preparation by cleaning and sanding before bonding is also important. Applying small amounts of putty at a time in small sections ensures that it adheres properly without any air pockets or gaps. Allowing ample time for curing before handling or using the brass object is also vital for creating a strong bond that will last over time.

So, there you have it – now you know how to achieve a successful bond between epoxy putty and brass.