Plastic is ubiquitous in our daily lives. From the toys we play with to the furniture we lounge on, plastic is a versatile material that’s both durable and easy to shape. But what happens when it breaks or needs to be joined together? Enter epoxy glue.

Epoxy glue is a potent adhesive that can bond different materials, including plastic. But does it work effectively on plastic? The answer is a resounding yes. However, the type of epoxy glue you use and the kind of plastic you’re working with can affect its efficacy.

If you’re someone who loves DIY projects or wants to make quick repairs at home, knowing how well epoxy glue works on plastic is crucial. Tired of cheap, temporary fixes? Epoxy glue provides a reliable, long-lasting solution for bonding plastic. From fixing broken toys to repairing outdoor patio furniture, epoxy glue should be your go-to choice.

In this blog post, we’ll delve into the world of epoxy glue and answer one of the most burning questions: “Does epoxy glue work on plastic?” We’ll explore the various types of epoxy glues available, which plastics they work best with, and some handy DIY tips for using them effectively. So sit tight and get ready to discover one of the most versatile adhesives out there.

What is Epoxy Glue?

Contents

- 1 What is Epoxy Glue?

- 2 Does Epoxy Glue Work on Plastic?

- 3 Types of Plastics that Can Be Bonded with Epoxy Glue

- 4 Preparing the Surface for Bonding with Epoxy Glue

- 5 Applying Epoxy Glue to Plastic

- 6 Pressing the Surfaces Together Firmly

- 7 Special Types of Epoxy Glues for Difficult-to-Bond Plastics

- 8 Conclusion

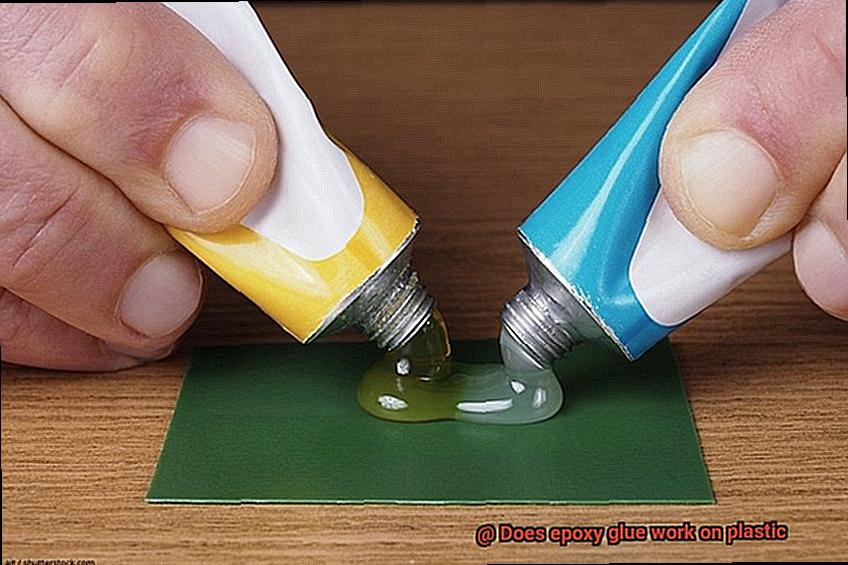

Epoxy glue is a versatile and powerful adhesive, comprised of two key components: resin and hardener. When mixed together, they create a chemical reaction that results in a strong and durable bond between materials. Epoxy glue is favored for its ability to bond a wide range of surfaces, including metals, woods, ceramics, and plastics.

One of the most significant advantages of epoxy glue is its exceptional strength. The cross-linked polymer structure created by the chemical reaction between resin and hardener makes it ideal for applications where durability and strength are essential. Additionally, it is resistant to moisture, chemicals, and even heat, making it a popular choice in harsh environments.

Many people are curious about whether or not epoxy glue works on plastic surfaces. The good news is that epoxy glue can bond a variety of plastic types, including PVC, polycarbonate, acrylics, and ABS. However, the success of the bond will depend on several factors such as the type of plastic used, surface preparation, and application technique.

Proper surface preparation is crucial before applying epoxy glue to plastic surfaces. It is essential to clean the surface thoroughly to eliminate any dirt, grease, or other contaminants that may adversely affect the bonding process. Moisture can also impact the curing process of the epoxy glue, so a dry surface is necessary.

It’s important to note that some types of plastics are resistant to adhesives such as polyethylene and polypropylene. In these cases, special types of epoxy glue designed for bonding these plastics are necessary.

Does Epoxy Glue Work on Plastic?

Epoxy glue is a powerful adhesive that can bond almost anything, including a wide variety of plastic types. However, before we can answer the question “Does Epoxy Glue Work on Plastic?”, it’s important to understand some key factors.

To begin with, not all plastics react the same way to epoxy glue. While epoxy glue can bond well with many types of plastic such as acrylic, PVC, polycarbonate, and ABS, others like polypropylene and polyethylene plastics require special treatment before using epoxy glue.

These plastics have low surface energy and may need to be chemically treated or abraded to increase their surface area for better bonding. Therefore, it’s crucial to ensure that the surfaces are compatible with the adhesive.

Choosing the right type of epoxy glue for plastic bonding is also essential. Specialized epoxy glues specifically formulated for plastic bonding exhibit better adhesion and durability than general-purpose epoxy glue. These specialized epoxy glues contain additives that enhance their bonding strength and resistance to environmental factors such as temperature changes and moisture.

However, even with the right type of epoxy glue, proper preparation and application procedures are critical for optimal adhesion. Carefully following the manufacturer’s instructions is a must. This includes preparing the surfaces to be bonded by cleaning them thoroughly with solvent or abrasive material, applying the adhesive evenly, and allowing sufficient curing time before subjecting the bond to stress or load.

Types of Plastics that Can Be Bonded with Epoxy Glue

Not all types of plastic are created equal, and some can be challenging to bond with traditional adhesives. That’s where epoxy glue comes in – it’s a versatile adhesive that can bond with various materials, including plastic. However, not all plastics are compatible with epoxy glue. Let’s take a closer look at the types of plastics that can be bonded effectively with epoxy glue.

Acrylic or Polymethyl Methacrylate (PMMA) is a transparent thermoplastic used in the manufacturing of products like signs, displays, and lenses. Epoxy glue works particularly well with acrylic because it has a high surface energy that allows it to penetrate and create a strong bond. The transparency of acrylic also makes it an attractive choice for many applications.

Polyethylene (PE) is another type of plastic commonly used in packaging materials, pipes, and toys. However, PE has a low surface energy, which can make it challenging for most adhesives to bond with it effectively. Epoxy glue can bond with PE by using a primer or by roughening the surface before applying the adhesive. By preparing the surface properly, you can ensure a strong and reliable bond.

Polyvinyl Chloride (PVC) is a thermoplastic widely used in construction materials such as pipes, window profiles, and flooring. Epoxy glue can bond well with PVC because it has a high surface energy and can penetrate the plastic’s surface to create a strong bond. This makes it an excellent choice for applications where durability is essential.

Polycarbonate (PC) is a transparent thermoplastic commonly used in eyewear, electronic components, and automotive parts. Epoxy glue is effective at bonding with PC because it has a high surface energy and can create a strong bond by penetrating the plastic’s surface. This makes it an ideal choice for high-stress applications where strength is essential.

When it comes to rigid plastics, epoxy glue can be effective at bonding materials like fiberglass, carbon fiber, and ABS. Fiberglass is commonly used in boat building and automotive repairs, while carbon fiber is used in aerospace and sporting goods industries. ABS is another thermoplastic often used in toys, automotive parts, and household appliances. While these plastics can be challenging to bond with traditional adhesives, epoxy glue can create a strong and reliable bond when applied correctly.

Preparing the Surface for Bonding with Epoxy Glue

If you’re looking to create a strong and reliable bond between plastic surfaces using epoxy glue, preparing the surface is crucial. As an expert in this field, I can guide you through the essential steps to ensure a durable bond that can withstand even the toughest conditions.

Firstly, it’s vital to clean the plastic surface thoroughly with a mild detergent and water. This will eliminate any dirt or grease that could hinder the bonding process. Once cleaned, dry it completely with a clean, lint-free cloth.

Next, roughen the plastic surface using sandpaper or a wire brush. This step provides better adhesion for the epoxy glue to attach to. However, it’s important not to overdo it as excessive roughening can weaken the plastic and cause it to crack or break.

After roughening the surface, clean it again with a solvent such as rubbing alcohol or acetone to remove any residual dust or debris from the sanding process. This step ensures that the surface is entirely clean and ready for bonding.

Finally, apply a primer or adhesion promoter specifically designed for use with epoxy glue. This will enhance the bond strength and improve overall durability. The primer should be applied in a thin, even layer and allowed to dry thoroughly before applying the epoxy glue.

Applying Epoxy Glue to Plastic

When it comes to bonding plastic surfaces, epoxy glue is one of the strongest adhesives available on the market. However, applying epoxy glue to plastic can be a bit tricky, as not all types of plastic are compatible with the adhesive.

To ensure a durable bond between your plastic surfaces and epoxy glue, it’s crucial to follow a few key steps. First and foremost, you need to verify that your plastic is compatible with the adhesive. Some plastics may have smooth and non-porous surfaces that make it difficult for the adhesive to bond. In such cases, you may need to roughen up the surface of the plastic to create a better bond.

Once you’ve confirmed that your plastic is compatible with epoxy glue, it’s time to prepare the surface properly. This means cleaning and removing any dust or debris from the surface. You can use a clean cloth and a mild solvent like isopropyl alcohol to achieve this.

Next up, it’s time to mix your epoxy glue. Make sure you carefully follow the manufacturer’s instructions and mix equal parts of resin and hardener together on a clean surface before applying it to the plastic. Be careful not to use too much glue as this can cause it to run or drip.

When applying the epoxy glue, be sure to apply enough to create a strong bond between the plastic surfaces. Once applied, hold the parts together firmly until curing is complete. The curing time can vary depending on various factors such as the type of epoxy glue used and environmental conditions like temperature and humidity. It can take anywhere from a few hours to several days for curing to complete.

In summary, applying epoxy glue to plastic requires careful preparation and attention to detail. By ensuring that your plastic is compatible with the adhesive, preparing the surface correctly, mixing and applying the adhesive correctly, and holding the parts together firmly until curing is complete, you can achieve a strong bond between plastic and epoxy glue.

Pressing the Surfaces Together Firmly

If you’re seeking a dependable and robust bond for your plastic materials, look no further than epoxy glue. However, to ensure maximum strength and durability, it is essential to press the surfaces together firmly during the bonding process.

To begin with, it’s crucial to have both surfaces cleaned and dried thoroughly before applying the epoxy glue. Any dirt or debris left behind can weaken the bond and decrease its strength. Once both surfaces are clean and dry, apply a small amount of epoxy glue to one surface.

Now, it’s time to press the surfaces together firmly. It is highly recommended to use clamps or other tools to hold the surfaces in place while the glue dries. This will help guarantee that the bond is strong and secure. Applying even pressure while pressing the surfaces together is vital to avoid any air pockets or gaps between them. These can greatly reduce the bond’s strength.

It’s crucial to follow the manufacturer’s instructions regarding drying time and any other specific instructions for using the epoxy glue. This will ensure that you achieve the strongest possible bond for your plastic materials.

In addition, here are some helpful sub-topics worth noting:

- The importance of cleaning and drying: Dirty surfaces lead to weak bonds that can easily break apart.

- The significance of using clamps: They help maintain even pressure on the surfaces during bonding.

- The significance of applying even pressure: This ensures that there are no air pockets or gaps between the surfaces.

- Following manufacturer’s instructions: This guarantees that you get the strongest possible bond for your plastic materials.

Special Types of Epoxy Glues for Difficult-to-Bond Plastics

Fortunately, there are special types of epoxy glues available that are designed specifically for these types of plastics. Let’s take a closer look at some of the different types of specialized epoxy glues and what they’re best suited for.

Toughened epoxies are one type of specialized epoxy glue that is designed with added elasticity and flexibility. These properties allow them to bond to plastics that may have different expansion and contraction rates than the glue itself. This makes toughened epoxies ideal for bonding plastics that are prone to cracking or breaking due to stress or movement.

Another type of specialized epoxy glue is the modified epoxy. These types of epoxies contain additives like rubber, which help improve the bonding strength and flexibility of the glue. They are particularly useful for bonding plastics with low surface energy, such as polyethylene and polypropylene.

Surface activators are yet another type of specialized epoxy glue. These activators work by increasing the surface energy of the plastic, making it more receptive to bonding with the glue. Surface activators are often used in conjunction with toughened or modified epoxies for optimal bonding strength.

If you need to bond high-density polyethylene (HDPE) and other low surface energy plastics, a plastic welder might be your solution. This type of epoxy glue chemically melts the plastic surface and bonds it to another surface.

For bonding plastics exposed to high-stress environments, such as automotive parts and construction materials, structural adhesives are a great choice. These specialized epoxy glues have high bonding strength and can withstand extreme temperatures and harsh chemicals.

Finally, there are specialized types of epoxy glues designed to bond with specific types of plastics, such as polycarbonate, PVC, and ABS. These types of epoxy glues have a specific formulation that allows them to bond strongly with the particular plastic they’re designed for.

DpDKTqnesMI” >

Also Read: Does Gorilla Glue Work on Plastic?

Conclusion

To sum it up, epoxy glue is a game-changer when it comes to bonding plastic surfaces. The answer to the question “Does epoxy glue work on plastic?” is a resounding yes. However, not all epoxies are created equal, and not all plastics are easy to bond. It’s crucial to choose the right type of epoxy glue for plastic bonding and prepare the surface meticulously before applying it.

Epoxy glues are versatile enough to work with various types of plastics such as acrylic, PVC, polycarbonate, ABS, fiberglass, carbon fiber, and HDPE. But some plastics like polyethylene and polypropylene require special treatment before using epoxy glue.

If you’re dealing with difficult-to-bond plastics, don’t worry because specialized epoxy glues have got your back. Toughened epoxies, modified epoxies, surface activators, plastic welders, structural adhesives – you name it; they’ve got it.

In conclusion, if you want a reliable adhesive that can withstand even the toughest conditions and bond plastic surfaces together or make quick repairs at home or in your workshop – look no further than epoxy glue.