Are you ready to take your home’s interior to the next level with stunning wooden floors or eye-catching wood paneling? If so, you might be wondering if it’s possible to attach wood directly to concrete. While concrete can be a challenging material to work with, the answer is yes – you can indeed attach wood directly to concrete.

With the right tools and guidance, installing wooden flooring, cladding or other wooden elements on top of concrete surfaces is achievable. However, before diving into your project headfirst, there are some crucial factors that you need to consider.

Choosing the appropriate materials, understanding the process of attaching wood to concrete and planning for potential problems are all essential steps in ensuring a successful outcome. But don’t worry – we’ve got you covered. In this post, we’ll provide you with everything you need to know about attaching wood directly to concrete.

From the best methods and materials to expert tips for a smooth installation process, we’ve got all the information you need. So whether you’re an experienced DIY’er or a first-time renovator, read on as we guide you through transforming your space with the beauty of wood and durability of concrete.

Can You Attach Wood Directly to Concrete?

Contents

- 1 Can You Attach Wood Directly to Concrete?

- 2 Factors to Consider When Attaching Wood to Concrete

- 3 Advantages and Disadvantages of Attaching Wood Directly to Concrete

- 4 Methods for Attaching Wood Directly to Concrete

- 5 Protective Barriers Between the Wood and the Concrete

- 6 Benefits of Using an Alternative Method for Attaching Wood to Concrete

- 7 Conclusion

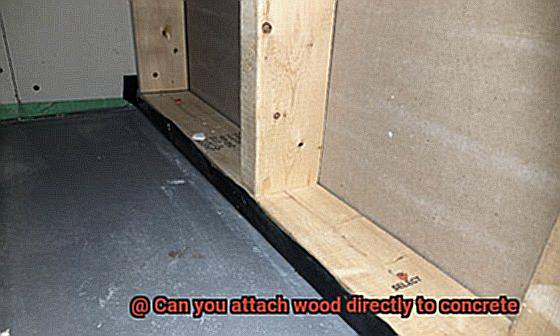

It’s definitely doable, but it requires some preparation and careful consideration. The first step is to ensure that the concrete surface is clean and free of any debris or coatings. Once that’s done, it’s important to choose the right adhesive or mechanical fastener that will work well with both the concrete and wood materials.

Adhesive glue is a popular option for attaching wood directly to concrete. It’s applied directly to the concrete surface, and then the wood is pressed onto the glue. Mechanical fasteners like screws or nails can also be used, but they need to be driven into the concrete first and then into the wood.

Moisture is always a concern when attaching wood directly to concrete. Concrete is porous, which means it can absorb moisture from its surroundings. Over time, this can cause the wood to warp or swell, potentially leading to structural issues or cosmetic damage. To prevent this, it’s important to use a moisture barrier between the concrete and wood, such as a layer of polyethylene film or a specially designed membrane.

Factors to Consider When Attaching Wood to Concrete

It may seem daunting, but fear not. By taking several important factors into consideration, you can create a successful and long-lasting project.

Type of Wood

When it comes to attaching wood directly to concrete, the type of wood you choose is crucial to the success of your project. Luckily, there are a few options to consider.

Pressure-treated wood is a top choice for its resistance to decay and rot, making it perfect for outdoor projects exposed to moisture. Hardwoods like oak or maple are another viable option for indoor projects that won’t be exposed to moisture. However, hardwoods can be pricier and less accessible than pressure-treated wood.

Steer clear of softwoods like pine or spruce when attaching directly to concrete. These woods are more susceptible to decay and rot, which can compromise the longevity of your project.

When selecting your wood, also keep in mind the grade. Higher-grade wood will be more durable and less likely to warp or crack over time.

Porosity of Concrete

Don’t overlook the importance of porosity. Porosity refers to the amount of air space in the concrete material and it can make all the difference when choosing the right adhesive for your project.

Different types of concrete have varying degrees of porosity. Lightweight concrete, for example, has larger pores, making it easier for adhesives to bond with the surface. High-density concrete, on the other hand, has smaller pores, making it more difficult for adhesives to penetrate and form a strong bond.

So, how do you determine the porosity of your concrete surface? It’s easy. Conduct a simple water test by pouring some water onto the surface and observing how quickly it is absorbed. If the water is quickly absorbed and forms small puddles on the surface, this indicates that the concrete has low porosity. Conversely, if the water is slowly absorbed and spreads out evenly across the surface, this indicates higher porosity.

Why does porosity matter? Well, when attaching wood directly to concrete with adhesive, it is important to choose an adhesive that is suitable for the porosity level of your concrete surface. For highly porous surfaces, it is recommended to use an adhesive that is specifically designed for porous materials. This will ensure that the adhesive can effectively penetrate into the surface and create a strong bond with the wood.

Advantages and Disadvantages of Attaching Wood Directly to Concrete

When it comes to construction projects, attaching wood directly to concrete can be a convenient and cost-effective solution. There are numerous advantages to this approach. First and foremost, it provides a sturdy and durable connection between the two materials, which is essential for building a solid foundation. Plus, it can save both time and money as there are fewer steps involved in the construction process.

However, as with any construction technique, there are also some downsides to keep in mind. One of the biggest concerns is moisture. Over time, the moisture within the concrete can cause the wood to deteriorate, leading to a weaker connection and potential problems down the line. Additionally, if the wood is not properly treated or sealed, it can be vulnerable to insect infestations.

Another challenge of attaching wood directly to concrete is that it can be difficult to remove or replace if necessary. Once attached, it may be challenging to remove without damaging either the wood or the concrete surface, making repairs or modifications more challenging and costly.

To ensure a strong and lasting connection between these two materials, proper preparation, treatment, and maintenance are crucial. Choosing an adhesive that matches your concrete’s porosity level is essential for ensuring a sturdy and long-lasting attachment between wood and concrete. Also, treating the wood with an appropriate sealer or preservative can help protect against moisture damage and insect infestations.

Methods for Attaching Wood Directly to Concrete

There are three common methods that you can use: concrete screws, anchor bolts, and adhesive. Each one has its own set of advantages and disadvantages, so it’s essential to choose the one that best suits your specific needs.

Adhesive Method

This approach involves using a powerful adhesive, such as epoxy, to bond the two materials together. However, before applying the adhesive, it is crucial to prepare both surfaces by ensuring they are clean, dry, and free of any dust or debris. This will ensure that the bond between the wood and concrete is strong and long-lasting.

To apply the adhesive, use a notched trowel to spread it evenly over the surface of the concrete. Then, press the wood firmly into place on top of the adhesive. Be sure to double-check that the wood is level and in the correct position before allowing the adhesive to dry.

Once dry, the adhesive forms an unyielding bond between the wood and concrete that can withstand heavy loads and provide reliable support. This method is commonly used in construction projects where wood framing needs to be attached directly to a concrete foundation.

However, it is essential to note that not all adhesives are suitable for this purpose. It’s important to choose an adhesive specifically designed for attaching wood directly to concrete and follow the manufacturer’s instructions carefully. Failure to do so could result in a weak bond that may not hold up over time.

Mechanical Anchors Method

The mechanical anchors method is a fantastic solution that offers a reliable and long-lasting connection. By using screws, bolts, or other fasteners, this method provides a secure hold that can withstand heavy loads.

But selecting the correct type of anchor is crucial for successful installation. With wedge anchors, sleeve anchors, and drop-in anchors being just a few options, it’s essential to choose the right one based on your specific needs. Whether you’re anchoring a fence post or mounting a shelf, there’s an anchor type appropriate for the job.

Properly preparing the concrete surface is also essential. Cleaning the surface thoroughly and drilling holes to the correct depth and diameter ensures that the anchor fits snugly and creates a secure connection. By taking these precautions, you’ll avoid any risk of loosening or detachment over time.

When it’s time to install the anchors, following the manufacturer’s instructions carefully will guarantee optimal results. This includes drilling precise holes and using the correct tools for the job. With this method, there’s no room for shortcuts or guesswork.

Protective Barriers Between the Wood and the Concrete

When it comes to attaching wood to concrete, you want to make sure you’re doing it right. But did you know that using protective barriers between the two surfaces is just as important as using the right tools? Here’s why.

Moisture is wood’s worst enemy. When wood is exposed to moisture, it can lead to serious damage, such as rot or warping, which can weaken the structure of your project. That’s where protective barriers come in.

There are a few different types of protective barriers you can use, such as plastic sheeting, roofing felt, and foam insulation. Plastic sheeting and roofing felt are easy to find and install, while foam insulation may require a bit more effort but offers excellent protection against moisture.

Protective barriers don’t just prevent moisture from seeping into the wood; they also create a barrier between the two surfaces, reducing noise transmission and vibration. This is especially important if you’re working on a building where sound insulation is key, like an office or apartment building.

Benefits of Using an Alternative Method for Attaching Wood to Concrete

There’s a better solution that saves time and effort while also providing a stronger bond – adhesive anchors or epoxy glue.

One of the most significant benefits of using adhesive anchors or epoxy glue is that it eliminates the need for drilling and screwing, saving you precious time and effort. Additionally, this method reduces the risk of damaging the concrete surface, ensuring a smooth and flawless finish.

But that’s not all – adhesive anchors or epoxy glue also create a stronger bond between the wood and concrete than screws. This means your project will have increased stability and durability, even in harsh weather conditions.

Another great advantage of using adhesive anchors or epoxy glue is the flexibility it provides in design. With screws, you’re limited to specific locations and angles for attaching the wood. However, with adhesive anchors or epoxy glue, you can attach the wood anywhere you want, even at different angles. This opens up a whole new world of possibilities for your project, allowing you to unleash your creativity.

And let’s talk about aesthetics. With no visible screws or bolts, your finished project will have a sleek and modern look that blends the wood into the concrete surface seamlessly. The result is a visually pleasing and polished final product that is sure to impress.

5cp-ZsLZQnk” >

Conclusion

To sum up, attaching wood directly to concrete is possible with the right materials and techniques. However, it’s crucial to consider several factors before starting the project. Choosing the appropriate type of wood, understanding the attachment process, and planning for potential issues are all key steps.

When selecting the wood for your project, pressure-treated lumber works best for outdoor projects exposed to moisture. On the other hand, hardwoods like oak or maple are suitable for indoor projects that won’t be exposed to moisture. Avoid softwoods like pine or spruce when attaching directly to concrete.

Porosity is another important factor since different types of concrete have varying degrees of porosity that affect adhesion. Moisture is always a concern when attaching wood directly to concrete, so using a moisture barrier between the two surfaces is necessary.

There are three common methods for attaching wood directly to concrete: adhesive glue, mechanical anchors, and screws. Each method has its advantages and disadvantages depending on specific project requirements.

To protect against moisture seeping into the wood and reduce noise transmission and vibration, use protective barriers between the wood and concrete. Adhesive anchors or epoxy glue can provide a stronger bond than screws while eliminating the need for drilling and screwing.