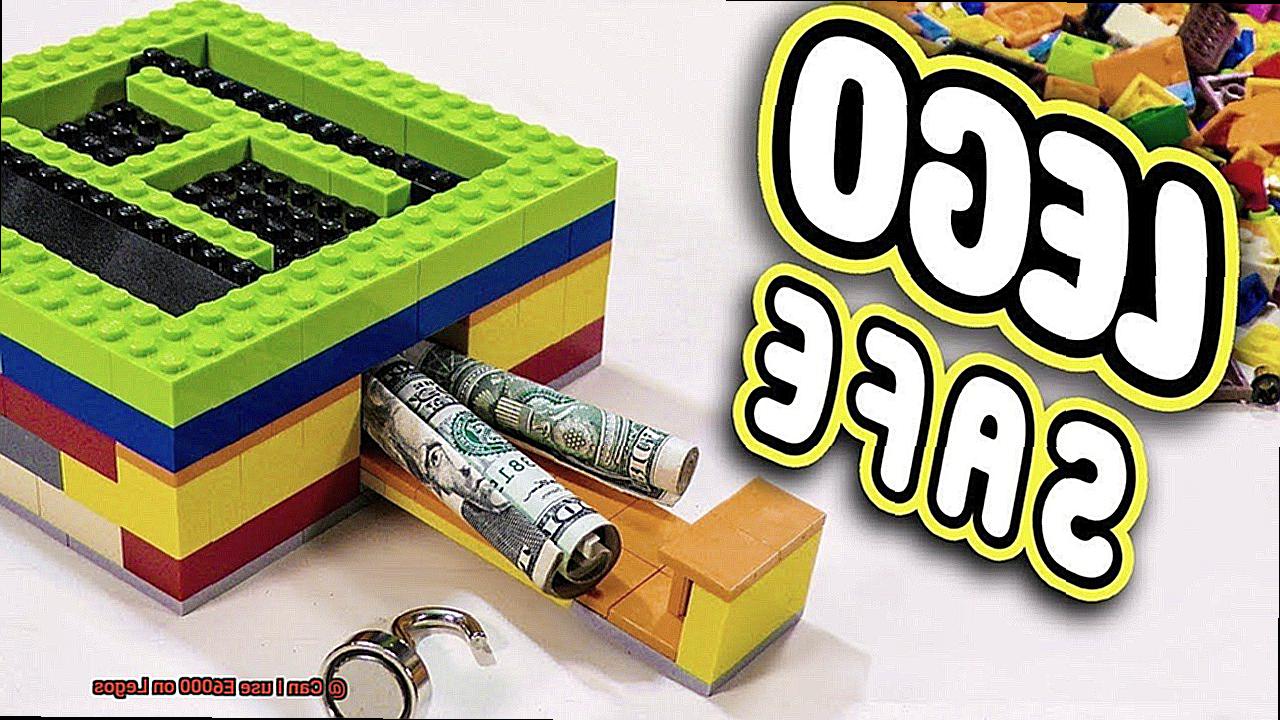

Picture this: you’ve just spent hours meticulously constructing an epic Lego masterpiece, only to have it tragically crumble before your eyes. We’ve all been there, and it’s a heart-wrenching experience. But fear not, my friends, because I’m about to introduce you to a game-changing solution: E6000 adhesive.

Now, I know what you’re thinking. Glue on Legos? Isn’t that sacrilege? Well, hear me out. E6000 adhesive has become the secret weapon of many seasoned Lego builders. This stuff is no ordinary glue; it’s like the superhero of adhesives. With its industrial-strength power, it can work wonders on those broken Lego pieces and give them a new lease on life.

Let’s talk about the pros of using E6000 on Legos because they are seriously impressive. This adhesive forms an unbreakable bond that will keep your creations intact for years to come. It doesn’t discriminate either – whether you’re dealing with plastic, metal, or even glass pieces in your Lego world, E6000 has got you covered. And get this: it’s waterproof and resistant to temperature changes too. So go ahead and proudly display your masterpieces without worrying about them melting or disintegrating in the rain or heat.

But hold your horses. Before you run off to grab a tube of this magical adhesive, there are a few things you need to consider. Not all Lego pieces are compatible with E6000. Transparent or translucent bricks may suffer from visible residue or discoloration if you use this glue on them. And here’s another thing – once E6000 dries, it becomes firm and rubbery. That means repositioning or disassembling becomes quite the challenge.

If you’re still keen on giving E6000 a shot (and who wouldn’t be?), here are some tips and advice to make your Lego repairs a success. Use the adhesive sparingly – a little goes a long way, my friends. You don’t want glue oozing out and ruining the aesthetics of your creation. Take your time to align the pieces perfectly before the adhesive sets because once that bond forms, there’s no turning back.

And please, take caution when handling E6000. It contains chemicals that can irritate your skin, so work in a well-ventilated area and consider rocking some gloves to protect those precious hands of yours.

What is E6000?

Contents

- 1 What is E6000?

- 2 What are Legos Made Of?

- 3 Is E6000 Suitable for Legos?

- 4 Potential Risks of Using E6000 on Legos

- 5 Safety Considerations When Using E6000 on Legos

- 6 Alternatives to E6000 for Bonding Legos

- 7 Testing the Adhesive on a Small Area First

- 8 Final Considerations Before Using E6000 on Legos

- 9 Conclusion

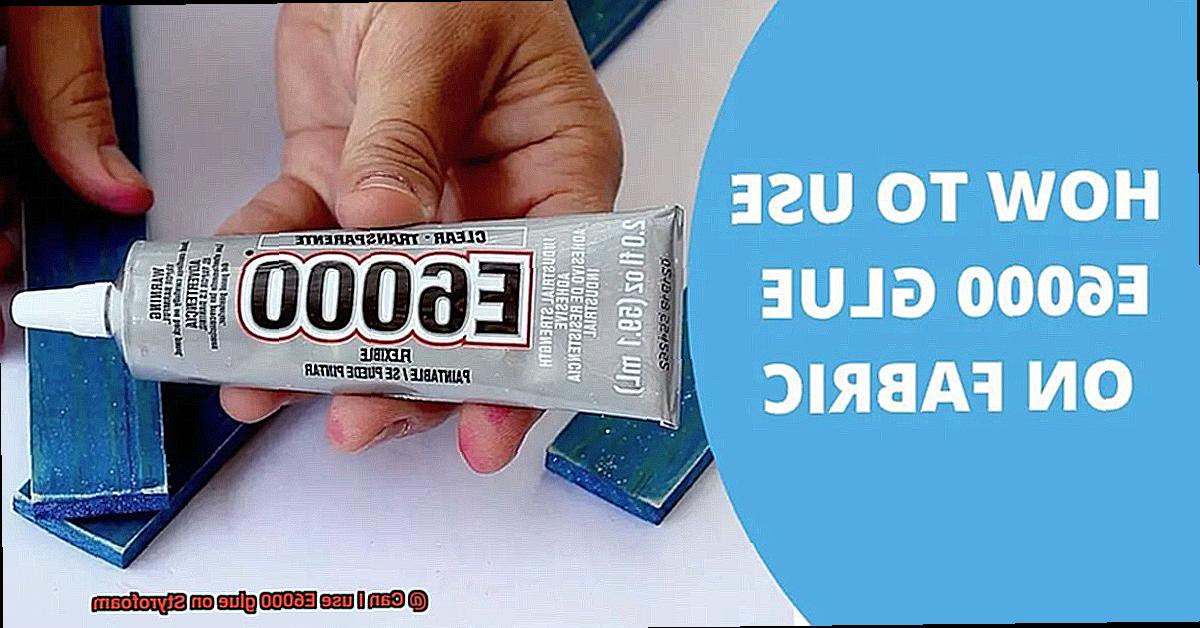

Crafting and DIY projects require an adhesive that can withstand the test of time, bond various materials, and meet the demands of different conditions. Look no further than E6000 – the adhesive that checks all the boxes and has become a staple in the crafting community.

Manufactured by Eclectic Products Inc., E6000 is a high-performance industrial adhesive that has gained popularity among hobbyists and professionals alike. Its versatility is unmatched, as it can bond plastics, metals, glass, wood, fabric, ceramics, and more. From jewelry-making to home decor projects, E6000 has proven to be a reliable companion.

One of the standout features of E6000 is its flexibility. Unlike other adhesives that become rigid once cured, E6000 remains pliable. This unique characteristic allows for slight movement or stress without compromising the bond. Whether you’re creating a delicate piece of jewelry or repairing a cherished item, E6000 ensures longevity.

In addition to its flexibility, E6000 boasts resistance to water, chemicals, and temperature fluctuations. Whether your project will brave the elements outdoors or come in contact with liquids, this adhesive won’t let you down. It has the strength to endure varying weather conditions without losing its adhesive properties.

However, it’s important to note that while E6000 offers exceptional bonding strength and versatility, safety precautions should be taken when using it. The adhesive emits potent fumes during application and curing, so it’s best to work in a well-ventilated area or wear a protective mask. Furthermore, E6000 contains chemicals that may cause skin irritation or allergic reactions. Wearing gloves and avoiding direct skin contact is paramount.

Now let’s address an intriguing question: Can you use E6000 on Legos? While E6000 can bond to ABS plastic, which is what Legos are made of, it may not be the optimal choice for this specific application. E6000 forms a permanent bond once cured, making it challenging to disassemble or reconfigure Legos in the future. It may also leave behind residue or marks on the Lego surfaces, impacting their appearance.

For strong and suitable adhesion with Legos, consider alternatives specifically designed for bonding plastic materials. Plastic cement or specialized Lego-compatible adhesives provide safer and more appropriate solutions without compromising structural integrity or aesthetics.

What are Legos Made Of?

Prepare to embark on a journey through the materials that bring Legos to life.

At the heart of every Lego brick lies a powerful plastic known as ABS, or Acrylonitrile Butadiene Styrene. This durable and robust material is a favorite among toy manufacturers due to its exceptional impact resistance. ABS can withstand the most vigorous play sessions and accidental tumbles without succumbing to breakage easily.

Now, let’s delve into the mesmerizing production process of these iconic bricks. Molten ABS plastic is injected into molds that shape the Lego bricks we know and love. As the plastic cools and hardens, it transforms into solid and perfectly interlocking pieces. The precision of this manufacturing technique allows Lego enthusiasts to effortlessly construct intricate structures and captivating designs.

But wait, there’s more to this enchanting tale. The ABS plastic used in Lego bricks is carefully formulated to possess remarkable properties. Its flexibility, strength, and vibrant colors ensure that each brick not only serves its functional purpose but also dazzles the eye. A world of creativity awaits within the vivid hues and dynamic shapes of Lego bricks.

Although ABS takes center stage, certain Lego sets feature additional materials that amplify their functionality and playability. Rubber tires for realistic movements or metal axles and gears for mechanical wonders are just a glimpse into the possibilities that await in these ingenious sets.

Now, let’s address a vital aspect: safety. Rest assured, Lego places paramount importance on ensuring their products meet stringent quality standards and comply with international safety regulations. The ABS plastic used in Lego bricks undergoes rigorous testing to guarantee its reliability, allowing you to indulge in your building adventures with complete peace of mind.

Is E6000 Suitable for Legos?

After all, E6000 is known for its strong bond and versatility. But before you break out the glue gun, it’s important to understand the potential risks involved.

One concern with using E6000 on Legos is the mess factor. This adhesive is thick and viscous, which means it can easily seep out from between the Lego pieces. Not only does this leave behind a visible residue, but it can also make your masterpiece look sloppy and unprofessional.

Another drawback is the long-term durability of the bond. While E6000 may initially hold your Lego pieces together, it may not withstand the stress and movement that Legos are often subjected to during play. Imagine spending hours building an intricate structure, only to have it fall apart after a few days of rough play. It’s a heartbreaking scenario that could easily be avoided by using a more suitable adhesive.

Furthermore, using E6000 adhesive on Legos can make it difficult to disassemble and reassemble the pieces later on. Legos are designed to be easily taken apart and reconfigured, but using a strong adhesive like E6000 could make this process challenging or even impossible. So if you’re someone who enjoys the flexibility and creativity that Legos offer, gluing them together may not be the best choice.

It’s also worth noting that using an adhesive on Legos may void any warranties or guarantees provided by the manufacturer. Lego sets often come with instructions for assembly and disassembly, and altering the pieces with glue could potentially void these instructions.

Potential Risks of Using E6000 on Legos

One of the main concerns is the presence of harmful chemicals in E6000, such as toluene. This toxic substance can be dangerous if inhaled or ingested, posing a risk to both the user and anyone who comes into contact with the Legos. It is crucial to exercise caution and work in a well-ventilated area when using this adhesive.

Furthermore, there is a possibility that the chemicals in E6000 can seep into the plastic of the Legos, potentially causing damage or weakening the structure of the bricks. This can lead to a decrease in the overall stability and durability of any constructions made with glued Legos. Nobody wants their carefully constructed Lego masterpiece to crumble into pieces due to weakened bricks.

In addition, using E6000 on Legos may make disassembling your creations a real challenge. The strong bonding properties of this adhesive can make it almost impossible to separate the bricks without causing damage. This can be frustrating for those who enjoy the versatility and creative freedom that Legos provide, as it limits their ability to rebuild and modify their designs.

Another risk to consider is the possibility of E6000 leaving behind residue or marks on your Lego pieces. This can alter their appearance and potentially reduce their value, especially if you have rare or collectible sets. Additionally, using an adhesive like E6000 on Legos could void any warranties or guarantees provided by the manufacturer, as it goes against their intended use.

It’s also worth noting that while E6000 may provide a strong bond initially, it may deteriorate over time due to exposure to sunlight, humidity, or temperature changes. This means that the glued Legos may not maintain their strength and stability in the long run.

Lastly, safety should always be a top priority. When using E6000 on Legos, it’s important to work in a well-ventilated area, as inhaling the fumes can be harmful. Additionally, keep this adhesive out of reach of young children to prevent any accidental ingestion.

Safety Considerations When Using E6000 on Legos

When it comes to using E6000 glue on Legos, safety considerations are paramount to ensure a smooth and risk-free crafting experience. This powerful adhesive can be a game-changer for your Lego creations, but it’s essential to take precautions before diving into this sticky adventure.

Ventilation is a crucial aspect to address when working with E6000. Unlike your average glue, E6000 emits strong fumes that can be potentially harmful if inhaled excessively. To protect yourself from these chemical vapors, make sure you’re working in a well-ventilated area. If adequate ventilation isn’t possible, consider wearing a respirator mask to keep those potent fumes at bay.

Skin contact is another safety concern when using E6000. This adhesive can cause irritation and allergic reactions in some individuals. To safeguard your skin, it’s best to avoid direct contact with the glue. Wearing gloves is highly recommended to protect your hands and maintain their softness and smoothness.

Keep in mind that E6000 should be kept out of reach from children and pets. This adhesive is not meant to be ingested and can be toxic if swallowed. Store it in a secure location where curious little hands or paws cannot access it.

When applying E6000 on your precious Legos, follow the instructions provided by the manufacturer diligently. Remember, less is more – use only the recommended amount of glue and apply it evenly onto the surfaces you want to join. Excessive glue can seep into the Lego pieces and potentially impact their functionality.

Exercise patience when working with E6000. While it may bond relatively quickly, allowing your glued Lego pieces to cure for at least 24 hours will result in a stronger bond. It can be tempting to play with your creation right away, but trust me, waiting will yield better results in the end.

Lastly, exercise caution when using any adhesive on Legos or other plastic materials. Certain adhesives can cause damage or discoloration to specific types of plastics. Before fully committing to E6000, test a small and inconspicuous area first to ensure compatibility and avoid any unpleasant surprises.

Alternatives to E6000 for Bonding Legos

We know that building with Lego bricks is an exhilarating and immersive experience. However, finding the right adhesive to bond those bricks together can be quite a challenge. While E6000 glue is popular for its strength and versatility, it may not be the best choice for bonding Legos. In this article, we will explore some alternative options that are both safer and more suitable for your Lego creations.

Option 1: Plastic-Specific Glues

When it comes to bonding plastic surfaces, consider using adhesives specifically designed for plastic, such as Loctite Plastics Bonding System or Testors Plastic Cement. These specialized glues are formulated to effectively bond plastic without causing any damage. With these glues, you can confidently create intricate Lego structures knowing that your bricks will securely hold together.

Option 2: Cyanoacrylate Adhesives

Another excellent alternative is super glue, also known as cyanoacrylate adhesive. Super glue works wonders on plastic surfaces and provides a strong bond. However, it’s important to use it sparingly as excessive amounts can make the bricks brittle. By applying just a small amount, you can ensure a secure connection between your Lego pieces.

Option 3: Double-Sided Adhesive Tapes

For temporary bonds or repositionable purposes, double-sided adhesive tapes can be a game-changer. Consider using Scotch Mounting Tape or 3M Command Strips. These tapes provide a strong hold while allowing you to easily remove and reposition your Lego bricks whenever necessary. They are perfect for those who love to experiment and build different creations.

Option 4: Silicone-Based Adhesives

If you prefer non-toxic and flexible alternatives, silicone-based adhesives like Goop Craft Glue or Aleene’s Original Tacky Glue are worth considering. These adhesives are safe to use on Legos and provide a strong bond without damaging the plastic bricks. Plus, they remain flexible once they set, ensuring your Lego creations can endure some rough play.

Testing the Adhesive on a Small Area First

Before you break out the E6000 glue, let’s talk about why it’s absolutely crucial to test the adhesive on a small area first. Trust me, you’ll thank me later.

Different adhesives can have different effects on various surfaces, and when it comes to our beloved Legos, we definitely don’t want any damage or alterations. That’s where testing the adhesive on a small area comes into play. It allows us to ensure that it won’t wreak havoc on our precious bricks.

So, how do we conduct this all-important test? Start by selecting a small and inconspicuous piece of Lego. This could be a spare brick or a less important part of your Lego creation. Apply a small amount of E6000 adhesive to the chosen Lego piece, making sure to follow the manufacturer’s instructions for proper application.

Now, here comes the hard part – patience. Allow the adhesive to dry completely according to the recommended drying time. This will give you an accurate assessment of how the adhesive will behave when fully cured.

Once the glue has dried, it’s time for inspection. Take a close look at the Lego piece and carefully check for any signs of damage or discoloration. Keep an eye out for changes in appearance or texture of the Lego surface. If everything looks good so far, it’s time to put the bond to the test.

Gently try to separate the glued Lego piece from another Lego piece. Apply some force and see if the bond holds strong or if it easily comes apart. This will give you a clear idea of the adhesive’s strength and effectiveness when it comes to Legos.

But hold on just a moment. Before you go gluing your entire Lego creation together based solely on this small test, there’s something important to remember. Even if the adhesive works well on a small scale, it doesn’t guarantee the same results on a larger scale. Factors like weight, stress, and environmental conditions can affect the adhesive’s performance. So, always exercise caution and conduct thorough testing before going all-in.

By testing the adhesive on a small area first, you minimize the risk of damaging your precious Lego pieces or compromising the structural integrity of your creations. It gives you the confidence to move forward with your glue choice or explore alternative options if needed.

Final Considerations Before Using E6000 on Legos

Before you embark on the journey of using E6000 to glue your Legos together, it’s important to consider a few final factors that could potentially impact the outcome. We all want our Lego creations to stand the test of time, so let’s delve into these considerations before reaching for that adhesive.

First and foremost, it’s crucial to understand that while E6000 is a strong adhesive that can bond various materials like plastic, metal, and fabric, it is not specifically designed for use with Legos. Legos are made of ABS plastic, and there is a chance that E6000 may not bond well with them. This means you could be risking damage or weakening of your precious Legos, which could lead to potential structural issues or breakage. And let’s face it, no one wants to see their masterpiece fall apart.

Another aspect to keep in mind is the strong odor and volatile organic compounds (VOCs) present in E6000. These fumes can be harmful if inhaled, so it’s imperative to use the adhesive in a well-ventilated area and minimize prolonged exposure to the fumes. Safety should always be a top priority.

Removing E6000 from Legos can also pose a challenge. Once applied, this adhesive forms a strong bond that can be quite stubborn to undo without causing damage. So, if you change your mind or want to reconfigure your creation, you might find yourself in a sticky situation (pun intended).

If you’re still determined to give E6000 a shot (no judgment here), I recommend conducting a small-scale test first. Choose a discreet Lego piece and carefully follow the manufacturer’s instructions for applying and drying times. Afterward, inspect for any signs of damage or discoloration. You can also test the bond by attempting to separate the glued piece from another with some gentle force.

However, bear in mind that even if everything looks good in this mini-test, it does not guarantee the same results on a larger scale. Factors like weight, stress, and environmental conditions can significantly affect the adhesive’s performance. Therefore, it’s essential to exercise caution and conduct thorough testing before committing to using E6000 on your entire Lego creation.

Lastly, before you dive into E6000, consider specialized Lego adhesives that are designed specifically for bonding Legos without damaging the plastic. These alternatives are often water-based, provide a strong bond, and still allow for disassembly if desired. It might be worth exploring these options before resorting to E6000.

lrDSayG_ymE” >

Conclusion

In conclusion, it is not recommended to use E6000 on Legos.

This adhesive may provide a strong bond, but it can also damage the plastic and leave permanent marks. Instead, it is best to use Lego-approved adhesives or rely on the interlocking design of the bricks for stability.

So, resist the temptation to reach for the E6000 and embrace a safer approach when working with Legos.