Ready to dive into the exciting realm of adhesive magic? Today, we’re here to unravel the mystery of using E6000 glue on Styrofoam. Get ready for a wild ride as we debunk myths and shed light on this powerful combo.

Styrofoam, that lightweight wonder material, has endless possibilities in crafting, model-making, and even home insulation. But finding the right glue? Talk about a headache. Fear not, because E6000 glue is here to save the day. This household superstar is known for its incredible strength and versatility.

In this all-inclusive guide, we’ll explore whether E6000 glue is a match made in heaven for your Styrofoam projects. We’ll bust common misconceptions and arm you with practical tips to ensure your bonding success. Get ready to unleash your creativity and take your crafty creations to new heights.

Whether you’re a seasoned pro searching for adhesive alternatives or a newbie venturing into Styrofoam crafts, join us as we unlock the wonders of E6000 glue on Styrofoam. Let’s get sticking.

Understanding the properties of E6000 glue

Contents

- 1 Understanding the properties of E6000 glue

- 2 Exploring the properties of Styrofoam

- 3 The concerns about using E6000 glue on Styrofoam

- 4 Experiences with using E6000 glue on Styrofoam

- 5 Tips for using E6000 glue on Styrofoam safely

- 6 Testing compatibility between E6000 glue and different types of Styrofoam

- 7 Alternative adhesive options for bonding Styrofoam

- 8 Precautions when working with E6000 glue and Styrofoam

- 9 Conclusion

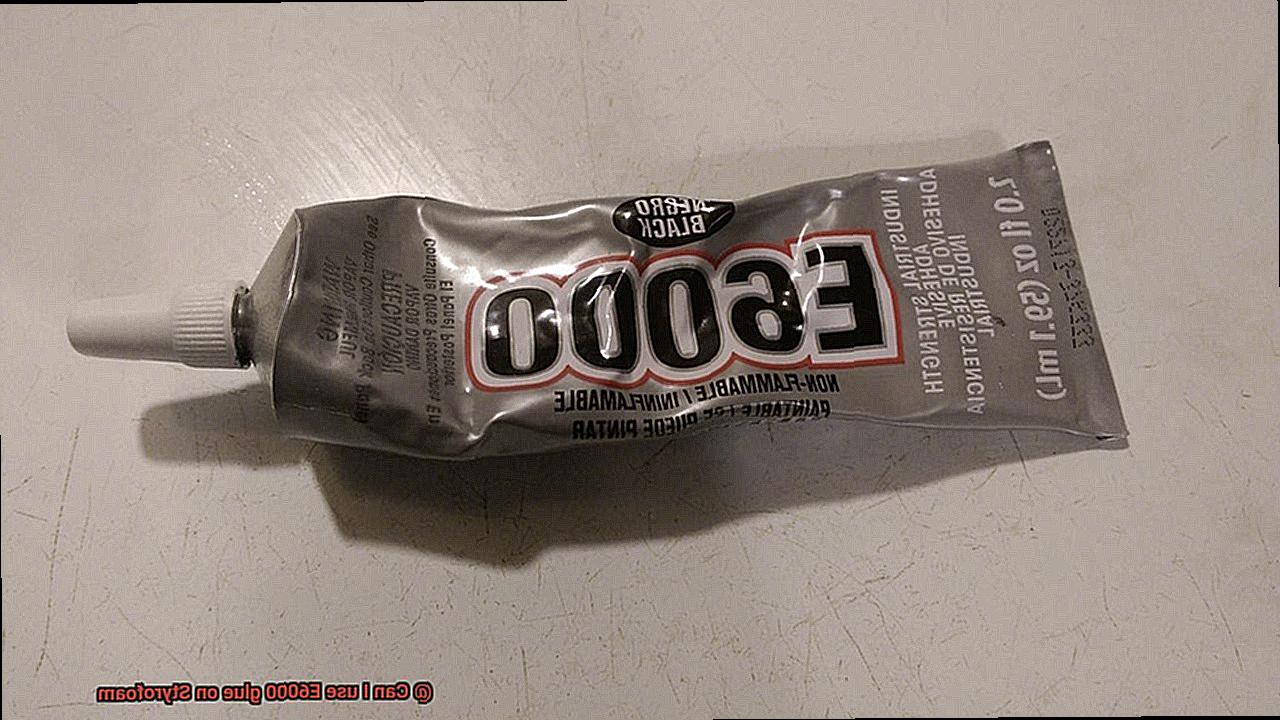

This adhesive powerhouse is a versatile wonder, renowned for its ability to create strong bonds that can withstand the test of time. Let’s dive into the captivating world of E6000 glue and explore its remarkable features.

First and foremost, E6000 glue boasts an impressive ability to bond to an array of materials. Whether you’re working with metal, wood, glass, fabric, or plastic, this adhesive will firmly unite them all. It becomes your steadfast companion for a multitude of crafts, repairs, and DIY endeavors.

But that’s not all—E6000 glue is not just versatile, it’s also highly flexible and durable. Once it sets, it forms an unyielding bond that laughs in the face of vibrations, impact, and extreme temperatures. No matter what challenges your projects face, they will remain intact and unphased.

In addition to its resilience, E6000 glue goes above and beyond with its clear and flexible drying process. Unlike other adhesives that dry hard and rigid, E6000 glue dries clear and retains its flexibility even after curing. This means you can infuse your projects with movement or flexibility without jeopardizing the bond. It’s like giving your creations the freedom to dance with grace.

To further solidify its brilliance, E6000 glue is also waterproof once fully cured. Rain or shine, indoor or outdoor, your projects are safe from the relentless onslaught of moisture. Whether you’re fixing outdoor decor or crafting a water-resistant masterpiece, E6000 glue has got your back—no leaks can penetrate its mighty grip.

Now, it’s important to mention that E6000 glue does come with a powerful odor. But fear not. Just make sure to work in a well-ventilated area or don a mask to conquer any olfactory challenges that may arise.

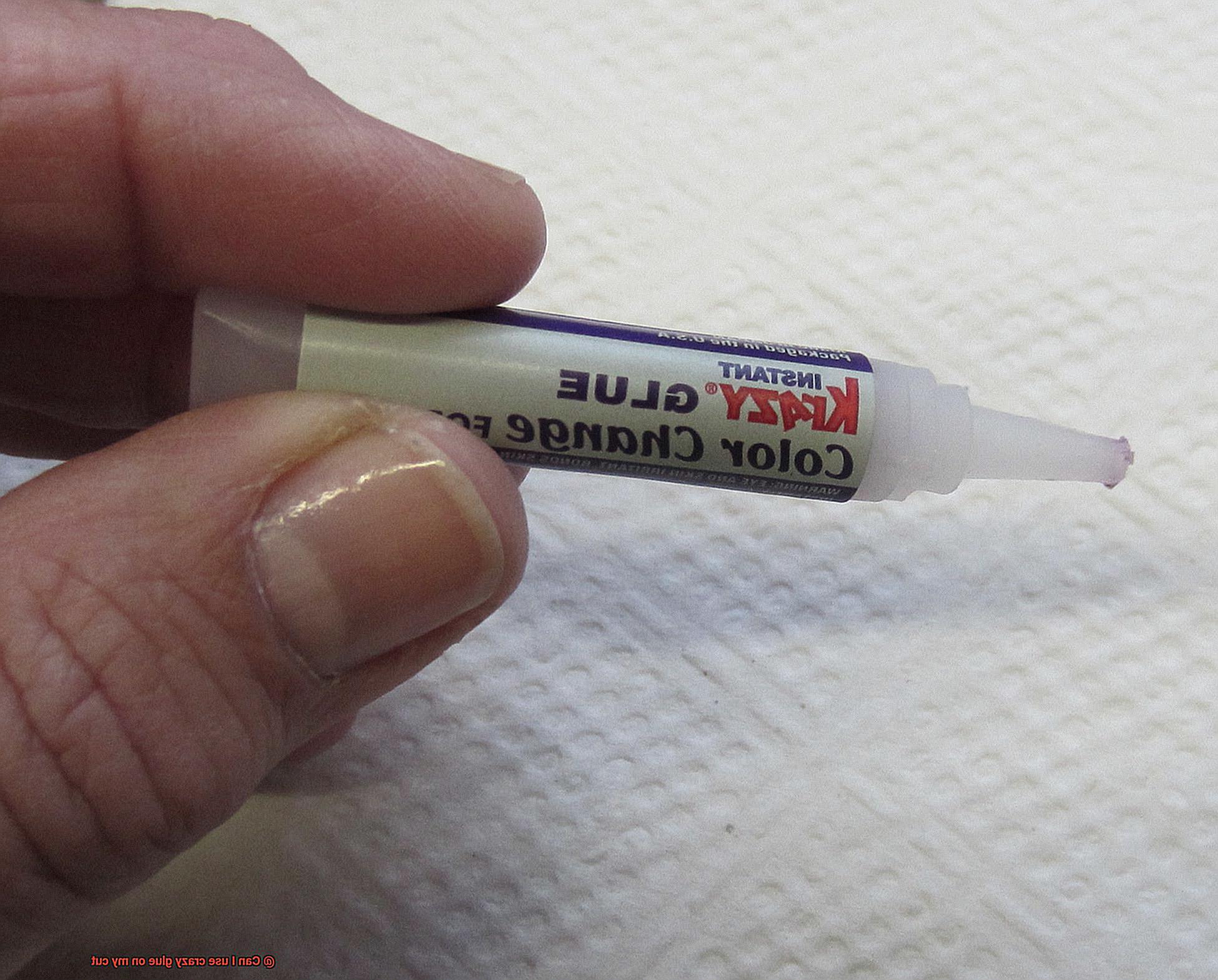

However, there is one thing to be cautious about—E6000 glue should never be used on polystyrene foam or Styrofoam. The potent chemicals in the adhesive can cause the foam to dissolve or melt, resulting in a sticky situation you’d rather avoid. Fear not, though, for specific adhesives designed for these materials, such as foam-safe glues or low-temperature hot glue guns, are available to provide a strong bond without causing harm.

Exploring the properties of Styrofoam

Step into a world of endless possibilities as we embark on an exploration of the extraordinary material known as Styrofoam. Its remarkable properties have made it a staple in crafting, packaging, and insulation. But before we dive into its creative potential, let us address a crucial question: which adhesive is safe and effective for bonding Styrofoam? Join us as we unravel the mysteries of adhesives, ensuring your projects stick together flawlessly without any unexpected mishaps.

Styrofoam’s Marvelous Properties:

Prepare to be amazed by the unparalleled characteristics of Styrofoam, also called expanded polystyrene (EPS). Its low density grants it an unmatched buoyancy, making it ideal for flotation devices and watercraft models.

Additionally, Styrofoam possesses exceptional thermal insulation properties, keeping our homes cozy and energy-efficient. With its resistance to moisture, this material becomes the perfect choice for food packaging and construction endeavors. And let’s not forget its lightweight nature, a dream come true for crafters seeking easy manipulation and limitless creativity.

The Glue Dilemma:

When it comes to bonding Styrofoam, caution is paramount. Certain adhesives may cause the foam to melt or dissolve due to their solvent content. We certainly don’t want our intricate projects turning into a pool of disappointment. Enter E6000 glue, renowned for its versatility and strong bonding capabilities. However, this adhesive contains solvents that react with polystyrene, compromising the foam’s structure and yielding a feeble bond. Thus, it is best to avoid using E6000 glue on Styrofoam.

Foam-Friendly Alternatives:

Fear not. Specialized adhesives designed explicitly for Styrofoam exist, ensuring robust bonds without harming the foam’s integrity. White craft glue proves to be a safe and reliable option, offering excellent bonding strength. For a quick-setting bond that poses no threat to Styrofoam, low-temperature hot glue emerges as a fantastic alternative. Meanwhile, foam-friendly spray adhesives step up to the plate for larger projects and surfaces, guaranteeing even application and secure bonds.

Don’t Skip the Test:

Before immersing yourself in your Styrofoam project, always remember the importance of a compatibility test. Apply a small amount of adhesive to an inconspicuous area of the foam and observe for any adverse reactions. This simple step ensures that the adhesive is compatible with your specific Styrofoam and eliminates any potential damage.

The concerns about using E6000 glue on Styrofoam

Attention all crafters and creators. Today, we’re tackling an issue that has left many in a sticky situation: can you safely use E6000 glue on Styrofoam? While this adhesive is renowned for its strength and versatility, it’s important to be aware of the potential risks and concerns associated with bonding it with Styrofoam. Join us as we dive into this topic and explore the hazards that come with this combination.

The Solvent Dilemma:

One of the primary concerns when using E6000 glue on Styrofoam is the presence of solvents in the adhesive. These solvents have the power to react with the foam, causing it to melt or disintegrate. Imagine your Styrofoam masterpiece reduced to a pile of goo. This is a risk that cannot be ignored.

Timing is Everything:

Another issue to consider is the curing time of E6000 glue. Unlike other specialized adhesives for Styrofoam, E6000 takes longer to fully bond. While the glue is drying, it may not provide sufficient support or adhesion, leading to potential shifting or separation of foam pieces. Don’t let all your hard work go to waste due to a weak bond.

The Right Tool for the Job:

When it comes to bonding Styrofoam, it’s essential to choose an adhesive specifically formulated for this purpose. While E6000 glue is versatile for other materials, it is not designed with Styrofoam in mind. Opting for a water-based adhesive that is free from harmful solvents will ensure a safer and more effective bond. Your Styrofoam creation will thank you for it.

Safety First:

Finally, let’s talk about your health. E6000 glue emits toxic fumes during the drying process, which can be harmful if inhaled excessively or over an extended period. It is crucial to always work in a well-ventilated area and take precautions to protect yourself from these fumes. Remember, crafting should be enjoyable and safe.

Experiences with using E6000 glue on Styrofoam

Crafters and creators, get ready to dive into the sticky world of using E6000 glue on Styrofoam. Experiences with this combination can be quite the rollercoaster ride, so let’s take a closer look at what users have to say.

On one hand, there are those who swear by the bond created when using E6000 glue on Styrofoam. They claim that this adhesive adheres well to the surface and creates a strong bond that can withstand the test of time. To achieve this, they recommend applying a thin layer of the glue onto the Styrofoam, allowing it to dry for a few minutes until it becomes tacky, and then firmly pressing the two surfaces together. For maximum strength, it’s advised to hold them together for at least 24 hours.

Some crafters even suggest roughening the surface of the Styrofoam with sandpaper before applying the glue. This extra step provides more texture for the glue to grab onto, resulting in a stronger and more reliable bond. Sounds promising, right?

However, there’s another side to this story. Some users have had negative experiences when using E6000 glue on Styrofoam. They’ve reported that the glue can eat away or dissolve the Styrofoam, causing it to melt or deform. Talk about a sticky situation.

To avoid this potential disaster, these users caution against using E6000 glue directly on Styrofoam. Instead, they recommend seeking alternative adhesives that are specifically designed for foam materials. After all, it’s better to be safe than sorry when it comes to preserving your precious creations.

Now, here’s something important to consider: E6000 glue contains chemicals that may not be compatible with all types of Styrofoam. Different brands or formulations of Styrofoam may have varying levels of resistance to certain chemicals. So, it’s wise to conduct a small test before going all in.

Apply a small amount of glue on an inconspicuous area of the Styrofoam and observe any reactions or changes over time. If the glue causes any adverse effects, like melting or deforming the Styrofoam, it’s best to say goodbye to E6000 and explore foam-friendly alternatives.

Ultimately, the decision of whether to use E6000 glue on Styrofoam is up to you. Some users have had success, while others have encountered issues. It’s important to evaluate the potential risks and conduct thorough research before diving in.

Tips for using E6000 glue on Styrofoam safely

E6000 glue is a versatile adhesive known for its strong bond, making it an excellent choice for bonding materials like Styrofoam. However, to ensure safe and effective bonding, there are crucial safety tips to consider. In this article, we will provide you with five essential safety tips to use E6000 glue on Styrofoam effectively and securely.

Work in a Well-Ventilated Area:

When using E6000 glue on Styrofoam, it’s vital to work in a well-ventilated area. The glue releases fumes that can be harmful if inhaled in large quantities. To protect yourself, open windows or use a fan to ensure proper air circulation. This will minimize your exposure to the fumes and create a safe working environment.

Use Gloves and Protective Eyewear:

E6000 glue contains chemicals that can irritate your skin and eyes. To avoid any direct contact with the glue, it is essential to wear gloves and protective eyewear while handling it. These simple precautions will prevent skin irritation or any other adverse reactions, ensuring your safety throughout the bonding process.

Thoroughly Clean the Styrofoam Surface:

Before applying E6000 glue, it is crucial to clean the surface of the Styrofoam thoroughly. Any dirt, dust, or oils on the surface can prevent the glue from adhering properly. Gently clean the surface using a mild soap and water solution, then dry it completely before applying the glue. This ensures a clean and smooth bonding surface, promoting strong adhesion.

Apply a Thin Layer of Glue:

Less is more when using E6000 glue on Styrofoam. It is recommended to apply a thin layer of glue onto the surfaces you want to bond using a small brush or toothpick. Avoid applying too much glue as it can create excess bulk and may not dry properly. A thin layer will provide sufficient adhesion without compromising the integrity of the Styrofoam.

Allow Sufficient Drying Time:

To achieve a strong bond, it is essential to allow the glue to dry completely before handling or moving the glued pieces. The drying time can vary depending on factors such as temperature and humidity, so it is best to follow the manufacturer’s instructions. Rushing the drying process can compromise the bond and result in a weaker hold. Patience is key to ensuring a secure and long-lasting bond.

Testing compatibility between E6000 glue and different types of Styrofoam

If you’ve ever wondered about the ideal way to bond Styrofoam using this beloved adhesive, you’ve come to the right place.

To grasp the significance of testing compatibility, let’s first understand why it matters. Styrofoam comes in two primary forms: extruded polystyrene (XPS) and expanded polystyrene (EPS). These materials possess varying densities and flexibilities, resulting in different reactions to E6000 glue.

Now, let’s dive into the testing process. To determine compatibility, it’s best to conduct a small-scale experiment. Cut small pieces of each Styrofoam type and apply a tiny amount of E6000 glue onto each piece. Allow them to dry completely according to the manufacturer’s instructions, and then observe any changes in appearance or texture.

If you notice signs of melting, warping, or disintegration, it’s a clear indication that the glue isn’t compatible with that particular Styrofoam type. This is because E6000 glue contains solvents like toluene and acetone that can react with the polystyrene material.

Of course, it’s also important to consider the intended use of your glued Styrofoam. If it’s for decorative purposes or non-load-bearing applications, compatibility may not be as critical. However, for structural or weight-bearing projects, it’s advisable to use adhesives specifically designed for Styrofoam or polystyrene materials.

In some cases, applying a primer or barrier coat to the Styrofoam before using E6000 glue can help protect the material from solvent damage and improve the bond. Just make sure to test the primer on a small piece of Styrofoam first to ensure compatibility.

If you’re still concerned about using E6000 glue on Styrofoam, fear not. There are alternative adhesives available that are specifically formulated for bonding Styrofoam and other polystyrene materials. These adhesives are usually water-based or foam-safe, ensuring compatibility and a strong bond without damaging the Styrofoam.

Alternative adhesive options for bonding Styrofoam

Well, your search ends here. In this article, we will explore a range of alternative adhesive options specifically designed for Styrofoam, ensuring a strong and durable bond without causing any damage.

Let’s start with the holy grail of Styrofoam adhesives: styrofoam adhesive. This specially formulated adhesive comes in a convenient spray form, allowing for easy and even application onto the foam’s surface. With its superior strength, it is perfect for various DIY projects involving Styrofoam, ensuring your creations withstand the test of time.

Next up on our list is the ever-reliable epoxy glue. Renowned for its exceptional strength and versatility, epoxy glue can also be used to bond Styrofoam. To ensure optimal results, select a low-viscosity epoxy with a longer working time. This enables the adhesive to fully penetrate the foam, creating an unbreakable bond that will not disappoint.

If you’re in need of an adhesive that fills gaps and voids, look no further than polyurethane adhesive. As this adhesive cures, it expands, seamlessly filling any imperfections in the foam and providing a robust bond. However, exercise caution when applying polyurethane adhesive—too much expansion can distort or even break the foam. Apply a thin layer and watch it work its magic.

For those seeking a quick and easy solution, hot glue is a viable option. Offering a fast-setting bond, hot glue is ideal for smaller projects or temporary bonds. However, keep in mind that hot glue may not provide the same level of durability as other adhesives—so use it wisely.

Silicone adhesive and construction adhesive are also alternative options worth considering. But before committing to these adhesives, it’s essential to conduct a small test on an inconspicuous part of the foam. This precaution ensures a strong bond without any unwanted damage.

When selecting an alternative adhesive for bonding Styrofoam, always consider the specific requirements of your project and choose an adhesive that is compatible with the foam. This will guarantee a strong and long-lasting bond, bringing your Styrofoam creations to life.

Precautions when working with E6000 glue and Styrofoam

Embarking on a creative project with E6000 glue and Styrofoam can be an exciting and rewarding experience. However, it is crucial to approach this task with caution to ensure your safety and the success of your project. Let’s dive into the key precautions you should keep in mind:

- Breathe Easy: In order to safeguard your respiratory system, it is imperative to work in a well-ventilated area. The E6000 glue contains chemicals that can release fumes, so open those windows wide or utilize fans to improve air circulation. Alternatively, consider wearing a respirator mask to shield yourself from inhaling any potentially harmful fumes.

- Less is More: While E6000 glue is renowned for its unmatched adhesive power, excessive amounts can actually lead to disastrous outcomes. Too much glue can cause the Styrofoam to dissolve or warp, resulting in weak bonds or irreversible damage to your project. Apply a small amount of glue and ensure an even distribution for optimal results.

- Mind the Edges: When applying the glue, exercise caution near the edges of the Styrofoam. As the glue dries, it has the tendency to expand. If it reaches the edges, it can cause the Styrofoam to fracture or deform. To avoid these mishaps, apply the glue slightly away from the edges, providing a buffer zone of protection.

- Handle with Care: The E6000 glue has the potential to irritate your skin or trigger allergic reactions upon contact. It is vital to handle this adhesive with great care and avoid any skin contact. Should you accidentally come into contact with the glue, rinse the affected area immediately with soap and water.

- Glove Up: To further safeguard your hands from direct contact with the adhesive, wearing gloves is highly recommended when working with E6000 glue and Styrofoam. This additional layer of protection will minimize the risk of skin irritation or allergic reactions, ensuring a safer and more enjoyable crafting experience.

- Patience is Key: E6000 glue requires ample drying time for a robust bond to form. Rushing this process can result in weakened bonds or damage to your project. It is essential to allow the glued Styrofoam to dry completely before handling or moving it. Consult the manufacturer’s instructions for the recommended drying time, which typically falls around 24 hours.

kg7Z8m5rSjY” >

Conclusion

Yes, you can use E6000 glue on Styrofoam.

This versatile adhesive is known for its strong bond and can be a great choice for attaching various materials, including Styrofoam. However, it is essential to use the glue properly to ensure the best results.

Allow the glue to dry completely before handling or moving the glued items.