Got a plumbing project on your hands and wondering if you can glue PEX to copper?

You’re not alone in this puzzling predicament. Whether you’re a seasoned DIYer or a pro plumber, knowing how different piping materials can connect is crucial.

Copper has been the go-to for ages, thanks to its toughness and resistance to rust. But lately, PEX (cross-linked polyethylene) has stolen the spotlight with its bendiness and easy installation.

So let’s dive right in and see if these two can really bond.

What Are PEX and Copper?

Contents

- 1 What Are PEX and Copper?

- 2 Why Glue is Not Used for Joining PEX and Copper Pipes

- 3 Alternatives to Gluing for Connecting PEX and Copper Pipes

- 4 Crimping Method for Connecting PEX Pipes

- 5 Cinching/Clamp/Ring Method for Connecting PEX Pipes

- 6 Soldering Method for Connecting Copper Pipes

- 7 Compression Fitting Method for Connecting Copper Pipes

- 8 Transition Fittings for Joining Different Materials

- 9 Conclusion

PEX (cross-linked polyethylene) and copper pipes are two commonly used materials in plumbing systems. While PEX pipes offer flexibility and resistance to corrosion, copper pipes provide durability and high temperature resistance. In this article, we will explore the advantages and disadvantages of both materials, as well as the various methods of connecting them.

Advantages of PEX Pipes:

- Flexibility: PEX pipes exhibit remarkable flexibility, allowing for easy installation in tight spaces and around corners, minimizing the need for additional fittings.

- Corrosion Resistance: Unlike copper pipes, PEX pipes are highly resistant to corrosion. This preserves water quality and extends the lifespan of the plumbing system.

- Freeze Resistance: PEX pipes can expand without bursting, making them more resistant to freezing temperatures, reducing the risk of pipe damage in colder climates.

- Cost-Effective: PEX pipes are generally less expensive than copper pipes, making them a cost-effective option for plumbing projects.

Disadvantages of PEX Pipes:

- UV Sensitivity: PEX pipes should not be exposed to sunlight for extended periods as UV rays can degrade the material over time. Proper insulation or encasement is necessary when installing PEX pipes outdoors or in areas exposed to direct sunlight.

- Temperature and Pressure Limitations: Although suitable for most residential plumbing needs, PEX pipes may not be ideal for high-temperature or high-pressure applications such as commercial or industrial settings.

- Local Code Restrictions: Some local building codes restrict the use of PEX pipes in certain applications or require additional fire-resistant coatings in specific areas, limiting their use in certain regions.

Advantages of Copper Pipes:

- Durability: Copper pipes have been used for decades and have a proven track record of durability and longevity. They can withstand harsh conditions and are less prone to damage from physical impact.

- High Temperature and Pressure Resistance: Copper pipes can withstand high temperatures and pressures, making them suitable for a wide range of applications, including hot water systems.

- Excellent Heat Conductivity: Copper pipes have excellent heat conductivity, allowing for quick and efficient transfer of heat in hot water systems, resulting in faster hot water delivery.

- Compatibility: Copper pipes can easily integrate with existing copper plumbing systems, reducing the need for additional modifications during renovation or repair projects.

Why Glue is Not Used for Joining PEX and Copper Pipes

In the realm of plumbing, PEX and copper pipes reign supreme, revolutionizing the way we design and build plumbing systems. But when it comes to joining these formidable materials, glue isn’t their chosen bonding agent. In this article, we’ll explore why glue is unsuitable for joining PEX and copper pipes and unveil alternative methods that ensure secure and leak-free connections.

Material Differences:

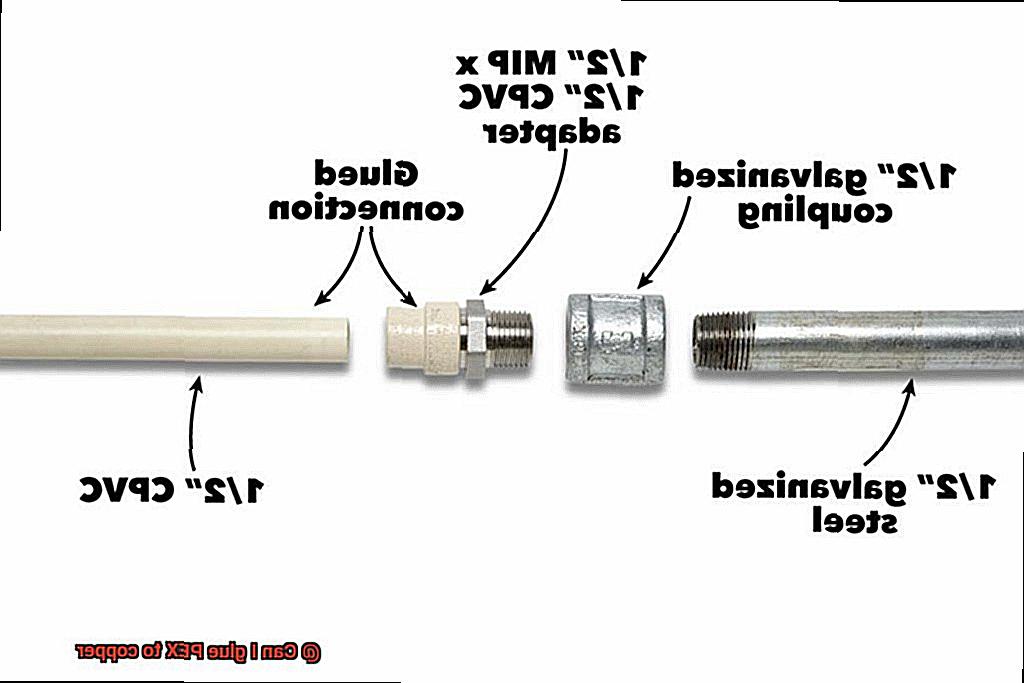

PEX, a flexible plastic pipe, and copper, a rigid metal pipe, possess distinct characteristics that make them unsuitable for conventional gluing. Glue may be the go-to adhesive for plastic pipes like PVC or CPVC, but it doesn’t adhere effectively to the metal surfaces of copper pipes.

Expansion and Contraction:

PEX and copper pipes have different expansion rates when exposed to temperature changes. Glue joints struggle to withstand these variations, risking leaks or disconnections. The thermal dynamics of these materials call for alternative methods that guarantee long-lasting connections.

Compression Fittings:

A popular method for joining PEX and copper pipes is through compression fittings. These fittings involve sliding a compression nut over the pipe and tightening it onto a compression sleeve or ferrule. This creates a watertight seal without relying on glue or adhesives.

Push-to-Connect Fittings:

Another reliable method for joining PEX and copper pipes is using push-to-connect fittings. These fittings feature specially designed O-rings or rubber gaskets that create secure connections when the pipes are pushed into them. This connection type requires no glue or tools, making it quick and hassle-free.

Dedicated Fittings:

Specific fittings and connectors are available for joining PEX and copper pipes, eliminating the need for glue altogether. These specialized fittings ensure proper and secure connections between the two materials, further enhancing their reliability.

Alternatives to Gluing for Connecting PEX and Copper Pipes

When it comes to connecting PEX and copper pipes, forget about glue. There’s a fascinating world of alternative methods waiting to be explored. These methods offer leak-free connections without the mess or hassle of adhesives. In this article, we’ll uncover these alternatives and help you select the perfect method for your plumbing needs.

Compression Fittings: The Seamless Solution

Compression fittings are a popular choice, providing a seamless seal by tightening a nut onto the fitting, compressing a ring or ferrule onto the pipe. With easy installation and disassembly, these fittings eliminate the need for glue or solvents.

Push-to-Connect Fittings: Embrace Simplicity

For all the DIY enthusiasts out there, push-to-connect fittings are your ultimate companion. These fittings feature a rubber o-ring or gripping mechanism that firmly holds the pipe in place once pushed into the fitting. No glue or soldering required.

Crimp Fittings: Trustworthy Connections

Crimp fittings are widely trusted by professionals and commonly used with PEX pipes. However, they can also be used with copper pipes. Utilizing a special tool, these fittings compress a metal ring around the pipe and fitting, ensuring a tight connection without any adhesives.

Threaded Connections: The Secure Haven

When you’re dealing with larger diameter pipes or applications requiring extra security, threaded connections come to the rescue. By using threaded adapters or unions, these connections provide a tight seal that can be further fortified with thread sealant tape or compound.

Transition Fittings: Bridging the Gap

To connect different types of piping materials, transition fittings save the day. Designed specifically for secure connections between PEX and copper pipes, these fittings often combine compression, push-fit, or crimp connections to ensure a reliable bond.

Crimping Method for Connecting PEX Pipes

The crimping method is a reliable and efficient way to connect PEX pipes. It involves using a crimping tool to compress a metal ring around the pipe and fitting, creating a secure and watertight connection.

To begin the crimping process, insert the PEX pipe into the fitting until it reaches the end, ensuring a snug fit. Slide a crimp ring over the connection point. Then, position the crimping tool over the crimp ring and apply pressure to the handles until you hear a satisfying click, indicating that the crimp ring has been securely compressed.

The crimping method offers several advantages over other methods like gluing. Firstly, it is a much simpler and less messy process. No more dealing with sticky glue that can get all over your hands and work area. With crimping, you can say goodbye to the mess and hello to a clean and efficient connection.

Furthermore, the crimping method provides durability and reliability. The compression force applied by the crimp ring ensures that your pipes will stay securely connected, even under high pressure or temperature fluctuations. This makes it a great choice for both residential and commercial plumbing applications.

Another advantage of the crimping method is its versatility. If repairs or modifications are needed in the future, the connections can be easily released by cutting off the crimp ring with a specialized removal tool. This provides flexibility and convenience that glue simply can’t match.

Cinching/Clamp/Ring Method for Connecting PEX Pipes

This technique relies on stainless steel rings or clamps to create a secure and long-lasting connection between the two pipe types. In this comprehensive guide, we will explore the ins and outs of this method, including step-by-step instructions and the benefits of ditching glue.

Step 1: Preparing the Pipes

Before beginning the connection process, it is essential to ensure that both the PEX and copper pipes are thoroughly cleaned and free from debris or contaminants. This crucial step guarantees optimal performance and minimizes the risk of future leaks.

Step 2: Inserting the PEX Fitting

Start by selecting a PEX fitting compatible with the cinching/clamp/ring method. Insert the fitting into one end of the PEX pipe, making sure to engage its barbed end securely. This design ensures a tight grip on the pipe, resulting in a reliable seal.

Step 3: Connecting the Copper Pipe

Next, insert the copper pipe into the opposite end of the PEX fitting. Align the pipes properly to achieve a seamless connection that will be both robust and watertight.

Step 4: Applying the Stainless Steel Ring/Clamp

To reinforce the connection point, place a stainless steel ring or clamp around it. These rings/clamps come in various sizes, so select one that fits snugly around your pipes for maximum effectiveness.

Step 5: Tightening with a Cinch Tool

Now comes the exciting part. Utilize a specialized tool known as a cinch tool to tighten the ring or clamp firmly into place. This process compresses the ring or clamp onto the pipes, creating a watertight seal that will withstand high water pressure and temperature fluctuations.

Why No Glue Needed?

The cinching/clamp/ring method eliminates the need for glue due to the inherent reliability of the stainless steel rings or clamps. Glue can be messy, time-consuming to apply, and may not provide a durable bond. By opting for the cinching/clamp/ring method, you can enjoy a simpler and more efficient alternative that guarantees a strong connection without the hassle of glue.

Soldering Method for Connecting Copper Pipes

In the world of plumbing, soldering is the method that ensures a strong and watertight connection for your copper pipes. It’s time to grab your soldering torch and dive into this exciting process.

Step 1: Cleanliness is Key

Before embarking on any soldering project, it’s crucial to prioritize cleanliness. Grab a wire brush or sandpaper and scrub your copper pipes and fittings until they shine. This step removes any dirt, debris, or corrosion that might compromise the joint’s strength.

Step 2: Flux to the Rescue

Once your pipes are sparkling clean, it’s time to introduce the superhero of soldering – flux. Flux eliminates oxidation and allows solder to flow smoothly. Apply an even coating of flux to both the pipes and fittings involved in your connection.

Step 3: Assemble with Care

With your prepped pipes and fittings, it’s time to assemble them with precision. Ensure a tight fit between the two pieces as this will guarantee a strong and leak-free joint.

Step 4: Heat It Up

Now for the fun part – igniting your trusty soldering torch. Apply heat evenly to both the pipe and fitting, making sure not to overheat them. Consistent heat application is essential for a successful soldered connection.

Step 5: Solder Away

Once the joint reaches the appropriate temperature, it’s time for the star of the show – solder wire. Apply the solder to the joint while maintaining heat with your torch. Witness how the heat melts the solder, allowing it to flow into the joint and create a sturdy bond as it cools.

Step 6: Check for Perfection

Take a moment to marvel at your handiwork. Ensure that the solder has fully filled the joint, forming a smooth and even fillet around the entire circumference of the connection. A visually appealing joint not only satisfies the eye but also indicates a job well done.

Step 7: Cool It Down

After soldering, exercise patience and allow your joint to cool naturally. Rushing this step could compromise the connection. Remember, creating reliable and leak-free plumbing requires time and attention.

Safety Precautions:

Safety is paramount. When soldering copper pipes, protect yourself with gloves and goggles to prevent burns or flying debris. Work in a well-ventilated area to avoid inhaling noxious fumes, and keep flammable materials away from your workspace.

Compression Fitting Method for Connecting Copper Pipes

This technique ensures a secure and watertight seal, without requiring specialized plumbing skills or tools. Let’s explore the world of compression fittings, from their basic components to their advantages and disadvantages.

The Basics:

Compression fittings consist of two essential parts: the brass compression nut and the compression ring, also known as a ferrule, made of brass or plastic. These fittings are designed to create a watertight seal by compressing the ring against the copper pipe.

Step-by-Step Guide:

- Prepare the pipe ends by ensuring they are clean and free from debris or burrs. Use a pipe cutter or deburring tool for this purpose.

- Slide the compression ring onto the pipe, followed by the compression nut.

- Tighten the nut onto the fitting using a wrench. As you tighten, the ring compresses against the pipe, creating a secure and leak-free seal.

Advantages of Compression Fittings:

- Strength and Durability: Compression fittings provide a reliable connection that can withstand normal operating conditions without any leaks.

- Disassemblable: Unlike soldered connections, compression fittings can be easily disconnected by loosening the nut, allowing for alterations or repairs in the future.

- User-Friendly: The compression fitting method is accessible to DIY enthusiasts and homeowners who don’t possess specialized plumbing skills or tools.

Disadvantages of Compression Fittings:

- Limited Application: Compression fittings are suitable only for connecting copper pipes and should not be used for joining PEX pipes to copper.

- Proper Selection is Crucial: Choosing high-quality compression fittings appropriate for your specific application is essential to avoid leaks or other issues. Consultation with a professional plumber or following manufacturer guidelines is highly recommended.

Transition Fittings for Joining Different Materials

Transition fittings are the superheroes of plumbing connections, bridging the gap between different materials to ensure secure and leak-free joints. In this blog post, we will explore the importance of using transition fittings, different types available, proper installation techniques, and key considerations when selecting these fittings.

Understanding Transition Fittings:

- Definition: Transition fittings are designed to provide a reliable connection between different materials in plumbing systems.

- Importance: They play a crucial role in creating secure and leak-free joints.

Types of Transition Fittings:

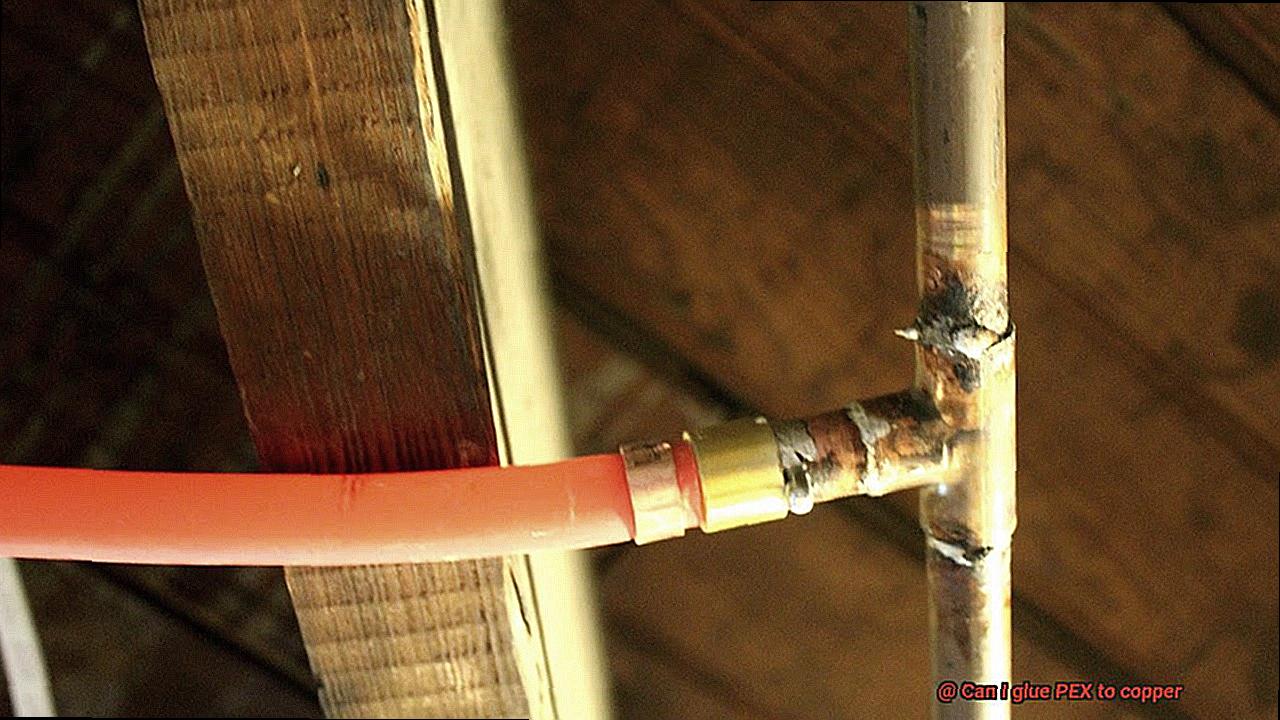

PEX-to-Copper Adapter:

- Features: Brass body with PEX connections on one end and a copper sweat connection on the other.

- Connection Method: Compatible with PEX pipe for push-fit or crimp connections, while the copper end can be soldered or brazed.

PEX-to-Copper Compression Fitting:

- Features: Utilizes compression rings or ferrules for a tight seal.

- Connection Method: Barbed insert holds the PEX pipe securely, while the compression nut tightens onto the copper pipe.

Proper Installation Techniques:

- Cleanliness: Ensure both ends of the fitting are clean and free from debris.

- Tools: Use appropriate tools like crimping tools or compression wrenches for making connections.

- Manufacturer Guidelines: Follow specific guidelines for compatibility and installation procedures.

Considerations when Selecting Transition Fittings:

Pipe Size Compatibility:

- Choose fittings that match the diameter of the pipes being connected.

Pressure Rating and Temperature Limitations:

- Select fittings rated for the maximum pressure and temperature encountered in the plumbing system.

Conclusion

In conclusion, gluing PEX to copper pipes is not the recommended method for joining them together. The adhesive used in glue does not effectively adhere to the metal surfaces of copper pipes and cannot withstand the expansion and contraction rates of both PEX and copper.

Fortunately, there are alternative methods available that ensure secure and leak-free connections. One popular choice is compression fittings. These fittings involve sliding a compression nut over the pipe and tightening it onto a compression sleeve or ferrule. This creates a watertight seal without relying on glue or adhesives.

Another reliable option is push-to-connect fittings. These fittings have specially designed O-rings or rubber gaskets that create secure connections when the pipes are pushed into them. No glue or tools are required for this quick and hassle-free connection method.

Crimp fittings can also be used with both PEX and copper pipes to create tight connections without any adhesives. These fittings compress a metal ring around the pipe and fitting, ensuring a secure seal.

For larger diameter pipes or applications requiring extra security, threaded connections using threaded adapters or unions provide a reliable seal.

Lastly, transition fittings specifically designed for joining PEX and copper pipes eliminate the need for glue altogether. These specialized fittings ensure proper and secure connections between the two materials.

Overall, there are several alternatives to gluing that offer reliable and durable connections between PEX and copper pipes. It is important to choose the appropriate method based on your specific plumbing needs.