Are you scratching your head, wondering if it’s possible to glue PVC to polyethylene? Well, fret not. You’ve stumbled upon the right place. We’re about to embark on a journey into the world of plastic bonding, where we’ll uncover the potential magic of joining these two common plastics.

Whether you’re a DIY enthusiast, an engineer extraordinaire, or just someone desperately seeking a quick fix, understanding the ins and outs of gluing PVC to polyethylene is key. These plastics have their own unique superpowers when it comes to different projects. But when it comes to bonding them together? That’s where things get interesting.

In this blog post, we’re diving deep into the nitty-gritty of plastic bonding. We’ll explore the compatibility (or lack thereof) between PVC and polyethylene, dish out some advice on suitable adhesives, and shed light on any pesky challenges that might pop up along the way.

So buckle up and get ready for an adventure. Together, we’ll find out if it’s possible to create a bond that’s as strong as Hercules’ biceps between PVC and polyethylene using good ol’ glue.

What is PVC and Polyethylene?

Contents

- 1 What is PVC and Polyethylene?

- 2 Challenges in Gluing PVC to Polyethylene

- 3 Adhesives Suitable for Bonding PVC to Polyethylene

- 4 Surface Preparation for Gluing PVC to Polyethylene

- 5 Applying the Adhesive Properly

- 6 Mechanical Fastening Methods for Joining PVC and Polyethylene

- 6.1 Mechanical Connectors: The Rhythm that Makes Pipes Sing

- 6.2 Compression Fittings: A Tight Seal that Never Misses a Beat

- 6.3 Threaded Fittings: The Perfect Pairing for Plumbing Systems

- 6.4 Push-To-Connect Fittings: Quick Steps with No Glue Required

- 6.5 Barbed Fittings: A Secure Grip that Keeps the Beat Going

- 7 Alternative Joining Methods for PVC and Polyethylene

- 8 Conclusion

In the realm of plastic bonding, compatibility is crucial. However, when it comes to marrying PVC and polyethylene, the task becomes more demanding due to their divergent chemical compositions and distinct qualities. This article delves into the fascinating world of PVC and polyethylene, exploring their disparities and potential bonding solutions.

Unveiling the Distinctions:

PVC, also known as polyvinyl chloride, emerges as a robust and durable plastic, flexing its strength in diverse industries like construction and electrical insulation. On the flip side, polyethylene emerges as a flexible warrior, renowned for its outstanding impact resistance and unwavering chemical stability. It reigns supreme in the realm of packaging materials and plastic bags.

The Compatibility Conundrum:

The main challenge in fusing PVC to polyethylene lies within their dissimilar molecular structures. PVC flaunts its polymer chain with chlorine atoms while polyethylene struts solely carbon and hydrogen atoms. This divergence in chemical composition impedes adhesive adhesion between these two materials, rendering traditional glues ineffective.

Specialized Adhesive Alchemy:

Thankfully, a glimmer of hope exists in the form of specialized adhesives engineered explicitly to bond PVC to polyethylene. These adhesive concoctions contain chemical additives that work their magic by forging mighty molecular bonds between these two plastics.

Surface Preparation Prowess:

To ensure a victorious bond, proper surface preparation reigns supreme. Thoroughly cleansing and degreasing both surfaces before applying the adhesive serves as an essential first step. Additionally, introducing roughness to the surface through sandpaper or an abrasive tool amplifies the surface area, enhancing adhesion.

Mastering the Application Technique:

Adhering to the manufacturer’s instructions with unwavering precision when applying the adhesive is vital. Ensuring even distribution on both surfaces and allowing ample time for curing or drying before subjecting the bond to any stress or load guarantees a triumphant outcome.

Alternative Joining Methods:

For those seeking an unyielding and everlasting bond, alternative joining methods like heat welding or solvent welding emerge as formidable contenders. These techniques involve melting or fusing the materials together, forging an indomitable alliance.

Challenges in Gluing PVC to Polyethylene

Prepare to be amazed as we dive into the challenges and techniques involved in creating a strong bond between these two materials.

Challenges Galore:

Chemical Composition Tango:

PVC and polyethylene have completely different molecular structures and bonding characteristics. It’s like trying to find the perfect dance partner in a crowded ballroom, where compatibility seems impossible.

Surface Properties Salsa:

PVC’s smooth and non-porous surface makes it a tough nut to crack for adhesives. Meanwhile, polyethylene’s low surface energy creates a slippery dance floor. Gluing them together feels like trying to fuse two dancers with completely different styles.

Expansion-Contraction Waltz:

PVC and polyethylene have different rates of expansion and contraction. It’s like a dance-off gone wrong. This mismatch can cause the adhesive bond to loosen over time, leading to heartbreak on the dance floor.

Stressful Tango Twist:

If you plan to put your glued joint under stress or load-bearing situations, the challenge intensifies. The adhesive needs to be strong enough to handle the pressure without missing a beat.

Environmental Cha-Cha-Cha:

Temperature changes, moisture, and chemical exposure can all disrupt your gluing endeavors. You need an adhesive that can withstand these elements and keep the dance going strong.

Conquering the Dance Floor:

The Adhesive Maestro:

Choose an adhesive specifically designed for bonding PVC to polyethylene. These specialized glues have unique formulations that make them stand out from the crowd, creating the perfect connection between our plastic partners.

Surface Preparation Shimmy:

Before gluing, clean the surfaces thoroughly with solvents or abrasion techniques. This removes contaminants and roughens up the surface, allowing the adhesive to grab hold like a dancer’s firm grip.

Application Technique Samba:

Apply the adhesive evenly to both surfaces and press them together firmly. It’s a smooth and confident dance move. Follow the manufacturer’s instructions for curing time and temperature, ensuring your bond has enough time to set and become strong.

Adhesives Suitable for Bonding PVC to Polyethylene

These materials may have different chemical properties, but with the right glue, they can form a strong and durable bond. Let’s explore some adhesive options that can make this magical union possible.

- Two-part epoxy adhesive: This type of adhesive is known for its exceptional bond strength and resistance to various chemicals and environmental conditions. It is a popular choice for bonding PVC to polyethylene. However, it is essential to select an epoxy adhesive specifically designed for this application to ensure a successful connection.

- Solvent-based adhesive: Solvent-based adhesives work by dissolving the surfaces of the materials and creating a strong bond as they dry. It is important to choose a solvent-based adhesive that is suitable for both PVC and polyethylene to achieve the desired result. Be cautious in your selection to ensure compatibility.

- Specialized PVC to PE adhesives: Some manufacturers have developed specialized adhesives explicitly formulated for bonding PVC to polyethylene. These magical potions deliver exceptional bonding strength between the two materials and are worth considering for your project.

Before applying any adhesive, proper surface preparation is key. Thoroughly clean both PVC and polyethylene surfaces, ensuring they are dry and free from any contaminants or debris. You can use solvents or sandpaper to roughen up the surfaces slightly, enhancing adhesion.

Always follow the manufacturer’s instructions when using adhesives. Apply the glue evenly and in the recommended amount, allowing sufficient curing time for it to set properly. Adequate ventilation is also essential during application.

While adhesives can create a strong bond between PVC and polyethylene, it’s important to note that the inherent differences in these materials may limit the overall strength of the joint. If maximum strength is required, consider using mechanical fastening methods in addition to adhesive bonding.

To ensure the chosen adhesive is suitable for your specific application, test the bonded joint under actual operating conditions. This will help determine if the bond strength meets the required standards and if the adhesive can withstand the demands of your project.

When in doubt, always consult adhesive manufacturers or experts in the field. They can provide guidance and recommend the best adhesive options based on your specific requirements and conditions.

Surface Preparation for Gluing PVC to Polyethylene

When it comes to gluing PVC to polyethylene, successful adhesion requires careful surface preparation. These two materials have distinct chemical compositions and surface characteristics, which can present challenges.

However, with the right techniques, you can create a bond that is strong and durable. In this article, we will explore the world of surface preparation and provide you with valuable tips and tricks to help you achieve a reliable connection between PVC and polyethylene.

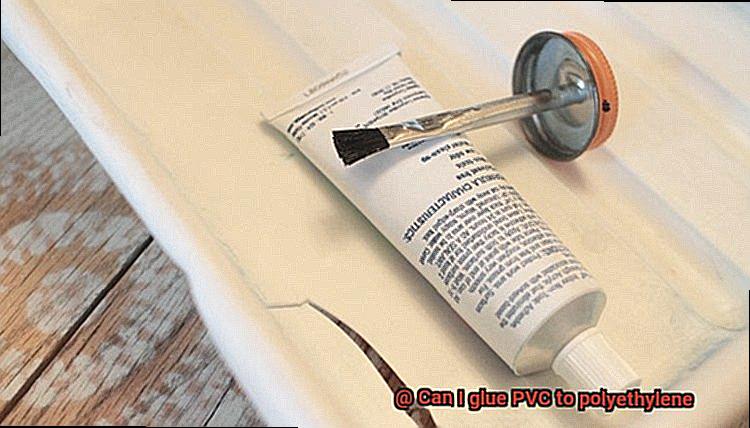

Step 1: Cleanliness is Key

Before beginning the gluing process, it is vital to ensure that both the PVC and polyethylene surfaces are clean and free from contaminants. Use a mild detergent or solvent to remove any dirt, dust, grease, or unwanted substances. Thoroughly rinse the surfaces, ensuring they are completely dry before proceeding.

Step 2: Roughening up the Surfaces

Once you’ve achieved spotless surfaces, it’s time to give them a bit of rough love. Lightly sanding both the PVC and polyethylene surfaces with fine-grit sandpaper will create tiny scratches that provide more surface area for the adhesive to grip onto. Alternatively, you can utilize a plastic primer containing solvents capable of etching the surfaces. This step is crucial for enhancing bond strength, so be sure not to skip it.

Step 3: Priming for Success

To further improve adhesion, apply a primer specifically designed for bonding PVC to polyethylene. This remarkable substance promotes chemical bonding between the adhesive and the plastic surfaces. Ensure an even application, following the manufacturer’s instructions for drying time.

Step 4: Choose Your Adhesive Wisely

With properly prepared surfaces, it’s time to select the right adhesive for the job. Numerous adhesives are formulated specifically for bonding PVC to polyethylene. From epoxy-based adhesives to specialized plastic adhesives, it is crucial to choose an adhesive that is compatible with both materials. Always adhere to the manufacturer’s instructions for application and curing time.

Step 5: Test, Test, Test.

Before diving into the gluing process, it is essential to conduct a small test on an inconspicuous area first. This will ensure that the adhesive is compatible with the materials and that the desired results are achieved. Once you are satisfied with the adhesive’s performance, you are ready to proceed.

Step 6: Apply and Secure

Apply an even and sufficient amount of adhesive to both surfaces, ensuring complete coverage. Carefully align the PVC and polyethylene surfaces and press them firmly together. To secure the bond while the adhesive cures, use clamps or other means of support as recommended by the adhesive manufacturer.

Applying the Adhesive Properly

Picture a dance floor where PVC and polyethylene effortlessly intertwine, moving in perfect sync. Like any dance, the secret lies in preparation and technique.

In this guide, we’ll unveil the steps to applying adhesive properly when gluing PVC to polyethylene, ensuring a strong and lasting bond that will make you want to dance with joy.

Step 1: Selecting the Perfect Dance Partner:

Not all adhesives are created equal. Choose an adhesive specifically designed for bonding PVC and polyethylene. Look for adhesives labeled as suitable for both materials, ensuring they have the right chemistry for a strong connection.

Step 2: Cleaning the Dance Floor:

Before the dance can begin, clean both PVC and polyethylene surfaces. Sweep away dirt, dust, and grease that could hinder bonding. Use a mild detergent or recommended solvent to ensure a pristine dance floor.

Step 3: Roughening Up the Moves:

Enhance adhesion by roughening up the surfaces. Give your dance partner some grip on the floor. Use sandpaper or an abrasive material to create a slightly rough texture on PVC and polyethylene surfaces. This step allows the adhesive to penetrate deeper, creating a robust bond.

Step 4: Applying the Adhesive with Finesse:

Now it’s time to apply the adhesive. Remember, less is more. Apply a thin layer of adhesive evenly on both surfaces. Use a brush or recommended applicator for precise application. Avoid excess glue that leads to messy moves and compromises bond strength.

Step 5: The Perfect Partner Alignment:

With adhesive applied, bring PVC and polyethylene together. Align the pieces carefully, ensuring perfect synchronization before pressing them firmly against each other. Gentle pressure helps achieve a strong bond.

Step 6: Let the Dance Begin:

Patience is key. Allow sufficient time for the adhesive to cure. Follow the manufacturer’s instructions for timing. This step is like waiting for the dance routine to begin – timing is everything. Follow the recommended curing time before subjecting the bond to stress.

Step 7: Creating the Perfect Dance Environment:

During curing, create a stable and controlled environment. Extreme temperatures or humidity can disrupt bonding. Follow the manufacturer’s recommendations for optimal curing conditions, ensuring a strong and steady bond.

Mechanical Fastening Methods for Joining PVC and Polyethylene

Let’s dance our way through this guide and discover the secrets to a strong and secure joint without relying on glue.

Mechanical Connectors: The Rhythm that Makes Pipes Sing

Imagine a dance partner that adds strength and stability to your moves. That’s exactly what mechanical connectors do. Made from durable materials like stainless steel or brass, these connectors come in various shapes and sizes (think couplings, tees, elbows, and adapters) for ultimate flexibility. Just make sure to match them with compatible pipes or fittings to create a leak-free connection that will leave you breathless.

Compression Fittings: A Tight Seal that Never Misses a Beat

Looking for an easy-to-install option? Compression fittings are your go-to move. With a compression nut, ring, and sleeve in their arsenal, these fittings create a tight seal by compressing the ring onto the pipe. Perfect for low-pressure systems and non-potable water applications, they ensure a secure connection with just a few simple steps. Remember to consult industry guidelines for compatibility.

Threaded Fittings: The Perfect Pairing for Plumbing Systems

Get ready to twist and turn with threaded fittings. These fittings have male and female threads that screw together, offering a strong and reliable joint. Whether made of PVC, brass, or stainless steel, they’re commonly used in plumbing systems. Remember to use thread tape or sealant to prevent leaks and avoid over-tightening – we don’t want any strained connections on our dance floor.

Push-To-Connect Fittings: Quick Steps with No Glue Required

Ready for a quick and easy installation without the need for tools or glue? Enter push-to-connect fittings. These fittings use push-fit technology, allowing you to connect PVC and polyethylene pipes effortlessly. Just push and lock – it’s as simple as that.

Barbed Fittings: A Secure Grip that Keeps the Beat Going

Imagine a dance partner with ridges or barbs that grip onto your moves, creating an unbreakable bond. Barbed fittings do just that. These fittings have ridges that grip onto the pipe when inserted, ensuring a secure connection. It’s a dance partnership you can rely on.

Remember, while mechanical fastening methods can create a strong joint between PVC and polyethylene, it’s essential to consider factors like pressure, temperature, and the fluid being transported. When in doubt, consult with a professional or refer to industry guidelines to ensure you’re selecting the right method.

Alternative Joining Methods for PVC and Polyethylene

There are alternative joining methods available that can give you a strong and secure joint without the sticky mess. So grab your dancing shoes and let’s explore these alternative methods.

First up is heat fusion, a method that involves using heat to melt the surfaces of the PVC and polyethylene materials and then pressing them together to form a bond. This method is commonly used in plumbing and provides a reliable and leak-proof joint. By using specialized equipment, such as hot plates or fusion machines, the materials can be heated to their melting points, allowing them to blend together seamlessly. The result is a joint that is as strong as the original material itself.

Next, we have mechanical joining. This method uses fittings or connectors to hold the materials together without the need for adhesives or heat. These fittings come in various shapes and sizes, including couplings, tees, and elbows, ensuring a secure joint that can be easily disassembled or reassembled when needed. With mechanical joining, there is no need to wait for glue to dry or worry about messy cleanup. It’s a straightforward and efficient way to join PVC and polyethylene materials.

If speed is your game, then ultrasonic welding is the method for you. This technique uses high-frequency vibrations to melt and bond the materials together quickly and efficiently. An ultrasonic welding machine applies pressure and vibration to the joint area, causing the molecules of the PVC and polyethylene materials to vibrate and generate heat.

This heat melts the surfaces of the materials, allowing them to fuse together. Ultrasonic welding is perfect for applications where time is of the essence, as it can create strong joints in a matter of seconds.

But wait, what about glue? While traditional glue might not be the best option for polyethylene, there are specialized adhesives available that are designed specifically for joining PVC and polyethylene. These adhesives provide a viable alternative for certain applications, just make sure to follow the manufacturer’s instructions for proper application and curing. These specialized adhesives can create a strong bond between PVC and polyethylene, ensuring a secure joint that can withstand various environmental conditions.

When deciding on the best joining method for your project, it’s important to consider factors such as the specific application, the materials being joined, and the required strength and durability of the joint. Consulting with experts or manufacturers can help ensure you make the right choice. They can provide valuable insights into the benefits and limitations of each joining method, helping you select the most appropriate option for your needs.

-SFWiCAhhHk” >

Conclusion

In conclusion, the answer to the question “Can I glue PVC to polyethylene?” is a resounding no. These two materials simply do not bond well together due to their different chemical compositions and physical properties. Attempting to glue PVC to polyethylene will likely result in a weak and unreliable bond that will eventually fail under stress or environmental conditions.

PVC, or polyvinyl chloride, is a rigid plastic that is commonly used in plumbing pipes, electrical insulation, and construction materials. On the other hand, polyethylene is a flexible plastic often found in packaging materials, water tanks, and outdoor furniture. The key difference between these two plastics lies in their molecular structure and bonding characteristics.

PVC is a thermoplastic polymer that can be easily softened by heat and then molded into various shapes. It has a high affinity for solvents such as acetone or MEK (methyl ethyl ketone), which can effectively dissolve its surface layer and create a strong bond when applied correctly. However, when it comes to bonding with polyethylene, PVC falls short.

Polyethylene, on the other hand, is known for its low surface energy and resistance to solvents. This makes it extremely difficult for adhesives or glues to form a strong bond with polyethylene surfaces. Even if you manage to find an adhesive specifically designed for bonding PVC to polyethylene, the resulting bond will still be weak and prone to failure.

If you need to join PVC and polyethylene components together, it’s best to explore alternative methods such as mechanical fasteners or heat welding techniques. These methods provide much stronger and more reliable connections compared to adhesive bonding.

In summary, attempting to glue PVC to polyethylene is not recommended due to the incompatible nature of these two materials. It’s important to understand the properties of each material before attempting any kind of joining process.