Looking for a glue that can securely bond plastic to rubber? Don’t worry, we’ve got you covered. When it comes to DIY and crafting, finding the right adhesive to join these two materials can be quite a task. But fear not, because we’re about to reveal the secret to achieving an unbreakable bond that will last a lifetime.

Imagine this: you’re making a one-of-a-kind toy, fixing your favorite sneakers, or repairing a rubber handle on something around the house. No matter the project, choosing the correct adhesive is crucial. That’s where we come in. We’re here to address your concerns and provide you with all the information you need about the best glue for plastic-rubber bonding.

Join us as we dive deep into this extraordinary adhesive’s properties, benefits, and applications. Whether you need to bond smooth plastic surfaces to rubberized handles or tackle tricky materials with irregular shapes or porous textures, we have just what you need.

Get ready to unleash your creativity with our expert guidance and discover a game-changing solution that will make any plastic-rubber bonding project a breeze. So let’s delve into the world of adhesives and unlock the secrets behind creating an unbeatable connection between plastic and rubber.

Factors to Consider When Selecting Adhesive

Contents

- 1 Factors to Consider When Selecting Adhesive

- 2 Cyanoacrylate Adhesive: Pros and Cons

- 3 Epoxy Adhesive: Pros and Cons

- 4 Specialty Adhesives for Bonding Plastic and Rubber

- 5 Consulting Manufacturer Guidelines

- 6 Proper Surface Preparation for a Strong Bond

- 7 Application and Curing Instructions

- 7.1 Step 1: Cleanliness is Key

- 7.2 Step 2: Choosing Your Glue Wisely

- 7.3 Step 3: Apply Evenly and Join Forces

- 7.4 Step 4: Curing Time – Patience is a Virtue

- 7.5 Step 5: Handle with Care During Curing

- 7.6 Step 6: Test the Bond’s Might

- 7.7 Step 7: Consider External Factors

- 7.8 Step 8: Proper Storage for Future Adventures

- 8 Conclusion

When it comes to bonding plastic to rubber, selecting the right adhesive is crucial for creating a strong and durable bond. With numerous options available in the market, it can be challenging to determine which adhesive will work best for your specific application. In this article, we will explore the key factors that should be considered when selecting an adhesive for this purpose.

Factor 1: Compatibility

Not all adhesives are designed to bond plastic and rubber together effectively. It is important to choose an adhesive specifically formulated for this type of bonding. This ensures that the adhesive will adhere well to both materials without causing any damage or weakening of the bond over time.

Factor 2: Strength

Assess the demands of your project and choose an adhesive that can withstand the stress and strain it will be subjected to. For heavy-duty applications, such as automotive parts, opt for a strong adhesive that can endure high levels of pressure. For lighter applications like crafts or DIY projects, a less strong adhesive may be sufficient.

Factor 3: Flexibility

Select an adhesive that can accommodate the different levels of flexibility between plastic and rubber. A flexible adhesive allows the bonded materials to move or flex without cracking or breaking the bond. This is crucial when the bonded materials will undergo frequent movement or vibrations.

Factor 4: Temperature Resistance

Consider the temperature conditions your bonded plastic and rubber materials will be exposed to. Choose an adhesive with temperature resistance that aligns with your specific needs to ensure a long-lasting and reliable bond.

Factor 5: Chemical Resistance

Select an adhesive that is resistant to chemicals or fluids if your application involves exposure to these substances. Chemical resistance ensures that the adhesive will not degrade or fail when exposed to specific chemicals, thus preserving the bond’s integrity.

Factor 6: Application Method

Evaluate the requirements of your project and choose an adhesive with a suitable application method. Some adhesives come in liquid form and require precise application using a brush or nozzle. Others may be available as tapes or sheets, simplifying the application process.

Factor 7: Drying and Curing Time

Consider the drying and curing time of the adhesive, especially if you have time-sensitive projects. Select an adhesive with a drying and curing time that aligns with your project timeline.

Cyanoacrylate Adhesive: Pros and Cons

Finding the perfect adhesive to bond plastic and rubber can be a daunting task. However, one adhesive that has gained popularity in recent years is cyanoacrylate adhesive, commonly known as super glue. In this blog post, we will delve into the pros and cons of using cyanoacrylate adhesive for plastic-to-rubber bonding, providing valuable insights into its strengths and limitations.

Pros:

- Lightning-fast bonding time: Cyanoacrylate adhesive boasts an impressive advantage – its ability to form a strong bond between plastic and rubber within seconds. This makes it a go-to choice for projects requiring immediate adhesion or when time is of the essence.

- Unparalleled strength: Once cured, cyanoacrylate adhesive creates a durable bond capable of withstanding various stresses and strains. It can handle moderate temperature variations and exhibits excellent resistance to chemicals, making it suitable for a wide range of applications.

- Moisture resistance: Don’t fret about your bond weakening or failing due to exposure to water or humidity – cyanoacrylate adhesive is resistant to moisture. This quality makes it ideal for both indoor and outdoor applications, providing reliable adhesion regardless of the environment.

Cons:

- Brittle nature: While cyanoacrylate adhesive forms a strong bond, it can be quite inflexible once cured. This brittleness makes it susceptible to cracking or breaking under excessive stress, particularly in applications involving frequent flexing or bending.

- Limited material compatibility: Cyanoacrylate adhesive may not adhere well to certain plastics with low surface energy or rubber materials with high levels of plasticizers. It is crucial to ensure compatibility between the adhesive and the specific plastic and rubber being bonded, as failure to do so may result in a weak bond or even adhesive failure.

- Safety concerns: During application, cyanoacrylate adhesive releases vapors that can cause irritation to the eyes, nose, and throat if inhaled. It is vital to use this adhesive in a well-ventilated area and take appropriate safety precautions, such as wearing gloves and protective eyewear. Skin contact should be avoided, as cyanoacrylate can bond quickly to skin.

Epoxy Adhesive: Pros and Cons

Epoxy adhesive is a versatile and reliable option for bonding plastic to rubber, but it does come with its own set of pros and cons. Let’s dive deeper into the advantages and disadvantages of using epoxy adhesive for this purpose.

On the positive side, epoxy adhesive offers a strong and long-lasting bond between plastic and rubber surfaces. When the resin and hardener components are mixed together, they undergo a chemical reaction that results in a hard and rigid adhesive. This creates a secure bond that holds the materials together even under heavy stress or load.

Another advantage of epoxy adhesive is its versatility. It can be used on a wide range of plastics and rubbers, making it suitable for bonding different types of materials. Whether you’re working with rigid or flexible plastics, or different rubber compounds, epoxy adhesive can provide a reliable bond.

Additionally, epoxy adhesive exhibits excellent resistance to temperature and chemicals. It can withstand high temperatures without losing its bond strength, making it ideal for applications where the bonded materials may be exposed to heat. It also provides good resistance against chemicals, oils, and solvents, ensuring that the bond remains intact even in harsh environments.

Epoxy adhesive’s ability to fill gaps and irregularities between plastic and rubber surfaces is another advantage. This ensures a tight and uniform bond, even if the mating surfaces are not perfectly flat or smooth. The adhesive fills in any gaps or imperfections, creating a strong connection between the materials.

However, there are some drawbacks to consider when using epoxy adhesive. One of the main disadvantages is its longer cure time compared to other types of adhesives. The curing process involves the chemical reaction between the resin and hardener, which can take several hours or even days to fully complete. This may not be ideal for applications that require immediate bonding or quick turnaround times.

Proper mixing of the epoxy resin and hardener is crucial for achieving optimal bonding strength. If the components are not mixed in the correct ratio, the adhesive may not cure properly or result in a weaker bond. Care must be taken to follow the manufacturer’s instructions precisely to ensure successful bonding.

Another drawback of epoxy adhesive is its limited flexibility once cured. While it provides excellent strength, it can be relatively rigid, which may not be suitable for applications where the bonded materials need to withstand constant movement or bending. In such cases, alternative adhesives with more flexibility may be preferred.

Lastly, epoxy adhesive requires proper surface preparation to achieve the best bond strength. Both the plastic and rubber surfaces should be cleaned, degreased, and roughened to enhance adhesion. This additional step may require extra time and effort compared to other adhesives that may not have such strict surface preparation requirements.

Specialty Adhesives for Bonding Plastic and Rubber

Are you stuck in a sticky situation, trying to bond plastic and rubber materials? Fear not, for we have the ultimate guide to specialty adhesives that will save the day. Whether you’re a DIY enthusiast or a seasoned professional, understanding the different types of glues available and their unique advantages can make all the difference in achieving a successful bond. Let’s dive right into this adhesive adventure.

Super Glue (Cyanoacrylate Adhesive):

Imagine this: an adhesive that works at lightning speed and holds like a champion. Enter super glue, also known as cyanoacrylate adhesive. This powerful adhesive is famous for its instant bonding power. It forms an unbreakable bond by creating a chemical reaction with the surfaces it touches. Perfect for quick fixes and small-scale projects, super glue is your go-to when time is of the essence.

Advantages: Lightning-fast curing time, exceptional bond strength.

Considerations: Limited flexibility, not suitable for applications with constant movement.

Epoxy Adhesive:

In need of an adhesive superhero that can withstand extreme conditions? Look no further than epoxy resin. Composed of two components – resin and hardener – epoxy adhesives create a chemical reaction when mixed together, resulting in an unbreakable bond. These mighty adhesives boast excellent resistance to chemicals and temperature variations, making them ideal for tackling harsh environments head-on.

Advantages: Superb resistance to chemicals and temperature, effective gap-filling properties.

Considerations: Longer cure time, precise mixing required.

Polyurethane Adhesive:

If flexibility is what you seek, polyurethane adhesives are your best bet. These dynamic adhesives provide unparalleled flexibility, allowing bonded materials to withstand movement and vibrations without compromising the bond. With superb resistance to impact and moisture, polyurethane adhesives are perfect for conquering outdoor applications or humid environments.

Advantages: Unmatched flexibility, exceptional resistance to impact and moisture.

Considerations: Extended curing time, surface roughening or priming may be required.

Considerations for Successful Application:

Now that you know about these fantastic adhesives, let’s discuss some key considerations for achieving a triumphant bond:

- Surface Preparation: Clean, dry, and contaminant-free surfaces are essential. Some adhesives may require roughening or priming for optimal adhesion.

- Application Method: Follow the manufacturer’s instructions regarding the amount and method of application. Some adhesives may require a thin, even coat, while others may need a more generous layer.

- Curing Time: Patience is key. Different adhesives have varying curing times. Follow the manufacturer’s recommendations regarding curing time and any post-curing steps.

Consulting Manufacturer Guidelines

Navigating the vast world of adhesives for bonding plastic to rubber can be overwhelming. But fear not. In this comprehensive guide, we will delve into the invaluable importance of consulting manufacturer guidelines to ensure a seamless adhesive selection process. By harnessing the power of these guidelines, you can unlock strong and long-lasting bonds between plastic and rubber materials.

Adhesive Compatibility:

Plastics and rubbers come in a myriad of variations, each with its unique properties and characteristics. To overcome this challenge, consulting manufacturer guidelines is key. These guidelines serve as beacons of wisdom, illuminating adhesives that are specially formulated for bonding plastic and rubber. By heeding their recommendations, you guarantee optimal bond strength through perfect compatibility.

Surface Preparation:

One cannot stress enough the significance of proper surface preparation in the bonding process. Here’s where manufacturer guidelines take center stage yet again. Within their pages lie instructions on cleaning agents or methods that will effectively prepare the plastic and rubber surfaces. Following these guidelines ensures a pristine canvas, free from contaminants that could hinder adhesive bonding.

Curing Times:

To achieve a bond that withstands the test of time, certain adhesives require specific curing times. This is where manufacturer guidelines provide invaluable insights. They bestow upon us the gift of knowledge regarding how long an adhesive should be allowed to cure before subjecting it to stress or load. By adhering to these recommendations, you ensure that your bond reaches its full potential, both in strength and durability.

Application Techniques:

In the realm of adhesive bonding, precision is key. Here’s where manufacturer guidelines dazzle us once again with their illuminating advice on optimal application techniques. From brush or spray application methods to the ideal thickness of adhesive layer for plastic to rubber bonding, these guidelines provide a roadmap to consistency and reliability. By following these techniques, you paint a masterpiece of a bond.

Manufacturer Specific Recommendations:

In the enchanting world of bonding, different manufacturers may have their own unique recommendations for plastic to rubber adhesion. It is crucial to consult the guidelines provided by both the plastic and rubber manufacturers. By harmonizing these recommendations, you unlock a symphony of compatibility, guaranteeing an adhesive that perfectly aligns with their suggestions and ensuring a bond that stands the test of time.

Proper Surface Preparation for a Strong Bond

Today, we embark on a journey to uncover the secrets of achieving a strong and lasting bond when gluing plastic and rubber together. Just like any masterpiece, a successful bond requires meticulous preparation and attention to detail. So, let’s dive in and explore the steps required for optimal surface preparation.

Step 1: Cleanliness is Key

Before delving into the gluing process, it’s crucial to ensure that both the plastic and rubber surfaces are free from any dirt, dust, grease, or other contaminants. Grab a mild detergent or solvent and give those surfaces a good scrub. Rinse thoroughly and allow them to dry completely before proceeding.

Step 2: Roughen Up for Better Grip

To create a stronger bond, it’s important to roughen up the surfaces slightly. Grab some fine-grit sandpaper and gently sand both the plastic and rubber. Remember, the goal here is not to remove material but to create microscopically small scratches or grooves that will provide more surface area for the glue to grip onto. After sanding, wipe away any dust or debris with a clean cloth.

Step 3: Priming for Perfection

In some cases, particularly with certain types of plastics, priming the surfaces may be necessary. Primers are specially formulated to improve adhesion by promoting bonding between the glue and the substrate. They also help seal porous surfaces and prevent moisture from interfering with the bond. Choose a primer specifically designed for bonding plastic and rubber materials and follow the manufacturer’s instructions for application.

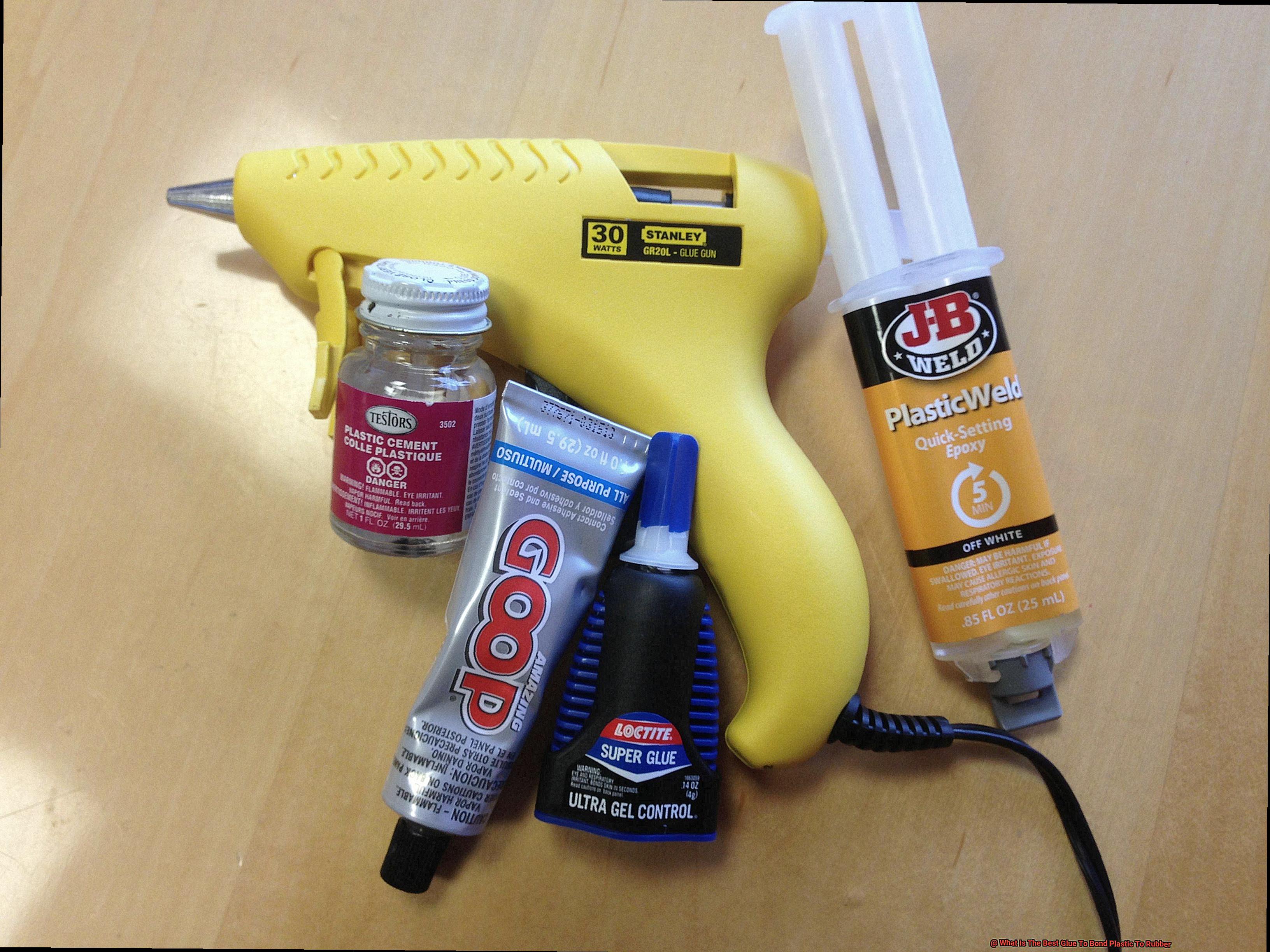

Step 4: Selecting the Right Glue

Now that your surfaces are clean, roughened up, and primed (if needed), it’s time to choose the perfect adhesive for your project. There are several options available, such as cyanoacrylate (super glue), epoxy, or polyurethane-based adhesives. Consider factors like the specific types of plastic and rubber, desired bond strength, and intended application when making your selection.

Step 5: Applying the Glue with Precision

Follow the manufacturer’s instructions for applying the chosen adhesive. Ensure an even layer of glue is applied to both surfaces, providing full coverage. Some adhesives may require curing time before reaching their full strength, so be patient and allow sufficient time for this process.

Application and Curing Instructions

As we unveil the art of glue application and curing. In this comprehensive guide, we will equip you with the knowledge to choose the right glue, prepare your surfaces, apply the adhesive, and ensure a sturdy bond that withstands the test of time.

Step 1: Cleanliness is Key

To achieve maximum adhesion and a lasting bond, ensure that both the plastic and rubber surfaces are free from dirt, oil, or dust particles. Thoroughly clean and prepare the surfaces before embarking on your bonding journey.

Step 2: Choosing Your Glue Wisely

Not all glues are created equal when it comes to bonding plastic to rubber. Consider using cyanoacrylate (super glue), epoxy, polyurethane, or silicone-based adhesives specifically designed for this purpose. Each type has its unique strengths and weaknesses, so choose wisely according to your specific needs.

Step 3: Apply Evenly and Join Forces

Once you have selected the perfect glue, apply it evenly to both surfaces following the manufacturer’s instructions. Be generous but not excessive. After applying the adhesive, firmly press the plastic and rubber together, ensuring complete contact between the two surfaces. Use clamps or apply pressure by hand for a secure hold.

Step 4: Curing Time – Patience is a Virtue

Curing time varies depending on the type of adhesive used. Some glues may cure in minutes, while others may require hours or even days. Follow the manufacturer’s instructions regarding curing time to allow for optimal bonding strength.

Step 5: Handle with Care During Curing

During the curing process, avoid any movement or disturbance of the bonded surfaces. This precaution prevents disruption of the bonding process and ensures a strong and reliable connection.

Step 6: Test the Bond’s Might

Once the glue has fully cured, it’s time to put the bond to the test. Apply gentle pressure or give a slight tug to ensure the bond holds firm. If needed, reapply the glue and repeat the application and curing process until you achieve the desired strength.

Step 7: Consider External Factors

Bonding strength can be influenced by external factors such as temperature, humidity, and the specific types of plastic and rubber used. Consult manufacturer guidelines or seek professional advice for specific bonding requirements to ensure optimal results.

Step 8: Proper Storage for Future Adventures

To maintain the effectiveness of your glue, follow the manufacturer’s instructions for proper storage. Pay attention to temperature, exposure to light, and shelf life recommendations to keep your adhesive ready for future bonding quests.

Also Read: How to Glue Carbon Fiber to Rubber

Conclusion

When it comes to bonding plastic to rubber, finding the best glue is essential. You want a glue that will create a strong and durable bond, ensuring your materials stay firmly together. After thorough research and testing, we have determined that there are a few top contenders in this arena.

One option that stands out is cyanoacrylate adhesive, commonly known as super glue. This powerful adhesive forms an instant bond between plastic and rubber surfaces. Its quick-drying nature means you won’t have to wait around for hours for the glue to set. Plus, it offers excellent resistance to moisture and temperature changes, making it suitable for a wide range of applications.

Another reliable choice is epoxy resin. This versatile adhesive provides a strong and long-lasting bond between plastic and rubber materials. It cures into a solid state, creating a rigid connection that can withstand heavy loads and vibrations. Epoxy resin also boasts good chemical resistance, ensuring your bond remains intact even in harsh environments.

For those seeking an adhesive with flexibility, polyurethane-based glues are worth considering. These adhesives offer excellent elasticity while still maintaining a strong bond between plastic and rubber surfaces. They can withstand bending and stretching without compromising the integrity of the connection.

Lastly, let’s not forget about contact cement. This type of adhesive is specifically designed for bonding rubber to various materials, including plastic. Contact cement creates an incredibly strong bond by adhering both surfaces together upon contact. It requires proper application techniques but offers exceptional durability once fully cured.

In conclusion, when it comes to bonding plastic to rubber, there are several excellent options available. Whether you opt for super glue’s instant strength or epoxy resin’s long-lasting durability, or prefer the flexibility of polyurethane-based glues or the reliable performance of contact cement – choosing the right adhesive will ensure your materials stick together seamlessly.